TITLE 26. Toxics

Preface

Organization of Title 26

Title 26 is a compilation of toxic regulations issued by State regulatory agencies and published for the first time in one Title of the California Administrative Code in August, 1986.* Please note these toxic regulations are also found in the original Titles assigned to each agency.

Title 26 is organized with the agencies listed in numerical sequence according to their original Title assignments. The regulatory sections within each Division of Title 26 also reflect the original section number assignments and are arranged in numerical sequence.

*The name California Administrative Code was changed to the California Code of Regulations effective January 1, 1988.

Division 1. State Lands Commission

(Title 2)

Note • History

(a) This Article 3.4 pertains to oil and gas drilling and production operations on State oil and gas leases located on State tide and submerged lands under the jurisdiction of the State Lands Commission, and is applicable to operations conducted from mobile rigs, fixed offshore structures and upland locations serving these leases.

(b) In addition to complying with Division 6 of the California Public Resources Code and with Title 2, Division 3, Chapter 1 of the California Administrative Code, the lessee shall comply with all applicable laws, rules and regulations now or hereafter promulgated of the United States of the State of California and of any respective political subdivision thereof, including, but not limited to, those of the Division of Oil and Gas, the Department of Fish and Game, the Division of Industrial Safety, the State Water Resources Control Board, and the Regional Water Quality Control Board, the California Coastal Commission, and any respective successors thereto.

(c) All operations conducted on State oil and gas leases shall be carried on in a proper and workmanlike manner in accordance with accepted good oilfield practice.

NOTE

Authority cited: Sections 6103, 6108, 6216, 6301, and 6873(d), Public Resources Code; and Section 11152, Government Code. Reference: Sections 6005, 6216, 6301, 6871, 6871.1, 6873(d), Public Resources Code.

HISTORY

1. New Article 3.4 (Sections 2133-2142) filed 6-13-80; effective thirtieth day thereafter (Register 80, No. 24).

Note

For purposes of this Article 3.4 the following definition shall apply:

(a) “Staff” shall mean the Executive Officer or other duly authorized member of the Staff of the State Lands Commission.

NOTE

Authority cited: Sections 6103, 6108, 6216, 6301, and 6873(d), Public Resources Code; and Section 11152, Government Code. Reference: Sections 6005, 6216, 6301, 6871, 6871.1, 6873(d), Public Resources Code.

Note

(a) The Staff shall administer this Article 3.4 and shall thereby seek to provide for the prevention and elimination of any contamination or pollution of the ocean and tidelands, for the prevention of waste and for the conservation of natural resources, and for the protection of human health and safety and of property.

(b) The Commission has designed these regulations in as great detail as possible. However, the Commission recognizes that situations may arise which are not specifically covered by this Article 3.4 and that emergency situations may arise which will require immediate decisions by the Staff. In such situations, the Executive Officer or his designee may authorize appropriate procedures to be followed.

NOTE

Authority cited: Sections 6103, 6108, 6216, 6301, and 6873(d), Public Resources Code; and Section 11152, Government Code. Reference: Sections 6005, 6216, 6301, 6871, 6871.1, 6873(d), Public Resources Code.

§2-2136. Prohibition of Pollution.

Note

(a) Pollution and contamination of the ocean and tidelands and any impairment of or interference with recreation, fishing, or navigation in the waters of the ocean or any bay or any inlet thereof is prohibited; and no oil, tar, residuary product of oil or any refuse of any kind from any well or facility that is deleterious to marine life shall be permitted to be deposited on or pass into the waters of the ocean or any bay or any inlet thereof.

(b) All drilling and production operations shall be conducted in a manner that will eliminate, insofar as is practical, any dust, noise, vibration, or noxious odors.

NOTE

Authority cited: Sections 6103, 6108, 6216, 6301 and 6873(d), Public Resources Code; and Section 11152, Government Code. Reference: Sections 6005, 6216, 6301, 6871, 6871.1, 6873(d), Public Resources Code.

§2-2137. Suspension of Operations and Corrective Action.

Note

A lessee shall suspend immediately any drilling and production operations, except those which are corrective, protective, or mitigative, in the event of any disaster of or contamination or pollution caused in any manner or resulting from drilling and/or production operations under its lease. Such drilling and/or production operations shall not be resumed until adequate corrective measures have been taken and authorization for resumption of such operations has been made by the Staff. Corrective measures shall be taken immediately whenever pollution has occurred.

NOTE

Authority cited: Sections 6103, 6108, 6216, 6301 and 6873(d), Public Resources Code; and Section 11152, Government Code. Reference: Sections 6005, 6216, 6301, 6871, 6871.1, 6873(d), Public Resources Code.

§2-2138. Disposal of Drill Cuttings and Drilling Muds.

Note

The lessee shall dispose of those drill cuttings and drilling muds associated with drilling and production well work, in accordance with regulations promulgated by the appropriate Regional Water Quality Control Board. The method employed to dispose of the drill cuttings and drilling muds shall be submitted to the Staff for approval along with the drilling mud program that is required in Section 2128(d)(1).

NOTE

Authority cited: Sections 6103, 6108, 6216, 6301 and 6873(d), Public Resources Code; and Section 11152, Government Code. Reference: Sections 6005, 6216, 6301, 6871, 6871.1, 6873(d), Public Resources Code.

§2-2139. Oil Spill Contingency Plan.

Note

Each lessee shall prepare and maintain a current oil spill contingency plan for initiating corrective action to control and recover oil spilled in or on the ocean. The plan shall cover both minor and major oil spills associated with lease drilling and production operations. The plan and any subsequent revisions thereto shall be submitted for approval by the Staff.

NOTE

Authority cited: Sections 6103, 6108, 6216, 6301 and 6873(d), Public Resources Code; and Section 11152, Government Code. Reference: Sections 6005, 6216, 6301, 6871, 6871.1, 6873(d), Public Resources Code.

§2-2140. Pollution Control and Removal Equipment.

Note

(a) Pollution control equipment and material shall be available immediately to each lessee for use in oil pollution control and removal operations on its lease. The equipment and material shall include, but need not be limited to, containment booms, skimming apparatus, licensed chemicals, and absorbents, and shall be the most effective available given the current state of pollution control and removal research and development at the time of acquisition. The lessee shall, however, update such equipment whenever any significant technological improvements are developed.

(b) Emergency equipment shall be maintained on each mobile drilling rig and fixed offshore drilling or production facility for immediate cleanup of small oil spills. Each mobile drilling rig shall be equipped with a minimum of 1500 feet of oil containment boom, an oil skimming or recovery device that is capable of open ocean use, and an amount of absorbent material sufficient to remove 15 barrels of spilled oil. In addition, a boat that is capable of deploying this equipment shall be maintained onsite or available to the rig within 15 minutes. The equipment and material required on each fixed offshore drilling or production facility shall be determined and approved by the staff on an individual basis considering the type of structure, location, current activity, oil production capability, method of well production and other factors peculiar to the facility.

Equipment for the control and removal of larger oil spills shall be maintained at an offshore or onshore location near the area of lease operations where deployment and response to the spill would provide the most feasible protection of coastal resources. All equipment shall be inspected regularly and shall be maintained in good condition for immediate use.

(c) The lessee shall conduct training classes and periodic drills in the deployment and use of pollution control and removal equipment, to ensure that designated personnel can carry out the assignments which are necessary for effective control and removal of oil spilled in or on the ocean.

(d) The lessee shall maintain an inventory of the emergency equipment that is stored on each mobile drilling rig and offshore drilling or production facility as well as an inventory showing the description, application, and location of all pollution control and removal equipment that is immediately available for a major oil spill. In addition, the lessee shall maintain a listing of equipment, material, services, and labor forces that are immediately available for beach cleanup and restoration operations. The inventories shall be updated as changes occur and current copies shall be filed with the Staff annually.

(e) All mobile drilling rigs and offshore drilling or production facilities shall be equipped in a manner that will prevent spilling of contaminants in the ocean. Any fluids spilled shall be collected in a sump(s) that is provided with appropriate pumping equipment, liquid level controls, and alarms to prevent accidental discharge of contaminants into the ocean waters.

NOTE

Authority cited: Sections 6103, 6108, 6216, 6301 and 6873(d), Public Resources Code; and Section 11152, Government Code. Reference: Sections 6005, 6216, 6301, 6871, 6871.1, 6873(d), Public Resources Code.

§2-2141. Critical Operations and Curtailment Plans.

