In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

BRITISH STANDARD

BS EN

13000:2004

The European Standard EN 13000:2004 has the status of a British Standard

ICS 53.020.20

NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW

This British Standard is the official English language version of EN 13000:2004. It supersedes BS 1757:1986 which is withdrawn.

The UK participation in its preparation was entrusted by Technical Committee MHE/3, Cranes and derricks, to Subcommittee MHE/3/5, Mobile cranes, which has the responsibility to:

— aid enquirers to understand the text;

— present to the responsible international/European committee any enquiries on the interpretation, or proposals for changes, and keep UK interests informed;

— monitor related international and European developments and promulgate them in the UK.

A list of organizations represented on this subcommittee can be obtained on request to its secretary.

Cross-references

The British Standards which implement international or European publications referred to in this document may be found in the BSI Catalogue under the section entitled “International Standards Correspondence Index”, or by using the “Search” facility of the BSI Electronic Catalogue or of British Standards Online.

This publication does not purport to include all the necessary provisions of a contract. Users are responsible for its correct application.

Compliance with a British Standard does not of itself confer immunity from legal obligations.

Summary of pages

This document comprises a front cover, an inside front cover, the EN title page, pages 2 to 108, an inside back cover and a back cover.

The BSI copyright notice displayed in this document indicates when the document was last issued.

Amendments issued since publication

| Amd. No. | Date | Comments | ||||

|---|---|---|---|---|---|---|

| Key:• = mandatory, ο = if required, – = not relevant, L = load test, F = functional check, V = visual check | ||||||

This British Standard was published under the authority of the Standards Policy and Strategy Committee on 4 January 2006

© BSI 4 January 2006

ISBN 0 580 47272 8

iiiEUROPEAN STANDARD

NORME EUROPÉENNE

EUROPäISCHE NORM

EN 13000

June 2004

ICS 53.020.20

English version

Cranes - Mobile cranes

Appareils de levage à charge suspendue - Grues mobiles Krane - Fahrzeugkrane

This European Standard was approved by CEN on 22 April 2004.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibilographical references concerning such national standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2004 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13000:2004: E

