In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

INTERNATIONAL STANDARD

ISO

18906

First edition

2000-12-15

Matériaux pour image—Films photographiques—Spécifications pour le film de sécurité

Reference number

ISO 18906:2000(E)

© ISO 2000

ii| PDF disclaimer |

| This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this area. Adobe is a trademark of Adobe Systems incorporated. Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below. |

© ISO 2000

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body in the country of the requester.

ISO copyright office

Case postale 56.• CH-1211 Geneva 20

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

iii| Page | |

| Foreword | iv |

| Introduction | v |

| 1 Scope | 1 |

| 2 Term and definition | 1 |

| 3 Property requirements | 1 |

| 4 Ignition time test | 2 |

| 5 Burning time test | 2 |

| Annex A (informative) Numbering systems for related International Standards | 4 |

| Annex B (informative) Field test | 6 |

| Annex C (informative) Marking | 7 |

| Annex D (informative) Float test | 8 |

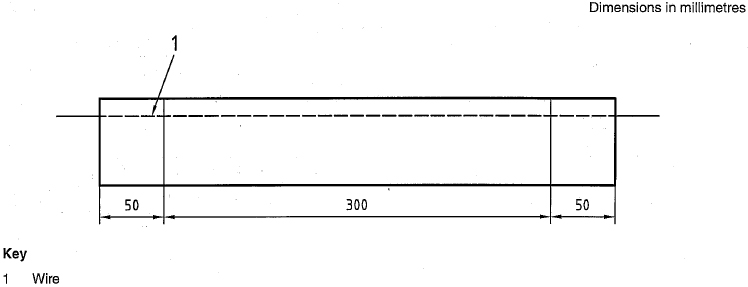

| Figure 1— Burning time test specimen (not to scale) | 3 |

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies). The work of preparing International Standards is normally carried out through ISO technical committees. Each member body interested in a subject for which a technical committee has been established has the right to be represented on that committee. International organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting. Publication as an International Standard requires approval by at least 75% of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 18906 was prepared by Technical Committee ISO/TC 42, Photography.

This first edition cancels and replaces the second edition of ISO 543:1990, of which it constitutes a minor revision.

This International Standard is one of a series of International Standards dealing with the physical properties and stability of imaging materials. To facilitate identification of these International Standards, they are assigned a number within the block from 18900—18999 (see annex A).

Annexes A to D of this International Standard are for information only.

vAlthough the manufacture of films not complying with this International Standard is currently very rare, if it takes place at all, there remains a great amount of such films stored in archives and libraries. Due to the risk of ignition caused by careless handling, of self-ignition after long and adverse storage conditions, or rapid burning characteristics, it is necessary to provide film owners with a method of determining whether their film is "safety photographic film". That is the objective of this International Standard.

vi viiImaging materials — Photographic films — Specifications for safety film

This International Standard provides specifications and test procedures for establishing the safety of photographic films with respect to hazards from fire. The specifications are applicable to both unprocessed and processed1) films on any type of currently known plastic support.

These specifications cover silver films (both gelatin and non-gelatin types), colour films, diazo films, vesicular films, and striped or full-width magnetic films. Magnetic tapes and video recording tapes are excluded.

A field test for burning behaviour is described in informative annex B, and methods of marking film are defined in informative annex C. A simple test to distinguish non-safety nitrate-base film from cellulose ester and polyesterbase film is given in informative annex D.

For the purposes of this International Standard, the following term and definition applies.

photographic film which passes the ignition time test and burning time test as specified in this International Standard

Photographic films are classified as having passed the ignition time test when the ignition time is not less than 10 min when tested as specified in clause 4.

Photographic films having a thickness equal to or greater than 0,08 mm are classified as having passed the burning time test when the burning time is greater than 45 s when tested as specified in clause 5.

Photographic films having a thickness less than 0,08 mm are classified as having passed the burning time test when the burning time is greater than 30 s.