The primary purpose of a Critical Operations and Curtailment Plan is to provide additional precautionary measures to minimize the likelihood of an oil spill incident occurring from offshore drilling and production well work during (1) adverse weather and sea conditions when oil spill containment and recovery equipment, material and techniques are not effective and marine transportation is severely hampered; and (2) the time that oil spill containment and recovery equipment, material, manpower, and transportation thereof are not readily available to the site of operation.

Certain operations performed in drilling and production well work are more critical than others with respect to well control and accidental discharge of oil and gas. This is particularly so when subsurface forations are exposed in the well that are capable of flowing oil and gas to the surface or when the well has been pressured by outside means. It is these critical operations that should be ceased, limited or not commenced in order to minimize the likelihood of an oil spill occurring during adverse weather and sea conditions which could seriously impede both well control and oil cleanup efforts.

The lessee shall file with the Staff, for its approval, a Critical Operations and Curtailment Plan to be followed while conducting drilling and/or production well work on the lease. A plan shall be filed for each exploratory well as required in Section 2128(d)(2) in order to accommodate different drilling rigs, circumstances and conditions. A separate plan shall be filed for development drilling and production well work on the lease. These plans shall contain the following:

(a) A descriptive list of the critical drilling and production well work that is likely to be conducted on the lease, such as:

(1) Drilling in close proximity to another well.

(2) Drilling into a known lost circulation zone or into a zone capable of flowing oil and/or gas.

(3) Continuation of drilling into zones that are suspected to be capable of flowing oil and/or gas or into zones suspected to be abnormally pressured.

(4) If zones capable of flowing oil and/or gas are exposed or suspected to be exposed in the well then the following are considered to be critical operations:

(A) Pulling out of the hole.

(B) Fishing operations.

(C) Drill-Stem testing.

(D) Wireline logging in open hole.

(E) Running casing.

(F) Cutting and recovering casing.

(G) Perforating casing.

(H) Well completion work.

(I) Remedial well work.

(J) Well stimulation.

(b) A descriptive list of circumstances or conditions under which the critical drilling and production well work shall be ceased, limited, or not commenced. This list shall be developed from all the factors and conditions relating to the lease and shall take into account but may not to be limited to the following:

(1) Whether or not well operations are being conducted from a mobile rig or a fixed structure.

(2) Adverse meteorological or oceanographical conditions exist or are anticipated soon.

(3) Limited availability and capability of oil containment and cleanup equipment.

(4) Significant increase in oil spill control system response time for any reason.

(5) Personnel or equipment for conducting a particular critical operation are not available.

(6) Insufficient supply of drilling mud materials on the drill site for emergency well control purposes.

(7) Transportation equipment for personnel, supplies and oil spill containment and cleanup equipment is not readily available.

(8) Construction and maintenance work involving welding, moving heavy equipment, etc. is being performed.

(9) Other factors peculiar to the particular lease under consideration.

(c) When any circumstance or condition listed or described in the plan occurs or other operational limits are encountered, the lessee shall cease, limit, or not commence the affected critical operation(s) as set forth in Section 2141(a).

(d) Any deviation from the approved plan shall require prior written approval by the Staff. If emergency action requires deviation from the plan, and there is inadequate time to seek the Staff's approval, the Staff shall be notified immediately after said deviation occurs.

(e) The plan shall be reviewed at least annually and any changes thereto shall be submitted to the Staff for approval.

Note

(a) All spills or leakage of oil and liquid pollutants originating from operations on State oil and gas leases shall be reported orally without delay to the United States Coast Guard and to the State Office of Emergency Services in Sacramento. Subsequent to oral notification, a written report shall be filed with the State Lands Commission, stating the source, cause, size of spill and the action taken.

(b) Lessees shall report orally to the three authorities indicated in Section 2142(a) any pollution of unknown source or pollution unassociated with lease operations that is observed on or in State waters.

(c) Lessees shall notify one another of information regarding equipment malfunction or of information regarding pollution resulting from another's operation.

NOTE

Authority cited: Sections 6103, 6108, 6216, 6301 and 6873(d), Public Resources Code; and Section 11152, Government Code. Reference: Sections 6005, 6216, 6301, 6871, 6871.1, 6873(d), Public Resources Code.

Division 2. Department of Food and Agriculture

(Title 3)

§3-300. Permit Processing Times (Including Licenses, Permits, Registrations and Certificates).

Note • History

(a) Within the number of calendar days of receipt of an application for a permit shown in column A of subsection (c), the Department shall inform the applicant in writing that the application is either complete and accepted for filing, or that it is deficient, and what specific information or documentation is required to complete the application. An application is considered complete if all necessary fees and information required by the application form have been submitted.

(b) Within the number of calendar days after receipt of a complete application, as shown in column B of subsection (c), the Department shall approve or disapprove the application.

(c) The Department's minimum, median, and maximum time periods, in calendar days, for processing an application from the receipt of the initial application to the final decision, based on the Department's actual performance during the two years immediately preceding the proposal of this section, are shown in columns C, D, and E of the chart which follows:

A B C D E

Maximum time Maximum time

for notifying after receipt

that applica- of a complete

tion is com-- application

plete or to approve or ACTUAL DAYS TO PROCESS

deficient deny permit BASED ON PRIOR TWO YEARS

Permit Type Minimum Median Maximum

(Days) (Days) (Days)

(1) Animal Health and Food Safety Services:

Livestock Meat Inspector License1 14 60 1 29 325

Poultry Meat Inspector License1 14 60 5 76 162

Retail Meat Processing Establishment License1 14 60 1 34 237

Custom Livestock Slaughter Establishment License1 14 60 6 62 163

Poultry Plant License1 14 60 19 68 194

Pet Food Processor1 14 60 48 116 185

Horsemeat and Pet Food Importers1 14 60 15 32 49

Dead Hauler License 14 60 4 11 13

--Renewal 14 60 2 4 5

Renderer License 14 60 22 37 216

--Renewal 14 60 7 10 33

Collection Center License 14 60 7 24 74

--Renewal 14 60 2 34 59

Inedible Kitchen Grease Transporter Registration 14 60 3 5 13

--Renewal 14 60 3 16 93

License for the Production of Biologics 30 30 12 27 169

--Renewal 30 30 2 21 47

License to Feed Garbage to Swine1 10 10 11 11 11

License for Vessel and Aircraft Garbage Collection2 14 45 8 37 60

Limited Dairy Inspector Certificate2 30 60 16 17 37

Registered Dairy Inspector Certificate2 60 140 36 68 142

Certificate of Proficiency in the Analysis of Milk

and Milk Products2 30 90 1 28 76

Frozen Milk Products Plant License1 60 90 4 29 161

Milk Products Plant License 60 90 16 29 130

--Renewal 30 60 1 10 53

Semi-Frozen Milk Products Plant License1 30 90 1 11 268

Bulk Milk Tanker Permit 60 90 No historical record.

-- Renewal 60 90 No historical record.

(2) Division of Inspection Services:

Commercial Feed License1 14 45 1 13 103

Fertilizing Materials License1 14 60 1 25 153

Fertilizing Materials Registration 14 90 1 61 240

--Renewal 14 90 4 54 239

Livestock Drug--Registration 14 60 1 28 162

--Renewal 14 45 1 16 243

Restricted Livestock Drug--License 14 60 1 12 83

--Renewal 14 45 1 22 58

(3) Division of Marketing Services

Produce Dealer Act Licenses1,3 45 90 1 36 195

Processor or Cash Buying Processor License1 45 90 9 48 147

Conjunctive License1 45 90 8 60 183

Agent's License1 45 90 1 9 70

Milk Handler License4 45 90 1 12 91

--Renewal 45 90 1 16 188

(4) Plant Health and Pest Prevention Services

Seed, Authorization to Sell 14 75 3 20 78

--Renewal 14 60 1 10 39

Nursery Stock, License to Sell 14 60 16 37 123

--Renewal 14 45 6 16 43

Permit to Move and Use Live Plant Pests or Insects

or Noxious Weeds2 30 90 1 14 102

Permit to Move and Use Plant Quarantine

Commodities2 30 90 1 17 150

Cotton Research Authorization 45 60 No historical record.

1Median processing time for renewals does not exceed 7 days.

2Not subject to Renewal.

3Includes Broker, Cash Buyer, Commission Merchant, Dealer, or any combination.

4Includes Handlers and Distributors.

NOTE

Authority cited: Section 15376, Government Code; and Section 407, Food and Agricultural Code. Reference: Section 15376, Government Code.

HISTORY

1. New section filed 11-28-89; operative 1-1-90 (Register 89, No. 49).

2. Change without regulatory effect pursuant to section 100, title 1, California Code of Regulations filed 5-2-90; operative 5-2-90 (Register 90, No. 24).