1| page | ||

| 1 | Scope | 7 |

| 2 | Normative references | 7 |

| 3 | Terms and definitions | 10 |

| 4 | Safety requirements and/or protective measures | 13 |

| 4.1 | Structures and components | 13 |

| 4.1.1 | General | 13 |

| 4.1.2 | Load effects | 14 |

| 4.1.3 | Limit states | 19 |

| 4.2 | Equipment and devices | 21 |

| 4.2.1 | General principles | 21 |

| 4.2.2 | Control station | 21 |

| 4.2.3 | Protection against falling tools | 23 |

| 4.2.4 | Seats | 24 |

| 4.2.5 | Controls and control systems | 24 |

| 4.2.6 | Limiting and indicating devices | 26 |

| 4.2.7 | Steering system | 30 |

| 4.2.8 | Braking systems | 31 |

| 4.2.9 | Protection devices | 33 |

| 4.2.10 | Hydraulic and pneumatic systems and components | 35 |

| 4.2.11 | Pressure vessels and fuel tanks | 36 |

| 4.2.12 | Electric and electronic and components and related phenomena | 37 |

| 4.2.13 | Hooks and hook blocks | 37 |

| 4.2.14 | Specific requirements for spare tyres/wheels | 37 |

| 4.2.15 | Specific requirements for pin jointed jib/fly jib connections | 38 |

| 4.3 | Visibility | 38 |

| 4.3.1 | Crane operator's field of view | 38 |

| 4.3.2 | Lighting | 38 |

| 4.4 | Noise and noise reduction | 38 |

| 4.4.1 | Noise and noise reduction at source by design | 38 |

| 4.4.2 | Noise reduction by information | 39 |

| 4.5 | Fire protection | 39 |

| 4.5.1 | Fire resistance | 39 |

| 4.5.2 | Fire extinguisher | 39 |

| 4.6 | Requirements for transport and travel | 39 |

| 5 | Verification | 40 |

| 5.1 | Methods of verification | 40 |

| 5.2 | Test procedures and conditions | 42 |

| 5.2.1 | General | 42 |

| 5.2.2 | Conceptual verification by calculation | 42 |

| 5.2.3 | Conceptual verification by experiment | 42 |

| 5.2.4 | Examination after test | 42 |

| 5.2.5 | Test report | 42 |

| 5.3 | Verification based on noise emission values | 43 |

| 6 | Information for use | 43 |

| 6.1 | Format of instruction | 43 |

| 6.1.1 | General | 43 |

| 6.1.2 | Technical data and Information | 43 |

| 6.2 | Instructions for use | 44 |

| 6.2.1 | General | 44 2 |

| 6.2.2 | Crane operator instructions | 45 |

| 6.3 | Instructions for assembly, erection, disassembly and transport | 46 |

| 6.4 | Instructions for maintenance and Inspection | 46 |

| 6.4.1 | General | 46 |

| 6.4.2 | Instructions for maintenance | 46 |

| 6.4.3 | Instructions for inspection | 47 |

| 6.5 | Instructions for training | 47 |

| 6.6 | Instructions for spare parts | 47 |

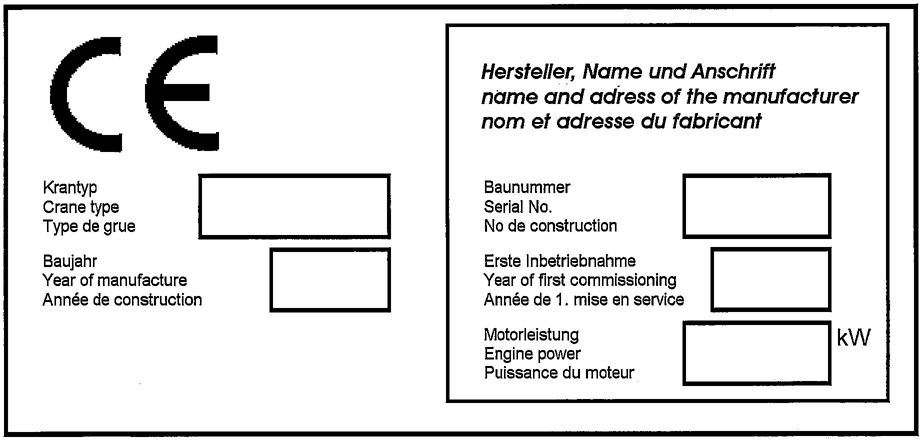

| 7 | Marking | 47 |

| 7.1 | Machine marking | 47 |

| 7.2 | Warning signs | 47 |

| 7.3 | Graphic symbols | 47 |

| 7.4 | Marking of crane parts | 48 |

| 7.5 | Marking of outriggers | 48 |

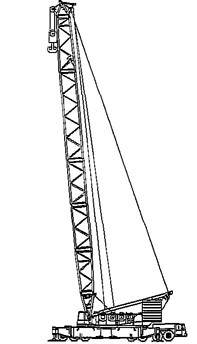

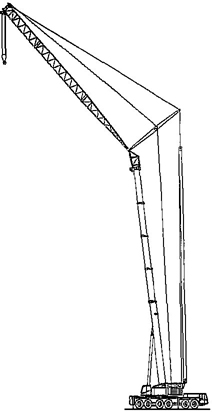

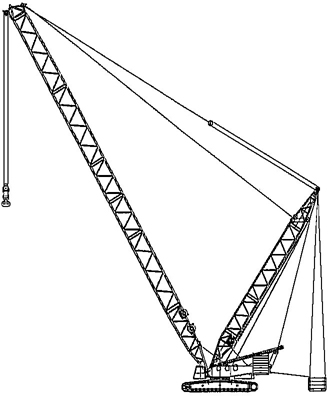

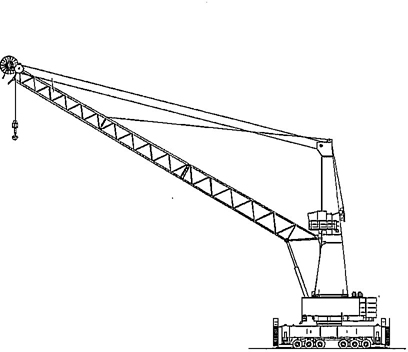

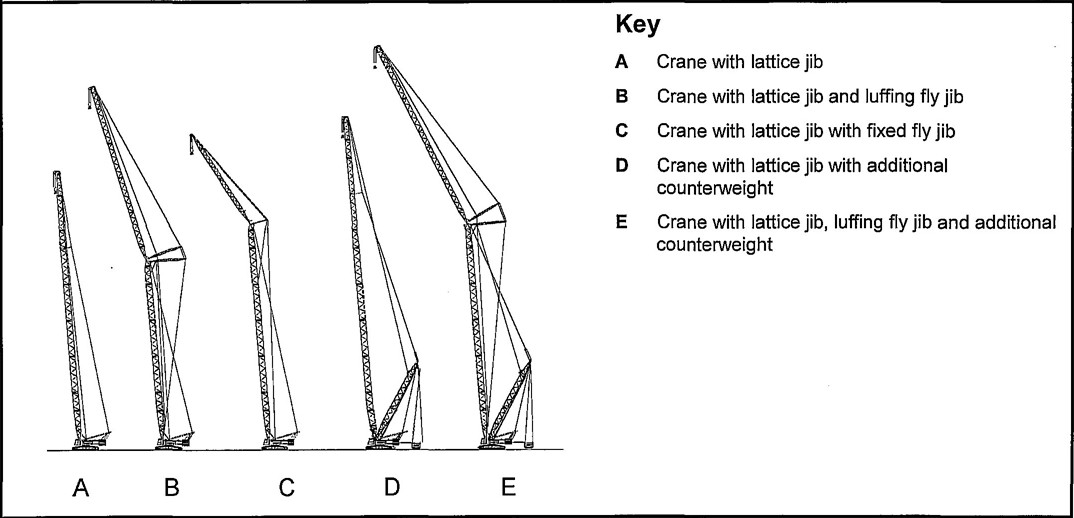

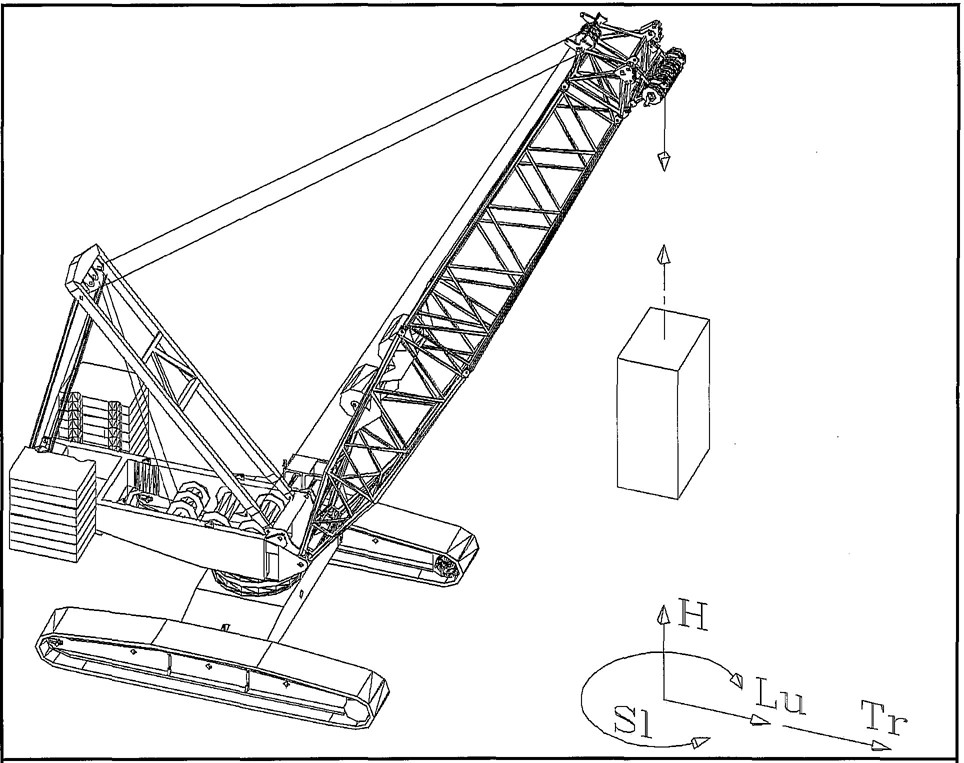

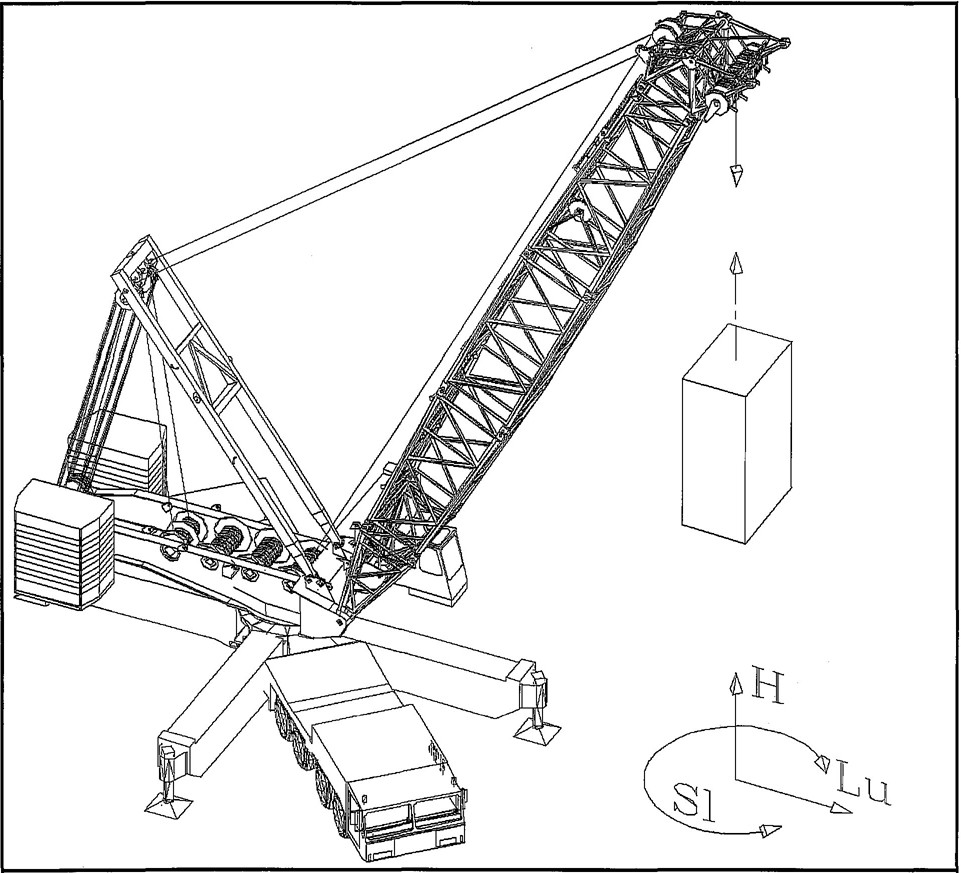

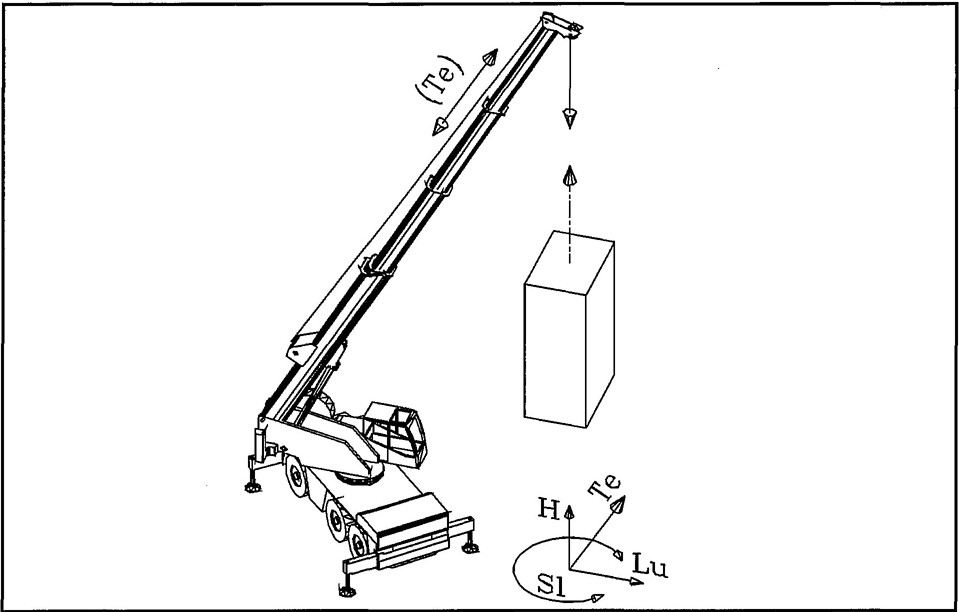

| Annex A (normative) Examples of mobile crane types | 50 | |

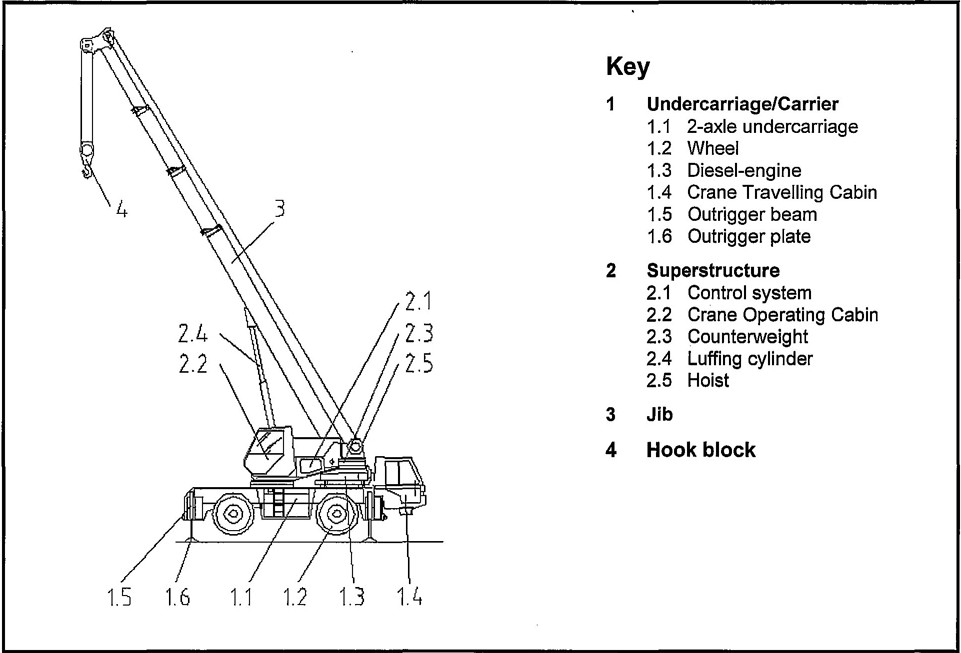

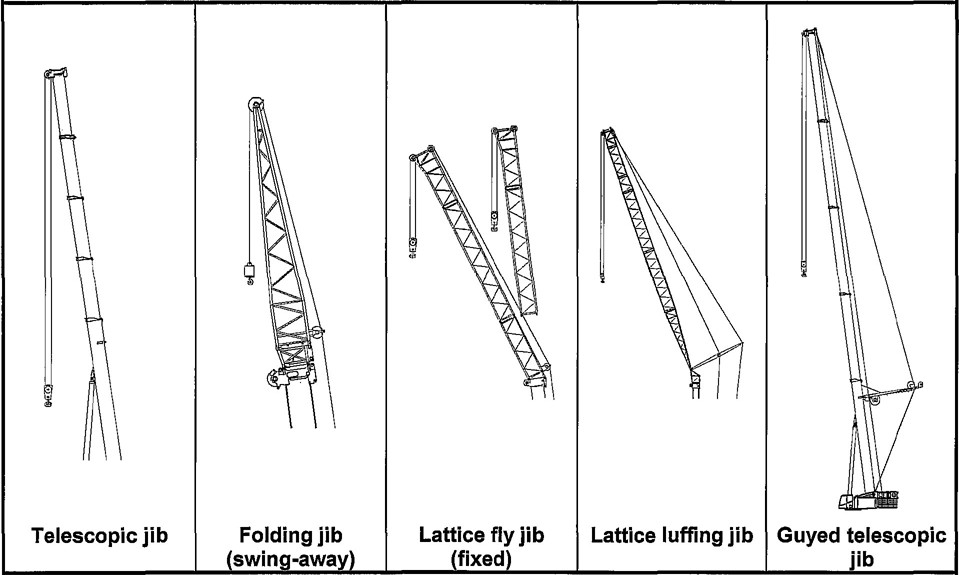

| Annex B.1 (informative) Major parts of telescopic cranes | 52 | |

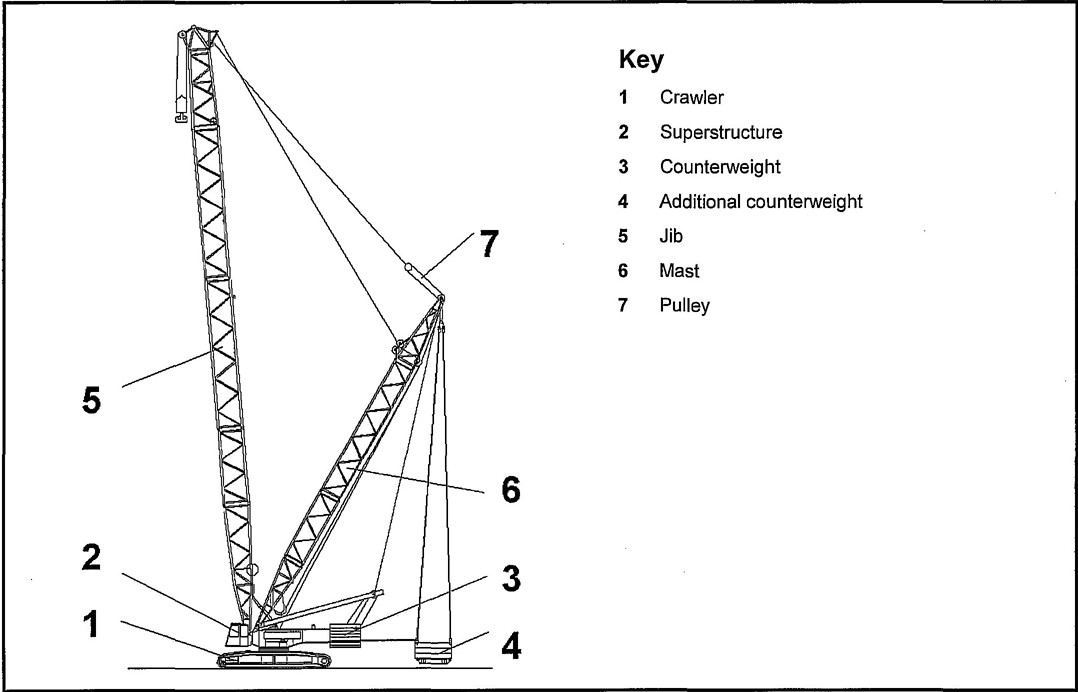

| Annex B.2 (informative) Major parts of lattice jib cranes | 53 | |

| Annex C (normative) List of hazards | 54 | |

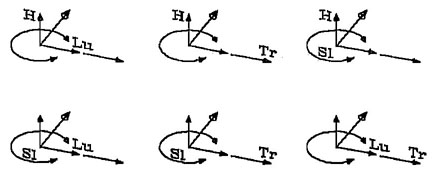

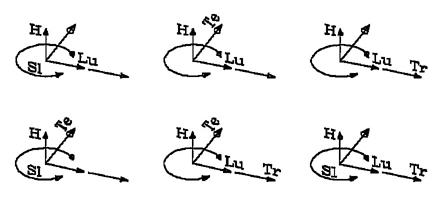

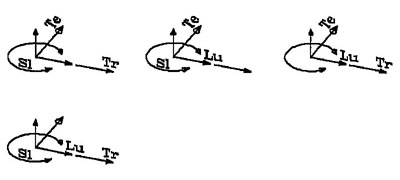

| Annex D (normative) Load effects of combined motions | 57 | |

