In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

NSF/ANSI 61 – 2001

NSF International Standard/

American National Standard

Developed by a consortium of:

With support from:

NSF International, an independent, not-for-profit, non-governmental organization, is dedicated to being the leading global supplier of public health and safety-based risk management services serving the interests of all stakeholders.

This Standard is subject to revision.

Contact NSF to confirm this revision is current.

Users of this Standard may request clarifications and interpretations, or propose revisions by contacting:

Chair, Joint Committee on Drinking Water Additives

c/o NSF International

789 North Dixboro Road, P.O. Box 130140

Ann Arbor, Michigan 48113-0140 USA

Phone: (734) 769-8010 Telex: 753215 NSF INTL

FAX: (734) 769-0109 E-mail: info@nsf.org

Web: http://www.nsf.org

American National Standard/

NSF International Standard

for Drinking Water Additives—

Drinking water system components—

Health effects

Standard Developer

NSF International

Adopted February 9, 2001

NSF International Board of Directors

Designated as an ANSI Standard

February 9, 2001

American National Standard Institute

Prepared by

The NSF Joint Committee on Drinking Water Additives

Recommended for Adoption by

The NSF Council of Public Health Consultants

Adopted by

The NSF Board of Directors

June 1988

Revised October 1988

Revised May 1990

Revised May 1991

Revised May 1992

Revised September 1994

Revised January 1995

Revised July 1996

Revised September 1996

Revised November 1996

Revised January 1997

Revised March 1997

Revised July 1997

Revised November 1998

Revised January 1999

Revised November 1999

Revised September 2000

Revised November 2000

Revised February 2001

Published by

NSF International

PO Box 130140, Ann Arbor, Michigan 48113-0140, USA

For ordering copies or for making inquiries with regard to this Standard, please reference the designation “NSF/ANSI 61– 2001.”

Copyright 2001 NSF International

Previous editions © 2000, 1999, 1998, 1997, 1996, 1995, 1994, 1992, 1991, 1990, 1988

Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from NSF International.

Printed in the United States of America.

iiDisclaimers1

NSF, in performing its functions in accordance with its objectives, does not assume or undertake to discharge any responsibility of the manufacturer or any other party. The opinions and findings of NSF represent its professional judgment. NSF shall not be responsible to anyone for the use of or reliance upon this Standard by anyone. NSF shall not incur any obligation or liability for damages, including consequential damages, arising out of or in connection with the use, interpretation of, or reliance upon this Standard.

NSF Standards provide basic criteria to promote sanitation and protection of the public health. Provisions for mechanical and electrical safety have not been included in this Standard because governmental agencies or other national standards-setting organizations provide safety requirements.

Participation in NSF Standards development activities by regulatory agency representatives (federal, local, state) shall not constitute their agency's endorsement of NSF or any of its Standards.

Preference is given to the use of performance criteria measurable by examination or testing in NSF Standards development when such performance criteria may reasonably be used in lieu of design, materials, or construction criteria.

The illustrations, if provided, are intended to assist in understanding their adjacent standard requirements. However, the illustrations may not include all requirements for a specific product or unit, nor do they show the only method of fabricating such arrangements. Such partial drawings shall not be used to justify improper or incomplete design and construction.

Unless otherwise referenced, the annexes are not considered an integral part of NSF Standards. The annexes are provided as general guidelines to the manufacturer, regulatory agency, user, or certifying organization.

1 The information contained in this Disclaimer is not part of this American National Standard (ANS) and has not been processed in accordance with ANSI’s requirements for an ANS. As such, this Disclaimer may contain material that has not been subjected to public review of a consensus process. In addition, it does not contain requirements necessary for conformance to the Standard.

iii iv| Foreword | ix | ||

| Consortium organizations | xi | ||

| 1 | Purpose, scope, and normative references | 1 | |

| 1.1 | Purpose | 1 | |

| 1.2 | Scope | 1 | |

| 1.3 | Normative references | 1 | |

| 1.4 | Limitations | 2 | |

| 1.5 | Alternate products or materials | 3 | |

| 2 | Definitions | 4 | |

| 3 | General requirements | 6 | |

| 3.1 | General | 6 | |

| 3.2 | Information and formulation requirements | 6 | |

| 3.3 | Identification of analytes of interest | 7 | |

| 3.4 | Products manufactured from annex C acceptable materials | 7 | |

| Table 3.1 – Material-specific analytes | 8 | ||

| 4 | Pipes and related products | 11 | |

| 4.1 | Scope | 11 | |

| 4.2 | Definitions | 11 | |

| 4.3 | General requirements | 11 | |

| 4.4 | Sample requirements | 12 | |

| 4.5 | Extraction procedures | 13 | |

| 4.6 | Analysis | 17 | |

| 4.7 | Normalization of contaminant concentrations | 17 | |

| 4.8 | Evaluation of contaminant concentrations | 19 | |

| Table 4.1 – Example single time point conditioning schedule | 20 | ||

| Table 4.2 – Single time point exposure schedule | 20 | ||

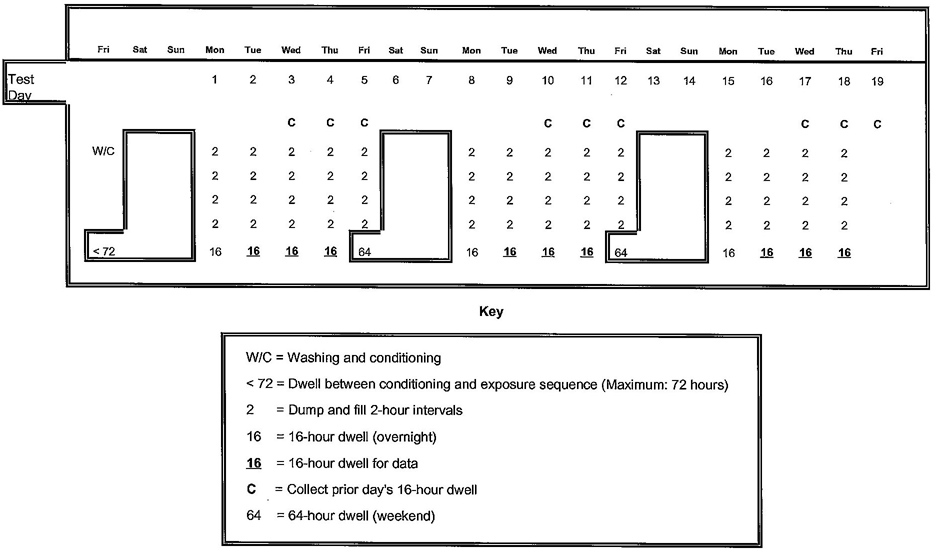

| Table 4.3 – Example multiple time point conditioning/exposure schedule | 21 | ||

| Table 4.4 – Pipes - normalization factors and assumptions | 22 | ||

| Table 4.5 – Fittings - (installed at regular intervals) normalization factors and assumptions | 23 | ||

| Table 4.6 – Example normalization calculations | 24 | ||

| 5 | Barrier materials | 25 | |

| 5.1 | Scope | 25 | |

| 5.2 | Definitions | 25 | |

| 5.3 | General requirements | 26 | |

| 5.4 | Sample requirements | 26 | |

| 5.5 | Extraction procedures | 27 | |

| 5.6 | Analysis of extraction water | 30 | |

| 5.7 | Normalization | 30 | |

| 5.8 | Evaluation of contaminant concentrations | 32 v | |

| Table 5.1 – Paint and coating system sample preparation | 33 | ||

| Table 5.2 – Single time point exposure sequence | 33 | ||

| Table 5.3 – Multiple time point exposure sequence | 34 | ||

| Table 5.4 – Surface area to volume ratios for tanks or storage vessels | 35 | ||

| 6 | Joining and sealing materials | 37 | |

| 6.1 | Coverage | 37 | |

| 6.2 | Definitions | 37 | |

| 6.3 | Material and extraction testing requirements | 37 | |

| 6.4 | Items of special significance | 37 | |

| 7 | Process media | 38 | |

| 7.1 | Scope | 38 | |

| 7.2 | Definitions | 38 | |

| 7.3 | General requirements | 38 | |

| 7.4 | Sample requirements | 39 | |

| 7.5 | Extraction procedures | 39 | |

| 7.6 | Analysis | 42 | |

| 7.7 | Normalization | 42 | |

| 7.8 | Evaluation of contaminant concentrations | 43 | |

| Table 7.1 – Product-specific minimum test batteries for process media products | 44 | ||

| Table 7.2 – Process media exposure dry weight per volume ratios | 45 | ||

| Table 7.3 – Maximum conditioning expansion rates for filtration and absorption media | 45 | ||

| Table 7.4 – Exposure schedule for process media of $0.25 mm in diameter | 46 | ||