3. Amendment of subsection (c) filed 6-4-90; operative 7-4-90 (Register 90, No. 29).

4. Editorial correction of printing error duplicating subsections (a)-(c) (Register 90, No. 46).

5. Amendment of subsection (c) filed 2-25-91; operative 3-27-91 (Register 91, No. 13).

6. Change without regulatory effect amending article heading and subsection (c) filed 9-2-93 pursuant to title 1, section 100, California Code of Regulations (Register 93, No. 36).

7. Amendment of subsection (c)(4) filed 3-4-99 as an emergency; operative 3-4-99 (Register 99, No. 10). A Certificate of Compliance must be transmitted to OAL by 7-2-99 or emergency language will be repealed by operation of law on the following day.

8. Certificate of Compliance as to 3-4-99 order transmitted to OAL 6-16-99 and filed 7-27-99 (Register 99, No. 31).

9. Amendment of subsection (c)(1) filed 10-25-2001 as an emergency; operative 10-25-2001 (Register 2001, No. 43). A Certificate of Compliance must be transmitted to OAL by 2-22-2002 or emergency language will be repealed by operation of law on the following day.

10. Certificate of Compliance as to 10-25-2001 order transmitted to OAL 2-15-2002 and filed 4-2-2002 (Register 2002, No. 14).

11. Amendment of subsection (c)(1) filed 7-1-2002; operative 7-31-2002 (Register 2002, No. 27).

12. Amendment of subsection (c)(1) filed 4-3-2003; operative 5-3-2003 (Register 2003, No. 14).

History

HISTORY

1. Removal of sections 3-2300.1--3-6920 from title 26 filed 3-25-96 pursuant to Cal. Code. Regs., tit. 1, section 100. For current versions or prior history, see corresponding section(s) in title 3 (Register 96, No. 13).

Division 3. Bureau of Home Furnishings

(Title 4)

§4-1251. Methods of Sanitization.

Note • History

(a) Any method of sanitization not provided for herein shall be submitted to the Bureau for testing and consultation with the State Department of Health Services before adoption or use.

(b) Unless otherwise specifically provided for, the chief of the bureau shall determine the method to be employed in the sanitization of any article or material subject to the provisions of the act and these regulations.

(c) Secondhand (used) fabrics shall not contain any of the following adulterants: visible soiling or stains, extraneous materials, sludge, oil, grease, fat, filth, excreta, skin, epidermis, blood, urine, feces, disagreeable odors or other contamination.

(d) Secondhand (used) materials which are contaminated shall be sanitized as set forth in Sections 1252 or 1253 of these regulations.

(e) Mattresses containing a porous material or fabric may be sanitized by using the dry heat method in Section 1252 or the chemical disinfectant, Steri-fab, as set forth in Section 1253.

(f) Baled filling materials shall not be sanitized while still in the bale.

(g) Detachable mattresses and pads within hide-a-beds shall be removed from such articles and sanitized.

NOTE

Authority cited: Section 19034, Business and Professions Code. Reference: Sections 19120, 19121, 19123.6 and 19124, Business and Professions Code.

HISTORY

1. New subsection (b) filed 7-1-68; effective thirtieth day thereafter (Register 68, No. 25).

2. New NOTE filed 12-10-81 as procedural and organizational; effective upon filing (Register 81, No. 50).

3. Amendment of subsection (a) filed 10-15-82; effective thirtieth day thereafter (Register 82, No. 42).

4. Amendment filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

5. Repealer and new section filed 8-19-98; operative 8-19-98 pursuant to Government Code section 11343.4(d) (Register 98, No. 34).

Note • History

(a) Records shall be kept in a bound log book and shall include:

(1) the date of sanitization;

(2) the chamber letter, if any;

(3) the lot numbers in consecutive order;

(4) the name of the person and or company for whom sanitized.

(b) The numbers and types of items sanitized must be recorded.

(c) Damaged labels shall be entered into the bound log book as “Damaged” and maintained for inspection.

(d) Records kept in the bound log book must be retained on the business premises for not less than 5 years.

(d) The following is a sample format for recording required information.

Dry Heat Sanitation Record Log (example)

Date Oven No. Lot No. Label Nos. Articles Company Name

1/7/98 A 1 1000-1011 5 mattresses Salvation Army

5 boxsprings

1/7/98 A 2 1012-1022 5 mattresses ABC Thrift

5 boxsprings

1/7/98 A 1 1010 VOID VOID

Chemical Sanitation Record Log (example)

Date Chemical Lot No. Label Nos. Articles Company Name

1/7/98 Steri-Fab 2 1023-1034 5 mattresses Salvation Army

5 boxsprings

1/7/98 Steri-Fab 3 1034-1040 3 mattresses Salvation Army

3 boxsprings

1/7/98 1033 VOID VOID

NOTE

Authority cited: Section 19034, Business and Professions Code. Reference: Sections 19124 and 19127.6, Business and Professions Code.

HISTORY

1. New section filed 8-19-98; operative 8-19-98 pursuant to Government Code section 11343.4(d) (Register 98, No. 34). For prior history, see Register 96, No. 30.

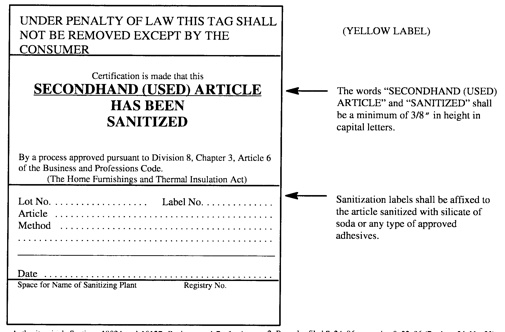

§4-1256. Official Sanitization Label Requirements.

Note • History

(a) All articles of bedding or bulk filling materials which have undergone an approved method of sanitization shall have a sanitization label firmly attached to the item in such an area so as to be easily and readily discernable. Sanitization labels shall be affixed to the item sanitized with silicate of soda or any type of adhesive approved by the Bureau.

(b) Sanitization labels shall be constructed of erasure-proof paper and shall be of a grade that will not change color on application of adhesive.

(c) Color of label shall be yellow and the printing shall be in black ink.

(d) Statements and headings on a sanitization label shall be as follows:

(1) “Under penalty of law this tag shall not be removed except by the consumer.”

(2) “Certification is made that this secondhand article has been sanitized by a process approved pursuant to Division 8, Chapter 3, Article 6, of the Business and Professions Code” (The Home Furnishings and Thermal Insulation Act).

(3) Lot number in which the article was sanitized.

(4) Sanitization label number. (Every label shall be numbered, the numbers shall run consecutively, and no duplicate numbers shall be used).

(5) Name of the article or filling material sanitized.

(6) Method must be printed or stamped: dry heat or chemical disinfectant.

(7) Date sanitized.

(8) Name and address of sanitizing plant.

(9) Registry number assigned to the sanitizing plant by the Bureau.

(e) Size of sanitization label and type of printing.

(1) The minimum size of labels shall be 3 x 3 inches.

(2) The words “Secondhand Article” and “Sanitized” shall be a minimum of 3/8” in height in capital letters.

(3) All printing shall be in English.

(f) Form of Label.

NOTE

Authority cited: Sections 19034 and 19127, Business and Professions Code. Reference: Sections 19124.5 and 19127, Business and Professions Code.

HISTORY

1. Amendment filed 8-17-66; effective thirtieth day thereafter (Register 66, No. 27).

2. New NOTE filed 12-10-81 as procedural and organizational; effective upon filing (Register 81, No. 50).

3. Amendment of section and form filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

4. Repealer and new section filed 8-19-98; operative 8-19-98 pursuant to Government Code section 11343.4(d) (Register 98, No. 34).

§4-1257. Storage of Formaldehyde.

Note • History

NOTE

Authority cited: Section 19034, Business and Professions Code. Reference: Section 19124, Business and Professions Code.

HISTORY

1. New NOTE filed 12-10-81 as procedural and organizational; effective upon filing (Register 81, No. 50).

2. Repealer filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

§4-1258. Method of Sanitization.

Note • History

NOTE

Authority cited: Section 19034, Business and Professions Code. Reference: Sections 19120, 19123.6 and 19124, Business and Professions Code.

HISTORY

1. Amendment filed 8-17-66; effective thirtieth day thereafter (Register 74, No. 19).

2. New NOTE filed 12-10-81 as procedural and organizational; effective upon filing (Register 81, No. 50).

3. Amendment filed 10-15-82; effective thirtieth day thereafter (Register 82, No. 42).

4. Amendment of section heading, section and Note filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

5. Repealer filed 8-19-98; operative 8-19-98 pursuant to Government Code section 11343.4(d) (Register 98, No. 34).

§4-1259. Vacuum Chemical Method.