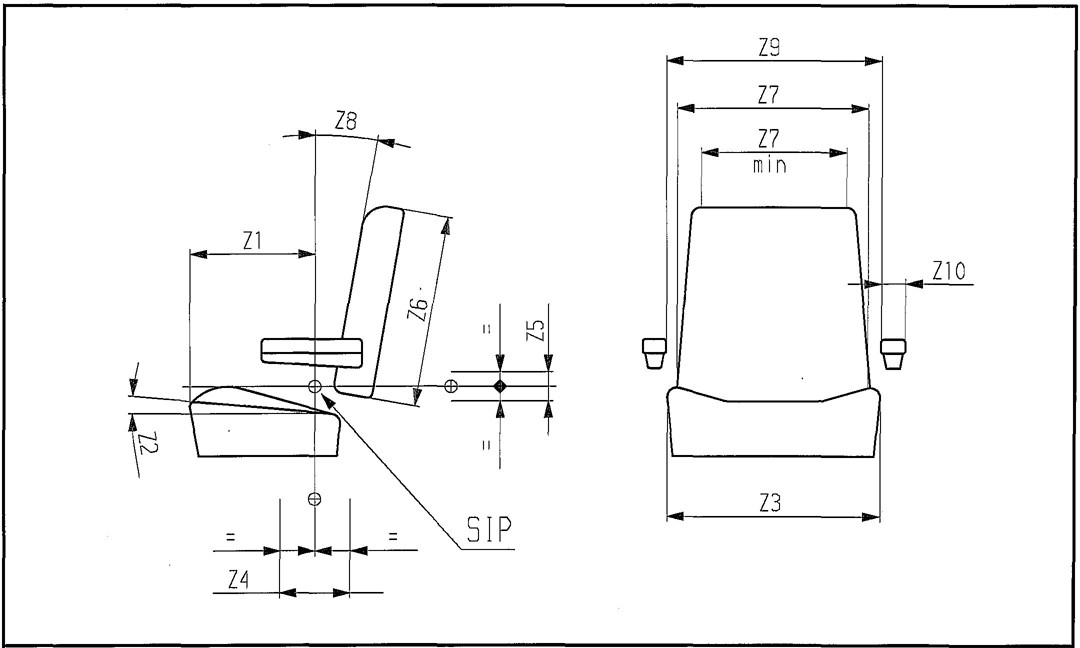

| Annex E (normative) Crane operator's seat dimensions | 61 | |

| E.1 | General | 61 |

| E.2 | Dimensions of crane driver's seat | 61 |

| E.3 | Other dimensions or adjustments | 61 |

| Annex F (normative) Rigid body stability: Load effects due to acceleration | 63 | |

| Annex G.1 (normative) Noise test code for mobile cranes | 65 | |

| G.1.1 | Introduction | 65 |

| G.1.2 | Normative references | 65 |

| G.1.3 | Terms and definitions | 65 |

| G.1.4 | Description of machinery family | 65 |

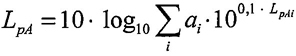

| G.1.5 | Sound power level determination | 66 |

| G.1.5.1 | Basic standard to be used | 66 |

| G.1.5.2 | Positioning of the crane | 66 |

| G.1.5.3 | Microphone positions | 66 |

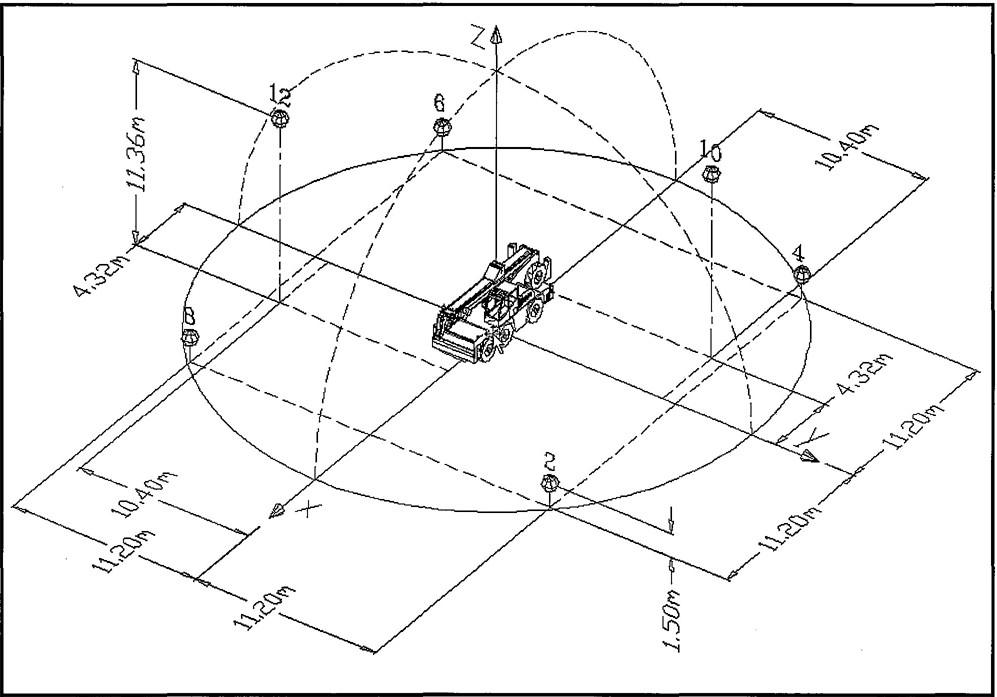

| G.1.5.4 | Measurement and calculation procedure | 66 |

| G.1.6 | Emission sound pressure level determination | 67 |

| G.1.6.1 | Basic standard to be used | 67 |

| G.1.6.2 | Crane operator position | 67 |

| G.1.6.3 | Specifications concerning the crane operating cabin | 67 |

| G.1.6.4 | Specifications relating to wind speed | 67 |

| G.1.6.5 | Measurement and calculation procedure | 67 |

| G.1.7 | Configuration | 68 |

| G.1.8 | Operating conditions | 68 |

| G.1.8.1 | General | 68 |

| G.1.8.2 | Test procedure | 68 |

| G.1.9 | Information on measurement uncertainties | 69 |

| G.1.10 | Information to be recorded | 69 |

| G.1.11 | Information to be reported | 69 |

| G.1.12 | Declaration and verification of noise emission values | 69 |

| Annex G.2 (normative) Noise measurement, test report | 71 | |

| G.2.1 | General data | 71 |

| G.2.2 | Measurements per motion | 72 |

| Annex H (normative) Limit values for structural and fine grain steel types | 74 | |

| Annex J.1 (normative) Minimum requirements for specification of hoist/derrick gears | 75 | |

| Annex J.2 (normative) Minimum requirements for specification of slewing gears | 77 3 | |

| Annex J.3 (normative) Minimum requirements for specification of travel gears | 79 | |

| Annex J.4 (normative) Minimum requirements for specification of drums | 81 | |

| Annex K.1 (normative) Minimum requirements for the specification of lifting hooks | 83 | |

| Annex K.2 (normative) Minimum requirements for specification of sheaves | 84 | |

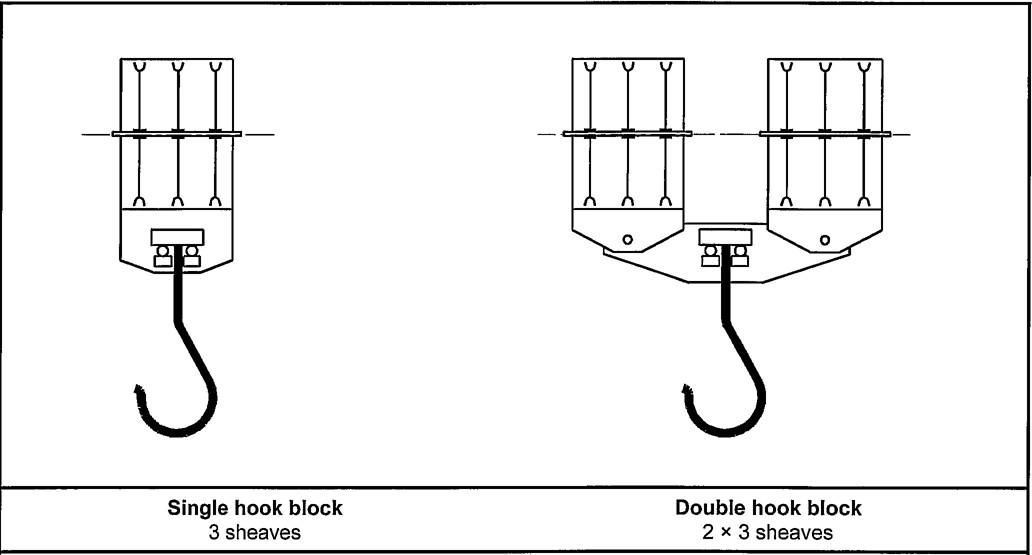

| Annex K.3 (normative) Minimum requirements for specification of hook blocks | 86 | |

| Annex K.4 (normative) Minimum requirements for the specification of hydraulic cylinders | 88 | |

| Annex K.5 (normative) Minimum requirements for the specification of slew rings | 90 | |

| Annex L (normative) Proof of competence | 92 | |

| L.1 | General | 92 |

| L.2 | Proof of competence for steel structures | 92 |

| L.2.1 | General | 92 |

| L.2.2 | Method of permissible stresses | 92 |

| L.2.3 | Method of partial safety coefficients and limiting stresses | 92 |

| L.3 | Proof of competence for non steel structures | 93 |

| L.4 | Proof of competence for load bearing components | 93 |

| L.4.1 | General | 93 |

| L.4.2 | Proof of competence for mechanisms | 93 |

| L.4.3 | Proof of competence for ropes | 93 |

| L.4.4 | Proof of competence for chains | 93 |

| L.4.5 | Proof of competence for other components | 94 |

| L.5 | Proof of competence of rigid body stability of the crane | 94 |

| L.6 | Proof of competence–experimental | 94 |

| L.6.1 | Structural tests | 94 |

| L.6.2 | Rigid body stability tests | 94 |

| Annex M (normative) Test of steering systems for off-road mobile cranes | 95 | |