| 8 | Mechanical devices | 47 | |

| 8.1 | Coverage | 47 | |

| 8.2 | Definitions | 47 | |

| 8.3 | Device, component, or material requirements | 47 | |

| Table 8.1 – Examples of mechanical devices | 49 | ||

| 9 | Mechanical plumbing devices | 50 | |

| 9.1 | Coverage | 50 | |

| 9.2 | Definitions | 51 | |

| 9.3 | Device, component, or material requirements | 51 | |

| 9.4 | Exposure and normalization | 52 | |

| 9.5 | Evaluation of normalized contaminant concentrations | 52 | |

| Annexes | |||

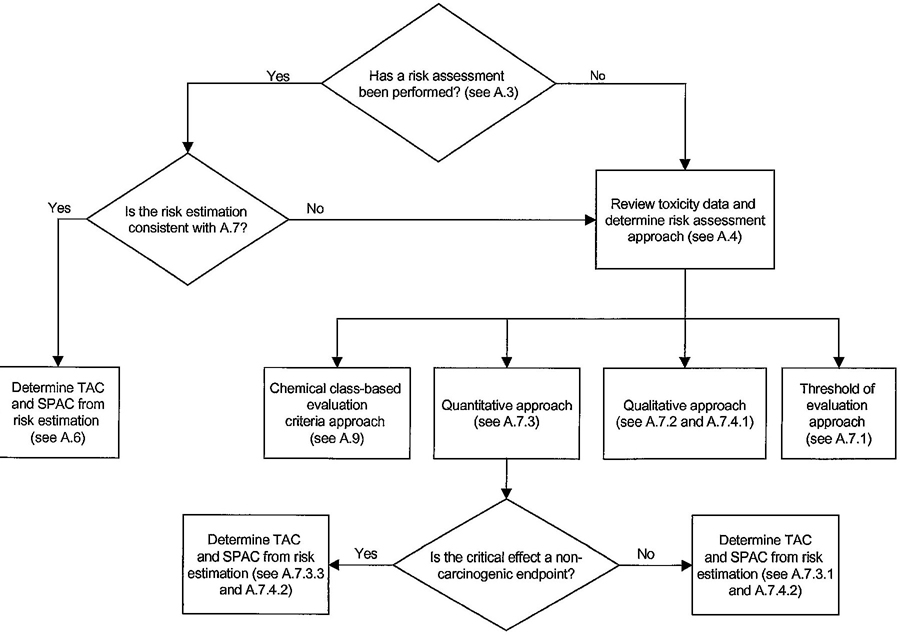

| A | Toxicology review and evaluation procedures (normative) | A1 | |

| A.1 | General requirements | A1 | |

| A.2 | Definitions | A1 | |

| A.3 | Data requirements for published risk assessments | A4 | |

| A.4 | Data requirements for new or updated risk assessments | A5 | |

| A.5 | Data requirements for evaluating short-term exposures | A6 | |

| A.6 | Risk estimation for published assessments | A7 | |

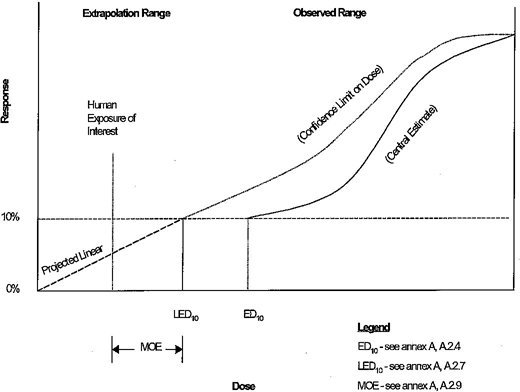

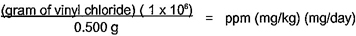

| A.7 | Risk estimation using new and updated risk assessments | A7 | |

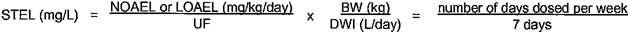

| A.8 | Risk estimation for short-term exposure (STEL calculation) | A14 vi | |

| A.9 | Development of chemical class-based evaluation criteria | A15 | |

| A.10 | Key elements of a risk assessment for DWA chemicals | A16 | |

| References | A21 | ||

| Figure A1 – Annex A toxicity data review process | A22 | ||

| Figure A2 – Graphical presentation of data and extrapolations | A23 | ||

| Table A1 – Qualitative risk assessment data requirements | A24 | ||

| Table A2 – Quantitative risk assessment data requirements | A25 | ||

| Table A3 – TACs for qualitative risk assessment | A26 | ||

| Table A4 – Uncertainty factors | A27 | ||

| B | Product/material evaluation (normative) | B1 | |

| B.1 | Background | B1 | |

| B.2 | General evaluation requirements | B1 | |

| B.3 | Joining and sealing materials | B4 | |

| B.4 | Mechanical devices | B7 | |

| B.5 | Mechanical plumbing devices | B8 | |

| B.6 | Collection and preservation of extraction media following exposure | B10 | |

| B.7 | Analysis methods | B11 | |

| B.8 | Normalization | B17 | |

| B.9 | Extraction water preparation | B23 | |

| Figure B1 – Exposure sequence for mechanical plumbing devices | B25 | ||

| Table B1 – NSF/ANSI 61 products | B26 | ||

| Table B2 – Exposure summary | B26 | ||

| Table B3 – Extraction water selection | B27 | ||

| Table B4 – Test samples joining and sealing materials | B27 | ||

| Table B5 – Additional conditioning for hot application samples | B27 | ||

| Table B6 – Product exposure | B28 | ||

| Table B7 – Exposure sequence | B28 | ||

| Table B8 – Extractant water collection and preservation | B29 | ||

| Table B9 – Normalization factors, assumptions, and examples | B30 | ||

| Table B10 – Data available for determination of lead test statistic | B36 | ||

| Table B11 – Values of k1 for determining test statistic Q | B36 | ||

| Table B12 – Values of k2 for determining retest statistic R | B37 | ||

| Table B13 – One liter volume of extraction water | B37 | ||

| C | Acceptable materials (normative) | C1 | |

| C.1 | Background | C1 | |

| C.2 | Evaluation of acceptable materials | C1 | |

| C.3 | Extraction testing | C1 | |

| C.4 | Documentation | C1 | |

| Table C1 – Acceptable materials | C2 | ||

| D | Normative drinking water criteria (normative) | D1 | |

| D.1 | General | D1 | |

| D.2 | USEPA and Health Canada drinking water criteria | D1 | |

| D.3 | NSF International peer-reviewed drinking water criteria | D2 | |

| D.4 | Drinking water criteria based on EPA guidance concentrations | D2 | |

| D.5 | Threshold of evaluation (TOE) chemical list | D2 | |

| Table D1 – U.S. Environmental Protection Agency and Health Canada Standard 61 drinking water criteria | D3 vii | ||

| Table D2 – NSF International peer-reviewed drinking water criteria | D9 | ||

| Table D3 – Drinking water criteria based on USEPA guidance concentrations | D10 | ||

| Table D4 – Threshold of evaluation chemicals | D16 | ||

| E | Informational drinking water criteria (informative) | E1 | |

| E.1 | General | E1 | |

| E.2 | NSF International drinking water criteria (not externally peer-reviewed) | E1 | |

| E.3 | Informational threshold of evaluation chemicals | E2 | |

| Table E1 – NSF International drinking water criteria (not externally peer-reviewed) | E3 | ||

| Table E2 – Threshold of evaluation chemicals having datasets from which specific TAC/SPAC values could possibly be setting using Annex A | E11 | ||