Note • History

NOTE

Authority cited: Section 19034, Business and Professions Code. Reference: Section 19124, Business and Professions Code.

HISTORY

1. New NOTE filed 12-10-81 as procedural and organizational; effective upon filing (Register 81, No. 50).

2. Repealer filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

Note • History

NOTE

Authority cited: Section 19034, Business and Professions Code. Reference: Section 19124, Business and Professions Code.

HISTORY

1. Amendment filed 7-31-56; effective thirtieth day thereafter (Register 74, No. 19).

2. Amendment filed 5-1-59; designated as effective June 1, 1959 (Register 59, No. 7).

3. New NOTE filed 12-10-81 as procedural and organizational; effective upon filing (Register 81, No. 50).

4. New subsection (d) filed 10-15-82; effective thirtieth day thereafter (Register 82, No. 42).

5. Amendment filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

6. Repealer filed 8-19-98; operative 8-19-98 pursuant to Government Code section 11343.4(d) (Register 98, No. 34).

Note • History

NOTE

Authority cited: Section 19034, Business and Professions Code. Reference: Section 19124, Business and Professions Code.

HISTORY

1. Repealer of former Section 1264 and renumbering and amendment of former Section 1266 to Section 1264 filed 10-15-82; effective thirtieth day thereafter (Register 82, No. 42). For prior history, see Register 81, No. 50; 68, No. 25; and 66, No. 27.

2. Amendment filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

3. Repealer filed 8-19-98; operative 8-19-98 pursuant to Government Code section 11343.4(d) (Register 98, No. 34).

Note • History

NOTE

Authorized cited: Section 19034, Business and Professions Code. Reference: Section 19124, Business and Professions Code.

HISTORY

1. Repealer of Section 1265 and renumbering and amendment of former Section 1266.1 to Section 1265 filed 10-15-82; effective thirtieth day thereafter (Register 82, No. 42). For prior history, see Registers 81, No. 50 and 68, No. 25).

2. Amendment filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

3. Repealer filed 8-19-98; operative 8-19-98 pursuant to Government Code section 11343.4(d) (Register 98, No. 34).

§4-1266. Official Sanitization Label Requirements.

Note • History

NOTE

Authority cited: Sections 19034 and 19127, Business and Professions Code. Reference: Sections 19124.5 and 19127, Business and Professions Code.

HISTORY

1. Renumbering of former Section 1266 to Section 1264, and renumbering and amendment of former Section 1267 to Section 1266 filed 10-15-82; effective thirtieth day thereafter (Register 82, No. 42). For prior history, see Registers 81, No. 50; 68, No. 25; and 66, No. 27.

2. Amendment of section heading, section and form filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

3. Repealer filed 8-19-98; operative 8-19-98 pursuant to Government Code section 11343.4(d) (Register 98, No. 34).

Note • History

NOTE

Authority cited: Section 19034, Business and Professions Code. Reference: Section 19124, Business and Professions Code.

HISTORY

1. New section filed 7-1-68; effective thirtieth day thereafter (Register 68, No. 25).

2. New NOTE filed 12-10-81 as procedural and organizational; effective upon filing (Register 81, No. 50).

3. Renumbering and amendment to Section 1265 filed 10-15-82; effective thirtieth day thereafter (Register 82, No. 42).

§4-1267. Removal of Red Tags After Sterilization.

Note • History

NOTE

Authority cited: Section 19034, Business and Professions Code. Reference: Sections 19121, 19202, 19203, and 19204, Business and Professions Code.

HISTORY

1. Renumbering and amendment of former Section 1267 to Section 1266, and new Section 1267 filed 10-15-82; effective thirtieth day thereafter (Register 82, No. 42). For prior history, see Registers 81, No. 50; 68, No. 25; and 66, No. 27.

2. Repealer filed 7-24-96; operative 8-23-96 (Register 96, No. 30).

Division 4. California Occupational Safety and Health Regulations (CAL/OSHA)

(Title 8)

§§ 8-337--8-8568. [Removed]

HISTORY

1. Removal of sections 8-337--8-8568 from title 26 filed 9-24-96 pursuant Cal. Code Regs., tit. 1, section 100. For current versions or prior history, see corresponding section(s) in title 8 (Register 96, No. 39).

Division 5. Insurance Commissioner

(Title 10)

§10-2321.

History

Marine and/or transportation policies may cover under the following conditions:

(a) Imports

(1) Imports on consignment may be covered wherever the property may be and without restriction as to time, provided the coverage of the issuing companies includes hazards of transportation. A shipment “on consignment” shall mean property consigned and intrusted to a factor or agent to be held in his care, or under his control for sale for account of another or for exhibit or trial or approval or auction, and if not disposed of, to be returned.

(2) Imports not on consignment in such places of storage as are usually employed by importers, provided the coverage of the issuing companies includes hazards of transportation. Such policies may also include the same coverage in respect to property purchased on C.I.F. terms or “spot” purchases for inclusion with or in substitution for bona fide importations. An import, as a proper subject of marine or transportation insurance, shall be deemed to maintain its character as such so long as the property remains segregated in the original form or package in such a way that it can be identified and has not become incorporated and mixed with the general mass of property in the United States, and shall be deemed to have been completed when such property has been:

(A) Sold and delivered by the importer, factor or consignee; or

(B) Removed from place of storage as described in paragraph “2” above and placed on sale as part of importer's stock in trade at a point of sale-distribution; or

(C) Delivered for manufacture, processing or change in form to premises of the importer or of another used for any such purposes.

(b) Exports

(1) Exports may be covered wherever the property may be without restriction as to time, provided the coverage of the issuing companies includes hazards of transportation. An export, as a proper subject of marine or transportation insurance, shall be deemed to acquire its character as such when designated or while being prepared for export and retain that character unless diverted for domestic trade, and when so diverted, the provisions of this article respecting domestic shipments shall apply, provided, however, that this provision shall not apply to long established methods of insuring certain commodities, e.g., cotton.

(c) Domestic Shipments

(1) Domestic shipments on consignment, provided the coverage of the issuing companies includes hazards of transportation.

(A) Property shipped on consignment for sale or distribution, while in transit and not exceeding one hundred and twenty (120) days after arrival at consignee's premises or other place of storage or deposit; and

(B) Property shipped on consignment for exhibit, or trial, or approval, or auction, while in transit, while in the custody of others and while being returned.

(2) Domestic shipments not on consignment, provided the coverage of the issuing companies includes hazards of transportation, beginning and ending within the United States, provided that such shipments shall not be covered at manufacturing premises nor after arrival at premises owned, leased or operated by assured or purchaser, not for more than ninety (90)days at other place of storage or deposit, except in premises of transportation companies or freight forwarders, when such storage is incident to transportation.

(d) Bridges, tunnels and other instrumentalities of transportation and communication (excluding buildings, their furniture and furnishings, fixed contents and supplies held in storage) unless fire, tornado, sprinkler leakage, hail, explosion, earthquake, riot and/or civil commotion are the only hazards to be covered. Piers, wharves, docks and slips, excluding the risks of fire, tornado, sprinkler leakage, hail, explosion, earthquake, riot and/or civil commotion. Other aids to navigation and transportation, including dry docks and marine railways, against all risks. The foregoing includes:

(1) Bridges, tunnels, other similar instrumentalities, unless fire, lightning, windstorm, sprinkler leakage, hail, explosion, earthquake, riot or civil commotion are the only perils to be covered.

(2) Piers, wharves, docks and slips, but excluding the risks of fire, lightning, windstorm, sprinkler leakage, hail, explosion, earthquake, riot or civil commotion.

(3) (A) Pipelines, including on-line propulsion, regulating and other equipment appurtenant to such pipelines, but excluding all property at manufacturing, producing, refining, converting, treating or conditioning plants.

(B) Power transmission and telephone and telegraph lines, excluding all property at generating, converting or transforming stations, substations and exchanges.

(4) Radio and television communication equipment in commercial use as such including towers and antennae with auxiliary equipment, and appurtenant electrical operating and control apparatus but excluding buildings, their improvements and betterments, furniture and furnishings and supplies held in storage therein.

(5) Outdoor cranes, loading bridges and similar equipment used to load, unload and transport.

(e) Personal Property Floater Risks

(1) Covering Individuals.

(A) Tourists Floater, Personal Effects Floater Policies.

(B) The Personal Property Floater.

(C) Government Service Floaters.

