In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

ASSE Standard #1008

ASSE Revised: 1986

Neither this Standard, nor any portion thereof, may be reproduced without the written consent of the American Society of Sanitary Engineering.

Although this Standard may be used as a benchmark for in-house evaluation, no product may be said to be A.S.S.E. approved unless the manufacturer has applied to the A.S.S.E., has had his product tested by an official A.S.S.E. recognized independent laboratory, according to the applicable A.S.S.E. Standard, and when the product has passed the test, displays the A.S.S.E. Seal on the product. Instructions for receiving the authorization to display the Seal are available from the A.S.S.E. Central Office.

It is recommended that all devices designed for plumbing systems, especially those which pertain to public health and safety, should be installed consistent with local codes by qualified and trained professionals.

American Society of Sanitary Engineering

Bay Village, Ohio

Copyright© 1989, 1986, 1970

All rights reserved.

The development of this sanitation performance standard was prompted by awareness that public health can be affected by the connection of domestic appliances to the domestic water supply and sanitary drainage systems.

This standard provides a basis for evaluating the adequacy of appliance design and performance to insure sanitary conditions and to protect the public from health hazards that could result from improper design or manufacture.

The performance criteria presented are based on extensive engineering research and board field experience on protection of the potable water supply and safe discharge of wastes into the sanitary plumbing system. Engineers and technicians representing manufacturers, public health officials, plumbing contractors, inspection agencies and plumbing testing laboratories contributed the technical expertise and experience necessary to develop a meaningful and scientifically sound evaluation method that takes into account conditions that could adversely affect the sanitary performance of these appliances.

iiiRobert C. Smith, P.E.

Standards Committee Chairman

U.S. Testing Company, Tulsa, Oklahoma

Julius Ballanco

B.O.C.A., Country Club Hills, Illinois

George H. Bliss, III

United Association, Washington, D. C.

Doug Connell

Southern Building Code, Birmingham, Alabama

Robert DuPont, C.I.P.E.

State of Wisconsin DILHR, Madison, Wisconsin

Richard Emmerson

Chicago Faucet Company, Des Plaines, Illinois

Patrick Higgins

P.J. Higgins & Associates, Frederick, Maryland

Valentine Lehr, P.E.

Lehr Associates, New York, New York

Herb Panzer, P.E.

Warren & Panzer Engineers, P.C., New York, New York

Shabbir Rawalpindiwala

I.A.P.M.O., Walnut, California

Sally Remedios, P.E.

Canadian Standards, Rexdale, Ontario, Canada

Walter H. Blanck, Jr.

AHAM Staff Representative

Dennis Haase

Kitchenaid

R. S. Hanson

Frigidaire (WCI)

Walter Kovacs

Tappan

M. R. Spielhaupter

In-Sink-Erator (Emerson Electric)

Charles Wicke

In-Sink-Erator (Emerson Electric)

J. C. Zambito

General Electric

| Section I | 1 | ||

| 1.0 | Purpose | 1 | |

| Section II | 1 | ||

| 2.0 | Scope | 1 | |

| Section III | 1 | ||

| 3.0 | Definitions | 1 | |

| Section IV | 2 | ||

| 4.0 | General Requirements | 2 | |

| 4.1 | Mounting Means | 2 | |

| 4.2 | Self-Cleaning Capability | 2 | |

| 4.3 | Feed Hopper Closure | 2 | |

| 4.4 | Product Identification | 2 | |

| 4.5 | Mechanical Shock Protection | 2 | |

| 4.6 | Conducting Tests | 2 | |

| 4.7 | Test Voltages | 2 | |

| Section V | 3 | ||

| 5.0 | Construction Requirements | 3 | |

| 5.1 | Terminal Outlet Description | 3 | |

| 5.2 | Discharge Volumetric Consideration | 3 | |

| 5.3 | Discharge Flooding Consideration | 3 | |

| Section VI | 3 | ||

| 6.0 | Test Procedures | 3 | |

| 6.1 | Particle Size Restriction | 3 | |

| Figure 1 | 3 | ||

| 6.2 | Test Load | 4 | |

| 6.3 | Performance Test - Flooding | 4 | |

Household Food Waste Disposer Units

The purpose of this standard is to supply manufacturers, plumbing enforcement agencies and others with what are considered reasonable criteria for performance of the appliance when connected to a system of plumbing and the methods of test for determining that performance.