| M.1 | Test conditions | 95 |

| M.2 | Test procedure | 95 |

| M.3 | Permitted steering control effort | 95 |

| Annex N.1 (informative) Wind speed as a function of elevation | 96 | |

| Annex N.2 (informative) Impact pressure as a function of elevation | 97 | |

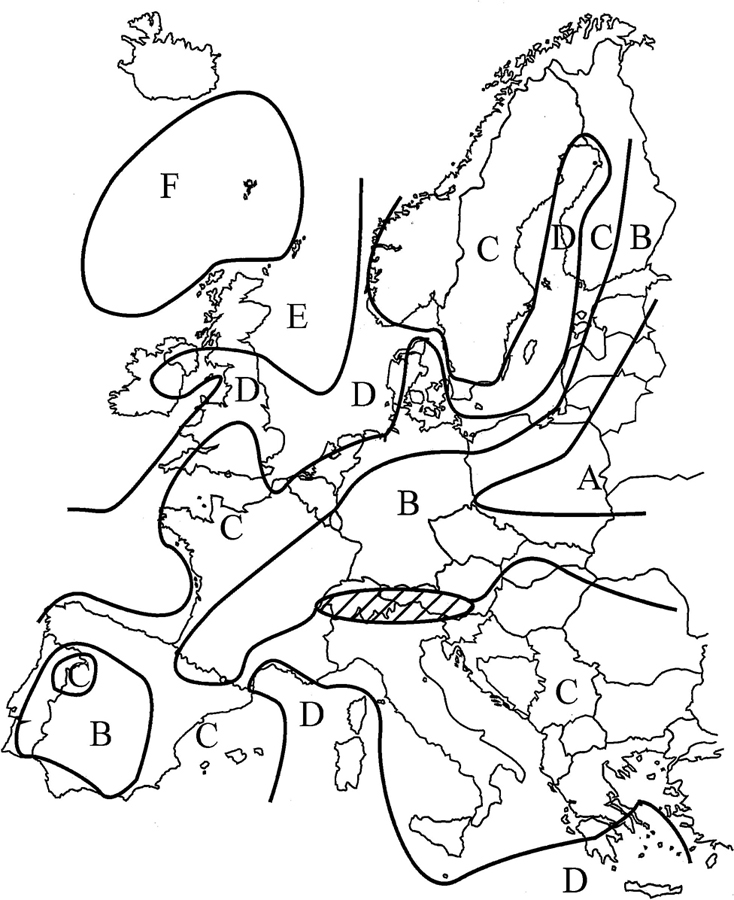

| Annex N.3 (informative) Storm wind map of Europe | 98 | |

| Annex P (normative) Efficiency of sheave sets | 99 | |

| Annex Q (informative) Manufacturer’s sign | 100 | |

| Annex R (normative) Certificate for wire rope, requirements | 101 | |

| Annex S (normative) Certificate for chain, requirements | 102 | |

| Annex T (informative) Test procedures: Selection of load cases | 103 | |

| Annex U (normative) Test certificate | 104 | |

| Annex V (informative) Selection of a suitable set of crane standards for a given application | 105 | |

| Annex ZA (informative) | 106 | |

| Relationship between this European Standard and the Essential Requirements of EU Directive 98/37EC | 106 | |

This document (EN 13000:2004) has been prepared by Technical Committee CEN/TC 147 “Cranes - Safety”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by December 2004, and conflicting national standards shall be withdrawn at the latest by December 2004.

This document has been prepared by Product Working Group CEN/TC147/WGP 1 “Mobile cranes”, the secretariat of which is held by DIN.

This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). For relationship with EU Directive(s), see informative annex ZA, which is an integral part of this document.

Annexes A, C, D, E, F, G.1 and G.2, H, J.1 to J.4, K.1 to K.5, L, M, P, R, S and U are normative. Annexes B, N.1 to N.3, Q, T and V are informative.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

5This European Standard is a type C standard as stated in EN 1070.

This European Standard has been prepared to provide one means for mobile cranes to conform with the essential health and safety requirements of the Machinery Directive.

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this document.

When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standards take precedence over the provisions of the other standards, for machines that have been designed and built according to the provisions of this type C standard.

6This European Standard is applicable to the design, construction, installation of safety devices, information for use, maintenance and testing of mobile cranes as defined in ISO 4306-2 with the exception of loader cranes (see 3.1.1 of EN 12999:2002). Examples of mobile crane types and of their major parts are given in annex A and B.

This standard does not cover hazards related to the lifting of persons.

NOTE The use of mobile cranes for the lifting of persons is subject to specific national regulations.

Mobile cranes covered by this European Standard are designed for a limited number of stress cycles and particular properties of motions, e.g. smooth application of the driving forces and loading conditions according to ISO 4301-2: group A1.

For a duty cycle such as grab, magnet or similar work, additional provisions are required which are outside the scope of this European Standard.

The hazards covered by this European Standard are identified by annex C.

This document is not applicable to mobile cranes which are manufactured before the date of publication of this document by CEN.

This European Standard incorporates by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies (including amendments).

EN 2:1992, Classification of fires

EN 294:1992, Safety of machinery—Safety distance to prevent danger zones being reached by the upper limbs

EN 349:1993, Safety of machinery—Minimum gaps to avoid crushing of parts of the human body

EN 457:1992, Safety of machinery—Auditory danger signals—General requirements, design and testing (ISO 7731:1986, modified)

EN 547-1:1996, Safety of machinery—Human body measurements—Part 1: Principles for determining the dimensions required for openings for whole body access into machinery

EN 563:1994, Safety of machinery—Temperatures of touchable surfaces—Ergonomics data to establish temperature limit for hot surfaces

EN 614-1:1995, Safety of machinery—Ergonomic design principles—Part 1: Terminology and general principles

EN 626-1:1994, Safety of machinery—Reduction of risk to health from hazardous substances emitted by machinery—Part 1: Principles and specifications for machinery manufacturers

EN 811:1996, Safety of machinery—Safety distances to prevent danger zones being reached by the lower limbs

EN 842:1996, Safety of machinery—Visual danger signals—General requirements, design and testing

EN 853:1996, Rubber hoses and hose assemblies—Wire braid reinforced hydraulic type—Specification

EN 854:1996, Rubber hoses and hose assemblies—Textile reinforced hydraulic type—Specification

7EN 856:1996, Rubber hoses and hose assemblies—Rubber-covered spiral wire reinforced hydraulic type—Specification

EN 894-2:1997, Safety of machinery—Ergonomics requirements for the design of displays and control actuators—Part 2: Displays.

EN 894-3:1992, Safety of machinery—Ergonomics requirements for the design of displays and control actuators—Part 3: Control actuators

EN 953:1997, Safety of machinery—Guards—General requirements for the design and construction of fixed and moveable guards

EN 954-1:1996, Safety of machinery—Safety-related parts of control systems— Part 1: General principles for design

EN 982:1996, Safety of machinery—Safety requirements for fluid power systems and their components—Hydraulics

EN 983:1996, Safety of machinery—Safety requirements for fluid power systems and their components—Pneumatics

EN 1005-3:2002, Safety of machinery—Human physical performance—Part 3: Recommended force limits for machinery operation

EN 1037:1995, Safety of machinery—Prevention of unexpected start-up

EN 1070:1998, Safety of machinery—Terminology

EN 10025:1993, Hot rolled products of non-alloy structural steels—Technical delivery conditions (includes amendment A1:1993)

EN 10113-2:1993, Hot-rolled products in weldable fine grain structural steels—Part 2: Delivery conditions for normalized/normalized rolled steels

EN 10137-2:1995, Plates and wide flats made of high yield strength structural steels in the quenched and tempered or precipitation hardened conditions—Part 2: Delivery conditions for quenched and tempered steels

EN 12077-2:1998, Cranes safety—Requirements for health and safety—Part 2: Limiting and indicating devices

EN 12644-1:2001, Cranes—Information for use and testing—Part 1:Instructions

EN 12999:2002, Cranes—Loader cranes

EN 13586:1999, Cranes—Access

EN 26385:1990, Ergonomic principles of the design of work systems (ISO 6385:1981.

EN 60204-32:1998, Safety of machinery—Electrical equipment of machines—Part 32: Requirements for hoisting machines (IEC 60204-32:1998)

EN 61000-6-4:2001, Electromagnetic compatibility (EMC)—Part 6-4: Generic standards; Emission standard for industrial environments (IEC 61000-6-2:1999, modified)

EN 61310-1:1995, Safety of machinery—Indication, making and actuation—Part 1: Requirements for visual, auditory and tactile signals (IEC 61310-1:1995)

8EN 61310-2:1995, Safety of machinery—Indication, marking and actuation—Part 2: Requirements for marking (IEC 61310-2:1995)

EN ISO 3411:1999, Earth-moving machinery—Human physical dimension of operators and minimum operator space envelope (ISO 3411:1995)

EN ISO 3744:1995, Acoustics—Determination of sound power levels of noise sources using sound pressure—Engineering method in an essentially free field over a reflecting plane (ISO 3744:1994)

EN ISO 4014:2000, Hexagon head bolts—Product grades A and B (ISO 4014:1999)

EN ISO 4871:1996, Acoustics —Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996)

EN ISO 5349-1:2001, Mechanical vibration—Measurement and evaluation of human exposure to hand-transmitted vibration—Part 1: General requirements (ISO 5349-1:2001)

EN ISO 5349-2:2001, Mechanical vibration—Measurement and evaluation of human exposure to hand transmitted vibration —Part 1: Practical guidance for measurement at the workplace (ISO 5349-2:2001)

EN ISO 5353:1998, Earth-moving machinery, and tractors and machinery for agriculture and forestry—Seat index point (ISO 5353:1995)

EN ISO 6683:1999, Earth-moving machinery —Seat belts and seat belt anchorages (ISO 6683:1981 + Amendment 1:1990)

EN ISO 7096:2000:, Earth-moving machinery —Laboratory evaluation of operator seat vibration (ISO 7096:2000)

EN ISO 7250:1997, Basic human body measurement for technological design (ISO 7250:1996)

EN ISO 11201:1995, Acoustics—Noise emitted by machinery and equipment —Measurement of emission sound pressure levels at a work station and at other specified positions—Engineering method in an essentially free field over a reflecting plane (ISO 11201:1995)

EN ISO 11688-1:1998, Acoustics —Recommended practice for the design of low-noise machinery and equipment—Part 1: Planning (ISO/TR 11688:1995.

EN ISO 12100-1:2003, Safety of machinery —Basic concepts, general principles for design—Part 1: Basic terminology, methodology (ISO 12100-1:2003)

EN ISO 12100-2:2003, Safety of machinery —Basic concepts, general principles for design—Part 2: Technical principles (ISO 12100-2:2003)

ISO 261:1998, ISO general-purpose metric screw threads—General plan

ISO 2631-1:1997, Mechanical vibration and shock—Evaluation of human exposure to whole-body vibration—Part 1:General requirements

ISO 3795: 1989, Road vehicles and tractors and machinery for agriculture and forestry—Determination of burning behaviour of interior materials

ISO 3864:1984, Safety colours and safety signs

ISO 4301-1:1986, Cranes and lifting appliances—Classification —Part 1:General.

ISO 4301-2:1985, Lifting appliances—Classification—Part 2: Mobile cranes.

ISO 4305:1991, Mobile cranes—Determination of stability.

ISO 4306-1:1990, Cranes—Vocabulary—Part 1: General.

9ISO 4306-2:1994, Cranes—Vocabulary—Part 2: Mobile cranes.

ISO 4308-1:2003, Cranes and lifting appliances—Selection of wire ropes—Part 1: General

ISO 4308-2:1988, Cranes and lifting appliances—Selection of wire ropes—Part 2: Mobile cranes—Coefficient of utilization

ISO 4309:1990, Cranes—Wire ropes—Code of practice for examination and discard

ISO 4310:1981, Cranes—Test code and procedures

ISO 6309:1987, Fire protection—Safety signs

ISO 7000:1989:, Graphical symbols for use on equipment—Index and synopsis

ISO 7296-1:1991, Cranes—Graphic symbols—Part 1: General

ISO 7296-2:1996, Cranes—Graphic symbols—Part 2: Mobile cranes

ISO 7752-2:1985, Lifting appliances—Controls- layout and characteristics—Part 2: Basic arrangement and requirements for mobile cranes

ISO 8087:1985, Mobile cranes—Drum and sheave sizes

ISO 8566-2:1995, Cranes—Cabins—Part 2: Mobile cranes

ISO/CIE 8995:2002, Lighting of indoor work places

ISO 11660-2:1994, Cranes—Access guards and restraints —Part 2: Mobile cranes

ISO 11662-1:1995, Mobile cranes—Experimental determination of crane performance—Part 1: Tipping loads and radii

ISO/CD 11662-2:1995, Mobile cranes—Experimental determination of crane performance—Part 2: Structural competence under static loading

ISO 12480-1:1997, Cranes—Safe use —Part 1: General

ISO 13200:1995, Cranes—Safety sings and hazard pictorials —General principles

FEM 1.001:1998, Rules for the design of hoisting appliances (3rd edition)

FEM 5.004:1994, Rules for the design of the steel structures of general use mobile cranes

For the purposes of this European Standard, the term and definition given in EN 1070:1998 applies. For specific definition and terminology applicable to mobile cranes the following terms and definition apply1). For other terms and definition ISO 4306-1:1990 and ISO 4306-2:1994 apply.

device to display the actual angle of parts of the crane to the horizontal, e. g. jib angle indicator, fixed fly jib angle indicator, luffing fly jib indicator

1) The definitions are listed alphabetically.