(D) Personal Fur Floaters.

(E) Personal Jewelry Floaters.

(F) Wedding Present Floaters for not exceeding ninety (90) days after the date of the wedding.

(G) Silverware Floaters.

(2) Covering Individuals and/or Generally.

(A) Fine Arts Floaters, Stamp and Coin Floaters. To cover objects of art such as pictures, statuary, bronzes and antiques, rare manuscripts and books, articles of virtu, etc.

(B) Musical Instrument Floaters. Radios, televisions, record players and combinations thereof are not deemed musical instruments.

(C) Radium Floaters.

(D) Physicians' and Surgeons' Instrument Floaters. Such policies may include coverage of such furniture, fixtures and tenant assured's interest in such improvements and betterments of buildings as are located in that portion of the premises occupied by the assured in the practice of his profession.

(E) Pattern and Die Floaters, excluding coverage on the owner's premises.

(F) Theatrical Floaters, excluding buildings and their improvements and betterments, and furniture and fixtures that do not travel about with theatrical troupes.

(G) Film Floaters, including builders' risk during the production and coverage on completed negatives and positives and sound records.

(H) Salesmen's Samples Floaters.

(I) Jewelers' Block Policies, including tenant assured's interest in improvements and betterments of buildings, furniture, fixtures, tools, machinery, patterns, molds and dies.

(J) Exhibition Policies on property while on exhibition and in transit to or from such exhibitions.

(K) Live Animal Floaters, covering wherever animals, wagons and mobile equipment may be.

(L) Installation risks, covering machinery and equipment including plumbing, heating, cooling and electrical systems (as distinguished from building materials) while in transit to place of installation and during the period of installation and testing. Coverage must cease:

(1) where such property is insured for the account of the seller or installer,when the interest of such insured ceases; or,

(2) in no case later than when such property has been accepted as satisfactory; whichever first occurs, as to (1) or (2).

Building materials (e.g., structural steel, lumber, bricks and mortar), while in transit to place of installation and after arrival thereat but such coverage must terminate when the materials are installed and have become a physical part of the realty or when the seller's interest ceases, whichever first occurs.

(M) Mobile Articles, Machinery and Equipment Floaters (excluding motor vehicles designed for highway use and auto homes, trailers and semitrailers except when hauled by tractors not designed for highway use and snow plows constructed exclusively for highway use), covering identified property of a mobile or floating nature, not on sale or consignment, or in course of manufacture, which has come into the custody or control of parties who intend to use such property for the purpose for which it was manufactured or created. Such policies shall not cover furniture and fixtures not customarily used away from premises where such property is usually kept.

(N) Property in transit to or from and in the custody of

(1) Bleacheries, throwsters, fumigatories, dyers, cleaners, laundries, and similar bailees;

(2) Needleworkers;

(3) Other bailees (not owned, controlled or operated by the bailor) for the purpose of performing work thereon (as distinguished from the making of a complete article) including the treatment of, or assemblage, of property on the premises of bailees. Such policies shall not cover bailee's property at his premises.

(O) Installment Sales and Leased Property. Policies covering property sold under conditional contract of sale, partial payment contract, installment sales contract, or leased but excluding motor vehicles designed for highway use. Such policies must cover in transit but shall not extend beyond the termination of the seller's or lessor's interest. This section is not intended to include machinery and equipment under certain “lease-back” contracts.

(P) Garment Contractors Floaters.

(Q) Furriers or Fur Storer's Customer's Policies (i.e., policies under which certificates or receipts are issued for furriers or fur storers) covering specified articles the property of customers.

(R) Accounts Receivable Policies, Valuable Papers and Records Policies.

(S) Cold Storage Locker Plant Policies, covering merchandise of customers consisting principally of meats, game, fish, poultry, fruit, vegetables and property of a similar nature.

(T) Floor Plan Policies, covering property for sale while in possession of dealers under a floor plan or any similar plan under which the dealer borrows money from a bank or lending institution with which to pay the manufacturer, provided:

(1) Such merchandise is specifically identifiable as encumbered to the bank or lending institution.

(2) The dealer's right to sell or otherwise dispose of such merchandise is conditioned upon its being released from encumbrance by the bank or lending institution.

(3) That such policies cover in transit and do not extend beyond the termination of the dealer's interest. Provided that such policies shall not cover automobiles or motor vehicles; merchandise for which the dealer's collateral is the stock or inventory as distinguished from merchandise specifically identifiable as encumbered to the lending institution.

(U) Sign and Street Clock Policies, covering neon signs, automatic or mechanical signs, street clocks, while in use as such.

(V) The following policies covering property which, when sold to the ultimate purchaser, may be covered specifically, by the owner, under Inland Marine Policies:

(1) Musical Instrument Dealers Policies, covering property consisting principally of musical instruments and their accessories. Radios, Telephones, recordplayers and combinations thereof are not deemed musical instruments.

(2) Camera Dealers Policies, covering property consisting principally of cameras and their accessories.

(3) Furrier's Dealers Policies, covering property consisting principally of furs and fur garments.

(4) Equipment Dealers Policies, covering mobile equipment consisting of binders, reapers, tractors, harvesters, harrows, tedders and other similar agricultural equipment and accessories therefor; construction equipment consisting of bulldozers, roadscrapers, tractors, compressors, pneumatic tools and similar equipment and accessories thereof; but excluding motor vehicles designed for highway use. All such policies shall exclude coverage of moneys and securities. Such policies may include coverage of tenant assured's interest in improvements and betterments of buildings,furniture, fixtures, tools, machinery, patterns, molds and dies.

(W) Wool Growers Floaters.

(X) Domestic Bulk Liquids Policies, covering domestic bulk liquids stored in tanks provided the risks of fire and inherent explosion, windstorm, sprinkler leakage, earthquake, hail, explosion, riot or civil commotion are excluded therefrom.

(Y) Furniture Shipment Policies, covering furniture, fixtures and equipment in bona fide course of shipment from one location to another location of the owner including in place of deposit incident to such transportation while awaiting determination or availability of final destination, in which event they must cover at time of issuance transportation to or from such place of deposit but may not cover after delivery at destination.

HISTORY

1. Amendment filed 5-31-66; effective thirtieth day thereafter (Register 66, No. 16). For prior history, see Register 61, No. 11.

Division 5.1. Department of Motor Vehicles

(Title 13)

§13-100.02. Requirements for Out-of-State Drivers.

Note • History

A driver from another state, territory, or a country is authorized to drive in California without the drivers' certificate required by Vehicle Code Section 12804.1 or 12804.3 providing the driver meets all of the following requirements:

(a) Has a valid driver's license of the class appropriate for the operation of the vehicle, issued by the state, territory or country in which the driver resides.

(b) Has met the physical qualification standards required of motor vehicle drivers by the Federal Highway Administration of the United States Department of Transportation as set forth in the Title 49, Code of Federal Regulations, Section 391.41, and has in his or her possession a medical certificate approved by the Federal Highway Administration and issued within the last two years.

(c) Has met the training requirements set forth in Section 100.07 of these regulations applicable to the type of load being transported (hazardous materials, hazardous waste) and/or type of vehicle being operated.

(d) Is not disqualified for such a certificate on the basis of his or her driving record or medical condition under the Vehicle Code Sections referenced below.

(e) Has in his or her possession one of the following:

(1) A valid Non-Resident Special Driver Certificate issued by this department to a non-California licensed driver that authorizes the driver to transport the type of load being transported (hazardous materials, hazardous waste) and/or to operate that particular type of vehicle or

(2) Notice from his or her employing motor carrier on a form approved by the department indicating that the driver has met the training requirements specified in (c) above. Such notice must be signed by the driver and the employer under penalty of perjury. The notice will be valid for 30 days from the date it is signed by the employer.

(A) When such notice is issued by an employer, the employer must at the same time send written notice of the issuance to this department. No driver shall be permitted to operate in California a vehicle subject to this Article beyond the 30-day validity period of the notice, unless he/she has obtained from this department the Non-Resident Special Driver Certificate specified in 1 above.

(B) The department, upon receipt of notice specified in Subsection A, above, shall update its records and issue Non-Resident Special Driver Certificates to qualified drivers. Such certificates shall be mailed to the drivers.

NOTE

Authority cited: Section 3100, Vehicle Code. Reference: Sections 3100, 12500, 12502, 12804.1, 12804.3, 12805, 12809, 12810, 12810.5, 13205, 13352, 13352.5, 13353, 13355, 13357, 13359, 13361, 13363, 13365, 13552, 13553, 13954, 14252, 15020, 15023, 15024, 23157, 23160, 23161 and 23166, Vehicle Code; and Title 49, Code of Federal Regulations, Section 391.41.