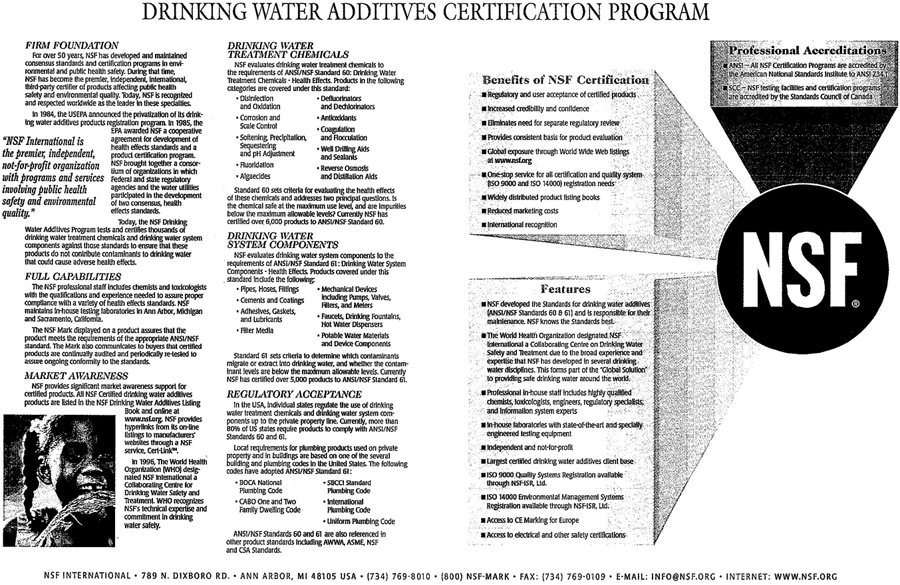

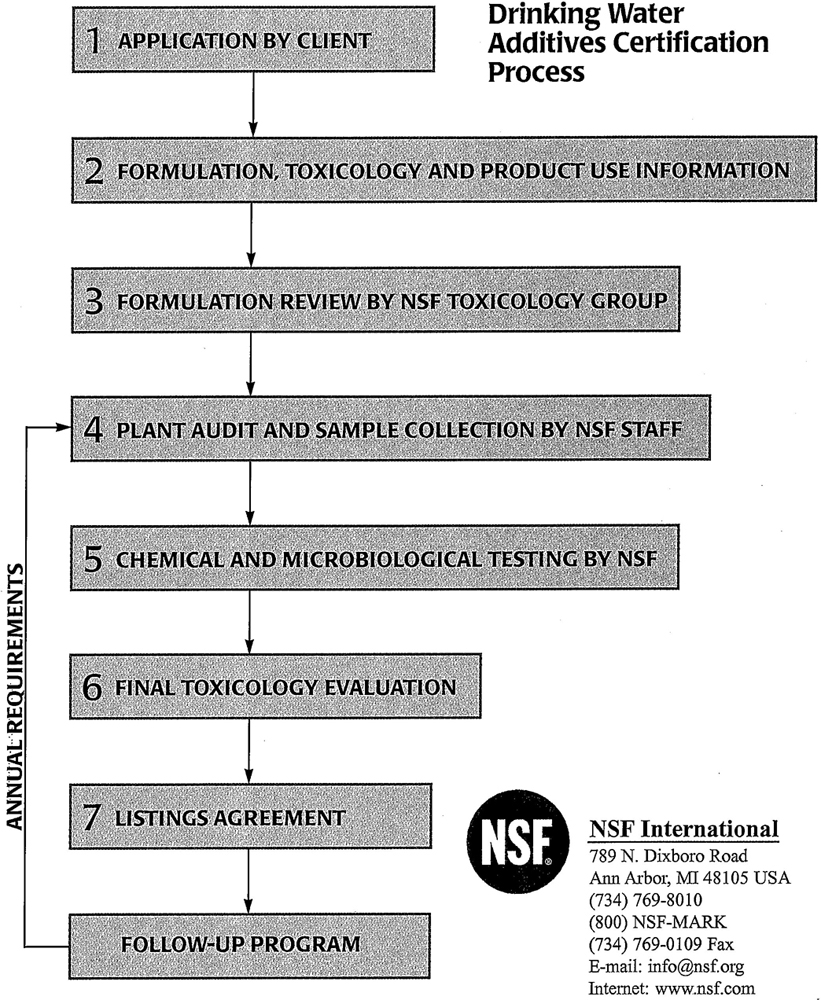

In response to a competitive request for proposals from the U.S. Environmental Protection Agency (USEPA), a Consortium led by NSF International (NSF) agreed to develop voluntary third-party consensus standards and a certification program for all direct and indirect drinking water additives. Other members of the Consortium include the American Water Works Association Research Foundation, the Association of State Drinking Water Administrators, the Conference of State Health and Environmental Managers, and the American Water Works Association. (COSHEM has since become inactive as an organization.) Each organization was represented on a steering committee with oversight responsibility for the administration of the cooperative agreement. The Steering Committee provides guidance on overall administration and management of the cooperative agreement. Currently, the member organizations remain active in an oversight role.

Two standards for additives products were developed. NSF/ANSI 60 – Drinking water treatment chemicals—Health effects covers many of the water treatment chemicals, also known as direct additives. This Standard, NSF/ANSI 61 – Drinking water system components—Health effects, covers all indirect additives products and materials. Testing to determine the potential of a product to impart taste and/or odor to drinking water is not included in this Standard.

NSF/ANSI 61 was developed to establish minimum requirements for the control of potential adverse human health effects from products that contact drinking water. It does not attempt to include product performance requirements that are currently addressed in other voluntary consensus standards established by such organizations as the American Water Works Association, the American Society for Testing and Materials, and the American National Standards Institute. Because this Standard complements the performance standards of these organizations, it is recommended that products also meet the appropriate performance requirements specified in the standards of such organizations.

NSF/ANSI 61, and subsequent product certification against it, has replaced the USEPA Additives Advisory Program for drinking water system components. USEPA terminated its advisory role in April 1990. For more information with regard to USEPA’s actions, refer to the July 7, 1988 Federal Register (53FR25586).

This Standard and the accompanying text are intended for voluntary use by certifying organizations, utilities, regulatory agencies, and/or manufacturers as a basis of providing assurances that adequate health protection exists for covered products. Product certification issues, including frequency of testing and requirements for follow-up testing, evaluation, enforcement, and other policy issues, are not addressed by this Standard.

This Standard was initially approved by ANSI in 1989. NSF and all stakeholders have worked since 1988 to complete NSF/ANSI 61 by including requirements for mechanical plumbing products. Devices used within the final one L of the distribution system are covered under section 9 and include end-point devices such as faucets, glass fillers, water coolers, residential ice makers, and supply stops.

Section 9 was accepted by the NSF Joint Committee on Drinking Water Additives, and the NSF Council of Public Health Consultants. It was adopted by the NSF Board of Trustees on September 9, 1994, and approved by ANSI on September 12, 1995.

2 The information contained in this Foreword is not part of this American National Standard (ANS) and has not been processed in accordance with ANSI’s requirements for an ANS. As such, this Foreword may contain material that has not been subjected to public review of a consensus process. In addition, it does not contain requirements necessary for conformance to the Standard.

ixWater contact materials in Drinking Water Treatment Units listed under NSF/ANSI 42, 44, 53, 55, 58, and 62 are tested and evaluated under a separate protocol from NSF/ANSI 61 with criteria which were developed specifically for the intended end-use. NSF 61 listing should not be additionally required for acceptance of these listed units for water contact application.

This version of the Standard (NSF/ANSI 61-2001) includes the following revisions:

– Minimum test batteries for common coating and paint materials were added to table 3.1.

– Section 4 was updated to specify that fitting products may be exposed as part of a pipe and fitting assembly to simulate their field exposure. For products having internal threaded areas, a requirement that 75% of the threaded area be covered during the exposure was added. Copper and copper alloy fittings can also be exposed using the pH 6.5 exposure water used for copper pipe. Normalization specifications for special use fittings were defined and an example normalization calculation provided.

– Section 5 requirements for Barrier Materials has been comprehensively updated. Technical revisions include the addition of guidelines for the determination of a representative test sample for similar product formulations, the exposure protocols were revised so that all sampling points are 24 hours in duration, the table for normalization factors was expanded to include many additional tank capacities, the assumptions for calculation of tank normalization factors were defined, and the sampling procedures for cement products was updated. The sample preparation, exposure, and normalization procedures have been moved from annex B to section 5.

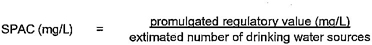

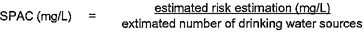

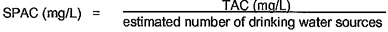

At the suggestion of the NSF Council of Public Health Consultants, the terminology defining the drinking water criteria used in this Standard has been revised. The Maximum Drinking Water Level (MDWL) has been revised to the Total Allowable Concentration (TAC) and the Maximum Allowable Level (MAL) has been revised to the Single Product Allowable Concentration (SPAC).

This Standard was developed by the NSF Joint Committee on Drinking Water Additives using the consensus process described by the American National Standards Institute.

Suggestions for improvement of this Standard are welcome. Comments should be sent to Chair, Joint Committee on Drinking Water Additives, c/o NSF International, Standards Department, PO Box 130140, Ann Arbor, Michigan 48113-0140, USA.

xNSF International

Popularly referred to as NSF, NSF International is a noncommercial agency. It is incorporated under the laws of Michigan as a not-for-profit organization devoted to research, education, and service. It seeks to solve problems involving man and his environment. It wishes to promote health and enrich the quality of life through conserving and improving that environment. Its fundamental principle of operation is to serve as a neutral medium in which business and industry, official regulatory agencies, and the public come together to deal with problems involving products, equipment, procedures, and services related to health and the environment. It is conceived and administered as a public service organization.

NSF is perhaps best known for its role in developing standards and criteria for equipment, products, and services that bear upon health. NSF was the lead organization in the Consortium responsible for developing this Standard. NSF conducts research; tests and evaluates equipment, products, and services for compliance with standards and criteria; and grants and controls the use of NSF registered Marks.

NSF offers product certification (Listing Services) for all products covered by its standards. Each program has established policies governing the associated product evaluation, Listing Services, follow-up and enforcement activities. The NSF Listing Mark is widely recognized as a sign that the product or service to which it relates complies with the applicable NSF standard(s).

AWWA Research Foundation

The mission of the American Water Works Association Research Foundation (AWWARF) is to sponsor practical, applied research in behalf of the drinking water industry of North America. The scope of the research program embraces all aspects of water supply operation, from development and maintenance of water resources to treatment technologies and water quality issues, from storage and distribution system operations to health effects studies and utility planning and management activities. AWWARF serves as the centralized industry institution for planning, managing, and funding cooperative research and development in drinking water, including the subsequent transfer of technology and results for practical application by the water utility community.

AWWARF’s purpose in this cooperative program is to provide a communication link with the water utilities throughout North America and serve as the focal point for identification of research needs of the water supply industry with respect to the additives program.

The Association of State Drinking Water Administrators

The Association of State Drinking Water Administrators (ASDWA) is a nonprofit organization whose eligible membership is comprised of drinking water program administrators in each of the 50 states and seven U.S. territories. Through the organization, representatives speak with a collective voice to Congressional committees, the United States Environmental Protection Agency (EPA), professional and trade associations, water utilities, and the general public on issues related to state drinking water programs. With its mission of protecting the public health through assurance of high quality drinking water, and promoting responsible,

3 The information contained in this section is not part of this American National Standard (ANS) and has not been processed in accordance with ANSI’s requirements for an ANS. As such, this section may contain material that has not been subjected to public review of a consensus process. In addition, it does not contain requirements necessary for conformance to the Standard.

xireasonable, and feasible drinking water programs at the state and federal levels, the Association is a valued contributor to the consortium, and to the program. It provides the link between the additives program and the state drinking water programs.