This standard applies to household type food waste disposers intended for installation in the household kitchen sink outlet, supplied with water from the sink supply faucet and discharged into the household plumbing drainage system.

This standard does not apply to commercial food waste disposers intended for installation in a food handling establishment.

Dishwasher Discharge Connection

An opening to permit the discharge from a domestic kitchen dishwasher to be drained into a disposer hopper.

Food

Any raw, cooked, or processed edible substance, beverage, or ingredient used or intended for use, or for sale in whole or in part for human or animal consumption.

Food Waste

Perishable food refuse resulting from the preparation, handling, serving and scrapping of food.

Food Waste Disposer Unit

An appliance that reduces the food waste to particle sizes which, with the aid of water, are discharged into the plumbing drainage system.

Food Waste Disposer Unit - Batch feed type

A disposer which is first loaded with food waste and requires the locating of a device (usually used also as a sink stopper) in the feed opening of the disposer in such a position that the disposer is energized.

1Food Waste Disposer Unit - Continuous feed type

A disposer type which may be loaded with food waste continuously.

Hopper

The space or cavity within a disposer for receiving and containing food waste prior to and during the reduction process.

Terminal Outlet (Drain Outlet)

A physical part of the disposer construction or a fitting supplied with a disposer to permit connection to the household plumbing drainage system.

A durable, cleanable, leakproof mounting to the sink shall be provided with the disposer.

The disposer shall provide sufficient agitation to insure the flushing of the interior surface of the hopper while operating with a minimum flow of 0.13 L/s (2 GPM) for a period of one (1) minute.

The disposer shall include a means to minimize the ejection of food waste through the feed opening.

The trade name, model designation, identifying numbers, and manufacturer's or private labeler's address shall be legibly displayed on a permanently affixed nameplate on each disposer.

The disposer shall be designed in such a manner that the starting and impact torque is cushioned and any resultant movement causes no leakage.

Test the disposer in accordance with the procedure of Section 6.

Conduct all running test with the disposer motor operating with constant nameplate rated voltage(s) input.

2The terminal outlet of the disposer shall be 38 mm (1.5 inch) nominal diameter.

Dishwasher discharge connection(s), when incorporated in the disposer, shall be capable of discharging not less the 0.36 L/s (6 GPM) at a head of not more than 254 mm (10 inches) of water measured above the dishwasher discharge connection(s) centerline. (Adaptor accessories offered for direct connection to a dishwasher drain line are exempt from this provision.)

Dishwasher discharge connection(s), when incorporated in the disposer, shall be designed in such a manner as to allow no rise of water in a vertical sight tube attached to the dishwasher discharge connection when tested in accordance with 6.3.

Place six (six) 13 ±0.5 mm (0.5 ±0.02 inch) balls of steel, or comparable material in the hopper of the disposer before mounting and wiring the appliance. Manually agitate the disposer. None of the balls shall pass beyond the cutting blade area into the discharge.