10device to limit the motion of parts of the crane regarding their angles, e. g. jib angle limiter, fly jib angle limiter and/or mast angle limiter

control station with protective enclosure (see 3.6, 3.7 and 3.9)

machine for cyclic lifting or cyclic lifting and handling of loads suspended on hooks or other load handling devices, whether manufactured to an individual design, in series or from, prefabricated components

NOTE “Suspended” can include additional means fitted to prevent swinging, rotation of the load etc.

device to indicate the “levelled position” of the crane

cabin provided for the operation of the crane motions to move the load

cabin provided for the transportation of the crane by road from one job site to another

combination of structural members, counterweights, support or outrigger position, hook block reeving and similar items assembled, positioned and erected according to manufacturer's instructions and ready for operation

permanent position of controls on or off the crane

device to prevent derricking (luffing) motions of the jib and/or fly jib beyond specified limits

device either to prevent the fixed load lifting attachment from being raised such that it strikes the crane structure, or a device to prevent any other specified upper limitation of the load lifting attachment from being exceeded. It can also include any other design limitation imposing a restriction on lifting

device to display the actual mass (weight) of the load

device which provides warnings and/or data to facilitate the competent control of the crane within its design parameters

device to display the actual jib length

11single part or assembly of parts of a crane, which are directly subjected to load effects (e. g. hooks, ropes (stationary or running), traverse beams, pendant bars, wheels, axles, gears, couplings, brakes, hoists, hydraulic cylinders, shafts and pins). In contrast to (steel) structures components can be regarded as independent units

device to display the locked condition of a part or function

device to ensure that the specified minimum number of turns of rope on the hoist drum is maintained at all times during operation

self powered jib crane capable of travelling loaded or unloaded without the need for fixed runways and relying on gravity for stability. Examples of mobile cranes are given in the annexes A, B.1 and B.2

NOTE 1 Mobile cranes can operate on tyres, crawlers or with other mobile arrangements. In fixed positions they can be supported by outriggers or other accessories increasing their stability.

NOTE 2 The superstructure of mobile cranes can be of the type of full circle slewing, of limited slewing or non slewing. It is normally equipped with one or more hoists and/or hydraulic cylinders for lifting and lowering the jib and the load.

NOTE 3 Mobile cranes can be equipped either with telescopic jibs, with articulated jibs, with lattice jibs–or a combination of these–of such a design that they can readily be lowered.

NOTE 4 Loads can be handled by hook block assemblies or other load-lifting attachments for special services.

mobile crane which travels on site (e. g. rough terrain crane, crawler crane)

mobile crane which has the necessary equipment to travel on public roads and on the job site (e. g. all terrain crane, truck crane)

safety margin for the method of limit states chosen as described in annex A of ISO 8689-1:1989 (see partial load coefficients γP)

device which automatically prevents a design performance characteristic from being exceeded

device to display the actual radius of the load

load that the crane is designed to lift for a given operating condition (e. g. configuration, position of the load). For mobile cranes the mass (weight) of the hook block is part of the load

12device which gives, within specified tolerance limits, at least a continuous indication that the rated capacity is exceeded, and another continuous indication of the approach to the rated capacity

device that automatically prevents the crane from handling loads in excess of its rated capacity, taking into account the dynamic effects during normal operational use

device to automatically prevent dangers from slack rope situations

device to indicate to the crane operator the actual slew position

device to indicate to the crane operator the permitted slew range for the selected configuration

device to prevent slewing beyond specified limits

device to prevent telescoping beyond specified limits

device to indicate to the crane operator the actual wind speed

load on the hook plus mass (weight) of hook and block

safety margin for the permissible stress method chosen as described in annex A of ISO 8686-1:1989 (see coefficients applied to the specified strength γF)

Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100 for hazards relevant but not significant, which are dealt with by this document (e. g. sharp edges).

Mechanical hazards can arise when loads acting on a crane exceed limiting conditions. Such an overload can cause the entire crane and/or its components to lose stability (elastic or rigid body) as well as cause the supporting structure and/or components to be subjected to failure.

13In order to prevent this potential danger, verification shall be provided for the extreme values of load effects based on all forces which act simultaneously on the crane multiplied by adequate (partial) safety factors to ensure that the corresponding loading limits are not exceeded.

This standard defines loads and load combinations as well as specific values of factors and coefficients to be applied to mobile cranes.

The limit state for materials and components shall be indicated in the form of nominal values, which are laid down in relation to the nominal load effects (internal forces or stresses) defined in the relevant standards.

All cases in which limits are exceeded and can endanger the mechanical structure, e. g. creeping, elastic instability, loss of stability, significant displacements, fatigue or wear (including discard of ropes), uncontrolled motions and temperature limits shall be taken into account.

The procedure for the design and calculations is described in this clause. The procedure consists of identifying load effects (see 4.1.2), determining the limit states (see 4.1.3) and the proof of competence (see annex L). Alternatively advanced and recognized theoretical methods (e.g. elastokinetic analysis to simulate load effects) or experimental methods (e. g. measurement of load effects or tests for determining limit states or strain gauge testing) may be used. These methods shall provide the same level of safety.

All loads which act on the crane or its supporting sections including dead weights, additional loads (e.g. due to gravity, wind loads or other ambient influences), test loads and special loads during erection or dismantling (of jib systems) shall not cause damage, such as fracturing, permanent deformations or unintentional displacements.

Load effects shall be determined based on an elastostatic/rigid body kinetic model of the crane and load models. Loads acting on the crane at the same time shall be combined as given in annex D.

It is assumed that:

With these assumptions it is not necessary to carry out a fatigue analysis on the load bearing structure.

When considering test loads the crane shall be in the same configurations as intended for use without any modification (e.g. without changing outriggers, counterweight, counterweight position).

When the method of permissible stresses (see L.2.2) is applied, the working load shall be multiplied by the working load factor.

When the method of partial safety coefficients and limiting stresses (see L.2.3) is applied, the working load shall be multiplied by the working load factor and its partial safety coefficients and all other loads by their respective partial safety coefficients.

Loads with a low number of stress cycles and low amplitudes are to be seen as mean values multiplied by the working load factor and/or the respective partial safety coefficients.

The analysis of load effects with alternative advanced methods, i.e. from individual events (dynamic factors) or representative use of a crane shall provide at least equivalent levels of safety. It shall take into account unfavourable operating conditions and sequences of movements of the crane and/or the load.

14To calculate the wind loads, it is assumed that the wind blows horizontally from the most unfavourable direction, but at an elevation-related speed.

The speed of a 3-second wind gust v(z) [m/s] acting on an elevated point z[m] and decisive for calculations is based on a mean wind speed determined over 10 minutes  [m/s] at 10 m above ground or sea level.

[m/s] at 10 m above ground or sea level.

v(z) = [(z/10)0,14 + 0,4].

for z = 10[m] ⇒ v(z) = 1,4.

see annex N.1

The quasi-static impact pressure q[N/m2] is as a result of:

q = 0,625. v(z)2

for z = 10[m] ⇒ q(z) = 1,225.

see annex N.2

The admissible wind speed for the crane in-service and out-of-service is derived from the wind guest speed v(z) acting on the highest elevated point taken in account for the verifications.

To calculate the wind load during crane operation conservatively, the wind gust speed determined at the highest elevated point vi (max. z) can be assumed to act all over the height of the crane and its jib.

Precise elevation-related calculations of the wind forces acting on the jib are permissible, e. g. in 10 m elevation intervals.

The wind forces acting on the crane and its components as well as the pertaining impact pressures determined shall be combined with the other in-service loads.

The permissible wind speed vi (max. z) shall be indicated in the rated capacity charts and in the instruction manual. The reference value used to determine the load (area exposed to wind per mass (weight) unit of the capacity) shall likewise be indicated; if not otherwise laid down, then the value is 1,2 m2/t.

NOTE 1 Value 1,2 m2/t based on cw = 1,2.

The wind loads acting on the suspended load shall be derived from the maximum lifting height of the suspended load. Special verification is required from case to case for lifting loads with a large “sail area” (>1,2 m2/t).

NOTE 2 Safe crane use is only possible within the range of the permissible wind speed vi (max. z) while the crane is in service, the speed at the highest elevation can be monitored by means of an anemometer. To prevent any danger, in particular, due to sudden changes in wind speed or direction during the passing of weather fronts, weather reports should be taken into account when lifting operations are being scheduled. Instructions should be laid down in the instruction manual providing suitable measures for lowering the crane to a safe position.

NOTE 3 Mobile cranes are normally equipped with jib systems which can be lowered quickly and readily. As a result, the hazards due to sudden changes in wind speeds and increases in gust speed at elevated points can be reduced in a short time, e. g. within 5 minutes.

a) Out-of-service storm winds

15To calculate the wind loads when the crane is not in operation, an average, regionally varying, reference wind speed can be assumed. The reference wind speed vref is determined over 10 minutes at 10 m above ground or sea level. In Europe the following figures are applicable (see annex N.3):

| Regions | A | B | C | D | E |

|---|---|---|---|---|---|

| vref[m/s] | 24 | 24 | 28 | 32 | 36 |

The design is considered safe when all the required verifications including the effect of 3 second elevation-related wind gusts are calculated based on a reference wind speed (see formulas in 4.1.2.2.1 and annexes N.1 and N.2).

b) Out-of-service limiting wind speed

To calculate the wind load effect when the crane is not in operation, the wind gust speed at the highest elevated point va (max. z) shall be considered. See annexes N.1 and N.2. The required safety shall be verified for all permitted configurations and/or positions of the crane.

Precise elevation-related calculations of the wind forces acting on the jib in such a configuration and/or position are permissible, e. g. in 10 m elevation intervals, for the relevant gust speeds (3-second gust speed).

The forces on the crane and its components resulting from the impact pressure shall be combined with the dead weights and, if required, with other geometric influences (e. g. out of level surfaces).

NOTE 1 A crane which is safe with respect to the effect of the wind speeds va (max. z) based on crane-specific limits, should only remain in this configuration and/or position up to the derived wind gust speed.

Information shall be provided in the instruction manual as to which measures shall be taken by the crane operator in order to maintain the crane in safe condition, e. g. by lowering or telescoping in the jib in the event that va (max. z) is exceeded. Instructions shall be laid down in the instruction manual providing suitable measures for securing the crane out-of-service.

NOTE 2 The safety of a crane is only maintained within the range of the permissible wind speed va (max. z) while the crane is (in-or) out-of-service. Therefore exceeding of the limiting wind speed out-of-service should be prevented by planning a lift including the weather forecast.

The loads acting on the steel structure of general use mobile cranes shall be calculated in accordance with the FEM 5.004:1994, where the group classification A1 of ISO 4301-1 and ISO 4301-2 applies.

If a mobile crane is designed to carry out simultaneous movements, the load effects of two of these movements shall be taken into account (see annex D). As a minimum requirement the load combinations of the load cases 1, 2 and 3 in Table 1 of FEM 5.004:1994 shall be calculated.