The Conference of State Health and Environmental Managers

The Conference of State Health and Environmental Managers (COSHEM), known formerly as the Conference of State Sanitary Engineers (CSSE), is currently inactive as an organization. It brought to the consortium expertise and involvement of state health and environmental program managers. The Conference was the focal point for health concerns of all state environmental programs, including drinking water, wastewater, air, solid and hazardous wastes, radiological, occupational, health, and food. A standing committee on water supply focused on drinking water issues and kept the membership informed. The Conference played an important role early in the program through two-way communication with state health and environmental program decision makers.

American Water Works Association

The purpose of the American Water Works Association (AWWA) is to promote public health, safety, and welfare by improving the quality and increasing the quantity of water delivered to the public, and to developing and furthering an understanding of the problems relating thereto by:

– advancing the knowledge of the design, construction, operation, water treatment and management of water utilities;

– developing standards for procedures, equipment, and materials used by public water supply systems;

– advancing the knowledge of problems involved in the development of resources, production, and distribution of safe and adequate water supplies;

– educating the public on the problems of water supply and promoting a spirit of cooperation between consumers and suppliers in solving these problems; and

– conducting research to determine the causes of problems of providing a safe and adequate water supply and proposing solutions thereto in an effort to improve the quality and quantity of the water supply provided to the public.

AWWA brings to the Consortium its established position as the largest public drinking water association in North America, with a broad membership that includes utilities, consultants, manufacturers/distributors/agents, contractors, and other organizations with a direct interest in drinking water.

xiiNSF/ANSI Standard for Drinking Water Additives—

Drinking water system components—Health effects

1.1 Purpose

This Standard establishes minimum health effects requirements for the chemical contaminants and impurities that are indirectly imparted to drinking water from products, components, and materials used in drinking water systems. This Standard does not establish performance, taste and odor, or microbial growth support requirements for drinking water system products, components, or materials.

1.2 Scope

1.2.1 This Standard is intended to cover specific materials or products that come into contact with: drinking water, drinking water treatment chemicals, or both. The focus of the standard is evaluation of contaminants or impurities imparted indirectly to drinking water. The products and materials covered include, but are not limited to, process media (carbon, sand, etc.), protective materials (coatings, linings, liners, etc.), joining and sealing materials (solvent cements, welding materials, gaskets, etc.), pipes and related products (pipes, tanks, fittings, etc.), mechanical devices used in treatment/transmission/distribution systems (valves, chlorinators, separation membranes, etc.), and mechanical plumbing devices (faucets, endpoint control valves, etc.).

1.2.2 Point-of-use and point-of-entry drinking water treatment devices are not covered by the scope of this Standard.

1.2.3 Fire hydrants are not covered by the scope of this Standard.

1.3 Normative references

The following documents contain requirements which, by reference in this text, constitute requirements of this Standard.

APHA, Standard Methods for the Examination of Water and Wastewater, twentieth edition1)

ASTM C31/C31M-96, Standard Practice for Making and Curing Concrete Test Specimens in the Field2)

ASTM C109/C109M-98, Standard Test Method for Compressive Strength of Hydraulic Cement Mortars2)

ASTM C192/C192M-95, Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory2

1) American Public Health Association (APHA), 800 I Street, NW, Washington, DC 20001

2) American Society for Testing and Materials (ASTM), 100 Barr Harbor Drive, West Conshohocken, PA 19428-2859

1ASTM C511-97, Standard Specification for Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic Cements and Concretes2)

ASTM C778-97, Standard Specification for Standard Sand2)

ASTM D1193-99, Standard Specification for Reagent Water2)

ASTM D2855-96, Standard Practice for Making Solvent-Cemented Joints with Poly(Vinyl Chloride) (PVC) Pipe and Fittings2)

ASTM D3182-89, Standard Practice for Rubber - Materials, Equipment, and Procedures for Mixing Standard Compounds and Preparing Standard Vulcanized Sheets2)

ASTM F493-97, Standard Specification for Solvent Cements for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe and Fittings2)

ANSI/AWWA B100-96, AWWA Standard for Filtering Material3)

ANSI/AWWA C652-92, AWWA Standard for Disinfection of Water-Storage Facilities3)

NSF/ANSI 60 - 2001, Drinking Water Treatment Chemicals - Health Effects

OECD, OECD Guidelines for the Testing of Chemicals, May 19964)

USEPA-600/4-79-020, Methods for the Chemical Analysis of Water and Wastes, March 19835)

USEPA-600/4-80-032, Prescribed Procedures for Measurement of Radioactivity in Drinking Water5)

USEPA Health Effects Testing Guidelines, 40 CFR Part 79866)

USEPA Good Laboratory Practice Standards, 40 CFR Part 7926)

USEPA Good Laboratory Practice for Non-Clinical Laboratory Studies, 21 CFR 587)

USFDA, Toxicological Principles for the Safety Assessment of Direct Food Additives and Color Additives in Food7)

1.4 Limitations

The requirements of this Standard are limited to addressing potential health effects, except where specific application and performance standards are referenced. This Standard does not establish taste and odor requirements for drinking water system products and materials. The criteria set forth in this Standard cover products produced by good manufacturing practices and generally recognized manufacturing processes. As

3) American Water Works Association (AWWA), 6666 Quincy Avenue, Denver, CO 80235-9913

4) Organization for Economic Cooperation and Development (OECD), 2 Rue Andre-Pascal, 75775 Paris Cedex 16, France

5) USEPA, Environmental Monitoring and Support Laboratory, Cincinnati, OH 45268

6) Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402

7) USFDA, 5600 Fishers Lane, Rockville, MD 20857

2the presence of unusual or unexpected impurities is frequently dependent upon the method of manufacture and the quality of raw material used, products prepared by other than recognized methods of manufacture or with unusual raw materials shall be fully evaluated in accordance with section 3 of this Standard (general requirements). Products that have been evaluated and found to meet other NSF standards having health requirements equivalent to this Standard as indicated in each section shall be acceptable for drinking water applications without separate evaluation under this Standard8)

1.5 Alternate products or materials

While specific materials are stipulated in this Standard, drinking water system products or components that incorporate alternate materials shall be acceptable when it is verified that the product or component meets the applicable requirements of the Standard based on its end use.

8) Final acceptance of a product for drinking water application is the responsibility of the appropriate federal, state, or local regulatory agent.

3Terms used in this Standard that have a specific technical meaning are defined here.

2.1 analytical summary: A list of the analytes and analytical procedures, both chemical and microbiological, which are selected to determine whether a product is compliant to the requirements of the Standard; analytes may be either product specific or formulation dependent.

2.2 at the tap: Referring to the point-of-delivery or point-of-use for drinking water.

2.3 cold water application: A product application which is not intended to result in exposure for extended periods to water in excess of ambient water temperature.

2.4 contaminant: Any physical, chemical, biological, or radiological substance or matter in water.

NOTE – Consistent with the definition in the Federal Safe Drinking Water Act, a contaminant can have either a beneficial or detrimental effect on the potability of water.

2.5 direct additives: A treatment chemical and its contaminants directly added to water during the production of drinking water.

2.6 distribution system: The system of conduits or the network of pipelines (located primarily in the streets) through which a primary domestic water supply is distributed to consumers. In plumbing codes this term is applied to all the hot and cold water piping installed in buildings.

2.7 drinking water: Water intended for human consumption.

2.8 good manufacturing practices: The practice of maximizing the purity of products and materials by maintaining and practicing appropriate quality control and quality assurance procedures.

2.9 hot water application: A product application which is intended to result in exposure for extended periods to water which has been raised from ambient temperature.

2.10 indirect additives: Contaminants which are extracted into drinking water through contact with the surfaces of materials, components, or products used for its treatment, storage, transmission, or distribution.

2.11 manufacturer: A corporation, company, or individual that produces, formulates, packages, or repackages products, components, and materials that are intended to be in contact with drinking water.

2.12 maximum contaminant level (MCL): The maximum concentration of a regulated contaminant that is permitted in a public drinking water supply, as defined under the Federal Safe Drinking Water Act.

NOTE – If the manufacturer requests review to relevant alternate regulatory requirements, the certifying agency can consider alternative regulatory levels, e.g. Canadian Maximum Acceptable Concentrations (MACs).

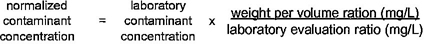

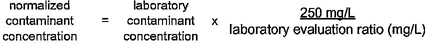

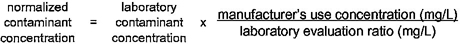

2.13 normalization: The process of adjusting laboratory extraction results by accounting for differences between laboratory and field surface area-to-volume ratios to reflect the contaminant concentration at the tap.

2.14 normalized concentration: A value for a contaminant concentration from a laboratory extraction test which has been adjusted to reflect the potential contaminant concentration at the tap.

2.15 point-of-entry system: A system with an inlet connection of 25.4 mm (1 in) or less which contacts all or a majority of the water entering the facility.

2.16 point-of-use system: A system located at a single tap or multiple taps which does not contact the

4majority of water entering the building or residence.

2.17 short-term exposure level (STEL): A maximum concentration of a contaminant which is permitted in drinking water for an acute exposure calculated in accordance with annex A of this Standard.

