In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

ANSI Z88.2-1992

American National Standards

for Respiratory Protection

ANSI®

Z88.2-1992

Revision of

ANSI Z88.2-1980

Secretariat

Lawrence Livermore National Laboratory

Approved August 6, 1992

American National Standards Institute, Inc.

D EAmerican National Standard

Approval of an American National Standard requires verification by ANSI that the requirements for due process, consensus, and other criteria for approval have been met by the standards developer.

Consensus is established when, in the judgment of the ANSI Board of Standards Review, substantial agreement has been reached by directly and materially affected interests. Substantial agreement means much more than a simple majority, but not necessarily unanimity. Consensus requires that all views and objections be considered, and that a concerted effort be made toward their resolution.

The use of American National Standards is completely voluntary; their existence does not in any respect preclude anyone, whether he has approved the standards or not, from manufacturing, marketing, purchasing, or using products, processes, or procedures not conforming to the standards.

The American National Standards Institute does not develop standards and will in no circumstances give an interpretation of any American National Standard. Moreover, no person shall have the right or authority to issue an interpretation of an American National Standard in the name if the American National Standards Institute. Requests for interpretations should be addressed to the secretariat or sponsor whose name appears on the title page of this standard.

CAUTION NOTICE: This American National Standard may be revised or withdrawn at any time. The procedures of the American National Standards Institute require that action be taken periodically to reaffirm, revise, or withdraw this standard. Purchasers of American National Standards may receive current information on all standards by calling or writing the American National Standards Institute.

Published by

American National Standards Institute

11 West 42nd Street, New York, New York 10036

Copyright © 1992 by American National Standards Institute

All rights reserved.

No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without prior written permission of the publisher.

Printed in the United States of America

APS1M293⁄60

F| Page | ||

|---|---|---|

| Foreword | ii | |

| 1 | Scope and purpose | 1 |

| 2 | Normative references | 1 |

| 3 | Definitions | 2 |

| 4 | Respirator program requirements | 4 |

| 5 | Program administration | 7 |

| 6 | Written standard operating procedures | 8 |

| 7 | Selection, limitation, and use of respirators | 9 |

| 8 | Training | 13 |

| 9 | Respirator fitting tests | 14 |

| 10 | Maintenance, inspection, and storage | 16 |

| Tables | ||

| 1 | Assigned protection factors | 6 |

| 2 | Combined effect of altitude and reduced percent of oxygen | 12 |

| 3 | Periodic air sampling guidance for purchased breathing gas | 17 |

| 4 | Periodic air sampling guidance for compression | 18 |

| Annexes | ||

| A | Supplemental information | 19 |

| B | Future research needs | 33 |

| C | Bibliography | 34 |

(This foreword is not part of American National Standard Z88.2-1992.)

The purpose of this standard is to help establish, implement, and administer an effective respiratory protection program. Changes have been made in this revision reflecting the current state of knowledge. The clause on the classification, description, and limitations of respirators has been combined with the clause on the selection of respirators to clarify the decision-making process by which a respirator is selected. A decision matrix for respirator selection has also been added to this clause to draw all the elements of respirator selection together. Respirator protection factors have been revised in this standard to reflect the current state of knowledge. A new definition has been developed for “oxygen deficiency –immediately dangerous to life or health.” The clauses for fit testing, breathing air supplies, and written procedures⁄records have been modified. A requirement for fit testing of atmosphere-supplying positive-pressure respirators has been added to this standard. Owing to the importance of the values of the assigned protection factors and the proliferation of new respirator designs, a new subcommittee has been formed to consider an extension of this material and to provide the rationale for the choice of each APF value.

The first version of ANSI Z88.2 was approved August 11, 1969 and was a revision of the respiratory protection portion of American National Standard safety code for head, eye, and respiratory protection, ANSI Z2.1-1959. The second revision of this American National Standard was approved May 22, 1980 and was entitled American National Standard practices for respiratory protection, ANSI Z88.2-1980.

Suggestions for the improvement of this standard will be welcome. They should be sent to Robert A. da Roza, Lawrence Livermore National Laboratory, P.O. Box 5505, L-386, Livermore, CA 94550.

This standard was processed and approved for submittal to ANSI by Accredited Standards Committee on Respiratory Protection, Z88. Committee approval of the standard does not necessarily imply that all committee members voted for its approval. At the time it approved this standard, the Z88 Committee had the following members:

Robert A. da Roza, Chair

James S. Johnson, Vice-Chair

| Organizations Represented | Name of Representative |

|---|---|

| American Conference of Government Industrial Hygienists | Darrel Douglas Edward Hyatt (Alt.) |

| American Gas Association | (Representation Vacant) Phil S. Runge (Alt.) |

| American Occupational Medicine Association | Philip Harber |

| American Industrial Hygiene Association | Doane E. Lucio |

| American Iron and Steel Institute | Jack Masaitis Peter Hernandez (Alt.) |

| American Petroleum Institute | Christopher E. Williams Gerry M. Walker (Alt.) |

| American Welding Society | Carol Dupraz Marvin E. Kennebeck (Alt.) |

| Brotherhood Boilermakers | Perry A. Day |

| Edison Electric Institute | Joseph S. Peri Matthew C. Mingoia (Alt.) |

| Electronics Industries | F. X. Worden |

| Goodyear Tire and Rubber Company | J. Holthouser |

| GPU Nuclear | Earl F. Gee, Jr. ii |

| Health Physics Society | David Steffes Timothy P. Lynch (Alt.) |

| Industrial Safety Equipment Association | Richard D. Grunberg Frank E. Wilcher, Jr. (Alt.) |

| International Association of Fire Chiefs | Garry Briese |

| International Association of Fire Fighters | Richard M. Duffy |

| International Union of Bricklayers | Albert R. Couillard |

| Lawrence Livermore National Laboratory | Robert A. da Roza James S. Johnson (Alt.) |

| Los Alamos National Laboratory | Bruce Reinert Alan Hack (Alt.) |

| Motor Vehicles Manufacturers Association | Sarunas S. Mingela Robert J. Ajemian (Alt.) Libardo Latorre (Alt.) |

| National Fire Protection Association | Bruce W. Teele |

| National Institute of Occupational Safety and Health | Nancy Bollinger |

| Rhone-Poulenc, Inc. | Gerald L. Cooper |

| U.S. Bureau of Mines | J. G. Kovac |

| U.S. Coast Guard | K. Wahle |

| U.S. Consumer Products Safety Commission | Colin B. Church |

| U.S. Department of the Army | Stephan C. Graham Debra S. McGlothlin (Alt.) |

| U.S. Department of Energy | Paul F. Wambach |

| U.S. Department of Labor | Ching-tsen Bien Chappell D. Pierce (Alt.) |

| U.S. General Services Administration | Dennis Davis |

| U.S. Nuclear Regulatory Commission | James E. Wigginton |

Individual Members

Darrel A. Bevis

Howard H. Fawcett

Earle P. Shoub

The Z88 Committee acknowledges the contributions of the following individuals in the development of this standard:

Donald Campbell

(National Institute of Occupational Safety and Health)

Kenneth W. Crase

(Health Physics Society)

Stan Morrow

(U.S. Consumer Products Safety Commission)

Grant Snider

(U.S. General Services Administration)

Subcommittee Z88.2 on Practices for Respiratory Protection, which revised this standard, had the following members:

| Thomas Nelson, Co-Chair | Darell Bevis | Alan Hack |

| Don Wilmes, Co-Chair | Ching-tsen Bien | Lynette Hendricks |

| Joe Bigler | Robert Martin | |

| Nancy Bollinger* | Warren Myers | |

| Donald Burd | Jay Parker | |

| Howard Cohen | Jeff Prather | |

| Zenora Gordon | Bruce Reinert | |

| Earl Gee, Jr. | Miriam Vaughn | |

| Stephen Graham | Jim Wigginton | |

| John Hale | ||

| *Participated as a nonvoting NIOSH advisor. | ||

American National Standard for Respiratory Protection

1.1 Scope

This standard sets forth accepted practices for respirator users; provides information and guidance on the proper selection, use, and care of respirators; and contains requirements for establishing and regulating respirator programs. The standard covers the use of respirators to protect persons against the inhalation of harmful air contaminants and against oxygen-deficient atmospheres in the work-place. The following subjects are not covered by this standard:

– underwater breathing devices;

– aircraft oxygen systems;

– use of respirators under military combat conditions; and

– medical inhalators and resuscitators.