Non steel structures shall be designed with equivalent safety margins as for steel structures for their intended lifetime. Special characteristics (e. g. tensile creeping, relaxation, anisotropy, thermal behaviour) shall be considered. The technical requirements for these materials are not dealt with in this standard. Sufficient knowledge and experience shall be proven by the manufacturer of the crane or the supplier of such structures.

For the purpose of this standard the term load bearing component applies to all single parts of assemblies of parts of a crane, which are directly subjected to load effects (see 3.15).

16There are two different procedures to design the components of a crane and to proof their competence. Either the components are designed individually, using the applicable standards concerning load effects and proof calculation or the pre-designed components have to be selected.

For individually designed components the load effects derived from the service conditions shall be established by the crane designer.

For pre-designed components the crane designer and the component designer/supplier shall identify and agree upon the relevant load effects derived from the service conditions (see 4.1.3.4).

Differing from the (steel) structures, which are loaded by only one important stress cycle per operating cycle, the mechanisms are loaded by multiple stress cycles depending on linear movements, distances and the number of rotational movements.

The estimation of the number of stress cycles during the assumed life time of the mechanisms is based upon the written agreement upon service conditions between the user and the manufacturer of the crane.

Where the use of mechanisms is unknown, the stress cycles and assumed life time shall correspond with those values available from previous experience.

The mechanism group classification shall be in accordance with Table 6 of ISO 4301-1:1986 and Table 2 of ISO 4301-2:1985 (complies with T.2.1.3.4 of FEM 1.001:1998 part 2).

The loads acting on running and stationary ropes used directly for lifting the load or supporting the crane structure shall be calculated from the dead loads and the nominal working loads as specified in Table 1 of FEM 5.004:1994, load combination case 1.

The coefficient of utilisation depending on the crane mechanism classification shall be in accordance with ISO 4308-2. The influences of dynamic effects and friction losses shall be covered. For crane classification A1 the working load factor Φ may be taken as 1.0. The friction losses have to be calculated according to annex P.

The loads acting on chains used as components for lifting the load or supporting the crane structure shall be taken as the maximum value from the two cases: maximum occurring force for the moving chain or calculating the dead loads and the nominal working loads as defined in Table 1 of FEM 5.004:1994, load combination case 1.

The chain group classification shall be in accordance with Table 6 of ISO 4301.1:1986 and Table 2 of ISO 4301-2:1985 (complies with T.2.1.3.4 of FEM 1.001:1998 part 2).

Dynamic effects have to be covered by increasing the load with the working load factor. Technical requirements for friction losses are not covered with in this standard.

The loads acting on other load bearing components shall be calculated as specified in 4.1.2.1, if they are loaded with only one important stress cycle per operating cycle and the other conditions of clause 6 of FEM 5.004:1994 are fulfilled.

The classification of each component, which is loaded by multiple stress cycles per operating cycle, shall be in accordance with 2.1.4 of FEM 1.001:1998, part 2. The load effects for these components shall be calculated in accordance with 2.2 and 2.3 of FEM 1.001:1998, part 2.

17The rigid body stability of the crane shall be in accordance with ISO 4305.

The values to be considered for the rigid body stability shall be taken as specified in Table 1 and 2 of ISO 4305:1991.

Tipping lines of mobile cranes depend on the individual design. Examples for tipping lines are given in annex A of ISO 4305:1991. For crawler cranes special attention has to be given to forward or backward tipping over the sprocket and/or first roller.

It is assumed that the crane is operated on a firm and level surface (up to 1% gradient of the ground). If greater gradients of the slewing plane are allowed by the manufacturer, special capacity charts shall be provided. A minimum side gradient of 0.5% for cranes on outriggers and/or 1% for cranes free on tyres or crawlers shall be taken into account.

The maximum values of forces and pressures resulting thereof shall correspond to the allowable values of the inclination of the crane level and the limits shall be established for the relevant capacity charts. Special attention shall be given to the elastic deformation of the crane structure and the crane movements (slewing, luffing, travelling etc.) increasing the supporting forces and ground pressure.

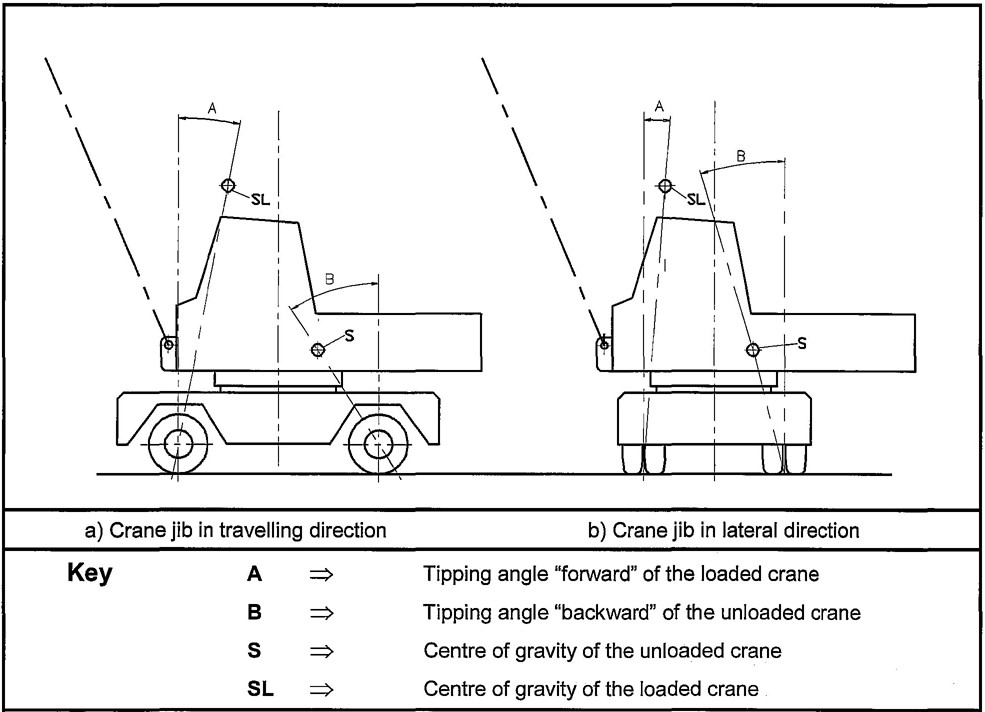

Accelerations due to sudden release of the load can cause tipping backwards of the crane or can cause unintended backward motions of parts of the crane. Instead of an exact calculation a vertical upward force acting on the unloaded crane without wind loads may be used.

The vertical upward force shall be taken as ≥ 10% of the rated capacity for cranes with classification A1 according to ISO 4301-2:.

The rigid body stability for erection of the unloaded crane and its dismantling procedure shall be considered as a special loading condition. The dead loads and the additional loads (gravitational, wind loads, etc.) increasing the tipping moment shall be amplified with a safety coefficient ≥ 1,1.

The following additional effects shall be considered to determine adequate stability of the crane:

Special attention shall be paid to the elastic behaviour of the crane, considering:

— effects due to elastic deformation of carrier, wheels, tyres, crawlers and outriggers;

— effects due to angle displacement of the jib system during slewing of the load according to different stiffness of the carrier in different slew ranges.

Accelerations due to abrupt starting/stopping of movements of the crane and/or the load can cause unintended movements of the crane and/or the load (kinetic energy). To determine adequate stability to avoid tipping of the crane sufficient potential energy shall be provided.

These dynamic effects shall be covered by calculation or by a simplified procedure using a tipping angle, see annex F.

Limit states shall be as specified below. Where the limit states of materials and components are not given below, they shall be laid down as written agreement between the crane manufacturer and the supplier of these materials and components on the basis of recognized methodology and standards.

The limiting values for materials shall include the static and dynamic (where required) properties for strength and ductility - depending on the dimension, the kind of fabrication (heat treatment), the allowed temperature for in- and out-of-service conditions, the elastic properties and their suitability for the production process and use.

NOTE The limit states may be found by tests of material specimen and of components or by applying theoretical methods and using basic test results additionally, if appropriate.

The limit values for structural and fine grained steel types of common use shall be taken from the Table in annex H (see Table 2 of FEM 5.004:1994).

The limit states for steel structures shall be calculated from the values of the relevant European Standards for materials or, where not existing, the specialized data sheets for those materials, which are not covered by harmonized standards, as provided by the manufacturers of these materials.

The permissible and/or limiting stresses of structural components and welds shall be calculated by the yield stresses and the (safety) factors according to L.2.2 and L.2.3.

The limit stated for non steel structures shall be calculated from the values of the relevant European Standards for materials or, where not existing, the specialized data sheets for those materials, which are not covered by harmonized standards, as provided by the manufacturers of these materials. The requirements for these materials are not dealt with in this standard.

The limit states for mechanisms shall be specified by the manufacturer/supplier of the mechanism. They are based upon information about dimensions, loading, assembly and service conditions which were taken into account when designing the crane.

The minimum requirements for the technical specification agreed between crane manufacturer and manufacturer/supplier of mechanisms shall be based upon uniform formats given for the particular type of mechanism. The technical specification for gears and drums shall include the parameters shown in the related annexes:

| — Gears: | Hoist/derrick gear | see annex J.1 |

| Slow gear | see annex J.2 | |

| Travel gear | see annex J.4 | |

| — Drums: | Hoist/derrick drum | see annex J.4 |

The design of a rope system including its end termination shall permit the desired lifetime under the estimated conditions of service specified for the particular application. The limit stated for ropes and/or the components of the

19rope system can be delivered either from European Standards or from long term experience and tests by the crane manufacturer and/or the rope manufacturer or by other equivalent experimental methods.

All ropes used shall have a rope certificate giving the limit stated as determined by the rope manufacturer (see annex R).

The limit states of a stationary rope are determined by the design of the rope and given as the minimum breaking load identified by series of tensile strength tests.

The minimum breaking load of the rope is the decisive value for the limit stated under the following conditions:

NOTE The limit states of a running rope depend on the design of the rope itself, the design of drums, sheaves and pulleys and on the ratio of the pitch diameters to the nominal diameter of the rope. The limit states of running ropes can be identified by the minimum breaking load and the permissible number of bending cycles.

The minimum breaking load shall be compared with the nominal load (see L.4.3, proof of competence for ropes).

Rope and termination shall not be made by means of rope clips (building clips). The use of rope clips on the tail and only of a rope passing through a wedge socket to prevent the rope slide back through the socket is permitted.

All chains used as components for a mobile crane shall have a chain certificate giving the limit stated as determined by the chain manufacturer (see annex S).

NOTE The limit states for chains are based upon information about dimensions, assembly, service conditions, cleaning and maintenance conditions specified by the crane manufacturer and a Worker curve given by the supplier in relation to the stress cycles occurring during the assumed life time.

NOTE The limit stated for other load bearing components should be specified by the manufacturer/supplier of the component. They are based upon information about the dimensions, loading, assembly and service conditions which were taken into account when designing the crane.

The minimum requirements for the technical specification agreed between crane manufacturer and manufacturer/supplier of components shall be based upon the uniform format given for the particular type of component. The technical specification shall include the parameters shown in the related annexes:

| — Lifting hooks: | see annex K.1 |

| — Sheaves: | see annex K.2 |

| — Hook blocks: | see annex K.3 |

| — Hydraulic cylinders: | see annex K.4 |

| — Slew rings: | see annex K.5 |

The ergonomic requirements for the general design of equipment and devices shall be in accordance with EN 547-1, EN ISO 7250, EN ISO 6385-1 and EN ISO 6385-2. The principles of EN 626-1 for selection of materials shall apply. Hazards shall be avoided according to EN 294, EN 349 and EN 811.

Sharp edges of equipment and devices which have to be accessed during normal use shall be avoided by means as laid down in 4.2.2.3.

Electrical cables shall not be installed to close proximity to hot pipes or hoses (e.g. hydraulic system, exhaust system) that are likely to cause damage to the cables.