1) Normally, unprocessed and processed films have the same safety characteristics, so either one may be tested for conformance to these specifications. If an additional treatment, such as a lacquer coating, has been applied after processing, the safety characteristics may or may not be affected. In case of doubt, both unprocessed and processed films must be tested.

14.1.1 Electric resistance oven, the interior of which is a cavity of appropriate size to hold the film specimen and an instrument for measuring the temperature (4.1.2) in the centre of the cavity.

The top of the oven shall be closed by means of a closely overlapping lid having two holes of diameter approximately 7 mm and 15 mm respectively, the centres being at a distance of about 15 mm from each other.

4.1.2 Thermocouple, having connecting wires with an insulated coating fitting tightly into the smaller hole of the lid of the oven (4.1.1).

Alternatively, the temperature in the cavity may be measured by means of other temperature measuring instruments such as a mercury thermometer fitted into the smaller hole, protected from the rising heat by means of a cork disc lying above the lid.

Cut three specimens 35 mm long and 8 mm wide from the film to be tested.

Specimens shall be free from perforations as far as is practicable.

Bring the oven to (300 ± 10) °C and maintain it at this temperature. When this temperature is reached, attach the specimen to a thin U-shaped wire hook and introduce it through the larger opening in the lid of the oven.

Fix the instrument for measuring the temperature (4.1.2) and the specimen in such a way that the thermojunction (or mercury bulb) and the centre of the specimen are at an equal depth of approximately 35 mm.

Record the time interval from the insertion of the specimen to the ignition time of the specimen as the ignition time.

Test the three specimens. Before each measurement, thoroughly air the oven.

If any one of the three specimens does not meet the ignition time requirement, the material is considered to have failed the test.

Cut three specimens each 400 mm long and 35 mm wide from the film to be tested. If only films narrower than 35 mm are available, specimens 400 mm long and of full width may be tested2). Mark each specimen at a point 50 mm from each end.

If the specimens are not already perforated, perforate them with holes approximately 3 mm in diameter along one edge, at intervals of not more than 20 mm.

2) Photographic films, when tested by this method, have similar flame propagation characteristics and approximately the same burning times, regardless of whether the width of the samples tested is 35 mm or less.

2If a continuous strip 400 mm long cannot be obtained from the film being tested, shorter lengths may be stapled together with a 1 mm to 2 mm overlap to give the required length.

Thread a wire having a diameter of not more than 0.5 mm through the perforations on one side so that the specimen is supported at points not more than 20 mm apart.

Though no conditioning other than the normal room temperature is required, the film shall be dry to the touch.

Carry out the test in a room free from draughts.

With the wire stretched horizontally and the specimen hanging vertically from it, ignite the bottom of one end (see Figure 1).

Record the time that elapses from the moment the flame reached the first mark until the time it reaches the second mark as the burning time.

Test the three specimens.

If the specimen does not ignite or if the flame does not reach the second mark within the stipulated time, classify the film as having passed the burning time test.

If any one of the three specimens does not pass the burning time test, the material is considered to have failed.

Figure 1 — Burning time test specimen (not to scale)

3The current numbering system for TC 42 documents dealing with the physical properties and stability of imaging materials is confusing since the five digit numbers that are used are not in any consecutive order. To facilitate remembering the numbers, ISO has set aside a block of numbers from 18900 to 18999 and all revisions and new International Standards will be given a number within this block. The last three digits will be identical to the current ANSI/PIMA numbers of published documents. This will be advantageous to the technical experts from Germany, Japan, United Kingdom and the USA who have prepared the standard and who are familiar with the ANSI/PIMA numbers.