HISTORY

1. New section filed 9-15-87; operative 10-15-87 (Register 87, No. 38).

§13-100.03. Renewal of Certificate.

Note • History

(a) The Non-Resident Special Driver Certificate issued to a non- California licensed driver shall expire 4 years from the date of issuance. Requirements to renew the certificate shall be the same as those to obtain an original certificate.

(b) The certificates issued to California-licensed drivers shall expire with the California license. Except for changes in training requirements noted in Section 100.07, requirements to renew the certificate shall be the same as for an original certificate.

NOTE

Authority cited: Section 3100, Vehicle Code. Reference: Sections 12804.1 and 12804.3, Vehicle Code.

HISTORY

1. New section filed 9-15-87; operative 10-15-87 (Register 87, No. 38).

§13-100.04. Exceptions to the Certificate Program.

Note • History

All drivers of vehicles specified in California Vehicle Code Sections 12804.1 or 12804.3 shall obtain special driver certificates, except those persons exempted pursuant to Section 25163 of the Health and Safety Code, persons operating a vehicle in an emergency situation at the direction of a peace officer pursuant to Vehicle Code Section 2800 and persons meeting the requirements for out-of-state drivers set forth in Section 100.02 of this Article.

NOTE

Authority cited: Section 3100, Vehicle Code. Reference: Sections 12804.1 and 12804.3, Vehicle Code; and Section 25163, Health and Safety Code.

HISTORY

1. New section filed 9-15-87; operative 10-15-87 (Register 87, No. 38).

§13-100.05. Refusal, Revocation, and Hearing.

Note • History

(a) The department may refuse to issue a certificate to any applicant under this article when the department is satisfied that any of the following exist:

(1) The applicant does not satisfy the requirements of Section 100.02, or California Vehicle Code Sections 12804.1 or 12804.3.

(2) As a result of the applicant's driving record, the applicant would be deemed to be a “Negligent Operator” under the provisions of Vehicle Code Section 12810.5(a).

(3) The applicant previously held a certificate issued under this article which has been revoked or suspended for cause and the cause for such suspension or revocation still exists.

(4) The applicant's driving record would be cause for suspension or revocation of the certificate and/or driving privilege under the provisions of the California Vehicle Code.

(5) The department has grounds for refusing to issue any license to the applicant under California Vehicle Code Sections 12805, 12807, or 12809, or would have cause for such refusal if the driver were otherwise required to be licensed under the provisions of the California Vehicle Code.

(6) The applicant would not currently qualify for a medical certificate approved by the Federal Highway Administration.

(b) The department may suspend or revoke a certificate issued under this article when the operator poses a risk to public health or safety or for any other cause which exists under these regulations, or the laws of California, regardless of when such cause arises which would either permit or require the department to refuse to issue such a certificate.

(c) The department may suspend or revoke the driving privilege of a non-California driver subject to the provisions of California Vehicle Code Section 3100 and these regulations, when the driver does not or no longer meets the requirements set forth in Section 100.02.

(d) The following provisions apply to a driver's right to a hearing:

(1) Whenever the department determines upon investigation or reexamination that the driver does not meet the qualifications for a certificate under this article and proposes to suspend or revoke the certificate privilege, notice and an opportunity to be heard shall be provided to the driver before such action is taken. Notice shall be given in accordance with procedures set forth in Vehicle Code Sections 13950, 13951, and 13952.

(2) The department may suspend or revoke the certificate privilege in accordance with the procedure set forth in Vehicle Code Section 13953 when such action is required for the safety of the driver or other persons upon the highway.

(e) Procedures pertaining to hearing requests and the conduct of hearings shall be governed by the provisions of Division 6, Chapter 3, of the California Vehicle Code.

NOTE

Authority cited: Section 3100, Vehicle Code. Reference: 3100, 12804.1, 12804.3, 12805, 12807, 12809, 12810.5 and 13950 through 14112, Vehicle Code.

HISTORY

1. New section filed 9-15-87; operative 10-15-87 (Register 87, No. 38). For prior history, see Register 87, No. 2.

§13-100.06. Employer Certification of Training for Hazardous Waste, Hazardous Materials, or Bulk Liquid Loads.

Note • History

(a) Certificate Of Driver Training. The department may waive the written test for an applicant for a hazardous waste, hazardous material, or bulk liquid load in combination certificate when the applicant presents a valid certificate of driver training issued by the employer of the applicant, if the employer has been authorized by the department to issue such certificates. Such certificates of driver training shall be signed by the employer or designated representative under penalty of perjury. One or more designated representative(s) may be identified by the employer in the application for employer number, which contains the designated representative(s) name(s), business address(es), and the signature(s) of the designated representative(s).

(b) Qualifications For Employer Number. The department shall issue an employer number to an employer, authorizing the employer to issue training certificates pursuant to this Article when the department is satisfied that the employer has met the qualifications set forth in this Article. The employer number shall remain valid for one year from date of issuance, unless earlier cancelled, suspended, or revoked by the department. The employer number is subject to annual renewal. The department shall require compliance with this section to renew the employer number. In order to qualify for an employer number, the employer must meet all of the following requirements:

(1) Provide for and require that its drivers participate in a driver testing and training program, to include an actual road test for each new driver employed. The road test must include the following: pre-trip safety inspection, placing in operation the vehicles or combination of the class for which the driver is issued the certificate, use of the vehicles' controls and emergency equipment, operating the vehicle or combination in traffic (on public roads and while passing other vehicles), turning the vehicle or combination, braking, slowing the vehicle or combination by means other than braking, and backing (if applicable) and parking the vehicle or combination.

(2) Provide documentation (such as a training schedule or contract with an entity which provides training) with the application for the employer number to show that the employer will provide the driver testing and training required above and in Section 100.07.

(3) Provide a current lesson plan for DMV monitoring purposes with each original application. Renewal applications must include any changes to the lesson plan.

(4) File an application, signed by the employer under penalty or perjury, with the department on forms furnished by the department.

(5) Require drivers, on an on-going basis, to operate vehicles subject to the certificate requirements of 12804.1 and/or 12804.3 applicable to the type of training certificate the employer wishes to issue. In addition, employers who qualify drivers for the bulk liquid load in combination certificate must ensure that the required on-the-road training and testing described above and in Section 100.07 are conducted in a Class 1 combination of tank vehicles used to transport bulk liquid loads.

NOTE

Authority cited: Section 3100, Vehicle Code. Reference: 12804, 12804.1 and 12804.3, Vehicle Code.

HISTORY

1. New section filed 9-15-87; operative 10-15-87 (Register 87, No. 38). For prior history, see Register 87, No. 2.

§13-100.07. Training Requirements.

Note • History

(a) Hazardous Waste. Employers who have been authorized by the department to issue certificates of training for drivers hauling hazardous wastes must provide training that meets or exceeds the following minimum requirements before issuing the certificate of training to any driver applying for an original certificate.

(1) Course Content:

(A) Products handled (including proper description(s) and characteristics)

(B) Documentation Requirements

1. Proper national uniform hazardous waste manifest form used.

2. Required entries and signatures.

3. Location during transportation and commerce.

(C) Packaging and Container Requirements

1. Marking

2. Labeling

3. Placarding

(D) Loading/Handling (characteristics and compatibility)

(E) Incident reporting and Emergency procedures

(F) State and Federal regulations applicable to hazardous waste vehicle/container operation

(G) Characteristics and safe operating requirements of hazardous waste vehicles/containers (including routing, driving and parking)

(H) Pre-operation inspection of vehicle/container (and written report when required)

(2) For drivers renewing a hazardous waste certificate, the training required above may be met by on-the-job instruction. However, the employer must keep records of such instruction as outlined in 100.10(a).

(b) Hazardous Materials. Employers who have been authorized by the department to issue certificates of training for drivers transporting hazardous materials must provide training that meets or exceeds the following minimum requirements before issuing the certificate of training to any driver applying for an original certificate.

(1) Course Content

(A) State and Federal regulations governing hazardous materials vehicle/container operation

(B) Pre-trip inspection of vehicle and load

(C) Shipping paper requirements:

1. proper basic description sequence and format

a. proper shipping name

b. hazard class

c. identification number

2. required description and entries

3. location during transportation and commerce

(D) Packaging and container requirements:

1. general packaging condition

2. proper marking and labeling

(E) Loading and unloading:

1. proper handling methods for different containers

2. mixed load compatibility

3. load securement

4. load accessibility

(F) Placarding requirements:

1. proper placards used

2. placards displayed correctly

(G) Driving and parking rules applicable to hazardous material transportation

(H) Incident reporting and emergency procedures

(2) For drivers renewing a hazardous materials certificate, the above required training may be met by on-the-job instruction. However, the employer must keep records of such instruction as outlined in 100.10(a).

(c) When training a driver to meet the requirements for both a hazardous waste and a hazardous materials certificate, training requirements which are identical for the two certificates need not be repeated. The training time required for the second certificate can be shortened as long as the driver receives the required training in the subject outline at least once.

(d) Bulk Liquid Loads in Combination. Employers who have been authorized by the department to issue certificates of training to drivers for the operation of combinations of vehicles with any tank configuration, which are required to be operated by Class 1 drivers and which are transporting bulk liquid loads, must provide training that meets or exceeds the following minimum requirements before issuing the certificate of training to any driver.

(1) Course Content

(A) Pre-trip inspection of vehicle and load

(B) Loading and unloading (operation of associated equipment)

(C) Special vehicle handling characteristics, to include:

1. Vehicle instability

2. High center of gravity

3. Fluid load subject to surge

4. Effect of curves on stability

5. Effect of braking on stability

6. Effect of speed on vehicle control

7. Dangers associated with evasive or sudden maneuvers

8. Danger commonly associated with maneuvering through curves, especially on and off ramps

9. Characteristic stability differences between clean bore, baffled, or multi-compartmented tanks

10. Effects of partial loads on basic vehicle stability

(2) In addition to completing the above training, the driver must demonstrate proficiency in operating the vehicle as required by Section 1229, of Title 13, California Administrative Code.

(3) For drivers renewing a certificate to transport bulk liquid loads in combination, the training requirements above may be met by on-the-job instruction. However, the employer must keep records of such instruction as outlined in 100.10(a).

NOTE

Authority cited: Section 3100, Vehicle Code. Reference: Sections 12804, 12804.1 and 12804.3, Vehicle Code; and Title 49 Code of Federal Regulations, Sections 172.200-172.204, 173.24, 177.800(a), 177.823, 177.855-177.861, 397.1-397.3, 397.7(b), 397.9(a) and 397.11-397.19.

HISTORY

1. New section filed 9-15-87; operative 10-15-87 (Register 87, No. 38). For prior history, see Register 87, No. 2.

§13-100.08. Certificate of Driving Experience.

Note • History

NOTE

Authority cited: Section 3100, Vehicle Code. Reference: Section 12804, Vehicle Code.

HISTORY

1. New section filed 9-15-87; operative 10-15-87 (Register 87, No. 38). For prior history, see Register 87, No. 2.

2. Change without regulatory effect renumbering former section 100.08 to section 25.08 filed 7-19-93 pursuant to title 1, section 100, California Code of Regulations (Register 93, No. 30).

§13-100.09. Employers Qualifying for Certification for Class 1 and/or Class 2 Operation and Special Certificate Approval.

Note • History

Employers who meet all of the qualifications contained in Sections 100.06, 100.07 and 100.08 may file a single application for authorization to certify to the training and testing required for Class 1 and/or 2 driving and the training required for the transport of hazardous waste, hazardous materials, and/or transport of bulk liquid loads in combination. There shall be a single fee for such multiple applications.

NOTE

Authority cited: Section 3100, Vehicle Code. Reference: Sections 12804, 12804.1 and 12804.3, Vehicle Code.

HISTORY

1. New section filed 9-15-87; operative 10-15-87 (Register 87, No. 38).

§13-100.10. Additional Employer Requirements.

Note • History

NOTE

Authority cited: Section 3100, Vehicle Code. Reference: Sections 12804, 12804.1, 12804.3 and 13950-14112, Vehicle Code.

HISTORY

1. Change without regulatory effect renumbering former section 100.10 to section 100.18 (Register 87, No. 38). For prior history, see Register 82, No. 33.

2. New section 100.10 filed 9-15-87; operative 10-15-87 (Register 87, No. 38).

3. Change without regulatory effect renumbering former section 100.10 to section 25.10 filed 7-19-93 pursuant to title 1, section 100, California Code of Regulations (Register 93, No. 30).

4. Editorial correction of Note (Register 97, No. 30).

Note • History

NOTE

Authority cited: Section 1651, Vehicle Code. Reference: Section 12804, Vehicle Code.

HISTORY

1. Change without regulatory effect renumbering former section 100.11 to section 100.19 (Register 87, No. 38). For prior history, see Register 82, No. 33.

2. New section 100.11 filed 9-15-87; operative 10-15-87 (Register 87, No. 38).

3. Change without regulatory effect amending subsection (b) filed 6-5-91 pursuant to section 100, title 1, California Code of Regulations (Register 91, No. 38).

4. Change without regulatory effect renumbering former section 100.11 to section 25.11 filed 7-19-93 pursuant to title 1, section 100, California Code of Regulations (Register 93, No. 30).

Division 6. California Highway Patrol

(Title 13)

Note • History

This article shall apply to the transportation of explosives subject to Division 14 (commencing with Section 31600) of the Vehicle Code.

NOTE

Authority cited: Section 31616, Vehicle Code. Reference: Sections 31601 and 31616, Vehicle Code.

HISTORY

1. Repealer and new section filed 10-28-92; operative 10-28-92 (Register 92, No. 44). For prior history, see Register 84, No. 16.

2. Amendment of Note filed 10-17-94; operative 11-16-94 (Register 94, No. 42).

3. Editorial correction of History (Register 94, No. 42).

§13-1150.1. Designation of Routes and Stopping Places.

Note • History

(a) The highways, safe stopping places, and inspection stops to be used for transportation of commodities listed in Section 1150 are set forth in Sections 1151.1 through 1153.12 (Maps 1 through 17A). Safe parking places are listed in Section 1154.

(b) Definitions.

(1) Safe Stopping Place. “Safe stopping place” means any place where a driver may stop for food, fuel, or other reason, provided the vehicle is attended at all times.

(2) Attended Vehicle. A vehicle is “attended” when the driver or person in charge of it is awake and occupies any part of it except the sleeper berth; or is within 100 ft. of the vehicle and has an unobstructed view of it.

(3) Safe Parking Place. “Safe parking place” means any off-highway location or terminal where the driver may park and leave a vehicle unattended.

(4) Inspection Stop. “Inspection stop” means any location specially designated as such in this article or any safe parking place or safe stopping place where vehicle inspections required by Section 31607 of the Vehicle Code may be performed.

(5) Required Inspection Stop. “Required inspection stop” means any place designated as such or any other place where vehicle inspection is mandatory.

NOTE

Authority cited: Section 31616, Vehicle Code. Reference: Sections 31602, 31614 and 31616, Vehicle Code.

HISTORY

1. Repealer and new section filed 10-28-92; operative 10-28-92 (Register 92, No. 44). For prior history, see Register 88, No. 26.

2. Amendment of Note filed 10-17-94; operative 11-16-94 (Register 94, No. 42).

3. Editorial correction of History (Register 94, No. 42).

§13-1150.2. Routes Traveled and Stopping.

Note • History

(a) Routes. No person shall drive or permit the driving of any vehicle transporting commodities listed in Section 1150 upon any highway not designated by this article. For pickup and delivery not over designated routes, the route selected must be the shortest-distance route from the pickup location to the nearest designated route entry location, and the shortest-distance route to the delivery location from the nearest designated route exit location.

(b) Access to Inspection Stops and Safe Stopping Places. If highway access is not provided, a highway other than one designated herein may be used to permit a vehicle or vehicle combination to proceed to and from an inspection stop or safe stopping place, provided the most direct route is used avoiding, to the extent practicable, places where crowds are assembled, streetcar tracks, tunnels, viaducts, and dangerous crossings.

(c) Stopping. No person shall stop a vehicle or vehicle combination transporting commodities listed in Section 1150 at any place not designated as a safe stopping place, safe parking place, improved public rest area as described in (d) of this section or inspection stop, except to comply with orders of a peace officer or an official traffic control device or unless the vehicle or vehicle combination is disabled.

(d) Public Rest Areas. An improved public rest area contiguous to a highway is deemed part of the highway for the purpose of this article.

NOTE

Authority cited: Section 31616, Vehicle Code. Reference: Sections 31602, 31614 and 31616, Vehicle Code.

HISTORY

1. Repealer and new section filed 10-28-92; operative 10-28-92 (Register 92, No. 44). For prior history, see Register 84, No. 16.

2. Amendment of subsections (c) and (d) and Note filed 10-17-94; operative 11-16-94 (Register 94, No. 42).

3. Editorial correction of History (Register 94, No. 42).

4. Amendment of subsection (a) filed 12-10-96; operative 12-10-96 pursuant to Vehicle Code section 31616 (Register 96, No. 50).