1.2 Purpose

The purpose of this standard is to provide information and guidance on the proper selection and use of respirators that will help safeguard the life and health of users. This standard is written for all persons concerned with respiratory protection but especially for those primarily responsible for establishing and administrating an acceptable respirator program. The standard contains requirements recommended for use by enforcement authorities in establishing regulations or codes on respiratory protection.

1.3 “Shall” and “should”

The provisions of this standard are mandatory in nature where the word “shall” is used and advisory in nature where the word “should” is used.

1.4 Exceptions

Users of this standard should be aware that regulatory agencies may have requirements that are different from this standard.

The following standards contain provisions which, through reference in this text, constitute provisions of this American National Standard. At the time of publication, the editions indicated were valid. All standards are subject to revision, and parties to agreements based on this American National Standard are encouraged to investigate the possibility of applying the most recent editions of the standards indicated below.

ANSI Z88.6-1984, Respiratory protection – Respirator use – Physical qualifications for personnel

ANSI Z88.10, Respirator fit test methods1)

ANSI/CGA C-4-1990, Method of marking portable compressed gas containers to identify the material contained

ANSI/CGA G-7.1-1989, Commodity specification for air

CGA G-7-1988, Compressed air for human respiration2)

Code of Federal Regulations, Title 49, Part 173, General requirements for shipping and packaging, and Part 178, Shipping container specifications3)

United States Pharmacopoeia, 1990.4)

1) This standard is currently under development. Contact the secretariat for more recent information.

2) Available from the Compressed Gas Association, 1725 Jeff Davis Highway, Arlington, VA 22202-3269.

3) Available from the Superintendent of Documents, US Government Printing Office, Washington, DC 20402.

4) Available from Mack Printing Company, Easton, PA.

13.1 abrasive blasting respirator: A respirator designed to protect the wearer from inhalation of, impact of, and abrasion by materials used or generated in abrasive blasting.

3.2 aerodynamic diameter: The diameter of a unit density sphere having the same terminal settling velocity as the particle in question.

3.3 aerosol: Particles, solid or liquid, suspended in air.

3.4 airline respirator: An atmosphere-supplying respirator in which the respirable gas is not designed to be carried by the wearer (formerly called supplied air respirators).

3.5 air-purifying respirator: A respirator in which ambient air is passed through an air-purifying element that removes the contaminant(s). Air is passed through the air-purifying element by means of the breathing action or by a blower.

3.6 approved: See certified.

3.7 assigned protection factor (APF): The expected workplace level of respiratory protection that would be provided by a properly functioning respirator or a class of respirators to properly fitted and trained users.

3.8 atmosphere-supplying respirator: A class of respirators that supply a respirable atmosphere, independent of the workplace atmosphere.

3.9 bloassay: A determination of the concentration of a substance in biological fluids and tissue by analysis of urine, feces, blood, bone, tissue, etc.

3.10 canister/cartridge: A container with a filter, sorbent, or catalyst, or combination of these items, which removes specific contaminants from the air passed through the container.

3.11 celling concentration: The concentration of an airborne substance that shall not be exceeded during any part of the working exposure.

3.12 certified: Evaluated and listed as permissible by the National Institute for Occupational Safety and Health (NIOSH), the Mine Safety and Health Administration (MSHA), or the Bureau of Mines (BM).

3.13 confined space: An enclosed space that has the following characteristics:

– Its primary function is something other than human occupancy;

– It has restricted entry and exit;

– It may contain potential or known hazards.

Examples of confined spaces include, but are not limited to:

– tanks;

– silos;

– vessels;

– pits;

– sewers;

– pipelines;

– tank cars;

– boilers;

– septic tanks;

– utility vaults.

Tanks and other structures under construction may not be considered confined spaces until completely closed. Restricted entry and exit means physical impediment of the body, e.g., use of the hands or contortion of the body to enter into or exit from the confined space.

3.14 contaminant: A harmful, irritating, or nuisance airborne material.

3.15 continuous flow respirator: An atmosphere-supplying respirator that provides a continuous flow of respirable gas to the respiratory inlet covering.

3.16 demand respirator: An atmosphere-supplying respirator that admits respirable gas to the facepiece only when a negative pressure is created inside the facepiece by inhalation.

3.17 disposable respirator: A respirator for which maintenance is not intended and that is designed to be discarded after excessive resistance, sorbent exhaustion, physical damage, or end-of-service-life renders it unsuitable for use. Examples of this type of respirator are a disposable half-mask respirator or a disposable escape-only self-contained breathing apparatus (SCBA).

23.18 dust: An aerosol consisting of mechanically produced solid particles derived from the breaking up of larger particles. Dusts generally have a larger particle size when compared to fumes.

3.19 end-of-service-life indicator: A system that warns the user of the approach of the end of adequate respiratory protection.

3.20 escape-only respirator: A respirator intended only for use during emergency egress from a hazardous atmosphere.

3.21 exposure limit: The maximum allowable concentration of a contaminant in the air to which an individual may be exposed. These may be time-weighted averages, short-term limits, or ceiling limits.

3.22 filter: A component used in respirators to remove solid or liquid aerosols from the inspired air.

3.23 fit check: A test conducted by the wearer to determine if the respirator is properly seated to the face.

3.24 fit factor: A quantitative measure of the fit of a particular respirator to a particular individual.

3.25 fit test: The use of a challenge agent to evaluate the fit of a respirator on an individual.

3.26 fume: Solid aerosols formed by condensation of a gas or vapor. Fumes generally have a smaller particle size when compared to dusts.

3.27 gas: A fluid that has neither independent shape nor volume and tends to expand indefinitely.

3.28 hazardous atmosphere: An atmosphere that contains a contaminant(s) in excess of the exposure limit or that is oxygen deficient.

3.29 hazard ratio: A number obtained by dividing the concentration of a contaminant by its exposure limit.

3.30 helmet: A hood that offers head protection against impact and penetration.

3.31 high-efficiency filter: A filter that removes from the air 99.97% or more of the aerosols having a diameter of 0.3 μm.

3.32 hood: A respiratory inlet covering that completely covers the head and neck and may cover portions of the shoulders.

3.33 Immediately dangerous to life or health (IDLH): Any atmosphere that poses an immediate hazard to life or poses immediate irreversible debilitating effects on health.

3.34 loose-fitting facepiece: A respiratory inlet covering that is designed to form a partial seal with the face, does not cover the neck and shoulders, and may or may not offer head protection against impact and penetration.

3.35 mass median aerodynamic diameter (MMAD): A point in an aerodynamic particle size distribution where half of the mass lies in particles with a diameter less than the MMAD and half in particles with diameters greater than the MMAD.

3.36 mist: An aerosol composed of liquid particles.

3.37 mouthpiece and nose-clamp assembly: A respiratory inlet covering that is held in the wearer's mouth and must always be used in conjunction with a nose clamp.

3.38 negative-pressure respirator: A respirator in which the air pressure inside the respiratory inlet covering is negative during inhalation with respect to the ambient air pressure.

3.39 occupational health professional: An individual whom, by experience and education, is competent at recognizing, evaluating, and controlling health hazards in the workplace.

3.40 poor warning properties: A substance whose odor, taste, or irritation effects are not detectable or not persistent at concentrations at or below the exposure limit.

3.41 positive-pressure respirator: A respirator in which the pressure inside the respiratory inlet covering is normally positive with respect to ambient air pressure.

3.42 powered air-purifying respirator: An air-purifying respirator that uses a blower to force the ambient atmosphere through air-purifying elements to the inlet covering.

33.43 pressure-demand respirator: A positive pressure atmosphere-supplying respirator gas to the facepiece when the positive pressure is reduced inside the facepiece by inhalation.

3.44 qualitative fit test: A pass⁄fail fit test that relies on the subject's sensory response to detect the challenge agent.

3.45 quantitative fit test: A fit test that uses an instrument to measure the challenge agent inside and outside the respirator.

3.46 radionuclide: An atom that spontaneously emits particles, gamma, or x-radiation.