Control stations and control devices shall be designed and placed to enable the safe use of the crane.

Control stations for the movement of the load and/or the travelling of the crane shall be provided with a cabin (crane operation cabin, crane travelling cabin). This does not apply to the provision of remote controls.

Elevated control stations shall be solidly designed and built. They shall be reliably attached to the crane. The material in the supporting structure shall be fire retardant. Damage to shock absorbers or absorbent material as a result of fire shall not allow the control station to come loose from its supports. For guidance see ISO 8566-2 and ISO 11660-2.

The dimension of railings (handrail, knee and foot ledge) shall be in accordance with Figures 4, 7, 12 and Table 6 of EN 13586:1999.

Covering and insulation of walls, floor and ceiling shall be made of fire retardant material, see 4.5.1. These materials shall minimize optical reflections disturbing the operator.

The cabin floor shall be designed to be cleaned easily without ledges preventing the removal of dirt.

The cabin floor shall have a slip resistant surface (e.g. bulb plate/checker plate, open mesh, sanded paint).

Space shall be available inside the cabin for the storage of documents needed to safely operate the crane. A first aid box shall be available at least in one cabin. Space for a fire extinguisher shall be provided in or adjacent to each cabin (see 4.5.2).

Where a cabin roof is to be used during assembly and/or dismantling the surface shall be slip resistant. The loads arising from persons standing on the roof, including tools etc. shall be taken into consideration. A proof load of 1 000 N applied evenly over an area of a 125 mm diameter disc anywhere on the surface shall not cause permanent deformation.

Where the surface of the cabin roof is intended to drain off water, the water shall not run down the windows.

Parts of the equipment inside the cabin which are accessible during normal use shall not present any sharp edges or points which could cause injuries. Edges shall have radii (minimum 1 mm) or be chamfered (minimum 1 mm × 1 mm) or be covered achieving an equivalent level of safety.

21The crane operating cabin shall have exit routes for emergency evacuation in at least two directions. Emergency exits shall be easily recognised and opened from inside the cabin. The emergency exit route in a direction other than that of the normal entrance to the cabin may take the form of an opening with a size of an emergency exit as specified in ISO 11660-2. E. g.: An opening window or a window opening with an easily removable window pane of that size is suitable.

The space inside the cabin shall permit all operating controls to be actuated from the working position. The space shall also afford accessibility for the supervision, repair etc. of the equipment inside the cabin. The minimum internal dimensions shall be in accordance with Figure 1 of ISO 8566-2:1995.

For cranes designed exclusively for use in confined spaces (e. g. lifting/travelling under low headroom conditions) the cabin dimensions can deviate from ISO 8566-2.

Means shall be provided to keep the air temperature inside the closed cabin at 18 °C minimum at a reference outside temperature of −10 °C. The cabin shall be such as to protect against draughts.

The cabin shall be provided with adjustable ventilating equipment. The equipment shall be capable of supplying air from the outside. The fresh air valve shall be adjustable.

Heating means which are powered by gas, petrol, diesel or burning oil shall be installed in such a way that there is an adequate supply of fresh air to ensure complete combustion and that the exhaust gases cannot ingress into the cabin regardless of wind direction and speed.

22All crane operating cabin doors, whether of sliding or swinging type, shall be provided with a means of restraint from inadvertent opening or closing during travelling or operation of the crane. The door adjacent to the crane operator shall open outward or slide backward to open. The door shall be capable of being retained in the open position.

Crane operating cabin doors shall be lockable from the outside but not the inside. The door shall always be able to be opened from the inside without a key whether locked or not.

Crane operating cabin windows shall be equipped with latches which guard against opening the windows from outside the cabin.

All cabin windows shall be made of a material which will not produce sharp edges if broken (e.g. toughened or laminated glass) and that do not lose transparency in exposure to natural light.

Roof windows shall withstand or be protected against falling tools, see 4.2.3.

All cabins shall be equipped with lighting to allow all information contained within the cabin, such as manuals, signs, labels or rated capacity charts, to be readily legible during operating conditions in accordance with ISO 8995. The lighting shall be provided by a permanent installation.

Crane travelling cabins with a floor higher than 0.65 m above ground shall have entrances and exits with:

Steps shall:

The access shall have ergonomic handrails.

Cabins with a floor higher than 1.0 m (to be measured from ground level) shall be provided with handholds. Other control stations or crane operating cabins with doors opening outwards above 1.0 m height shall be provided railings which prevent the operator from an accidental headlong fall.

Cabins with a floor higher than 2.5 m (to be measured from ground level) shall be provided with a platform and railings. The platform shall have enough space for at least two persons. Other control stations above 2.5 m height shall be provided with a platform with handholds and railings.

As a minimum the roof of the crane operating cabin including windows in the roof shall be able to withstand the impact of a steel ball weighing 7 kg, falling from a height of 2 m, without plastic deformations exceeding 50 mm.

23The crane operating cabin shall be fitted with a seat having sufficient adjustments to enable the crane operator to operate the crane according to the ergonomic principles given in ENV 26385.

The seat shall be able to be locked in its adjusted positions. If foot supports and/or arm rests are provided, accessibility to the crane operator’s seat shall be maintained and the operation of the crane shall not be limited.

NOTE The seat should be provided with an adjustable headrest.

The seat dimensions shall conform to annex E. The Seat Index Point (SIP) is given in EN ISO 5353.

NOTE The dimensions are based on EN 23411:1988.

All adjustments to accommodate the crane operator’s size and weight shall be readily achievable without the use of any tool.

The value of vibrations transmitted by the crane operator's seat shall not exceed the limiting values specified in ISO 7096 and ISO 2631-1. The weighted acceleration shall be less than the given health guidance zones in ISO 2631-a. The vibration transmitted by the crane operator's handles/armrests shall be measured and valued according to EN ISO 5349-1 and EN ISO 5349-2.

If a restraint system is required, it shall conform to EN ISO 6683 unless otherwise specified by prevailing road regulations.

It is preferred to have the seat belt anchorage attached to the seat with the belt locking device to the side of the crane operator. Anchorage shall permit the restraint system to be readily installed or replaced.

All safety related parts of the controls mentioned in the sub-clause below shall be in accordance with EN 954-1:1996 category 1, all electronic evaluation devices with category 2.

NOTE 1 The crane operator interacts via a man-machine interface with the machine in an open loop system. This interface consists of control devices by means of which the crane operator initiates actions and by indicators the crane operator receives information. In addition certain motions of the crane are limited by motion/performance limiters and the rated capacity limiter. These limiters from an integral part of the control system.

NOTE 2 With the present state of art the control system of a mobile crane with the crane operator as a part of the system cannot prevent every dangerous situation. There are several influences which cannot be automatically controlled. The following list is not exhaustive:

— wind forces on the crane and/or the load;

— dynamic influences due to abrupt motions (influences outside the control system);

— ground conditions;

— demolition work.

24Control devices shall be in accordance with EN 614-1, EN 894-3, EN 1005-3 and EN 61310-2. The arrangement and the direction of movements of the control devices shall be in accordance with ISO 7752-2.

The starting of a movement shall be possible only by intended actuation of a control device provided for this purpose.

The crane shall be provided with means to give an audible warning to persons in the vicinity of the crane (e.g. when the engine is started, when motions are initiated). This device shall only be able to be activated by the crane operator. The warning shall conform to the appropriate clauses of EN 457.

Control devices for extending/retracting the outrigger beams shall be in a position or provided with means where the movements of the outriggers can clearly be see by the crane operator and from where crushing of the crane operator is not possible. If the horizontal movement of the outriggers is controlled from ground level, it shall only be possible to affect that movement on the side where the controls are situated.

With the present state of art it is not possible to provide a complete view of all the danger zones from one control station. Therefore means for the viewing of danger zones (e. g. mirrors, TV-Cameras) or control stations at different places related to the hazardous movement shall be provided.

Resetting devices where fitted require additional protection to avoid inadvertent activation (e. g. key switch).

On systems with electronic selector switches (e. g. keyboards) the breakdown of the power supply with loss of the stored information, the recovery of power supply shall result in a reset whereby no selection is activated.

To enable the crane operator to check the selected configuration and compare it easily with the configuration of the machine itself the following shall be provided:

— symbols and figures at or near to the configuration selector switch, or

— in case of coded information (e. g. thumbwheel with code numbers) the code number shall refer to each different configuration. Each code number shall be printed in the relevant place on the capacity chart.

The starting system shall be in accordance with EN 1037.

Means shall be provided so that no unintended movement of the crane is possible until the crane operator is in the prescribed operating position (e. g. armrest switch, dead man switch, seat switch).

All control devices shall move to the neutral position (stop) when released.

An engine cut off with a red push button of mushroom type on a yellow surface, that remains in the off-position, to enable the stopping of the engine(s) shall be provided. It shall be located at a prominent place in the cabin within easy reach through the door. These stopping devices are required only on engine(s) for load motions and are not required on specific engine(s) related to travel and outrigger motions only.

NOTE Emergency stop equipment according to EN 418 does not reduce the stopping time for dangerous motions. Contrarily emergency stop can generate additional hazards due to inertia of moving masses if they are stopped abruptly (e. g. swinging of the load).

25The requirements of EN 12077-2 apply.

All information provided by the indicators and displays shall be visible from the control positions, including remote controls, where that information is required.

Indicators and displays to ensure safe operation of the crane shall be in accordance with the appropriate clauses of EN 894-2 and EN 61310-1. Audible indicators shall be in accordance with EN 457. Visual indicators and displays shall be in accordance with the appropriate clauses of EN 842.

All safety related parts of limiting and indicating devices mentioned in the sub-clause below shall be in accordance to EN 954-1:1996 category 1, all electronic evaluation devices with category 2.

If two or more motions can be carried out simultaneously, the motion/performance limiters shall take into account the effects of the possible combinations.

The effect of one motion upon another shall also be taken into account by the system where movement of that motion may cause another limit of motion or characteristic of performance to be exceeded.

The response of indicators and displays shall follow the corresponding motion with a suitable precision (e. g. ± 5%) and speed, so that they always show the current situation.

For stepped values (e. g. lattice jib length, or telescoping jib length with locking pins) the indicated values shall correspond directly to the related capacity chart.

At or near to each indicator at the control station(s) there shall be a legible and durable explanation of the function of the device (preferably by a symbol, see 7.3 or e. g. by the position of a selection device, by a turnwheel for falls of hoisting line).

Any motion which has a designed restriction of movement has to be kept in the designed range. This can be done either by motion limiters or by the design of the device itself, e. g. limited stroke of a hydraulic cylinder.

NOTE 1 Regarding the state of the art, it is impossible to prevent automatically every dangerous motion or to prevent automatically every collision, e. g. man-machine, machine-machine, machine-fixed obstacle.

NOTE 2 Working space limiters and/or anti-collision devices can be provided if agreed between manufacturer and user of the crane. These devices cannot prevent hazards due to swinging of the load and/or the crane or parts of the crane caused by abrupt starting or stopping of movements caused by incorrect operation.

Where a motion is provided with a motion limiter, after the triggering of that motion limiter, movement in the opposite direction to a safe condition shall be possible without resetting.

Motions with restricted visibility and design restrictions which cannot be easily monitored by the operator and/or supervisor, shall be equipped with two consecutive motion limiters or by other means providing the same level of safety (e. g. two independent angle sensors).

Where a motion is provided with two consecutive limiters, it shall not be possible to operate the limited motion after the second limiter has been activated. A reset action is necessary before the movement in the opposite direction is possible.

26A motion shall have a performance limiter if:

— the motion has a designed performance limitation which if exceeded can cause a failure of the structure or the mechanisms, overturning of the crane or falling of the load;

— there is an external influence which can cause the performance limitation to be exceeded (e. g. gravity).

NOTE Performance limiters are often an integral part of the system (e. g.: a given diameter of a tube in a hydraulic system restricts the flow of hydraulic oil and therefore restricts the speed of lowering the load).