§13-1150.3. En Route Inspections.

Note • History

Inspection of tires and brakes required by Section 31607(c) of the Vehicle Code shall be performed at the following locations:

(a) En Route Inspection Stops. Inspection shall be performed at an inspection stop at least every four hours or 150 miles traveled, whichever occurs first, or as close thereto as is practicable, depending upon the proximity of such inspection stops.

(b) Top-of-Grade Inspection Stops. Regardless of elapsed time or miles traveled, vehicles shall be inspected at the top of and prior to descending any grade upon which the Department of Transportation has declared a speed limit for trucks of less than 55 miles per hour as provided by Section 22407 of the Vehicle Code. Such inspection shall be made off the roadway.

(c) Required Inspection Stops. Regardless of elapsed time or miles traveled, vehicles shall be inspected at any location designated herein as a required inspection stop.

NOTE

Authority cited: Section 31616, Vehicle Code. Reference: Sections 31602, 31607, 31608, 31614 and 31616, Vehicle Code.

HISTORY

1. Repealer and new section filed 10-28-92; operative 10-28-92 (Register 92, No. 44). For prior history, see Register 74, No. 14.

2. Amendment of Note filed 10-17-94; operative 11-16-94 (Register 94, No. 42).

3. Editorial correction of History (Register 94, No. 42).

Note • History

Detours established on highways designated in this article may be used for transportation of commodities listed in Section 1150 pending subsequent revision of this article or designation of emergency routes as provided by Section 31617 of the Vehicle Code.

NOTE

Authority cited: Section 31616, Vehicle Code. Reference: Sections 31602 and 31616, Vehicle Code.

HISTORY

1. Repealer and new section filed 10-28-92; operative 10-28-92 (Register 92, No. 44). For prior history, see Register 84, No. 16.

2. Amendment of Note filed 10-17-94; operative 11-16-94 (Register 94, No. 42).

3. Editorial correction of History (Register 94, No. 42).

§13-1150.5. Services and Products.

Note • History

Services available at safe stopping places are indicated for purposes of convenience, but no recommendation of any product, service, or location is intended or should be inferred.

NOTE

Authority cited: Section 31616, Vehicle Code. Reference: Sections 31602 and 31616, Vehicle Code.

HISTORY

1. Repealer and new section filed 10-28-92; operative 10-28-92 (Register 92, No. 44).

2. Amendment of Note filed 10-17-94; operative 11-16-94 (Register 94, No. 42).

Note • History

NOTE

Authority cited: Section 31616, Vehicle Code. Reference: Sections 31601, 31602, 31611, 31614 and 31616, Vehicle Code.

HISTORY

1. Repealer and new section filed 10-28-92; operative 10-28-92 (Register 92, No. 44). For prior history, see Register 88, No. 26.

2. Amendment of Note filed 10-17-94; operative 11-16-94 (Register 94, No. 42).

3. Editorial correction of History (Register 94, No. 42).

§13-1151.1. Routes and Stops--Map 1.

Note • History

(a) Map 1.

(b) Safe Stopping Places and Inspection Stops--Map 1.

(1) U.S. HIGHWAY 101.

(A) REQUIRED INSPECTION STOP (southbound vehicles): 9.7 miles south of Crescent City. West shoulder, immediately to the north of the following signs: “Down Grade - Trucks Use Low Gears” and “Trucks 30 MPH.”

(B) REQUIRED INSPECTION STOP (northbound vehicles): 20.5 miles north of Humboldt County line at marker DN-101-20.62. East shoulder. Marked by flashing lights and sign: “Brake Check Area.”

(C) REQUIRED INSPECTION STOP (southbound vehicles): 52.2 miles south of Eureka at marker HUM-101-23.1, State of California scale pit.

(D) REQUIRED INSPECTION STOP (northbound vehicles): 8.3 miles north of Garberville at marker HUM-101-19.4, State of California scale pit.

(E) * INSPECTION STOP (southbound vehicles): State of California platform scales. (Little River) at Marker 101-HUM-120.8.

(F) Orick: A&P Truck Service, 120635 Highway 101, at Marker 101-HUM-120.8. 24 hour towing service, call (707) 488-6885.

(2) U.S. HIGHWAY 199.

(A) REQUIRED INSPECTION STOP (westbound vehicles): At west end of Collier Tunnel. Park on wide shoulder, west of rest area turnoff.

(3) STATE HIGHWAY 96.

(A) INSPECTION STOP: Milepost 71.31 at convergence of highway and Scott River. Known locally as “Steelhead,” but not sign posted as such. No services.

(4) STATE HIGHWAY 299.

(A) * INSPECTION STOP (westbound vehicles): State of California platform scales, 31.5 miles west of Willow Creek.

(B) INSPECTION STOP: Oregon Mountain Summit, west of Weaverville at Milepost TRI-299-48.47.

* May be used as a “Safe Parking Place” when driver is given specific instructions by a member of the California Highway Patrol.

NOTE

Authority cited: Section 31616, Vehicle Code. Reference: Sections 31601, 31602, 31611, 31614 and 31616, Vehicle Code.

HISTORY

1. Repealer and new section filed 10-28-92; operative 10-28-92 (Register 92, No. 44). For prior history, see Register 90, No. 7.

2. Amendment of subsections (b)(1)(B), (E), (F) and (G) filed 10-17-94; operative 11-16-94 (Register 94, No. 42).

3. Editorial correction of History (Register 94, No. 42).

4. Amendment of subsections (b)(1)(E)-(F) and repealer of subsection (b)(1)(G) filed 12-23-2004; operative 1-22-2005 (Register 2004, No. 52).

§13-1151.2. Routes and Stops--Map 2.

Note • History

(a) Map 2.

(b) Safe Stopping Places and Inspection Stops--Map 2.

(1) INTERSTATE HIGHWAY 5.

(A) *REQUIRED INSPECTION STOP (southbound vehicles): Mt. Shasta Vehicle Inspection Facility.

(B) *REQUIRED INSPECTION STOP (northbound vehicles): Cottonwood Inspection Facility, 2.5 miles south of Cottonwood. No Services. Scales closed when signs display “Scales Closed, Do Not Enter.”

(C) *REQUIRED INSPECTION STOP (southbound vehicles): Cottonwood Platform Scales, 2 miles south of Cottonwood. No Services.

(D) Redding: Redding Truck Stop, 2731 South Market Street. Food, gasoline, diesel, propane, CFN Cardlock: 0700-2100 (Monday-Friday), 0700-1700 (Saturday), Closed Sunday.

(E) Pollard Flat: Pollard Flat USA, 24235 Eagles Roost Road, 33 miles north of Redding. Food, gasoline, diesel: 24 hours.

(2) STATE HIGHWAY 299.

(A) *INSPECTION STOP (eastbound vehicles): State of California platform scales, 6 miles west of Shasta. No services.

(c) Restrictions--Redding. Travel into or through Redding, except through traffic on I-5, shall be in accordance with the following:

(1) North and southbound traffic going west on SR-299 exit at the Central Redding-Eureka (SR-299) exit, proceed west on SR-299 to Pine Street, then north on Pine Street to Eureka Way, then west on Eureka Way (SR-299).

(2) North and southbound traffic going east on SR-299 shall exit I-5 at the Burney-Alturas (SR-299) exit, then proceed east.

(3) North and southbound traffic going east on SR-44 shall exit I-5 at Lassen Park (SR-44) exit, and proceed east.

*May be used as a “Safe Parking Place” when driver is given specific instructions by a member of the California Highway Patrol.

NOTE

Authority cited: Section 31616, Vehicle Code. Reference: Sections 31601, 31602, 31607, 31611, 31614 and 31616, Vehicle Code.

HISTORY

1. Repealer and new section filed 10-28-92; operative 10-28-92 (Register 92, No. 44). For prior history, see Register 92, No. 12.

2. Repealer of subsection (b)(1)(D), redesignation and amendment of former subsection (b)(1)(E) to (b)(1)(D), new subsection (b)(1)(E) and amendment of subsection (b)(1)(F) filed 10-17-94; operative 11-16-94 (Register 94, No. 42).

3. Editorial correction of History (Register 94, No. 42).

4. Amendment of subsections (b)(1)(B)-(C), repealer of subsections (b)(1)(E) and (c)(1) and subsection renumbering filed 12-23-2004; operative 1-22-2005 (Register 2004, No. 52).

§13-1151.3. Routes and Stops--Map 3.

Note • History

(a) Map 3.