3.47 respirator: A personal device designed to protect the wearer from the inhalation of hazardous atmospheres.

3.48 respiratory Inlet covering: That portion of a respirator that connects the wearer's respiratory tract to an air-purifying device or respirable gas source, or both. It may be a facepiece, helmet, hood, suit, or mouthpiece/nose clamp.

3.49 sanitization: The removal of contaminants and the inhibiting of the action of the agents that cause infection or disease.

3.50 self-contained breathing apparatus (SCBA): An atmosphere-supplying respirator in which the respirable gas source is designed to be carried by the wearer.

3.51 service life: The period of time that a respirator provides adequate protection to the wearer.

3.52 sorbent: A material that is contained in a cartridge or canister and removes specific gases and vapors from the inhaled air.

3.53 suit: A respiratory inlet covering designed to cover the entire body. This term does not include protective clothing that only provides skin protection.

3.54 tight-fitting facepiece: A respiratory inlet covering that is designed to form a complete seal with the face. A half-facepiece (includes quarter masks, disposable masks, and masks with elastomeric facepieces) covers the nose and mouth; a full facepiece covers the nose, mouth, and eyes.

3.55 time-weighted average (TWA): The average concentration of a contaminant in air during a specific time period.

3.56 vapor: The gaseous phase of matter that normally exists in a liquid or solid state at room temperature.

4.1 Purpose

This subclause establishes requirements for an occupational health program for the use of respirators. The following requirements are supplemented by recommended practices in subsequent clauses of this standard.

4.2 Permissible practice

In the control of those occupational diseases caused by breathing air contaminated with potentially harmful dusts, fumes, sprays, mists, fogs, smokes, vapors, or gases, the primary objective shall be to minimize workplace contamination. This shall be accomplished as far as feasible by accepted engineering control measures (for example, enclosure or confinement of the operation, general and local ventilation, and substitution of less toxic materials). When effective engineering controls are not feasible, or while they are being implemented or evaluated, appropriate respirators shall be used pursuant to the following requirements.

4.3 Employer responsibility

4.3.1 Respirators shall be provided by the employer when such equipment is necessary to protect the employee.

4.3.2 The employer shall provide the respirators that are applicable and suitable for the purpose intended.

4.3.3 The employer shall be responsible for the establishment and maintenance of a respiratory protection program that shall include the requirements outlined in 4.5.

4.3.4 A respirator wearer shall be permitted by the employer to leave the hazardous area for any respirator-related cause. Reasons may include, but are not limited to, the following:

4– failure of the respirator to provide adequate protection:

– malfunction of the respirator:

– detection of leakage of air contaminant into the respirator:

– increase in resistance of respirator during breathing;

– severe discomfort in wearing the respirator;

– illness of the respirator wearer, including: sensation of dizziness, nausea, weakness, breathing difficulty, coughing, sneezing, vomiting, fever, and chills;

– to wash his⁄her face and the respirator facepiece to minimize skin irritation;

– to change the air-purifying elements or other components, whenever needed;

– to take periodic breaks in an uncontaminated area.

4.3.5 Malfunctions of respiratory protective equipment shall be investigated by the employer to determine the cause and to assure corrective measures are taken. Suspected manufacturing defects should be reported to the manufacturer and the certifying agency.

4.4 Employee responsibility

4.4.1 The employee shall use the provided respiratory protection in accordance with instructions and training received.

4.4.2 The employee shall guard against damage to the respirator.

4.4.3 If a respirator malfunction occurs, the employee shall immediately leave the contaminated area and report the malfunction to a responsible person designated by the employer in the written standard operating procedures.

4.4.4 The employee shall report to the responsible person any change in his⁄her medical status that may impact the employee's ability to wear a respirator safely.

4.5 Minimal acceptable respirator program

4.5.1 Program administration

The responsibility and authority for the respirator program shall be assigned by the employer to a single person. The administrator shall have knowledge of respiratory protection sufficient to supervise the respirator program properly. The program administrator's responsibilities include the monitoring of the respiratory hazards, maintaining records, and conducting program evaluations (clause 5).

4.5.2 Standard operating procedures

Written standard operating procedures covering the complete respirator program shall be established and implemented (clause 6).

4.5.3 Physiological and psychological limitations for respirator wearers

A physician shall determine whether or not an employee has any medical conditions that would preclude the use of respirators. The physician shall follow the guidance in ANSI Z88.6 on the frequency and content of the examination.

The program administrator shall advise the physician of the following conditions to aid in the determination of the medical evaluation required:

a) types of respirators for normal and emergency use;

b) typical work activities, environmental conditions, frequency and duration of use;

c) hazards for which the respiratory equipments will be worn including the potential exposures to reduced oxygen environments.

4.5.4 Respirator selection

The selection of the proper type(s) of respirator(s) shall be based upon

5(a) the nature of the hazardous operation or process;

(b) the type of respiratory hazard (including physical properties, oxygen deficiency, physiological effects on the body, concentration of toxic material or airborne radioactivity level, established exposure limits for the toxic materials, established permissible airborne concentration for radioactive material, and established immediately dangerous to life or health concentration for toxic material);

(c) the location of the hazardous area in relation to the nearest area having respirable air;

(d) the period of time for which respiratory protection must be worn;

(e) the activities of workers in the hazardous area;

(f) the physical characteristics and functional capabilities and limitations of the various types of respirators;

| Respiratory inlet covering | ||||

| Type of respirator | Half mask1) | Full facepiece | ||

| Air purifying | 10 | 100 | ||

| Atmosphere supplying | ||||

| SCBA(demand)2) | 10 | 100 | ||

| Airline(demand) | 10 | 100 | ||

| Type of respirator | Respiratory inlet covering | |||

| Half mask | Full face | Helmet⁄Hood | Loose-fitting facepiece | |

| Powered air purifying | 50 | 10003) | 10003) | 25 |

| Atmosphere supplying airline | ||||

| pressure demand | 50 | 1000 | - | - |

| continuous flow | 50 | 1000 | 1000 | 25 |

| Self-contained breathing apparatus Pressure demand open/closed circuit |

- | 4) | - | - |

| 1) Includes 1⁄4 mask, disposable half masks, and half masks with elastomeric facepieces. 2) Demand SCBA shall not be used for emergency situations such as fire fighting. 3) Protection factors listed are for high-efficiency filters and sorbents (cartridges and canisters). With dust filters, and assigned protection factor of 100 is to be used due to the limitations of the filter. 4) Although positive-pressure respirators are currently regarded as providing the highest level of respiratory protection, a limited number of recent simulated workplace studies concluded that all users may not achieve protection factors of 10,000. Based on this limited data, a definitive assigned protection factor could not be listed for positive-pressure SCBAs. For emergency planning purposes where hazardous concentrations can be estimated, an assigned protection factor of no higher than 10,000 should be used. NOTE – Assigned protection factors are not applicable for escape respirators. For combination respirators, e.g., airline respirators equipped with an air-purifying filter, the mode of operation in use will dictate the assigned protection factor to be applied. |

||||

(g) respirator-assigned protection factors listed in table 1 (clause 7).

4.5.5 Training

Each respirator wearer shall be given training (and retraining), which shall include explanations and discussions of

a) the respiratory hazard and the effect on the wearer if the respirator is not used properly;

b) the engineering and administrative controls being used and the need for respirators to provide protection;

c) the reason for selecting a particular type of respirator;

d) the function, capabilities, and limitations of the selected respirator;

e) the method of donning the respirator and checking its fit and operation;

6f) the proper wearing of the respirator;

g) respirator maintenance, inspection, and storage;

h) recognizing and handling emergency situations;

i) applicable governmental regulations for specific substances (clause 8).

4.5.6 Respirator fit

Each person shall be fit tested before being assigned a tight-fitting respirator (clause 9). Each person using a tight-fitting respirator shall conduct a fit check of the respirator by appropriate means each time the respirator is donned or adjusted (clause A.6) in annex A.

4.5.7 Maintenance, inspection, and storage

Maintenance shall be carried out according to the manufacturer's instructions and on a schedule that ensures that each respirator wearer is provided with a respirator that is clean, sanitary, and in good operating condition. Each respirator shall be inspected by the wearer prior to its use to ensure that it is in proper working condition. Respirators shall be stored in a convenient, clean, and sanitary location (clause 10).