2.18 single product allowable concentration (SPAC): The maximum concentration of a contaminant in drinking water that a single product is allowed to contribute as defined by annex A of this Standard.

2.19 total allowable concentration (TAC): The maximum concentration of a nonregulated contaminant allowed in a public drinking water supply as defined by annex A of this Standard.

2.20 transmission system: A system of conduits through which a primary water supply is transmitted to the distribution system.

53.1 General

3.1.1 Product and material information described in 3.2 shall be used to determine the specific section (sections 4 through 9) under which a product or material shall be evaluated.

3.1.2 Products or materials whose intended uses fall under more than one section of this Standard shall be evaluated under the section having the most rigorous evaluation conditions.

NOTE – Rigorous conditions are typically associated with shorter conditioning periods, longer exposure periods, higher surface area-to-volume ratios, and higher exposure temperatures.

3.2 Information and formulation requirements

The following information shall be reviewed to determine the appropriate analytical testing and to ensure that the potential health effects of products or materials are accurately and adequately identified:

6– the product section(s) under which the product, component, or material is covered, and the intended function or end use of the product or the material;

– for assembled products or components, a list of all of components and materials and their corresponding surface areas which come into direct contact with water;

– when appropriate, the total volume of water that the product can hold when filled to capacity;

– the expected service life of the product;

– the anticipated minimum, maximum, and average volumes of water that come into contact with the product, component, or material during a 24-hour period;

– complete formulation information for each water contact material as applicable;

– the composition of the formulation (e.g. percent or parts by weight for each chemical in the formulation or reference to a standardized material specification);

– a chemical abstract number (CAS no.), name, trade designation, and supplier for each chemical present in the formulation, and a Material Safety Data Sheet (MSDS) when available;

– an indication as to whether the chemical is an ingredient, reactant, or processing aid.

– the maximum temperature to which the product, component, or material is exposed during its intended end use;

– a description/classification of the manner in which the product or material is manufactured, handled, and packaged;

– when available, a list of the known or suspected impurities within the product or material, and the maximum percent or parts by weight of each impurity;

– when available, the solubility, hydrolysis products, and extraction rates of chemicals within the product or material; and

– when available, a list of published and unpublished toxicological studies relevant to the chemicals and impurities present in the product, component, or material.

3.3 Identification of analytes

For all products and materials, the formulation information required in 3.2 shall be reviewed for completeness (e.g., all formulations total 100%), and to determine whether a minimum test battery has been established for each water contact material (see table 3.1). The availability of an established minimum test battery shall not preclude performance of a formulation review to identify any formulation-dependent analytes (see 3.3.1).

3.3.1 Formulation-dependent analysis selection

For all water contact materials, the formulation information described in section 3.2 shall be reviewed and formulation-dependent analytes shall be identified for each water contact material. The criteria for selection of a formulation dependent analyte shall include, but not be limited to the following:

– known or suspected toxicity of the substance or its byproduct(s);

– high water solubility of the substance;

– monomer(s) of polymeric ingredients;

– high probability of extraction of a substance or its byproduct(s) at toxicologically significant concentrations; and

– extraction or migration information for the substance provided by the manufacturer.

3.3.2 Established minimum test batteries

The materials listed in table 3.1 shall be tested for the indicated analyses and any formulation-dependent analyses identified during the formulation-dependent analyte selection.

3.4 Products manufactured from annex C acceptable materials

Products manufactured entirely from annex C materials shall not be required to undergo extraction testing for material-specific analytes of interest. However, extraction testing for contaminants contributed by processes specific to a production site shall be considered as formulation-dependent analytes. Annex C contains the evaluation requirements for qualification as an acceptable material.

7| Material type | Required analyses |

|---|---|

| Pipe/fitting/device materials | |

| Asphaltic-coated ductile iron | GC/MS base/neutral scan (specific for carbonyls and non-aromatic hydrocarbons)1), volatile organic chemicals (VOCs), polynuclear aromatic hydrocarbons (PNAs), regulated metals2), molybdenum, vanadium, manganese |

| Brass | regulated metals2), zinc, nickel |

| Concrete | regulated metals2) |

| Copper | regulated metals2) |

| Galvanized steel | regulated metals2), zinc, nickel |

| Stainless steel | regulated metals2), nickel |

| Plastic materials | |

| Acetal (AC)/Polyoxymethylene (POM) | formaldehyde, VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1), acetal oligomers (by GC/MS base/acid scan)1) |

| Acrylonitrile-butadiene-styrene (ABS) | acrylonitrile, 1,3-butadiene, styrene, regulated metals2), VOCs, phenolics (by GC/MS based/acid scan)1) |

| Cross linked polyethylene (PEX) | GC/MS1), VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1), methanol, tert-butyl alcohol3) |

| Nylon 6 | caprolactam, nitrogen-containing extractants (by GC/MS base/neutral scan)1), VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1) |

| Other nylons | nitrogen-containing extractants (by GC/MS base/neutral scan)1), VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1), nylon monomers |

| Polybutylene (PB) | VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1) |

| Polyethylene (PE) | VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1) |

| Polyphenylene oxide (PPO) | dimethyl phenol, VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1) |

| Polyphthalamide (PPA) | hexamethylene diamine, terephthalic acid, isophthalic acid, VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1) |

| Polypropylene (PP) | VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1) |

| Polysulphone including poly[phenylene sulphone] (PPSU) | sulphone monomer, VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1) |

| Polysulphone including poly [phenylene sulphone] (PPSU) | sulphone monomer, VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1) |

| Polyurethane (PUR) | GC/MS1), VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1) |

| Polyvinyl chloride (PVC) and Chlorinated polyvinyl chloride (CPVC) | regulated metals2), phenolics1), VOCs, tin4), antimony5), residual vinyl chloride monomer (RVCM)6) |

| Polyvinyl chloride (flexible) | VOCs, regulated metals2), phenolics (by GC/MS base/acid scan)1), phthalates7), RVCM6), tin4), zinc8) 8 |

| Elastomer materials | |

| Ethylene-propylene-diene monomer (EPDM) | GC/MS1), VOCs, phenolics (by GC/MS base/acid scan)1), phthalates7), PNAs1) |

| Fluoroelastomer | GC/MS1), VOCs, phthalates7), |

| Isoprene | GC/MS1), VOCs, phenolics (by GC/MS base/acid scan)1), phthalates7), PNAs1), isoprene monomer |

| Neoprene | GC/MS1), VOCs, phenolics (by GC/MS base/acid scan)1), phthalates7), PNAs1), chloroprene |

| Nitrile-butadiene rubber (NBR, BUNA-N) | GC/MS1). VOCs, phenolics(by GC/MS base/acid scan)1), phthalates7), PNAs1), 1,3-butadience, acrylonitrille |

| Styrene-butadiene rubber (SBR) | GC/MS1), VOCs, phenolics (by GC/MS base/acid scan)1), phthalates1), PNAs1), 1,3-butadience, styrene |

| Barrier materials | |

| Asphaltic coatings | regulated metals2), molybdenum, vanadium, manganese, VOCs, GC/MS base/neutral scan (specific for carbonyls an non-aromatic hydrocarbons)1), PNAs1) |

| Epoxy coatings (liquid and powder) | GC/MS (base/neutral/acid scan), bisphenol A, bisphenol A-diglycideryl ether9), bisphenol A-diglycideryl ether9), bisphenol A-propoxylate9), epichlorohydrin, VOCs, solvent and reactive diluents additives10) |

| Polyester coatings | GC/MS (base/neutral/acid scan), VOCs, residual monomers11) |

| Polyester coatings | GC/MS (base/neutral/acid scan), VOCs |

| Portland and hydraulic cements | GC/MS1), regulated metals2), dioxins and furans12), radionuclides, glycols and ethanolamines13) 9 |

| 1) See annex B, section B.7 2) Antimony, arsenic, barium, beryllium, cadmium, chromium, copper, lead, mercury, selenium, thallium 3) tert-butyl alcohol analysis is required for PEX materials except those crosslinked via 3-beam methodology. 4) The analysis for tin is required when tin-based stabilizers are used. 5) The analysis for antimony is required when antimony-based stabilizers are used. 6) The level of RVCM within the walls of PVC or CPVC products and materials shall be directly determined (annex B, section B,7). 7) The analysis for phthalates is required when phthalate ester plasticizers are used. Analysis shall be for the specific phthalate ester(s) used in the formulation. 8) The analysis for zinc is required when zinc-based stabilizers are used. 9) Analysis shall be performed using Liquid Chromatography with Ultraviolet detection (LC/UV). 10) Analysis shall be performed for the specific solvent and reactive diluents additives used in the individual product formulation, such as benzyl alcohol. 11) Analysis shall be performed for residual concentrations of the specific ester monomer’s used in the individual product formulation. 12) Dioxin and furan analysis to be performed on cements using fuel or material sources which are defined as hazardous waste by the U.S. Resource Conservation and Recovery Act (RCRA). 13) Glycol and ethanolamine analyses shall be performed on cements containing these compounds as grinding aids. |

|

4.1 Scope

4.1.1 The requirements in this section apply to pipes and pipe-related products and the water-contact materials associated with these products. Pipe-related products include, but are not limited to, the following items: fittings, couplings, flexible and rigid tubing, riser tubing, dip tubes, hoses, well casings, drop pipes, screens, and pipe-related coatings.

4.1.2 Coatings and other barrier materials not exclusively intended for application to pipes or pipe-related products are evaluated under 5.