Performance limiters shall operate automatically when the respective performance limit is reached.

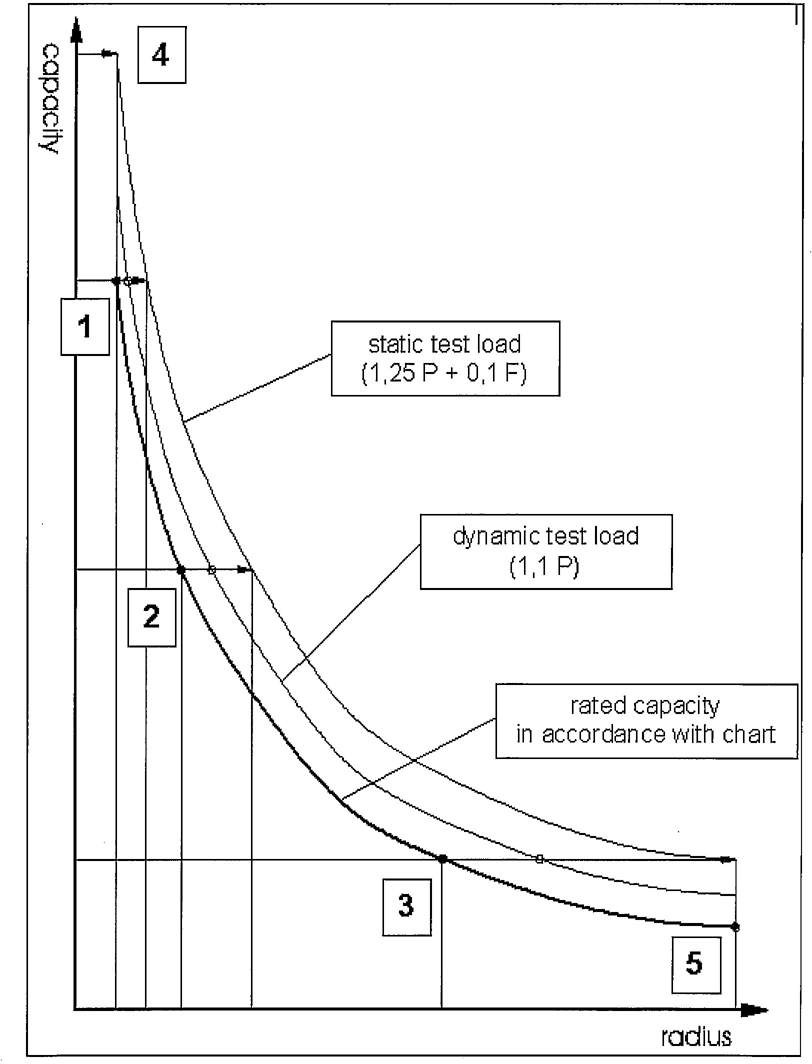

The rated capacity limiter/indicator shall conform to 4.2.6.3.2 and 4.2.6.3.3 for all rated capacities given on the rated capacity chart and the test certificate for the crane.

A rated capacity limiter/indicator shall operate automatically without the need for resetting during a lifting cycle.

Where a crane can be operated in different configurations, there shall be a precise and continuous indication of the crane configuration for which the rated capacity limiter/indicator has been set. As a minimum requirement, the configuration selection device shall provide a direct description of the configuration selected, or indicate a code which can be checked against a separate list of codes/configurations which are given on the capacity chart or attached to it.

The location/design of any configuration selecting device shall prevent alternation of the setting by the operator from the application of a load to the release of that load, but it shall be readily accessible whenever the configuration is changed.

On mobile cranes which can be operated in different configurations (e. g. on wheels, on outriggers, different counterweights, different jib length, different number of falls) no unintended change of the configuration selection shall be possible (e. g. location of selection device, separate confirmation of settings).

NOTE Normally there is no check (automatic plausibility check), whether the selected configuration corresponds with the real configuration.

Selections of configurations not referring to configurations of the crane permitted by the manufacturer shall not allow the crane to operate.

The design and installation of rated capacity limiters and indicators shall be able to withstand overloads during test and verification without dismantling and without affecting their performance (see 5.1).

All mobile cranes having a rated capacity of not less than 1000 kg or an overturning moment of not less than 40 000 Nm shall be fitted with a rated capacity limiter.

The rated capacity limiter shall prevent the crane from supporting a load outside the limits of the permitted radii, and outside the positions and loads shown and/or described on the rated capacity chart and current test certificate or the permissible working load of the ropes.

The rated capacity limiter shall operate, with lowest possible working speed, between 100% and 110% of the rated capacity. This tolerance shall be achieved by the complete installation as fitted to the crane.

In case of increased tolerances additional structural strength and stability shall be provided to achieve the same level of safety as for above mentioned standard tolerance. The values of increased tolerances shall be given in the crane documentation.

27The rated capacity limiter shall operate to override the controls of the crane:

For a mobile crane the motions that shall normally be overridden by the rated capacity limiter when triggered are:

NOTE 1 An override key for ii) may be provided within the reach of the operator (for derricking in a suspended load).

NOTE 2 The derricking in/luffing in of a grounded load is not to be permitted (see 6.2.2.2 g).

The rated capacity limiter shall not prevent the crane operator from returning the controls to the ‘stop’ position and starting any motions that will move the crane to a safer condition.

The rated capacity limiter, once triggered, shall remain active until the overload has been removed.

When bridging devices are required for overload testing, rigging and de-rigging of the crane, the bridging device of the rated capacity limiter shall not be in direct reach of the crane operator and shall be under lock and key (e. g. in a switch cabinet). The rated capacity limiter shall automatically return to its normal operation when the engine is shut down and started again.

All mobile cranes having a rated capacity of not less than 1000 kg or an overturning moment of not less than 40 000 Nm shall be fitted with a rated capacity indicator.

The rated capacity indicator shall give warnings in accordance with EN 457 and EN 842, for all motions that induce an approach to the rated capacity or an excess of the rated capacity as shown on the rated capacity chart and the test certificate for the crane.

The rated capacity indicator shall warn:

Warnings for both the approach to the rated capacity, and for the rated capacity being exceeded, shall be continuous. There shall be a clear difference between the warning for approach and the warning for overload.

The rated capacity indicator shall give a warning of approach to the rated capacity starting between 90% and 97.5% of the rated capacity of the crane.

NOTE This gives the crane operator time to react to the warning and prevent the crane from being overloaded, e. g. slowing down of movements, to prevent the load from swinging.

No provisions shall be made for the crane operator to cancel a warning from the control station, except for the audible warning required by a) and b) above where a cancellation facility may be provided for this warning that only becomes operable after the warning has been active for 5 seconds. If such a cancellation facility is used, followed by the crane returning to a condition requiring an audible warning, the warning shall automatically operate.

28The rated capacity indicator shall continue its function when the rated capacity limiter is overridden during testing, rigging or de-rigging.

Provisions can be made to cancel the audible warning during calibration and testing of the crane. Provisions can also be made for a rigging setting that inhibits audible warnings during the rigging of the crane.

The rated capacity indicator shall be such that its operation, but not necessarily its accuracy, can be checked without applying loads to the crane.

The crane level shall be indicated at or near at the crane operating cabin within the view of the crane operator. Mobile cranes supported by outriggers shall have in addition a crane level indicator at each outrigger control station where the levelling motion(s) can be controlled. The crane level indicator shall have an accuracy better than ± 0,1 of a degree.

All cranes shall be fitted with a hoisting limiter to stop all motions which can cause the hook block to make contact with the jib/jib head and cause damage. Bridging of the hoisting limiter shall only be possible for rigging operations and transport. The bridging device has to be of the type that requires to be held in the override position.

All cranes shall be fitted with a lowering limiter. As a minimum the lowering limiter shall ensure three turns of rope on the drum. Bridging the lowering limiter shall only be possible for rigging operations, transport and changing of the rope. The bridging device has to be of the type that requires to be held in the override position.

All mobile cranes having a rated capacity of not less than 1 000 kg or an overturning moment of not less than 40 000 Nm the following indications shall be given for the current configuration and position of the crane under the following conditions:

continuous display during crane operation:

| a) utilisation of rated capacity | for all configurations, given as an analogue display with marking of the loading status of the crane (e. g, green; yellow— approach to rated capacity; rated— overload condition); |

| b) rated capacity | for cranes with a rated capacity in excess of 5 tonnes a display of permitted load in accordance with the rated capacity at the actual radius/outreach or jib angle; |

| c) working load | for cranes with a rated capacity in excess of 5 tonnes (indication of load on the hook plus mass (weight) of hook and block). |

NOTE For the purpose of error checking or adjustments special displays superseding the continuos display may be selected temporarily during crane operation(s).

selected display (to be selected manually by the crane operator):

| d 1) radius/outreach | when the crane is on radius/outreach related rated capacities, on non-slewing cranes the outreach to the tipping axis shall be displayed; |

| d 2) jib angle | when the crane is on angle related rated capacities; |

| d 3) fly jib angle | for luffing fly jib configurations, when the crane is on angle related rated capacities; |

| e) wind speed | when the crane has a jib combination length in excess of 65 m, or where the stowing time is more than 5 min; |

| f) slew range | when the crane has slew range related rated capacities; |

| g) jib length | for telescopic jib cranes; |

| h) jib lock | for telescopic jibs with locking mechanisms; |

| i) axle lock | for cranes with axle locking mechanisms; |

| j) falls of hoisting line | for all configurations; |

| k) slew position | when the crane is on slew range related rated capacities; |

| l) travelling (audible warning) | on cranes (on tyres and crawlers) where the operator has no clear view immediately behind the crane when travelling backwards. On cranes with additional counterweight (see A.7) when slewing. |

The following mandatory limiters shall be fitted to the crane under the following conditions:

| a) maximum and minimum jib angle | for all configurations; |

| b) maximum and minimum fly jib angle | for luffing fly jib configurations; |

| c) telescoping | for telescopic jib cranes; |

| d) slewing | where there are slew range related rated capacities; |

| e) control station position | for cranes with moveable control stations; |

| f) mast/A-frame position | where mast/A-frame shall be kept within limits; |

| g) slack rope special hazard. | on special configurations (see A.7) where slack rope may cause a |

The steering shall ensure safe handling of the vehicle at speeds up to those permitted. The steering systems shall have power assistance with minimum 2 independent circuits and an automatic indication if the power assistance of one of the circuits fails.

NOTE1 The steering system of on-road mobile cranes is subjected to national and European regulations (e. g. 70/311/EEC as amended, with vehicle category N3).

NOTE2 Since the above covers steering control effort in the event of a single failure it can be assumed to meet the requirements of A.3.3.5 of EN ISO 12100-2:2003.

The steering equipment shall ensure safe handling of the vehicle, including where the crane is permitted to travel with load, at speeds up to those permitted by the manufacturer.

Any crane conforming to the requirements of 4.2.7.1 can be considered to conform to the requirements of this clause.

30For on site travel design speeds of 25 km/h and below it is not necessary to fit additional equipment to cater for a power assistance failure.

For travel design speeds on site greater than 25 km/h the steering shall not become inoperative because of the failure of a single power supply (electric, hydraulic, pneumatic) to either the power assistance of the steering system or the controls.

The permitted steering control effort requirements shall be as given in annex M.

Steering controls for crawler cranes shall meet the requirements of 4.2.5.

Where the crane is steered from a crane operation cabin on the rotating upper structure an indication of the direction of movement or an automatic change of the direction of steering – depending on the position of the rotating upper structure – shall be provided.

This sub-clause covers static holding brakes and dynamic braking systems for crane mechanisms (e. g. hoisting, derricking and slewing mechanisms).

Smooth deceleration of each crane motion shall be achieved by a braking system (e. g. hydraulic brake, electric brake, mechanical friction brake). The minimum requirements shall be as follows: