In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

SAE Standard

Report of the Lighting Division, approved March 1918, last revised by the Lighting Committee August 1981, editorial change October 1981. Rationale statement available.

1. Scope—This Engineering Design Standard contains parameters and general requirements for vehicular license plate lamps. It may be augmented by a separate service performance specification.

2. Definition—License Plate Lamp—A lamp used to illuminate the license plate on the rear of a vehicle. If a tail or a stop lamp is combined with a license plate lamp, the combination shall also meet the requirements for these devices.

3. Laboratory Requirements—The following sections from SAE J575 are a part of this standard:

Section 2—Samples for Test

Section 2.2—Bulbs

Section 2.3—Test Fixture

Section 3—Laboratory Facilities

Section 4.1—Vibration Test

Section 4.2—Moisture Test

Section 4.3—Dust Test

Section 4.4—Corrosion Test

Section 4.8—Warpage Test on Devices with Plastic Components

4. Plastic Materials—Any plastic materials used in optical parts shall comply with the requirements set forth in SAE J576.

5. Color—The color of the light emitted from license plate lamps shall be white in accordance with SAE J578.

6. General Requirements

6.1 The design should be such that, when the lamp is mounted on a vehicle as intended, the angle between the plane of the license plate and the plane on which the vehicle stands will be 90±15 deg.

6.2 The License plate holder shall be designed and constructed to provide a substantial plane surface on which to mount the plate.

6.3 License plate lamp(s) for vehicles other than motorcycles and motor driven cycles shall be of such size and design as to provide illumination on all parts of a 150 × 300 mm (6 × 12 in) test plate. License plate lamp(s) for motorcycles and motor driven cycles shall be of such size and design as to provide illumination of all parts of a 100 × 175 mm (4 × 7 in) test plate. The light rays shall reach all portions of an imaginary plate of the same size at least 25mm (1 in) ahead of the actual test plate measured perpendicular to the plane of the plate.

φ 6.4 The license plate lamp or lamps for vehicles other than motorcycles and motor driven cycles shall be mounted so as to illuminate the plate without obstruction from any designed feature unless the device(s) is designed to comply with all the photometric requirements with these obstructions considered.

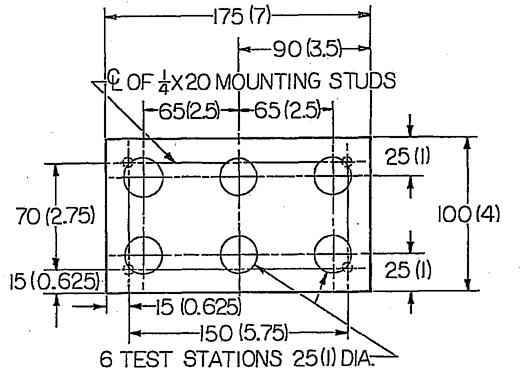

φ 6.5 When a single lamp is used to illuminate the plate, the lamp and license plate holder shall bear such relation to each other that at no point on the plate will the incident light make an angle of less than 8 deg to the plane of the plate, this angle being measured from the edge of the light emitting surface of the device farthest from the surface of the plate (see Fig. 3).

φ 6.6 When two or more lamps are used to illuminate the plate, the minimum 8 deg incident light angle shall apply only to that portion of the plate which the particular lamp is designed to illuminate. The incident light angle shall be measured in the same way as provided in paragraph 6.5.

φ 6.7 All illumination measurements shall be made on a rectangular test plate of clean, white blotting paper mounted on the license plate holder in the position ordinarily taken by the license plate. The face of the test plate shall be 1.5 mm (1/16 in) from the face of the license plate holder.

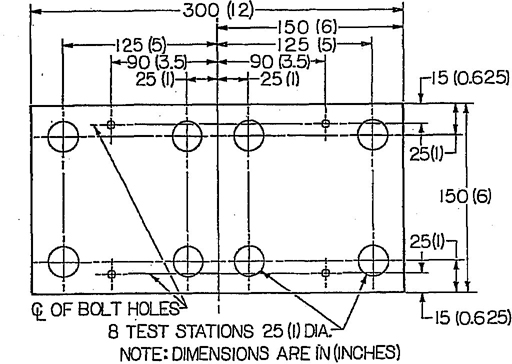

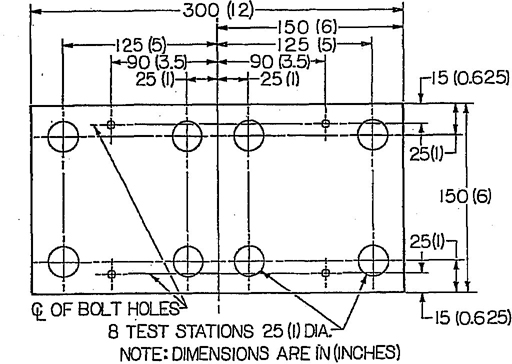

φ 6.8 For lamps used on vehicles other than motorcycles and motor driven cycles, the test stations shall be located on the face of the test plate as shown in Fig. I. For lamps used on motorcycles and motor driven cycles, the test stations shall be located on the face of the test plate as shown in Fig. 2.

φ FIG. 1—TEST PLATE FOR VEHICLES OTHER THAN MOTORCYCLES AND MOTOR DRIVEN CYCLES

φ FIG. 2—TEST PLATE FOR MOTORCYCLES AND MOTOR DRIVEN CYCLES

2

φ FIG. 3—MEASUREMENT OF INCIDENT LIGHT ANGLE

7. Photometric Test—The illumination of each of the stations on the test plate shall be at least 8 1× (0.75 ft-c). The ratio of maximum to minimum illumination shall not exceed 20/1 for the 150 × 300 mm (6 × 12 in) plate and shall not exceed 15/1 for the 100 × 175 mm (4 × 7 in) plate. The average of the two highest and the two lowest illumination values recorded at the eight test stations in the test plate of Fig. 1 shall be taken as maximum and minimum, respectively. The highest illumination value, and the average of the two lowest illumination values recorded at the six test stations in the test plate of Fig. 2, shall be taken as maximum and minimum, respectively.

A1. As a matter of information, attention is called to SAE J567 for requirements and gages to be used in socket design.

A2. Since some license lamps may be mounted in shaded locations, attention is particularly called to the section of SAE J576 which covers exposure time and conditions.

3