NOTE – Coatings and other barrier materials which meet the requirements of 5 at a specific surface area-to-volume ratio, shall be considered to meet the requirements of a pipe or pipe-related product application for a surface area-to-volume ratio less than or equal to the ratio accepted under the 5 evaluation.

4.1.3 Individual ingredients of cement-based pipes and related products (including portland and blended hydraulic cement and admixtures) are evaluated under 5.

4.1.4 Products and materials intended to join or seal pipes or pipe-related products are evaluated under 6.

4.2 Definitions

4.2.1 Cold water application: A product application which is intended to result in continuous exposure to water of ambient temperature. Products are tested for an end-use temperature of 23 ± 2EC (73 ± 4EF).

4.2.2 commercial hot water applications: A product application which is intended to result in continuous or intermittent exposure to water which has been raised from ambient temperature. Intermittent exposure is considered to be any hot water contact which is not continuous. Products are tested for an end-use temperature of 82 ± 2EC (180 ± 3EF).

4.2.3 domestic hot water applications: A product application which is intended to result in continuous or intermittent exposure to water which has been raised from ambient temperature. Intermittent exposure is considered to be any hot water contact which is not continuous. Products are tested for an end-use temperature of 60 ± 2EC (140 ± 3EF).

4.2.4 nominal diameter: A designation system used to specify a pipe size, where the designation for a specific size is approximately equal to the average inside diameter of the pipe.

4.3 General requirements

4.3.1 The product size with the most conservative normalization conditions shall be evaluated. Successful evaluation of such product shall qualify all products of less conservative normalization conditions, provided the materials of construction are identical as specified in 4.4.1.

11NOTE – For products of ½ in to 4 in nominal diameter (1.3 cm to 10 cm) and products of 4 in diameter and greater (10 cm and greater), the most stringent normalization condition is typically the smallest inner diameter product within the nominal diameter range. Products of less than ½ in nominal diameter (1.3 cm) are assumed to have limited exposure in the distribution system (see assumptions in tables 4.4 and 4.5). Successful qualification of products of less than ½ in nominal diameter (1.3 cm) may not demonstrate the acceptability of all products ½ in nominal diameter (1.3 cm) and greater.

4.3.2 Residual vinyl chloride evaluation

Polyvinyl chloride and chlorinated polyvinyl chloride products and materials shall be evaluated for the level of residual vinyl chloride monomer (RVCM) in the product wall or in the material according to annex B, section B.7.

4.4 Sample requirements

4.4.1 General

A sample can represent a product line of various sizes when:

– materials are of the same alloy, composition, or formulation;

– materials have undergone the same manufacturing process, e.g., casting, extrusion;

– designs and manufacturing processes are analogous; and

– it has the most stringent normalization requirements (see 4.3.1).

4.4.2 Materials

When a material is proposed for evaluation, a representative sample of the material shall be used. Material test samples (e.g. plaque or sheet) shall be used only if no chemical or physical difference exists between the material sample and the material as it is used in applications covered by 4. A material intended to be processed by more than one method (e.g. injection molding, extrusion, stamping, etc.) shall be tested in each of its processed forms.

4.4.3 Finished products

When a finished product (e.g. pipe or fitting) is proposed for evaluation, a sample of the finished product shall be used of testing except in the following specific instances:

– concrete cylinders, cubes, or other concrete surrogate samples can be evaluated on behalf of concrete-lined pipes and other concrete-based products;

– coatings, applied to the appropriate substrate, can be evaluated on behalf of products whose entire water contact surface is covered by the coating; and

– Finished products, for which finished product evaluation is impractical due to one or more of the following reasons, shall be permitted to be evaluated using material samples:

a) an internal volume greater than 20 L (5.3 gallons);

b) a weight greater than 34 kilograms (75 lbs);

c) in situ manufacture of the finished product.

Material samples shall be permitted to be evaluated on behalf of a finished product if the first and second criteria listed under 4.4.1 are satisfied.

124.5 Extraction procedures

4.5.1 Analytical summary

An analytical summary shall be prepared for each product or material. The analytical summary shall consist of the formulation-dependent analytes identified in 3.2 and the applicable material-specific analytes listed in table 3.1.

4.5.2 Preparation of test samples

4.5.2.1 In all cases, test samples shall be prepared so that the laboratory surface area-to-volume ratio is equal to or greater than the surface area-to-volume ratio at which the product is intended to be used in the field.

NOTE – To facilitate the exposure of product samples that are connected to pipe or tubing products under normal installation conditions (e.g., fittings), the samples may be attached to lengths of pipe or tubing of the appropriate nominal diameter. When preparing a test sample in this manner, the exposed surface area of the fitting test sample shall represent a percentage of the total exposed surface area (test sample plus the attached pipe or tubing) that is equal to or greater than the percentage specified in the table 4.5 normalization assumptions, for the specific nominal diameter and end use of the product (flexible or rigid piping system). The pipe or tubing material shall also be present in the method blank as required in annex B, section B.2.8.1.

4.5.2.2 Unless manufacturer’s instructions direct otherwise, test samples shall be rinsed in cold tap water until any extraneous debris or contamination which occurred during shipping and handling is removed. The samples shall then be rinsed in deionized water (ASTM D 1193 Type II).

4.5.2.3 If the exterior surface of a product is to be exposed, all markings which are not integral to the product (e.g. ink markings) shall be removed.

4.5.2.4 When the test sample contains internal threaded outlets, 75% of the threaded surface area shall be covered by insertion of a threaded component of the appropriate diameter to produce a water tight seal.

4.5.3 Exposure water

4.5.3.1 General

Exposure water selection shall be determined by the analytes of interest identified on the analytical summary (see 4.5.1). Exposure water(s) shall be selected in accordance with annex B, section B.2.5.

4.5.3.2 Copper and copper alloys

Copper and copper alloy pipe and tubing shall be exposed in the pH 6.5 and in the pH 10 exposure waters as described in annex B, section B.9. Copper and copper alloy fittings intended to be used with copper pipe and tubing shall be exposed in either the pH 5 or the pH 6.5 exposure waters (at the discretion of the manufacturer) and in the pH 10 exposure water, as described in annex B, section B.9. For all copper and copper alloy pipes, tubing, and fittings tested using the pH 6.5 exposure water, the manufacturer’s literature shall indicate this use limitation. The manufacturer’s use instructions or product literature that references this Standard shall indicate this use limitation by inclusion of the following statement.

“Copper [tube, pipe, or fitting] (Alloy [alloy designation]) has been evaluated by [Testing Organization] to NSF/ANSI 61 for use in drinking water supplies of pH 6.5 and above. Drinking water supplies which are less than pH 6.5 may require corrosion control to limit leaching of copper into the drinking water.”

134.5.4 Conditioning and exposure options

4.5.4.1 In-product conditioning and exposure

During in-product conditioning and exposure, the test sample shall be filled completely with exposure water. The product having the greatest surface area-to-volume ratio (typically the smallest diameter) shall be preferentially used. When necessary to prevent the loss of exposure water, samples shall be capped with inert materials (e.g. glass).

4.5.4.2 In-vessel conditioning and exposure

During in-vessel conditioning and exposure, samples shall be placed in containers composed of a material that is inert to the exposure water having polytetrafluoroethylene lined lids. The exposure water shall completely immerse the sample. All samples shall be exposed at a surface area-to-volume ratio which is equal to or greater than that of the intended end use. The actual wetted surface area-to-volume ratio achieved during the exposure shall be recorded.

NOTE – The stated duration of the conditioning period at the hot temperature does not include any time needed to elevate the product sample or exposure vessel to the required exposure temperature.

4.5.4.3 Multiple time point protocol

When the normalized concentration of a contaminant exceeds, or is expected to exceed, its acceptable level when evaluated as a single time point exposure (see 4.5.6), determination of the contaminant leaching rate as a multiple time point exposure shall be considered (see 4.5.7). For the purpose of contaminant concentration evaluation (see 4.8.2), Day 1 shall be defined as the time point at which extractant water is collected for analysis under the single time point exposure protocol in table 4.2 (17 days in elapsed time). Day 90 shall be defined as 90 days following this time point.

NOTE – When employing a multiple time point protocol to the evaluation of a contaminant, consideration shall be given to the leaching characteristics of the contaminant, e.g. does the leaching pattern demonstrate a linear regression. Consideration shall also be given to the availability of appropriate toxicity data to define an acute exposure limit for the contaminant, as required in 4.8.2.

4.5.5 Single time point conditioning protocols

A separate sample shall be conditioned for each type of exposure water selected in 4.5.3.

4.5.5.1 Single time point conditioning –cold application

Products which are intended to be in contact with only cold water shall be conditioned in the exposure water(s) selected in 4.5.3 at 23 ±;2°C (73 ± 4°F) for 14 days. During the 14-day period, the exposure water shall be changed at least 10 times with a minimum period of 24 ± 1 hour between water changes. The free available chlorine concentration during the conditioning period shall be 2 mg/L. After the 14-day conditioning period, the exposure water in the product or in the vessel shall be decanted and discarded. Shortened conditioning periods shall be used at the request of the manufacturer. Exposure of the sample according to 4.5.6 shall immediately follow conditioning.

14NOTE – Table 4.1 provides an example single time point conditioning protocol. Alternate protocols shall be permitted as long as the requirements of 4.5.5.1 are met.