4.5.8 Escape-only respirators

Where escape-only respirators are provided because of the potential for an emergency, personnel assigned to the area shall be trained in their use.

Personnel not assigned to the work area and visitors shall be briefed in the use of these respirators. Other requirements such as medical approval for use and detailed training are not required for these people.

5.1 Description

An individual shall be assigned responsibility and authority for administration of each respirator program. It is preferable that the administrator be in the company's industrial hygiene, health physics, or safety engineering department. In plants or companies having no formal industrial hygiene, health physics, or safety engineering department, the respirator program shall be administered by a qualified person responsible to the facility manager.

5.2 Qualifications

Respirator program administrators, in order to exercise their responsibility, shall be knowledgeable in respiratory protection. Administrators shall keep abreast of current issues⁄advances and regulations.

5.3 Responsibilities

The administrator's responsibilities shall include

– measuring, estimating, or reviewing information on the concentration of an airborne contaminant in the work area prior to respirator selection and periodically during respirator use to ensure that the proper type of respirator is being used;

– selecting the appropriate type or class of respirator that will provide adequate protection for each contaminant, present or anticipated;

– maintaining records and written procedures in a manner that documents the respirator program and allows for the evaluation of the program's effectiveness;

– evaluating the respiratory protection program's effectiveness.

The most comprehensive respiratory protection program is of little value if it is not maintained and implemented as designed. Therefore, in addition to ongoing surveillance, the program shall be periodically audited to ensure that (a) the program procedures reflect the requirements of current applicable regulations and industry accepted standards and (b) the program as implemented reflects the written procedures.

To aid objectivity, the audit should be conducted by a knowledgeable person not directly associated with the program, rather than the respiratory protection program administrator. An audit checklist should be prepared and updated as necessary. The audit program should focus, as a minimum, on the following areas:

7– program administration;

– training;

– medical evaluation;

– fit testing;

– air sampling⁄classification of hazard;

– selection and issuance;

– use;

– equipment cleaning, maintenance, and inspection;

– breathing air supplies;

– storage;

– emergency preparedness;

– special problems.

When applicable, medical surveillance, including bioassay shall be carried out periodically to determine if respirator wearers are adequately protected. An occupational health professional shall determine the requirements of the medical surveillance program.

Action shall be taken to correct any defects or shortcomings found during the audit. Findings shall be documented, including plans to correct problem areas and target dates for completion.

Written standard operating procedures for the proper use of respirators in routine and emergency situations shall be established by the employer. Copies of the procedures shall be available for employees to read. The procedures shall be periodically reviewed and revised by the employer as necessary. The procedures shall include the following elements:

a) Operating procedures for routine use: Written standard operating procedures shall cover a complete respirator program and shall include information necessary for the proper use of respirators, including, as a minimum:

1) training of wearers;

2) fit tests;

3) issuance;

4) cleaning, storage, and maintenance;

5) inspection;

6) monitoring use;

7) monitoring hazards;

8) selection;

9) company policies.

b) Operating procedures for emergency and rescue use: It is recognized that it is not possible to foresee every emergency and rescue use of respirators for every kind of operation. Nevertheless, a wide variety of possible conditions requiring the emergency or rescue use of respirators can be envisioned. An adequate emergency and rescue respirator response capability can be achieved through a serious effort to plan for the worst foreseeable consequences of particular malfunctions or mishaps.

The written procedures for the emergency and rescue uses of respirators shall be developed in the following manner:

1) An analysis of the emergency and rescue uses of respirators that may occur in each operation shall be made by careful consideration of materials, equipment, work area, processes, and personnel involved;

2) Based upon the analysis, a determination should be made whether the respirators available can provide adequate protection to allow workers to enter the potentially hazardous environments. There are situations where equipment limitations may preclude workers entering an IDLH environment (for example, potentially flammable or explosive environments);

3) Appropriate types of respirators shall be selected, and an adequate number shall be provided where they may be needed for emergency or rescue use;

4) These respirators shall be maintained, inspected, and stored so that they are readily accessible and operational when needed.

The procedure shall be reviewed by a person who is thoroughly familiar with the particular process or operation. Consideration shall be given to past occurrences requiring emergency

8or rescue uses of respirators as well as conditions that resulted in such respirator applications. The possible consequences of equipment or power failures, uncontrolled chemical reactions, fire, explosion, or human error shall be given consideration. Potential hazards that may result in emergency or rescue use of respirators shall be identified.

7.1 General Considerations

7.1.1 Worker activity

Worker activity and worker location in a hazardous area shall be considered in selecting the proper respirator (for example, whether the worker is in the hazardous area continuously or intermittently during the work shift and whether the work rate is light, medium, or heavy).

7.1.2 Respirator use conditions

The period of time that a respirator must be worn is an important factor that shall be taken into account in selecting a respirator. Consideration shall be given to the type of respirator application, such as for routine, nonroutine, emergency, or rescue use.

7.1.3 Location of the potential hazardous area

The location of the hazardous area with respect to a safe area having respirable air shall be considered in selecting a respirator. This will permit planning for the escape of workers if an emergency occurs, for the entry of workers to perform maintenance duties, and for rescue operations.

7.1.4 Respirator characteristics, capabilities, and limitations

The physical characteristics, the functional capabilities, and the performance limitations of the various types shall be considered in selecting a respirator. These are described in annex A.

7.1.5 Operational limitations

Environmental conditions and level of effort required of the respirator wearer may affect respirator service life. For example, extreme physical exertion can cause the user to deplete the air supply in a SCBA such that service life is reduced by half or more.

7.2 Selection of respirators for routine use

7.2.1 Approved respirators

Approved or authorized respirators shall be used. Any change or modification, however minor, may void the respirator approval and significantly affect the performance of the respirator. In the event that there is no approved commercially available respirator that can do the required task, the user may seek authorization from the appropriate regulatory agency to use an unapproved device.

7.2.2 Selection

Respirator selection involves reviewing each operation to (a) determine what hazards may be present (hazard determination) and (b) select which type or class of respirators can offer adequate protection.

7.2.2.1 Hazard determination steps

The nature of the hazard shall be determined as follows:

a) Determine what contaminant(s) may be present in the workplace;

b) Determine whether there is a published Threshold Limit Value, Permissible Exposure Limit, or any other available exposure limit or estimate of toxicity for the contaminant(s). Determine if the IDLH concentration for the contaminant is available;

c) Determine if there is a comprehensive health standard (e.g., lead, asbestos) for the contaminant(s). If so, there may be specific respirators required that will influence the selection process;

d) If the potential for an oxygen-deficient environment exists, measure the oxygen content;

e) Measure or estimate the concentration of the contaminant(s);

f) Determine the physical state of the contaminant. If an aerosol, determine or estimate the particle size. Determine if vapor pressure of the aerosol is significant at the maximum expected temperature of the work environment;

9g) Determine whether the contaminant(s) present can be absorbed through the skin, produce skin sensitization, or be irritating or corrosive to the eyes or skin;

h) Determine for a gas or vapor contaminant(s) if a known odor, taste, or irritation concentration exists.

7.2.2.2 Selection steps

The proper respirator shall be selected as follows:

a) If unable to determine what potentially hazardous contaminant may be present, the atmosphere shall be considered IDLH; go to 7.3;

b) If no exposure limit or guideline is available, and estimates of the toxicity cannot be made, the atmosphere shall be considered IDLH; go to 7.3;

c) If a specific standard exists for the contaminant, follow those guidelines/requirements;

d) If there is an oxygen-deficient atmosphere, the type of respirator selected depends on the partial pressure and concentration of oxygen and the concentration of the other contaminant(s) that may be present; go to (e) and to 7.3.1 through 7.3.4;

e) If the measured or estimated concentration of the contaminant(s) is considered IDLH; go to 7.3;

f) Divide the measured or estimated concentration of each contaminant by the exposure limit or guideline to obtain a hazard ratio. When two or more substances are present, consideration needs to be given if there is a synergistic or combined effect of exposure rather than considering each substance individually. Select a respirator with an assigned protection factor greater than the value of the hazard ratio, as listed in table 1. If an air-purifying respirator is selected, continue with (g);

g) If the contaminant(s) is a gas or vapor only, select a device with an assigned protection factor that is greater than the hazard ratio. The concentration shall also be less than the maximum use concentration of the cartridge/canister, go to (m). If an aerosol contaminant is present, go to (h) below;

h) If the contaminant is a paint, lacquer, or enamel, select a respirator approved specifically for paint mists or an atmosphere-supplying respirator. (Approval label or regulatory provision may preclude use for some paints.);

i) If the contaminant is a pesticide, select a respirator and filtration system specifically approved for pesticides or an atmosphere-supplying respirator. (Approval label may preclude use for some pesticides.);

j) If the contaminant is an aerosol, with an unknown particle size or less than 2 am (MMAD), a high-efficiency filter shall be used;

k) If the contaminant is a fume, use a filter approved for fumes or a high-efficiency filter;

l) If the contaminant is an aerosol, with a particle size greater than 2μm(MMAD), any filter type (dust, fumes, mist, or high efficiency) may be used;

m) If the contaminant is a gas or vapor and has poor warning properties, the use of an atmosphere-supplying respirator is generally recommended. When atmosphere-supplying respirators cannot be used because of the need for worker mobility, air-purifying devices should be used only if:

1) the air-purifying respirator has a reliable end-of-service-life indicator that will warn the user prior to contaminant break through or

2) a cartridge change schedule is implemented based on cartridge service data including desorption studies (unless cartridges are changed daily), expected concentration, pattern of use, and duration of exposure have been established, and the chemical does not have a ceiling limit.

7.3 Selection of respirators for atmospheres immediately dangerous to life or health, for use in confined spaces, or reduced-pressure atmospheres

7.3.1 Atmospheres immediately dangerous to life or health

A location is considered IDLH when:

a) it is an atmosphere known or suspected to have concentrations above the IDLH level, or

10b) it is a confined space that contains less than the normal 20.9% oxygen, unless the source of the oxygen reduction is understood and controlled, or

c) oxygen content is below 12.5% (95 mmHg ppO2) at sea-level atmospheric pressure, or;

d) it contains total atmospheric pressure less than 450 mmHg (8.6 psi) equivalent to 14 000 ft (4270 m) altitude or any combination of reduced percentage of oxygen or reduced pressure that leads to an oxygen partial pressure less than 95 mmHg.

7.3.2 Respirators for use under IDLH conditions at normal atmospheric pressure

The required respiratory protection for IDLH conditions caused by the presence of toxic materials or a reduced percentage of oxygen as described in conditions (a), (b), (c) in 7.3.1 is a positive-pressure SCBA or a combination of a supplied-air respirator with SCBA.

When respirators are worn under IDLH conditions, at least one standby person shall be present in a safe area. The standby person shall have the proper equipment available to assist the respirator wearer in case of difficulty. Communications (visual, voice, signal line, telephone, radio, or other suitable means) shall be maintained between the standby person and the wearer. While working in the IDLH atmosphere, the wearer shall be equipped with safety harness and safety lines to permit removal to a safe area, if necessary. Provisions for rescue other than safety harness and lines may be used, if equivalent.

7.3.3 Special considerations for confined spaces

Confined spaces continue to be the cause of numerous deaths and serious injuries. Therefore, any confined space containing less than 20.9% oxygen is to be considered IDLH, unless the source of the oxygen reduction is understood and controlled. This restriction is imposed because any reduction in the percentage of oxygen present is proof, at a minimum, that the confined space is not adequately ventilated. It may be possible to permit entry into a confined space that contains between 16% and 20.9% oxygen (at sea level) without respiratory protection, but only if extraordinary precautions are taken. It will be necessary to fully understand the source of the reduction in oxygen and control the level such that assurance can be given that there are no poorly ventilated areas that the worker may encounter. Without complete understanding and control of the atmosphere within the confined space, it shall be considered IDLH.

7.3.4 Reduced atmospheric pressure

Reduced total atmospheric pressure can lead to very low oxygen pressure. Therefore, when operating under conditions of reduced total atmospheric pressure, it is necessary to further define the oxygen concentration by means of partial pressure.

7.3.4.1 Definition of oxygen-deficiency IDLH involving reduced pressure

A oxygen partial pressure of 95 mmHg or less shall be considered IDLH. The oxygen deficiency may be caused by either a reduction in the normal 20.9% oxygen content, by reduced total atmospheric pressure to 477 mmHg (8.6 psi) (equivalent to 14 000 feet elevation), or any combination of reduced percentage of oxygen and reduced pressure. Table 2 indicates the conditions that require an SCBA or combination airline/SCBA.

7.3.4.2 Definition of oxygen-deficiency non-IDLH

A oxygen partial pressure of 95 to 122 mmHg shall be considered an oxygen-deficient atmosphere that is not immediately dangerous to life. Such an atmosphere may adversely affect a person with reduced tolerance to reduced oxygen levels or adversely affect the unacclimatized person performing work requiring a high degree of mental acuity or heavy stress. Under these conditions, a supplied air respirator is required. Table 2 indicates the conditions for which respiratory protection is recommended to reduce impairment.

Any medical condition that may adversely affect an individual's tolerance to reduced oxygen levels should be considered. For these individuals, an air-supplied respirator may be required at a higher ppO2 value. This decision should be made by the examining physician prior to work assignment.

11| Altitude/pressure | Ambient O2 | ppO2 mmHg |

Reduced oxygen level requiring atmosphere supplying respirator | Reduced oxygen level requiring SCBA or combination airline/SCBA | ||

|---|---|---|---|---|---|---|

| O2% | ppO2 mmHg |

O2% | ppO2 mmHg |

|||

| Sea level/760 mmHg(14.7 psi) | 20.9% | 160 | 16% | 122 | 12.5% | 95 |

| 2 500 ft./694 mmHg(13.4 psi) | 20.9% | 145 | 17.6% | 122 | 13.7% | 95 |

| 5 000ft./632 mmHg(12.2 psi) | 20.9% | 133 | 19.3% | 122 | 15% | 95 |

| 7 500 ft./575 mmHg(11.1 psi) | 20.9% | 121 | <20.9% | – | 16.5% | 95 |

| 10 000 ft./523 mmHg(10.1 psi) | 20.9% | 110 | <20.9% (Note 2) |

– | 18.2% | 95 |

| 12 500 ft./474 mmHg(9.16 psi) | 20.9% | 99 | (Note 2) | – | <20.9% | – |

| 14 000 ft./450 mmHg(8.63 psi) | 20.9% | 94 | (Note 2) | – | <20.9% | – |

| NOTES 1. The 95-mmHg ppO2 level, which dictates the need for an SCBA or a combination airline/SCBA respirator, assumes a normal healthy worker. Any medical condition that may adversely affect an individual's tolerance to reduced oxygen levels should be considered. For these individuals, an SCBA may be required at a higher ppO2 value. This decision should be made by the examining physician. Also, see clause A.5 in annex A for other considerations in using respirators in reduced oxygen atmospheres. 2. At 10 000 feet or higher, an ordinary supplied-air respirator or SCBA that provides 20.9% oxygen cannot generate 121-mmHg oxygen partial pressure. Therefore, in cases in which a respirator is required because of oxygen content of less than 20.9% oxygen, use of a specially designed and approved respirator supplying enriched oxygen or a rebreather SCBA shall be used. At least 23% oxygen is required at 10 000 feet and 27% at 14 000 feet. |

||||||

7.4 Abrasive blasting

Respirators specifically approved for abrasive blasting shall be selected for use in abrasive blasting. Abrasive blasting in confined spaces may generate contaminant levels that exceed the capabilities of any respirator, requiring the use of engineering controls to reduce the hazard ratio below the assigned protection factor of the respirator used.

7.5 Additional considerations affecting respirator selection

7.5.1 Facial hair

A respirator, either positive or negative pressure, equipped with a facepiece (tight or loose fitting) shall not be worn if facial hair comes between the sealing surface of the facepiece and the face or if facial hair interferes with valve function.

7.5.2 Communications

Ambient noise environment and communication needs shall be considered when specific respirators are selected. (See clause A.13 in annex A.)