As the current International Standards are revised and published, their new numbers will be as given in Table A.1.

| Current or former ISO number | Title | New ISO number |

|---|---|---|

| 10602 | Photography — Processed silver-gelatin type black-and-white film — Specifications for stability | 18901 |

| 10214 | Photography — Processed photographic materials — Filing enclosures for storage | 18902 |

| 6221 | Photography — Films and papers — Determination of dimensional change | 18903 |

| 5769 | Photography — Processed films — Method for determining lubrication | 18904 |

| 8225 | Photography — Ammonia-processed diazo photographic film — Specifications for stability | 18905 |

| 543 | Photography — Photographic films — Specifications for safety film | 18906 |

| 6077 | Photography — Photographic films and papers — Wedge test for brittleness | 18907 |

| 8776 | Photography — Photographic film — Determination of folding endurance | 18908 |

| 10977 | Photography — Processed photographic colour films and paper prints — Methods for measuring image stability | 18909 |

| 4330 | Photography — Determination of the curl of photographic film and paper | 18910 |

| 5466 | Photography — Processed safety photographic films — Storage practices | 18911 |

| 9718 | Photography — Processed vesicular photographic film — Specifications for stability | 18912 |

| 12206 | Photography — Methods for the evaluation of the effectiveness of chemical conversion of silver images against oxidation | 18915 |

| 14523 | Photography — Processed photographic materials — Photographic activity test for enclosure materials | 18916 |

| 417 | Photography — Determination of residual thiosulfate and other related chemicals in processed photographic materials — Methods using iodine-amylose, methylene blue and silver sulfide | 18917 |

| 3897 | Photography — Processed photographic plates — Storage practices | 18918 4 |

| 14806 | Photography—Thermally processed silver (TPS) microfilm—Specifications for stability | 18919 |

| 6051 | Photography—Processed reflection prints—Storage practices | 18920 |

| 15524 | Photography—Polyester-base magnetic tape—Storage practices | 18923 |

| 15640 | Photography—Imaging materials—Test method for Arrhenius-type predictions | 18924 |

The following test method may be used for quickly identifying whether most photographic films are of the safety or the nitrate variety, without technical equipment or the expenditure of large amounts of specimen film. However, this test does not determine compliance of a film with this International Standard.

Anyone unfamiliar with the burning of safety and nitrate photographic films should first conduct this test on samples of both types of film, the identities of which are known.

Cut a piece of film approximately 16 mm wide and 35 mm long. Bend the film lengthwise and crease it sufficiently so that when released it will stand upright.

Stand the specimen (with the crease vertical) on a flat fireproof surface, such as an ashtray, glass plate, concrete floor, etc.

WARNING—This must be done at a safe distance from all film stocks.

With a match flame, ignite one of the top corners of the film.

If the specimen ignites easily, burns downward rapidly and vigorously with a bright yellow flame, and is completely consumed in less than 15 s, the film probably contains dangerous quantities of cellulose nitrate and probably will not pass the tests of this International Standard for safety film.

If the specimen ignites with difficulty and burns only partially, or if it burns completely in a time not under 15 s, it is likely but not assured that the film will pass the tests described in this International Standard.

6Photographic film which meets the requirements of this International Standard may be suitably marked as such.

In some countries, markings between perforations or along the edge of the film comprising S or SAFETY have been used. An alternative or supplementary way of marking is by means of a fluorescent compound in or on the film base. National regulations may require these or other markings, but this practice is not a mandatory requirement of this International Standard.

A safety identification marking applied at the time of film manufacture may sometimes be obliterated or be transferred from another film in printing operations, so the identification is lost or confused. If the film cannot be positively identified as safety film by the marking, it should be identified by the laboratory tests specified in this International Standard.

Where there is a very limited quantity of film and a small degree of uncertainty is acceptable, the field test given in informative annex B may be sufficient.

7The following test method may be used for easy distinguishing of nitrate-base photographic films from safety-base films. This method does not determine compliance of a film with this International Standard.

Place a 6 mm square piece of dry film in a test tube containing trichloroethylene. Shake the tube to make sure that the film sample is completely wetted. If the sample sinks, it is cellulose nitrate; if it floats, it is acetate or polyester.

WARNING—Although trichloroethylene is not flammable, it is volatile and its vapour should not be inhaled.

8 9ICS 37.040.20

Price based on 8 pages