4.5.5.2 Single time point conditioning–hot applications

4.5.5.2.1 Intermittent hot water conditioning

Products which are intended to be in intermittent contact with hot water shall undergo the cold application conditioning according to 4.5.5.1. At the conclusion of the cold application conditioning, the products shall be further conditioned in the exposure water(s) selected in 4.5.3 at either 60 ± 2EC (140 ±3EF) or 82 ±2EC (180 ± 3EF) for two consecutive 1 hour ± 5 minute periods. The exposure water shall be decanted and discarded after each 1-hour period. Exposure of the sample according to 4.5.6 shall immediately follow completion of the further conditioning.

NOTE – The stated duration of the conditioning period at the hot temperature does not include any time needed to elevate the product sample or exposure vessel to the required exposure temperature.

4.5.5.2.2 Continuous hot water conditioning

Products which are intended to be in continuous contact with hot water shall be conditioned in the exposure water(s) selected in 4.5.3 at either 60 ± 2EC (140 ± 3EF) for 14 days. During the 14-day period, the exposure water shall be changed at least 10 times with a minimum period of 24 ± 1 hour between water changes. The free available chlorine concentration during the conditioning period shall be 2 mg/L. After the 14-day conditioning period, the exposure water in the product or in the vessel shall be decanted and discarded. Shortened conditioning periods shall be permitted at the request of the manufacturer. Exposure of the sample according to 4.5.6 shall immediately follow conditioning.

NOTE – Table 4.1 provides an example single time point conditioning protocol. Alternate protocols shall be permitted as long as the requirements of 4.5.5.2 are met.

4.5.6 Single time point exposure protocols

Products to be evaluated at a single time point shall be exposed according to the schedule in table 4.2. The first two 24-hour exposure periods shall be optional at the discretion of the manufacturer. A separate sample shall be exposed for each type of exposure water selected in 4.5.3. For each sample, the exposure water shall be of the same pH as the water used for conditioning of the sample.

4.5.6.1 Single time point exposure–cold application

Immediately following conditioning, the product shall be exposed at 23 ± 1°C (73 ± 2°F) according to the schedule in table 4.2.

4.5.6.2 Single time point exposure–hot applications

4.5.6.2.1 Intermittent hot water exposure

Immediately following conditioning, the product shall undergo the cold application exposure according to 4.5.6.1. Prior to the final 16-hour exposure, the product shall be exposed at the selected elevated temperature, either 60±1EC (140 ± 2EF) or 82 ± 1EC (180 ± 2EF), for 0.5 hour ± 5 minutes. The product shall then be exposed at 23 ± 1°C (73 ± 2°F) for the duration of the exposure period. The exposure water shall not be decanted prior to initiation of the final 16-hour exposure.

154.5.6.2.2 Continuous hot water exposure

Immediately following conditioning, the product (in-product exposures) or the exposure vessel (in-vessel exposures) shall be filled with fresh exposure water of the applicable pH (see 4.5.3). The product shall then be exposed at the selected elevated temperature, either 60 ± 1EC (140 ± 2EF) or 82 ± 1EC (180 ± 2EF), according to the schedule in table 4.2.

4.5.7 Multiple time point conditioning/exposure protocols

For the purpose of determining a contaminant leaching rate as a function of time, extractrant water samples shall be collected during the conditioning period of products for which multiple time point exposure has been elected, according to the protocols in 4.5.7.1 and 4.5.7.2. A separate sample shall be conditioned and exposed for each type of exposure water selected in 4.5.3.

4.5.7.1 Cold application

Products which are intended to be in contact with only cold water shall be maintained at 23 ± 1°C (73 ± 2°F) for 19 days. During the 19-day period, the exposure water shall be changed at least 12 times, with a minimum period of 24 ± 1 hour between water changes. At seven of these water changes, extraction water shall be collected for analysis after a 24-hour exposure. For extrapolation and normalization purposes, the number of hours elapsed since the most recent water change (or sample collection) and the number of days elapsed since the initiation of the exposure shall be recorded at the time of each extraction water collection.

NOTE – Table 4.3 provides an example multiple time point conditioning/exposure protocol. Alternate protocols shall be permitted as long as the requirements of 4.5.7.1 are met.

At the discretion of the manufacturer, direct measurement of a Day 90 extraction shall be permitted. The products shall be maintained at 23 ± 1°C (73 ± 2°F). Extraction water shall be collected for analysis at a minimum of two time points: after Day 1 (representing 14 days of conditioning and 1 day of acute exposure), and after the final exposure terminating on Day 90 (representing 14 days of conditioning, 1 day of acute exposure, and 90 days of chronic exposure). The exposure water shall be changed at least 4 days per week during the interval between the initial and final exposures. Exposures which are used for the collection of extractant water for analysis shall not exceed 24 ± 1 hour in duration.

4.5.7.2 Hot applications

4.5.7.2.1 Intermittent hot water exposure

Products which are intended to be in intermittent contact with hot water shall undergo the cold application exposure according to 4.5.7.1. At the initiation of each exposure which will be collected for analysis, the product shall be exposed at the selected elevated temperature, either 60 ± 1EC (140 ± 2EF) or 82 ± 1EC (180 ± 2EF), for 0.5 hour ± 5 minutes. The product shall then be exposed at 23 ± 1°C (73 ± 2°F) for the duration of the exposure period. The exposure water shall not be decanted prior to the completion of the exposure period.

NOTE 1 – Table 4.3 provides an example multiple time point conditioning/exposure protocol. Alternate protocols shall be permitted as long as the requirements of 4.5.7.2.1 are met.

NOTE 2 – The stated duration of the conditioning period at the hot temperature does not include any time needed to elevate the product sample or exposure vessel to the required exposure temperature.

At the discretion of the manufacturer, direct measurement of a Day 90 extraction shall be permitted. At the initiation of each exposure which will be collected for analysis, the products shall be exposed at the selected elevated temperature, either 60 ± 1EC (140 ± 2EF) or 82 ± 1EC (180 ± 2EF), for 0.5 hour ± 5 minutes. The product shall then be exposed at 23 ± 1°&C (73 ± 2°F) for the duration of the exposure period. The exposure

16water shall not be decanted prior to the completion of the exposure period. Extraction water shall be collected for analysis at a minimum of two time points: after Day 1 (representing 14 days of conditioning and 1 day of acute exposure), and after the final exposure terminating on Day 90 (representing 14 days of conditioning, 1 day of acute exposure, and 90 days of chronic exposure). The exposure water shall be changed at least four days per week during the interval between the initial and final exposures. Exposures which are used for the collection of extractant water for analysis shall not exceed 24 ± 1 hour in duration.

4.5.7.2.2 Continuous hot water exposure

Products which are intended to be in continuous contact with hot water shall be maintained at the selected elevated temperature, either 60 ± 1°C (140 ± 2°F) or 82 ± 1°C (180 ± 2°F) for 19 days. During the 19-day period, the exposure water shall be changed at least 12 times with a minimum period, of 24 ± 1 hour between water changes. At seven of these water changes, extraction water shall be collected for analysis after a 24-hour exposure. For extrapolation and normalization purposes, the number of hours elapsed since the most recent water change (or sample collection) and the number of days elapsed since the initiation of the exposure shall be recorded at the time of each extraction water collection.

NOTE – Table 4.3 provides an example multiple time point conditioning/exposure protocol. Alternate protocols shall be permitted as long as the requirements of 4.5.7.2.2 are met.

At the discretion of the manufacturer, direct measurement of a Day 90 extraction shall be permitted. The products shall be maintained at the selected elevated temperature, either 60 ± 1°C (140 ± 2°F) or 82 ± 1°C (180 ± 2°F). Extraction water shall be collected for analysis at a minimum of two time points: after Day 1 (representing 14 days of conditioning and 1 day of acute exposure), and after the final exposure terminating on Day 90 (representing 14 days of conditioning, 1 day of acute exposure, and 90 days of chronic exposure). The exposure water shall be changed at least 4 days per week during the interval between the initial and final exposures. Exposures which are used for the collection of extractant water for analysis shall not exceed 24 ± 1 hour in duration.

4.5.8 Collection and preservation of extraction water

Immediately following exposure, extraction waters collected for analysis shall be poured into previously prepared sample containers for storage until analysis, as specified in annex B, section B.6.

4.6 Analysis

4.6.1 Extraction waters shall be analyzed with the methods listed in annex B, section B.7.

4.6.2 Samples requiring analysis for residual vinyl chloride monomer shall be evaluated according to the method in annex B, section B.7.

4.7 Normalization of contaminant concentrations

4.7.1 General

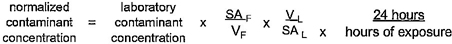

The concentration of analytes detected in the extraction water shall be multiplied by a calculated normalization factor (NF) to account for differences between laboratory and field surface area-to-volume ratios. The normalization factor shall be based on calculations and assumptions relevant to the end-use of the product.