7.5.3 Vision

7.5.3.1 When a respirator user must wear corrective lenses, a protective spectacle or goggle, a face shield, a welding helmet, or other eye- and face-protective devices, the item shall be fitted to provide good vision and shall be worn in such a manner as not to interfere with the seal of the respirator.

7.5.3.2 Spectacles with straps or temple bars that pass through the sealing surface of either negative- or positive-pressure, tight-fitting, full-facepiece respirators shall not be used.

7.5.3.3 Contact lenses may be worn with respirators, provided the individual has previously demonstrated that he or she has had successful experience wearing contact lenses. The contact lens wearer shall practice wearing the respirator while wearing the contact lenses.

7.5.4 Respirator sealing problems

7.5.4.1 A head covering that passes between the sealing surface of a tight-fitting respirator facepiece and the wearer's face shall not be used.

7.5.4.2 The head harness straps of tight-fitting respirators shall not be positioned or worn over hard hats.

7.5.4.3 The wearing of a hard hat or other protective equipment shall not interfere with the seal of a respirator.

7.5.5 Respirator use in low-temperature environments

Low temperatures may cause detrimental effects on the performance of respirators. The effects of low temperatures shall be considered in the selection and maintenance of respirators and respirable gas supplies. See clause A. 11 of annex A for more information.

7.5.6 Respirator use in high-temperature environments

High temperatures may affect the performance of the respirator and may add undue physiological stress. The effects of high temperatures shall be considered in respirator selection and for medical approvals. See clause A. 12 of annex A for more information.

8.1 Training for employees

The supervisor, person issuing respirators, respirator wearers, and emergency⁄rescue teams shall be given adequate training (and periodic retraining) by a qualified person(s) to ensure the proper use of respirators. Written records shall be kept of the names of persons trained and the dates when training occurred.

8.1.1 Supervisor

A supervisor – that is, a person who has the responsibility of overseeing the work activities of one or more persons who must wear respirators – shall be given adequate training including the following subjects as a minimum:

13– basic respiratory protection practices;

– nature and extent of respiratory hazards to which persons under his⁄her supervision may be exposed;

– recognition and resolution of respirator use problems;

– principles and criteria for selecting respirators used by persons under his⁄her supervision;

– training of respirator wearers;

– fitting and issuance of respirators;

– inspection of respirators;

– use of respirators, including monitoring of use;

– maintenance and storage of respirators;

– regulations concerning respirator use.

8.1.2 Person issuing respirators

A person assigned the task of issuing respirators shall be given adequate training to ensure that the correct respirator is issued for each application in accordance with written standard operating procedures.

8.1.3 Respirator wearer

To ensure the proper and safe use of a respirators, the minimum training of each respirator wearer shall include the following elements;

– the need for respiratory protection;

– the nature, extent, and effects of respiratory hazards in the workplace;

– the need to inform their supervisor of any problems experienced by them or their co-workers;

– an explanation of why engineering controls are not being applied or are not adequate and what effort is being made to reduce or eliminate the need for respirators;

– an explanation of why a particular type of respirator has been selected for a specific respiratory hazard;

– an explanation of the operation, capabilities, and limitations of the respirator selected;

– instruction for inspecting and donning the respirator. This includes a requirement that a fit check shall be done each time the respirator is donned or adjusted;

– Successful completion of a fit test in accordance with ANSI Z88.10. (Until ANSI Z88.10 is published, the protocol given in the OSHA Asbestos Standard, 29 CFR 1910.1001, should be followed).

– An explanation of how to maintain and store the respirator;

– Instructions in emergency procedures and the use of emergency escape devices;

– Regulations concerning respirator use.

8.1.4 Emergency and rescue teams

Teams that are established by employers for the purpose of responding to emergencies and⁄or rescues, such as industrial fire brigades, shall be properly trained in the use of respirators. A suitable training program shall be established that includes emergency drills to ensure the proficiency and familiarity of team members to use the respirators effectively while performing such emergency and⁄or rescue operations.

8.2 Training frequency

Each respirator wearer shall be trained upon initial assignment and be retrained once every 12 months.

8.3 Records

For each employee, records shall be maintained that give the date and type of training received, performance results (as appropriate), and the instructor's name.

A qualitative or quantitative respirator fit test shall be used to determine the ability of each individual respirator wearer to obtain a satisfactory fit with a tight-fitting respirator. The results of fitting tests among other criteria shall be used to select specific types, makes, and models of respirators for use by individual respirator wearers.

Requirements for acceptable tests are given in ANSI Z88.10 (Until ANSI Z88.10 is published, the protocol given in the OSHA Asbestos Standard, 29 CFR 1910.1001 should be followed).

9.1 Fit test requirements

9.1.1 Acceptance criteria

If a quantitative fit test is used, a fit factor that is at least 10 times greater than the assigned protection factor (table 1) of a negative-pressure respirator shall be obtained before that sure respirator is assigned to an individual. If a qualitative test is used, only validated protocols are acceptable. The test shall be

14designed to assess fit factors 10 times greater than the assigned protection factor.

9.1.2 Positive-pressure respirators

Those respirators that have a tight seal to the face shall be qualitatively or quantitatively fit tested in a negative-pressure mode. The purpose of the test is to ensure that an unacceptable fit of the respirator to the wearer that degrades protection through leakage and would reduce service life for self-contained breathing apparatus does not occur. A fit factor of at least 100 shall be obtained.

9.1.3 Facepiece

If the facepiece of a positive-pressure, tight-fitting respirator is modified for fit testing,

– the modification shall not affect the normal fit of the device;

– the modification should not add significant weight, or causes significant imbalance;

– the air flow shall not be restricted;

– the modified facepiece should be leak tested on a mannequin head or similar device;

– such modified devices shall only be used for fit testing.

9.1.4 Respirator

A respirator fit test shall be carried out for each wearer of a tight-fitting respirator at least once every 12 months.

9.1.5 Repeated testing

A fit test shall be repeated when a person has a condition that may interfere with facepiece sealing, such as a significant change in weight (10% or more), significant scarring in the area of the faceseal, dental changes, reconstructive or cosmetic surgery, or any other condition that may affect the fit of the facepiece seal.

9.1.6 Protective equipment

Fit testing shall be done while wearing protective equipment, such as spectacles, goggles, face shield, or welding helmet, that will be worn during work activities and could interfere with the fit. The respirator should be configured in the way that it will be used, i.e., with a chin canister or cartridge.

9.1.7 Cleaning

Respirators used for fit testing shall be cleaned in accordance with the requirements in 10.2.

9.2 Fitting problems and alternatives

If facial features such as scars, hollow temples, excessively protruding cheekbones, deep creases in facial skin, the absence of teeth or dentures, or unusual facial configurations prevent a seal of a respirator facepiece to a wearer's face, the person shall not be permitted to wear the respirator.

If a situation is encountered whereby a worker cannot obtain a satisfactory fit with a tight-fitting respirator, recommended alternatives to provide adequate respiratory protection are:

– providing the worker with a loose-fitting facepiece, helmet, or hooded device of sufficient assigned protection factor for the hazard;

– transferring the worker to a job or work site where respiratory protection is not required.

9.3 Test considerations

9.3.1 Number of respirators

No one size or model of respirator will fit all types of faces. Different sizes and models will accommodate more facial types. Therefore, an appropriate number of sizes and models shall be available from which a satisfactory respirator can be selected.

The number of models and sizes necessary to fulfill the intent of this requirement will vary for workplaces. For example, in a workplace with four workers, one model and size may fulfill the requirement; whereas a workplace with a hundred wearers may require different models in various sizes.

9.3.2 Employee acceptance

Respirator comfort is an important factor in wearer acceptance of the device. Other factors that influence wearer acceptance include breathing resistance, impairment of vision, impairment of communications, and respirator weight. Devices with greater wearer acceptance are likely to be worn more continually and thus provide more protection. Employee acceptance of a particular respirator model within a class shall be considered in selecting a respirator since this may determine whether

15or not the respirator is worn properly. If the results of the respirator fit test show that the person can obtain an acceptable fit with two or more models of the selected class of respirator, then the person should be permitted to use the preferred respirator model.