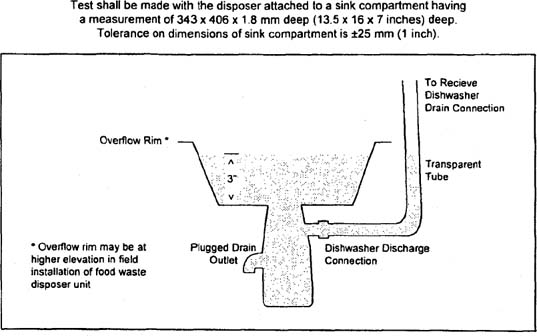

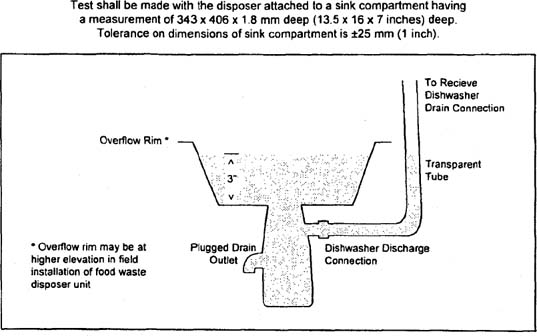

Mount and wire the disposer using the test sink specified in Figure 1.

Figure 1

The test load consists of 113.4 grams (0.25 pounds) steer rib bones, 25 mm to 52 mm (1 to 2 inches) long that have been boiled in water one (1) hour, plus 113.4 grams (0.25 pounds) each fresh raw carrots, celery and head lettuce.

6.2.1 Feed the test load into the disposer, mixed or at random, and supply the disposer with water at a rate of 0.13 L/s (2 GPM) at a maximum water temperature of 28.°C (80°F).

6.2.2 The mixture of water and food waste shall flow from the disposer into the plumbing drainage system in a manner which avoids stoppages when discharged through a "P" type trap and 1524 mm (5 feet) of 38 mm (1.5 inches) I.D. nominally horizontal transparent pipe with 0.02 cm/cm (0.25 inch/foot) pitch.

6.2.3 All discharge from the disposer, expect those fibers which may lodge on the sieve crossbars, shall pass through a 13 mm (0.5 inch) sieve (U.S. Standard Sieve).

6.2.3.1 Retain the ground product on a 6 mm (0.25 inch) sieve (U.S. Standard Sieve).

6.2.3.2 Wash with a water spray from a spray head having sixteen (16) 1 mm (0.05 inch) holes and a flow rate of 1.8 L/s (3 GPM). The spray head is to held 305 mm (12 inches) above the sieve and continuously moved with a circular motion for 15 seconds; the angle of the spray streams to be at 90° to the sieve.

6.2.3.3 Allow the ground product to drop dray after washing. The amount of ground product retained on the 6 mm (0.25 inch) sieve shall not exceed 28.4 grams (1 ounce).

46.3.1 For disposers equipped with a dishwashing discharge connection(s) refer to Figure 1 and proceed as follows:

6.3.1.1 Attach a vertical sight tube to the dishwasher discharge connection.

6.3.1.2 Close or obstruct the disposer drain outlet.

6.3.1.3 With the fill opening of the disposer in a normal operating condition, flood the hopper and fill the sink with water to a depth of 76 mm (3 inches) above the sink flange. (In batch feed type, stopper must be in position and open.)

6.3.1.4 Operate the disposer continuously and observe the water level in the sight tube.

6.1.3.5 A rise in water level indicated failure of the dishwasher discharge connection(s) design to meet the requirement of Section 5.3. If disposer motor is reversible, tests shall be made with motor operating in each direction.

6.3.2 For disposers not equipped with dishwasher discharge connections, proceed as follows:

6.3.2.1 Equip the non-loaded, non-operating disposer with any drain fitting(s) normally provided by the manufacturer.

6.3.2.2 Remove or render ineffective the sink stopper and splash guard.

6.3.2.3 Introduce water at a rate of 4.5 L/s (7.5 GPM) directly into the hopper through the sink mounting flange for a three (3) minute period and observe the water level in the hopper.

6.3.3 For disposers having dishwasher connection(s), the water level shall not rise above the bottom of the dishwasher discharge connection(s).

6.3.4 For disposers without dishwasher discharge connection(s), the water level shall not rise above the bottom of the sink flange.

Note: It is recommended that the disposer be listed or approved by Underwriters Laboratories or other electrical testing agencies, where applicable.

5 6