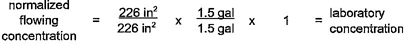

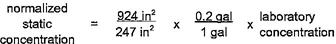

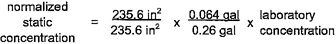

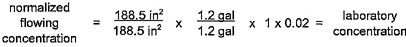

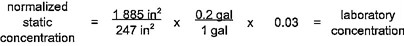

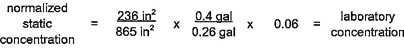

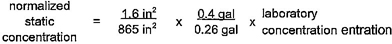

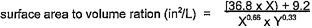

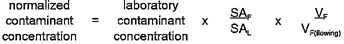

17The general formula for the derivation of the normalization factor is described in the following equations:

NF = N1 × N2

Where:

SAF = Surface area exposed in the field

SAL = Surface area exposed in the laboratory

VL = Volume of extraction water used in the laboratory

VF(static) = Volume of water to which the product is exposed under static conditions

VF(flowing) = Volume of water to which the product is exposed under flowing conditions during a period of time equivalent to the laboratory test

When the length of the exposure being normalized is other than 16 hours in length, the normalized value shall be adjusted to reflect a 16-hour exposure (e.g. multiply the normalized value by 16/24 when a 24-hour exposure was used.) The nominal diameter of the product shall determine which assumptions are used for normalization (see tables 4.4 and 4.5.) The actual inner diameter of the product shall be used for the normalization calculations of surface area and volume.

NOTE – Adjustment of the normalized contaminant concentration for the duration of the exposure period shall consider the extraction kinetics of the contaminant under evaluation. For contaminants which do not exhibit linear extraction kinetics, adjustment for the duration of exposure shall be done in accordance with the demonstrated kinetics of the contaminant or shall not be applied if this information is not available.

4.7.2 Products installed at regularly repeating intervals

For products installed at regularly repeating intervals (e.g., pipes, fittings), the SAF shall be calculated from the assumed length of pipe corresponding to the segment of the system in which the product is used (e.g., 100 feet of pipe in the service line or 280 feet of pipe in the residence). The VF(static) component of the N1 term shall be the volume of water contained within the assumed length of pipe. For fittings, the actual inner diameter of the pipe used with the fittings shall be used to calculate both SAF and VF(static).

4.7.3 Products not installed at regularly repeating intervals

Products not installed at regularly repeating intervals shall be identified through review of the manufacturer's recommended product end use. For products not installed at regularly repeating intervals (e.g., transition fittings, repair couplings, drop ear elbow fittings, and copper stub outs), the SAF shall be the wetted surface area of a single product. The VF(static) component of the N1 term shall be the volume of water a single product contains when filled to capacity, except that VF(static)shall equal 1 L(0.264 gal) for all products that contain less than 1 L of water when filled to capacity.

4.7.4 Sample calculations for normalization of section 4 products are provided in table 4.6.

4.7.5 Selection of normalization conditions

Pipe and fitting products of nominal diameter greater than or equal to 4 in (10 cm) shall be normalized to the flowing condition. Pipe and fitting products of nominal diameter of less than 4 in (10 cm) shall be normalized to the static condition when the value of N2 is less than or equal to 0.1. Pipe and fitting products of nominal

18diameter of less than 4 in (10 cm) shall be normalized to the flowing condition when the value of N2 is greater than 0.1.

4.7.6 Multiple time point exposure calculations

Laboratory values from each time point at which extractant water was collected (a minimum of five data points shall be required for extrapolation) shall be normalized as indicated in 4.7.1, depending on product end use. A decay curve of these normalized contaminant concentrations in relation to elapsed exposure time shall be plotted. Contaminant concentrations shall be determined for two time point as follows: at Day 1 (representing 14 days of conditioning and 1 day of acute exposure) and at Day 90 (representing 14 days of conditioning, 1 day of acute exposure, and 90 days of chronic exposure) shall be extrapolated from this curve (see 4.5.7).

If direct measurement of a Day 90 exposure has been performed, laboratory values from each time point at which extractant water was collected (a minimum of two time points as defined in 4.5.7.1 and 4.5.7.2) shall be normalized as indicated in 4.7.1, depending on product end use.

4.8 Evaluation of contaminant concentrations.

4.8.1 Contaminants measured in a single time point extraction

For pipe and fitting products, normalized static contaminant concentrations shall be no greater than their respective MCLs or TACs, and normalized flowing contaminant concentrations shall be no greater than their respective SPACs calculated in accordance with annex A.

4.8.2 Contaminants measured in a multiple time point extraction

Normalized Day 1 contaminant concentrations shall not exceed the short-term exposure level (STEL) as defined in annex A, section A.5.

Normalized extrapolated or directly measured Day 90 contaminant concentrations shall not exceed the limits defined in 4.8.1.

4.8.3 Residual vinyl chloride monomer (RVCM)

The average RVCM concentration shall be less than or equal to 3.2 mg/kg as evaluated in the product wall.

19| Conditioning time | Elapsed time | Comment |

|---|---|---|

| 24 ± 1 hour | 1 day | Exposure water is decanted and discarded; the exposure vessel or product is refilled with exposure water and conditioning is continued. |

| 24 ± 1 hour | 2 days | Exposure water is decanted and discarded; the exposure vessel or product is refilled with exposure water and conditioning is continued. |

| 24 ± 1 hour | 3 days | Exposure water is decanted and discarded; the exposure vessel or product is refilled with exposure water and conditioning is continued. |

| 24 ± 1 hour | 4 days | Exposure water is decanted and discarded; the exposure vessel or product is refilled with exposure water and conditioning is continued. |

| 72 ± 1 hour | 7 days | Exposure water is decanted and discarded; the exposure vessel or product is refilled with exposure water and conditioning is continued. |

| 24 ± 1 hour | 8 days | Exposure water is decanted and discarded; the exposure vessel or product is refilled with exposure water and conditioning is continued. |

| 24 ± 1 hour | 9 days | Exposure water is decanted and discarded; the exposure vessel or product is refilled with exposure water and conditioning is continued. |

| 24 ± 1 hour | 10 days | Exposure water is decanted and discarded; the exposure vessel or product is refilled with exposure water and conditioning is continued. |

| 24 ± 1 hour | 11 days | Exposure water is decanted and discarded; the exposure vessel or product is refilled with exposure water and conditioning is continued. |

| 72 ± 1 hour | 14 days | Exposure water is decanted and discarded; conditioning is terminated. |

| Exposure time | Elapsed time1) | Comment |

|---|---|---|

| 24 ± 1 hour (optional) | 15 days (optional) | Extraction water is decanted and discarded; the exposure vessel or product is refilled with exposure water and exposure is continued. |

| 24 ± 1 hour (optional) | 16 days (optional) | Extraction water is decanted and discarded; the exposure vessel or product is refilled with exposure water and exposure is continued. |

| 16 hours | 17 days (15 days if the two optional exposure periods are not elected) | Extraction water is collected for analysis. |

| 1) Elapsed time indicated includes the 14 days of conditioning preceding the exposure. | ||

| Exposure time | Elapsed time | Sample collection |

|---|---|---|

| 24 ± 1 hour | 1 day | Extraction water is collected for analysis at completion of the exposure period; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 24 ± 1 hour | 2 days | Extraction water is collected for analysis at completion of the exposure period; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 24 ± 1 hour | 3 days | Extraction water is decanted and discarded; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 24 ± 1 hour | 4 days | Extraction water is collected for analysis at completion of the exposure period; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 72 ± 1 hour | 7 days | Extraction water is decanted and discarded; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 24 ± 1 hour | 8 days | Extraction water is collected for analysis at completion of the exposure period; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 24 ± 1 hour | 9 days | Extraction water is decanted and discarded; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 24 ± 1 hour | 10 days | Extraction water is collected for analysis at completion of the exposure period; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 96 ± 1 hour | 14 days | Extraction water is decanted and discarded; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 24 ± 1 hour | 15 days | Extraction water is collected for analysis at completion of the exposure period; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 72 ± 1 hour | 18 days | Extraction water is decanted and discarded; the product or exposure vessel is refilled with exposure water and the exposure is continued. |

| 24 ± 1 hour | 19 days | Extraction water is collected for analysis at completion of the exposure period; the exposure is terminated. |

| Product nominal diameter | Assumptions | Exposure type | N1 | N2 (flowing condition) |

|---|---|---|---|---|

| nominal $ 10 cm (4 in) | – water is exposed to the same material from the treatment plant to the service line – a 16-hour exposure period is evaluated |

in-product | 1 | 1 |

| in-vessel | calculated according to 4.7.1 | 1 | ||

| 10 cm (4 in) > nominal ≥ 1.3 cm (½ in) | – a 16-hour exposure period is evaluated – residential water usage is 681 L (180 gal) per 24 hours –100 feet of service line from water main to residence |

in-product | 1 | calculated according to 4.7.1 |

| in-vessel | calculated according to 4.7.1 | calculated according to 4.7.1 | ||

| nominal < 1.3 cm (½ in) | – a maximum run of 25 ft (7.6 m) of small diameter product is installed – for products with an internal volume less than 1L, VF(static) is set equal to 1 L – a 16-hour exposure period is evaluated – residential water usage is 681 L (180 gal) per 24 hours – 280 feet per residence (140 feet each for hot and cold sides) |

in-product | 1 | calculated according to 4.7.1 |

| in-vessel | calculated according to 4.7.1 | calculated according to 4.7.1 |

| Product nominal diameter | Assumptions | Exposure type | N1 | N2(flowing condition) |

|---|---|---|---|---|

| nominal $ 10 cm (4 in) | – water is exposed to the same material from the treatment plant to the service line – fittings represent 2% of the distribution system surface area – a 16-hour exposure period is evaluated |

in-product | 0.02 | 1 |

| in-vessel | calculated according to 4.7.1 and multiplied by 0.02 | 1 | ||