9.4 Respirator fit test records

Respirator fit test records shall include the following information:

– written standard operating procedures for the respirator fit testing program including pass⁄fail criteria;

– type of respirator fit test(s) used, including the specific fit test protocol;

– type of respirator fit test instrumentation and equipment used;

– instrument and equipment calibration, maintenance, and repair, where applicable;

– name or identification of the test operator;

– specific make, model, and size of the exact respiratory protective device tested;

– name or identification of the person tested;

– date of test;

– results of respirator fitting tests, including:

– fit factor based upon quantitative fit test(s);

– success or failure to obtain a satisfactory fit based on qualitative fit test(s);

– any special considerations or difficulties in wearing (contact lenses or glasses worn, dentures, forehead scars, etc.).

10 Maintenance, inspection, and storage

A program for the maintenance of respirators shall include the following:

a) cleaning and sanitizing (10.1);

b) inspection for defects (10.2);

c) maintenance and repair (10.3);

d) storage (10.4);

e) assurance of breathing air quality (10.5).

10.1 Cleaning and sanitizing

Respirators issued to an individual shall be cleaned and sanitized regularly. Each respirator shall be cleaned and sanitized before being worn by different individuals. Respirators intended for emergency use shall be cleaned and sanitized after being used. (Clause A.4 in annex A provides a suggested procedure for cleaning and sanitizing.)

10.2 Inspection

The user shall inspect the respirator immediately prior to each use to ensure that it is in proper working condition. After cleaning and sanitizing, each respirator shall be inspected to determine if it is in proper working condition, if it needs replacement of parts or repairs, or if it should be discarded. Each respirator stored for emergency or rescue use shall be inspected at least monthly.

Respirator inspection shall include a check for tightness of connections; for the condition of the respiratory inlet covering, head harness, valves, connecting tubes, harness assemblies, hoses, filters, cartridges, canisters, end-of-service-life indicator, electrical components, and shelf-life date(s); and for the proper function of regulators, alarms, and other warning systems. Each rubber or other elastomeric part shall be inspected for pliability and signs of deterioration. Each air and oxygen cylinder shall be inspected to ensure that it is fully charged according to the manufacturer's instructions.

A record of inspection dates shall be kept for each respirator maintained for emergency or rescue use. Respirators that do not meet applicable inspection criteria shall be immediately removed from service and repaired or replaced.

10.3 Parts replacement and repair

Replacement of parts or repairs shall be done only by persons trained in proper respirator maintenance and assembly. Replacement parts shall be only those designated for the specific respirator repaired. Reducing or admission valves, regulators, and alarms shall be adjusted or repaired by the respirator manufacturer or a technician trained by the manufacturer. Instrumentation for valve, regulator, and alarm adjustments and tests should be calibrated to a standard traceable to the

16| Method of preparation | Analysis recommended |

|---|---|

| Compression - Supplier does not fill cylinders with any other gases | Check 10% of cylinders from each lot for ppm CO and odor |

| Compression - Supplier fills cylinders with gases other than air | Analyze all cylinders for percent oxygen. Check 10% of cylinders from each lot for ppm CO and odor |

| Reconstitution | Analyze all cylinders for percent oxygen. Check 10% of cylinders from each lot for ppm CO and odor |

National Institute of Standards and Technology (NIST), at a minimum of every 3 years.

10.4 Storage

Respirators shall be stored in a manner that will protect them against physical and chemical agents such as vibration, shocks, sunlight, heat, extreme cold, excessive moisture, or damaging chemicals. Respirators shall be stored to prevent distortion of rubber or other elastomeric parts. Respirators shall not be stored in such places as lockers and tool boxes, unless they are protected from contamination, distortion, and damage. Emergency and rescue use respirators that are placed in work areas shall be quickly accessible at all times, and the storage cabinet or container in which they are stored shall be clearly marked.

10.5 Respirable air and oxygen for self-contained breathing apparatus and supplied air respirators

10.5.1 Air quality

Compressed gaseous air, compressed gaseous oxygen, liquid air, and liquid oxygen used for respiration shall be of high purity. Compressed gaseous or liquid oxygen shall meet the requirements of the United States Pharmacopoeia for medical or breathing oxygen. Compressed gaseous air shall meet at least the requirements of the specification for Type I – Grade D breathing air, and liquid air shall meet at least the requirements for Type II – Grade B breathing air as described in ANSI/CGA G-7.1-1989.

10.5.2 Special considerations for oxygen systems

Compressed gaseous air may contain low concentrations of oil introduced from equipment during processing or normal operation. If high-pressure oxygen passes through an oil-or grease-coated orifice, an explosion or fire may occur. Therefore, compressed gaseous oxygen shall not be used in supplied-air respirators or in open-circuit-type self-contained breathing apparatus that have previously used compressed air. Oxygen concentrations greater than 23.5% shall be used only in equipment designed for oxygen service or distribution.

10.5.3 Dew point

The dew point of air used to recharge self-contained breathing apparatus shall be – 65°F or lower (less than 25 ppm water vapor). The driest air obtainable (dew point of – 100°F or lower) should be used for recharging SCBA cylinders to be used in environments with ambient temperatures below – 25°F.

10.5.4 Breathing air from cylinders or air compressors

Breathing air may be supplied to supplied-air respirators from cylinders or air compressors.

10.5.4.1 Cylinders shall be tested and maintained in accordance with applicable Department of Transportation specifications for shipping containers (Title 49, Code of Federal Regulations, Part 173, and Part 178).5) Specific test recommendations for purchased breathing air are given in table 3.

5) See Clause 2, Normative references.

17| Type/sample | Oil lubricated | Non-oil lubricated | Combustion engine powered |

|---|---|---|---|

| Water vapor | × | × | × |

| CO | × | × | |

| Condensed hydrocarbon | × | × | |

| CO2 | × | ||

| Odor | × | × | × |

| NOTES 1. When using air compressors, intake location shall be carefully selected and monitored closely to ensure air supplied to the compressor is of adequate quality. 2. No frequency for periodic checks of air quality is specified, due to wide variation in equipment type, use and working environments, and operating experience. 3. Continuous monitoring of temperature and carbon monoxide are not required. 4. For non-oil lubricated compressors that operate at less than 35 psi, no sampling for water is required. 5. These requirements apply to systems designed for breathing air, other air-supply systems need to be evaluated on a case-by-case basis for the type and frequency of testing. |

|||

10.5.4.2 A compressor shall be constructed so as to avoid entry of contaminated air. For all air compressors, including portable types, the air intake location shall be carefully selected, and monitored closely to ensure continued quality of air supply to the compressor. The system shall be equipped as necessary with a suitable in-line air-purifying sorbent bed and filter to further assure breathing air quality. Maintenance and replacement/refurbishment of compressor and associated air-purifying/filter media shall be performed periodically, by trained personnel following manufacturer's recommendations and instructions.

10.5.4.3 As part of acceptance testing, and prior to initial use, representative sampling of the compressor air output shall be performed to ensure that it complies with the requirements in 10.5.1 and 10.5.4. To ensure a continued high-quality air supply, and to account for any distribution system contaminant input, a representative sample should be taken at distribution supply points. Samples should be collected on a periodic basis, as directed by the program administrator. Specific test recommendations are given in table 4.

10.5.4.4 The dew point of breathing air used with supplied air respirators should be lower than the lowest ambient temperature to which any regulator or control valve on the respirator or air-supplied system will be exposed.

10.5.4.5 Breathing air couplings shall be incompatible with outlets for nonrespirable plant air or other gas systems to prevent inadvertent servicing of supplied-air respirators with nonrespirable gases. Breathing air outlets shall be labeled.

10.5.4.6 Breathing gas containers shall be marked in accordance with ANSI/CGA C-4-1990. Further details on sources of compressed air and its safe use will be found in CGA G-7-1988.

18A.1.1 National Institute for Occupational Safety and Health (NIOSH)

Title 30, CFR, Part 11 gave jurisdiction for joint approval of respirators to the National Institute for Occupational Safety and Health (NIOSH), U. S. Department of Health and Human Services, and to the Bureau of Mines (BM), U.S. Department of the Interior.

A.1.2 Mining Enforcement and Safety Administration (MESA)

In 1974, a reorganization of the U.S. Department of the Interior resulted in the formation of the Mining Enforcement and Safety Administration (MESA), which assumed the health and safety activities of the Bureau of Mines (BM), including the respirator testing and approving functions. Subsequent respirator approvals were issued jointly by the National Institute for Occupational Safety and Health (NIOSH) and the Mining Enforcement and Safety Administration (MESA).

A.1.3 Mine Safety and Health Administration (MSHA)

The Federal Mine Safety and Health Amendments Act of 1977 transferred the authority for enforcement of mining safety and health from the U.S. Department of Interior to the U.S. Department of Labor. Taking effect in March 1978, the act created the Mine Safety and Health Administration (MSHA) in the U.S. Department of Labor, which replaced the Mining Enforcement and Safety Administration (MESA) of the U.S. Department of Interior. The Mine Safety and Health Administration (MSHA) has assumed the respirator testing and approving functions of the Mining Enforcement and Safety Administration (MESA). Respirator approvals are now issued jointly by the National Institute for Occupational Safety and Health (NIOSH) and the Mine Safety and Health Administration (MSHA).

Respirators approved jointly by NIOSH and MSHA under provisions of Title 30 CFR Part 11 are listed in “NIOSH Certified Personal Protective Equipment.” Supplements are issued periodically. (See annex C.)

The level of exposures of respirator wearers to respiratory hazards is determined by using instruments to measure the concentrations of air contaminants or oxygen in the breathing zone of the respirator wearers. Adequate air sampling and analysis or appropriate calculations should be carried out to determine both the time-weighted average (TWA) concentration and, when appropriate, the short-term concentration of the respiratory hazard to which a respirator wearer may be potentially exposed or is actually exposed. The concentrations of a substance in air may be affected by changes in process operation, changes in temperature from day to night operation, and changes in seasons; these factors should be taken into account in carrying out a program for monitoring respiratory hazards.

It is essential that the volume of air sampled during a test contain a sufficient quantity of the hazardous substance for accurate determination of workplace concentration. The volume of air to be sampled or the duration of the air-sampling period depends upon the following factors:

19– estimated concentration of the substance in air;

– sensitivity of the sampling instrument and sampling procedures;

– established time-weighted average concentration and established short-term exposure levels for the substance in air.

Although it is recognized that the concentration of a hazardous substance, which occurs during an emergency, cannot always be measured or calculated, every reasonable effort should be made to estimate what this concentration would be.

Consideration should be given to the use of a continuously operating air monitor and alarm to alert respirator wearers when a high concentration of a hazardous substance suddenly occurs.

Procedures in addition to the manufacturer's instructions are as follows:

a) Remove, when necessary, the following components of respiratory inlet covering assemblies before cleaning and sanitizing:

1) filters, cartridges, canisters;

2) speaking diaphragms;

3) valve assemblies;

4) any components recommended by the respiratory manufacturers;

b) Wash respiratory inlet covering assemblies in warm (43°C or 110°F maximum temperature) cleaner sanitizer solution. A stiff bristle (not wire) brush may be used to facilitate removal of dirt or other foreign material;

c) Rinse respiratory inlet covering assemblies in clean, warm (43°C or 110°F maximum temperature) water;

d) Drain all water, and air dry the respiratory inlet covering assemblies;

e) Clean and sanitize all parts removed from respiratory inlet covering as recommended by the manufacturers;

f) Dry parts. If necessary to remove foreign material, hand wipe respiratory inlet covering assemblies, all parts, and all gasket- and valve-sealing surfaces with damp, lint-free cloth;

g) Inspect parts and replace any that are defective;

h) Reassemble parts on respiratory inlet covering assemblies;

i) Attach filters, cartridges, and canisters to respiratory inlet coverings;

j) Visually inspect and, where possible, test parts and respirator assemblies for proper function;

k) Place assembled respirators in appropriate containers for storage.

Machines may be used to expedite the cleaning, sanitizing, rinsing, and drying of large numbers of respirators. Extreme care shall be taken to ensure against tumbling, agitation, or exposure to temperatures above those recommended by the manufacturer (normally 43°C or 110°F, maximum), as these conditions are likely to result in damage to the respirators. Ultrasonic cleaners, clothes washing machines, dishwashers, and clothes dryers have been specially adapted and successfully used for cleaning and drying respirators.

Cleaner sanitizers that effectively clean the respirator and contain a bactericidal agent are commercially available. The bactericidal agent frequently used is a quaternary ammonium compound.

Strong cleaning and sanitizing agents and many solvents can damage rubber or elastomeric respirator parts. These materials must be used with caution.

Alternatively, respirators may be washed in a detergent solution and then sanitized by immersion in a sanitizing solution. Some sanitizing solutions that have proven effective are: (a) a hypochlorite (bleach) solution (50 parts per million chlorine), 2-minute immersion; (b) an aqueous iodine solution (50 parts per million of iodine), 2-minute immersion; or (c) a quaternary ammonium solution (200 parts per million of quaternary ammonium compounds in water with less than 500 parts per million total hardness), 2-minute immersion.

Different concentrations of quaternary ammonium salts are required to achieve a sanitizing solution with waters of varying hardness. Inflammation of the skin of the respirator user (dermatitis) may occur if the quaternary ammonium compounds are not completely rinsed from the respirator. The hypochlorite and iodine solutions are unstable and break down with time; they may cause deterioration of rubber or other elastomeric parts and may

20be corrosive to metallic parts. Immersion times should not be extended beyond the mentioned time periods, and the sanitizers shall be thoroughly rinsed from the respirator parts.

Respirators may become contaminated with toxic materials. If the contamination is light, normal cleaning procedures should provide satisfactory decontamination; otherwise, separate decontamination steps may be required before cleaning.

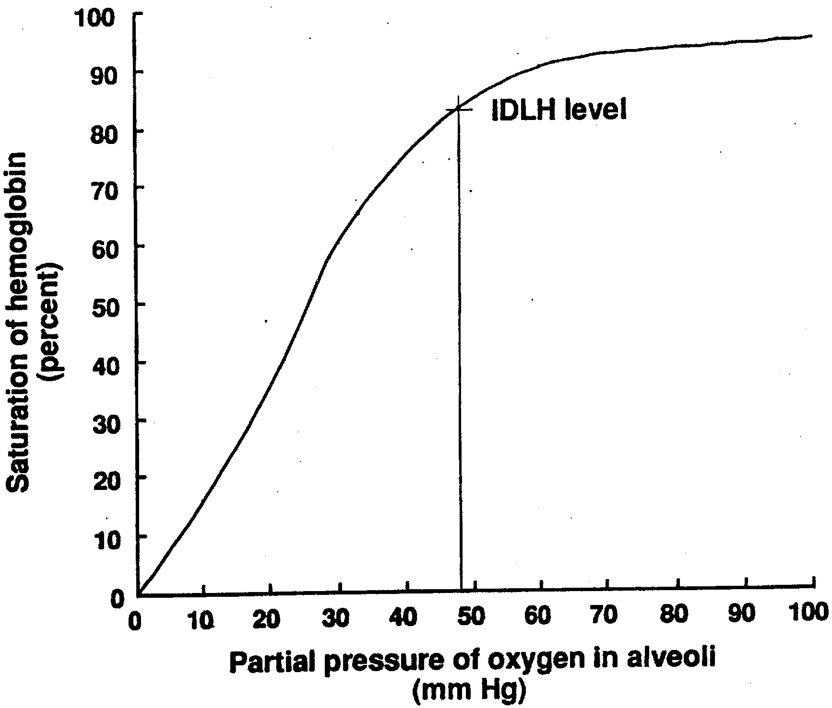

A.5.1 Introduction

Oxygen is a normal component of our atmospheric environment, which is necessary to sustain life.

Earth's atmosphere is made up of the following gases, excluding water vapor, in the proportions noted:

| Gas | Volume (%) | Partial pressure mmHg at sea level |

| Nitrogen | 78.1 | 593 |

| Oxygen | 20.9 | 159 |

| Argon | 0.9 | 7.1 |

| NOTE –Small amounts of other gases, such as carbon dioxide, neon, krypton, and helium, are also present, as is water vapor. Partial pressure equals the fractional concentration of the gas in question times the total atmospheric pressure. | ||

The percent by volume of these gases does not vary with altitude; however, the partial pressures decrease with increasing altitude because the total pressure decreases.

A reduction in the partial pressure of oxygen (ppO2) may result from the following: