In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

ANSI Z87.1-2003

AMERICAN NATIONAL STANDARD

Occupational and Educational

Personal Eye and Face

Protection Devices

ANSI®

Z87.1-2003

Secretariat

American Society of Safety Engineers

1800 East Oakton Street

Des Plaines, Illinois 60018-2187

Approved June 19, 2003

American National Standards Institute, Inc.

Effective August 19, 2003

1American National Standard

An American National Standard implies a consensus of those substantially concerned with its scope and provisions. An American National Standard is intended as a guide to aid the manufacturer, the consumer, and the general public. The existence of an American National Standard does not in any respect preclude anyone, whether he/she has approved the standard or not, from manufacturing, marketing, purchasing, or using products, processes, or procedures not conforming to the standard. American National Standards are subject to periodic review and users are cautioned to obtain the latest editions.

The American National Standards Institute does not develop standards and will in no circumstances give an interpretation of any American National Standard. Moreover, no person shall have the right or authority to issue an interpretation of an American National Standard in the name of the American National Standards Institute.

CAUTION NOTICE: This American National Standard may be revised or withdrawn at any time. The procedures of the American National Standards Institute require that action be taken to reaffirm, revise, or withdraw this standard no later than five years from the date of approval. Purchasers of American National Standards may receive current information on all standards by calling or writing the American National Standards Institute.

Published by

American Society of Safety Engineers

1800 East Oakton Street, Des Plaines, Illinois 60018-2187

Copyright © 2003 by American Society of Safety Engineers

All rights reserved.

No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission of the publisher.

Printed in the United States of America

2

For additional copies contact:

American Society of Safety Engineers

1800 East Oakton Street

Des Plaines, Illinois 60018-2187

8476-699-2929

(This Foreword is not a part of American National Standard Z87.1-2003)

The history of Z87 began with the first edition of the Z2 standard for head and eye protection and was developed from a set of safety standards originally prepared cooperatively by the War and Navy Departments and the National Bureau of Standards.

The second edition of Z2 was developed by a standards committee organized under the American Standards Association and was published in 1922 as the National Bureau of Standards Handbook H2.

In 1938, Z2 was revised to include respiratory protection and was published as the National Bureau of Standards Handbook H24.

In 1946, Z2 was revised to include advances in safety equipment technology such as the use of plastics for eye protection. Three subcommittees were organized. A subcommittee on eye protection was organized under the supervision of the National Bureau of Standards. A subcommittee on respiratory protection was organized under the supervision of the U.S. Bureau of Mines and a subcommittee for head protection was organized under the Department of the Navy. In 1959, Z2 was approved as the American Standard Safety Code for Head, Eye and Respiratory Protection, Z2.1-1959.

On November 24, 1961, the Standards Safety Board approved to divide the Z2 project into three separate standards: Z87 - Industrial Eye Protection; Z88 - Industrial Respiratory Protection; Z89 - Industrial Head Protection. The Z87.1 Standards Committee under the procedures of the USA Standards Institute, formally the American Standards Association, revised the 1959 version, which was approved on September 18, 1968 as the USA Standard Z87.1 - 1968. The USA Standards Institute changed its name in October 1969 to the American National Standards Institute and the Z87.1 Standard became the American National Standard for Occupational and Educational Eye and Face Protection, ANSI Z87.1 - 1968.

In the Z87 Standards Committee, membership was reconstituted and broadened in 1973 to include all organizations with a substantial interest in the design or use of eye and face protection. The Committee revised the 1968 version, which was approved on February 27, 1979 as the American National Standard for Occupational and Educational Eye and Face Protection, ANSI Z87.1 - 1979.

In 1980 the Z87 Standards Committee reconvened to begin their update of the 1979 version. In order to better accommodate advancements in safety equipment technology more emphasis was placed on developing performance oriented standards. A Bureau of Labor Statistics study revealed that most eye injuries to those wearing protectors were caused by insufficient angular protection. Therefore, angular impact testing requirements were included. In 1983, an American Welding Society study was used to update and improve the transmittance requirements for filter lenses. The standard was approved on February 2, 1989 as the American National Standard Practice for Occupational and Educational Eye and Face Protection, ANSI Z87.1-1989. The standard was subsequently reaffirmed by the Z87 Committee per ANSI procedure in 1998 and is still cited by reference by the U.S. Occupational Safety and Health Administration, (OSHA).

This newest edition of the Z87 Standard is considered by the committee members to be significant, as it will strengthen the impact resistance requirements of the standard while still allowing for future technologies and science. This standard once again while voluntary also offers an enhanced user selection chart, which indicates a system of selecting eyewear appropriate to identified hazards. Of importance to users is the knowledge that different types of products, (spectacles, goggles, and face shields) are tested to different levels of impact resistance, thus, it is incumbent upon the user to select a product being tested to the hazard being exposed to.

Suggestions for improvement of this standard are welcome. They should be sent to the American Society of Safety Engineers, 1800 East Oakton Street, Des Plaines, IL 60018 - 2187.

3This standard was processed and approved for submittal to ANSI by the Accredited Standards Committee on Safety Standards for Eye Protection, Z87. Committee approval of the standard does not necessarily imply that all committee members voted for its approval. At the time it approved this standard, the Z87 Committee had the following members:

Tod Turriff, Chairman

Daniel Torgersen, Vice-Chairman

Timothy R. Fisher, CSP, ARM, CPEA, Secretary

Patrick Arkins, Assistant Secretary

| Organization Represented | Name of Representative |

|---|---|

| Alliance for Telecommunications | Steve Barclay |

| Industry Solutions | |

| American Academy of Ophthalmology | Paul F. Vinger, M.D. |

| American Academy of Optometry | Bernard A. Morewitz, O.D., F.A.A.O. |

| American Ceramic Society | W. Paul Holbrook, Executive Director |

| American Gas Association | Phillip Bennett |

| Kimberly Denbow | |

| American Insurance Association | John Arlington |

| American Optometric Association | Lowell Glatt, O.D. |

| Gregory Good, Ph.D | |

| American Society of Safety Engineers | Jack B. Hirschmann |

| Richard Casey, CSP | |

| American Welding Society | Philip M. Johnson |

| Jean Francois Laterre | |

| Edison Electric Institute | Richard Montgomery, CSP |

| Charles J. Kelly | |

| Glass Lens Council | John Miller |

| Dick Emery | |

| International Safety Equipment Association | John E. Salce |

| Janice Comer Bradley, CSP | |

| National Education Association | Richard Verdugo |

| National Association of Optometrists and Opticians | Lee Handel |

| Franklin D. Rozak | |

| National Institute for Occupational | Larry L. Jackson, Ph. D. |

| Safety and Health (NIOSH) | James R. Harris, P.E. |

| Optical Laboratories Association | Daniel Torgersen |

| Jeffrey Kosh | |

| Opticians Association of America | John M. Young |

| Prevent Blindness America | Tod Turriff |

| Society of the Plastics Industry | Hugh Patrick Toner |

| U.S. Department of Labor/OSHA | Joseph Pipkin |

| U.S. Department of the Air Force | Anthony Okoren, Lt. Colonel |

| U.S. Dept. of the Army | Donald McDuffie, Lt. Colonel |

| U.S. Dept. of the Navy | Dale Barrette, Commander |

| United Auto Workers Union | Jim Howe, CIH |

| Tim McClain | |

| Vision Council of America | Kenneth Wood |

| David Devine | |

| ANSI Z80 Committee Ophthalmic Lenses | Robert Dziuban |

| Jeffrey Kosh | |

| ANSI Z88 Committee Respiratory Protection | William E. Newcomb, CSP |

| Z89 Committee Head Protection | James K. Byrnes |

| Janice C. Bradley, CSP | |

| ICS Laboratories, Inc. | Dale B. Pfriem, Individual Expert |

| Individual Expert | Michael W. Schaus |

| TOPIC | PAGE | |

|---|---|---|

| FORWARD | 2 | |

| 1 | Preface | 9 |

| 2 | Scope, Purpose, Application, Exceptions, Interpretations | 9 |

| 2.1 | Scope | 9 |

| 2.2 | Purpose | 9 |

| 2.3 | Application | 9 |

| 2.4 | Exceptions | 10 |

| 2.5 | Interpretations | 10 |

| 3 | Eye Incident Injury Data/History | 10 |

| 4 | Definitions | 10 |

| 5 | Referenced Publications | 13 |

| 6 | Selection, Use and Maintenance of Protectors | 14 |

| 6.1 | Protectors | 14 |

| 6.2 | Hazard Assessment and Protector Selection | 18 |

| 7 | Spectacles | 22 |

| 7.1 | Introduction | 22 |

| 7.2 | Spectacle Frame Tests | 22 |

| 7.3 | Basic Impact Lens Requirements | 22 |

| 7.4 | Plano Spectacle Lens Requirements | 23 |

| 7.5 | Non-Plano Spectacle Lens Requirements | 24 |

| 7.6 | Flammability | 24 |

| 7.7 | Corrosion Resistance | 25 |

| 7.8 | Cleanability | 25 |

| 7.9 | Replacement Spectacle Lenses | 25 |

| 7.10 | Marking | 25 |

| 8 | Goggles | 26 |

| 8.1 | Introduction | 26 |

| 8.2 | Impact Testing Requirements | 26 |

| 8.3 | High Impact Testing Requirements | 27 |

| 8.4 | Optical Requirements for Plano Goggle Lenses | 27 |

| 8.5 | Optical Requirements for Non-Plano Goggle Performance | 28 |

| 8.6 | Flammability | 28 |

| 8.7 | Corrosion Resistance | 28 |

| 8.8 | Cleanability | 28 |

| 8.9 | Ventilation Requirements | 28 |

| 8.10 | Transmittance of Non-Lens Areas | 28 |

| 8.11 | Replacement Goggle Lenses | 28 |

| 8.12 | Marking | 29 5 |

| 9 | Faceshields | 29 |

| 9.1 | Introduction | 29 |

| 9.2 | Impact Testing Requirements | 30 |

| 9.3 | High Impact Testing Requirements | 30 |

| 9.4 | Optical Requirements for Plano Faceshield Windows | 31 |

| 9.5 | Requirements for Wire-Screen Windows | 31 |

| 9.6 | Flammability | 31 |

| 9.7 | Corrosion Resistance | 31 |

| 9.8 | Cleanability | 32 |

| 9.9 | Replacement Faceshield Windows | 32 |

| 9.10 | Marking | 32 |

| 10 | Welding Helmets and Handshields | 33 |

| 10.1 | Introduction | 33 |

| 10.2 | Impact Testing Requirements | 33 |

| 10.3 | High Impact Testing Requirements | 34 |

| 10.4 | Optical Requirements for Plano Welding Helmet Lenses | 34 |

| 10.5 | Optical Requirements for Non-Plano Welding Helmet Lenses | 35 |

| 10.6 | Flammability | 35 |

| 10.7 | Corrosion Resistance | 35 |

| 10.8 | Cleanability | 35 |

| 10.9 | Non-Lens Area Transmittance and Light Tightness | 35 |

| 10.10 | Replacement Welding Helmet Lenses | 35 |

| 10.11 | Marking | 36 |

| 10.12 | Transmittance Requirement, Automatic Darkening Welding Filter Lenses | 36 |

| 10.13 | Cover Lenses | 37 |

| 11 | Respirators | 37 |

| 11.1 | Introduction | 37 |

| 11.2 | Full Facepiece Respirators | 37 |

| 11.3 | Loose Fitting Respirators | 37 |

| 11.4 | Full Facepiece Welding Respirators | 37 |

| 11.5 | Loose Fitting Welding Respirators | 37 |

| 12 | Transmittance Requirements for Clear Lenses, Filter Lenses and Automatic Darkening Filter Lenses | 37 |

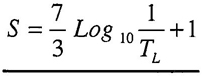

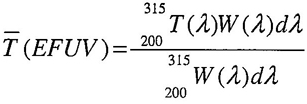

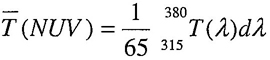

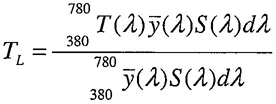

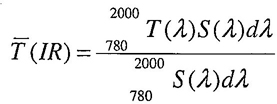

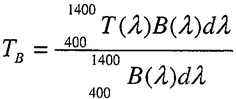

| 12.1 | Formulae | 38 |

| 12.2 | Transmittance Requirements | 39 |

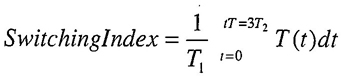

| 12.3 | Switching Index Requirements | 41 |

| 13 | Instructions, Use and Maintenance | 42 |

| 13.1 | General Requirements | 42 |

| 13.2 | Instructions | 42 |

| 13.3 | Inspections | 42 |

| 13.4 | Maintenance | 42 |

| 13.5 | Care | 42 |

| 13.6 | Training | 42 6 |

| 14 | Test Methods | 42 |

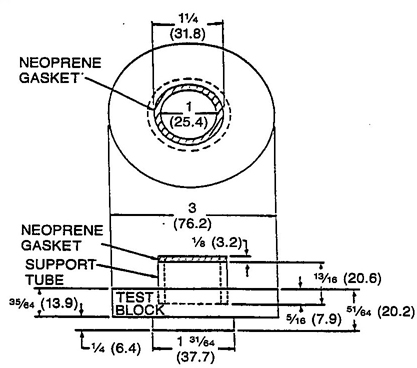

| 14.1 | High Mass Impact Test | 43 |

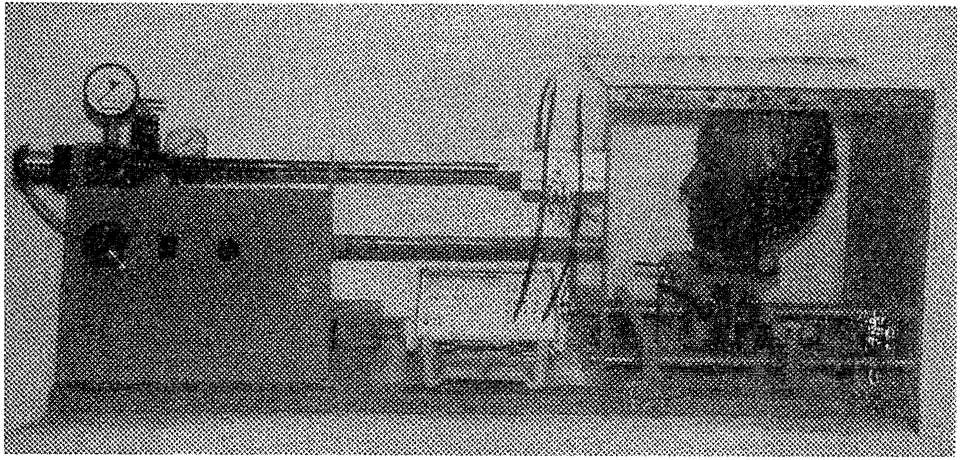

| 14.2 | High Velocity Impact Test | 43 |

| 14.3 | Tests for High Impact Prescription Lenses | 44 |

| 14.4 | Drop-Ball Impact Test | 45 |

| 14.5 | Penetration Test | 46 |

| 14.6 | Flammability Test | 47 |

| 14.7 | Corrosion Resistance Test | 47 |

| 14.8 | Cleanability Test | 47 |

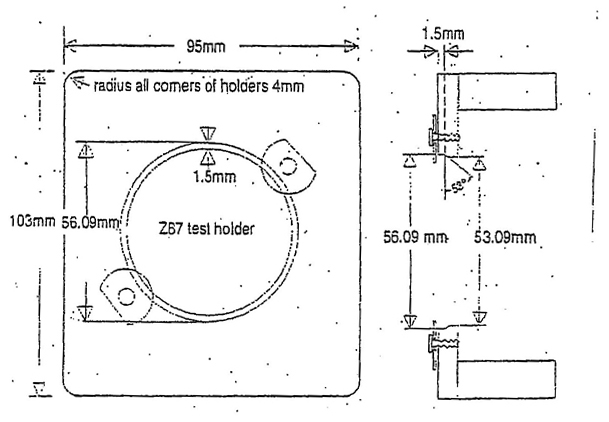

| 14.9 | Prismatic Power Test | 48 |

| 14.10 | Refractive Power, Resolving Power and Astigmatism Tests | 48 |

| 14.11 | Haze Test | 49 |

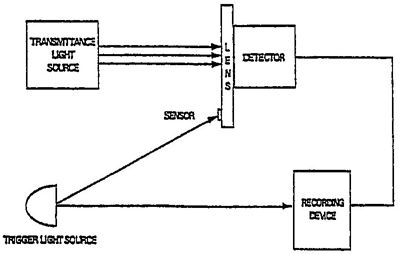

| 14.12 | Transmittance Test | 49 |

| 14.13 | Switching Index Test | 49 |

| 14.14 | Light Tightness Test | 50 |

| 15 | Warning Label | 51 |

| 15.1 | Purpose | 51 |

| 15.2 | Label or Tag Requirements | 51 |

| TABLES | ||

| Table 1 – Transmittance Requirements for Clear and Filter Lenses | 40 | |

| Table 2 – Transmittance Requirements for Special-Purpose Lenses | 41 | |

| Table 3 – Switching Index Requirements for Automatic Darkening Welding Filter Lenses | 41 | |

| FIGURES | ||

| Figure 1 – Spectacles | 14 | |

| Figure 2 – Temples | 14 | |

| Figure 3 – Fronts | 14 | |

| Figure 4 – Bridges | 15 | |

| Figure 5 – Side Protection | 15 | |

| Figure 6 – Life-front spectacles | 16 | |

| Figure 7 – Goggles | 16 | |

| Figure 8 – Faceshield | 17 | |

| Figure 9 – Welding Helmets | 18 | |

| ANNEXES | ||

| Annex A – Spectral Factor Tables (normative) | 52 | |

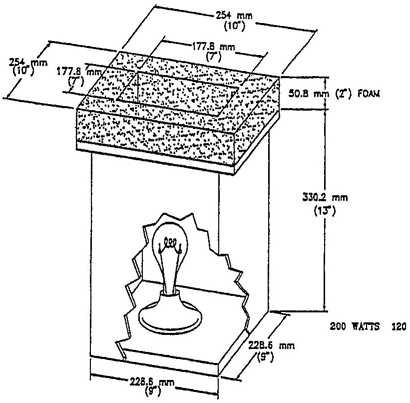

| Annex B – Test Apparatus (normative) | 56 | |

| Annex C – Test Apparatus (informative) | 58 | |

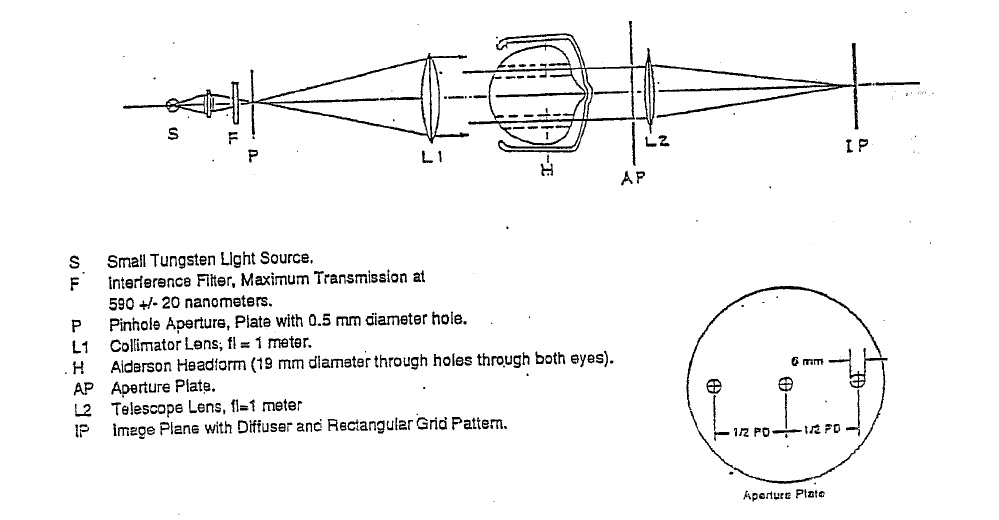

| Annex D – Calibration of Test Telescope (informative) | 60 | |

| Annex E – Sources for Test Apparatus (informative) | 61 | |

| Annex F – Referenced Publications (informative) | 62 | |

| Annex G – Required Marks and Marking Locations by Product Category (informative) | 63 | |

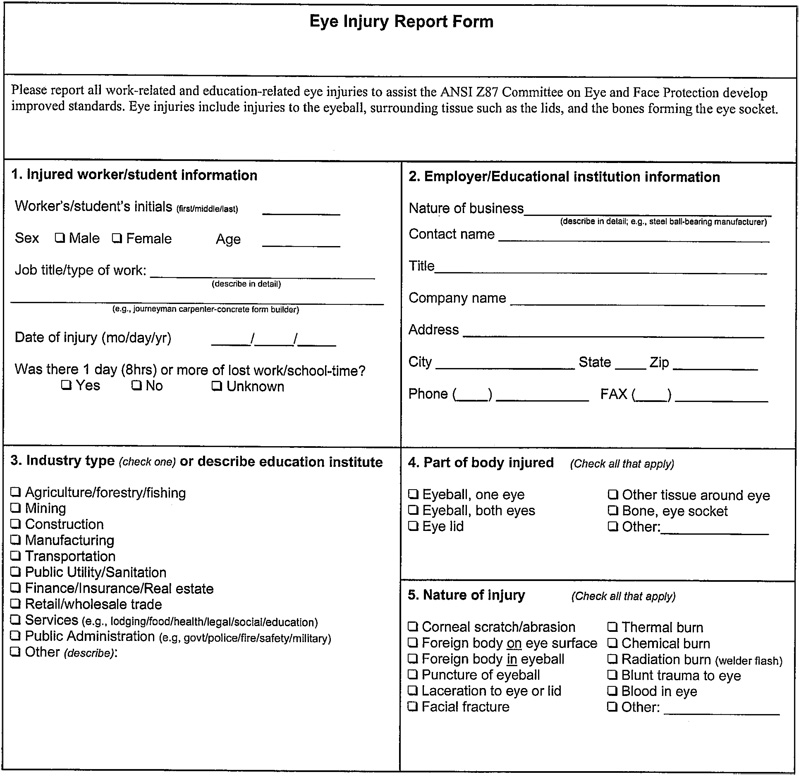

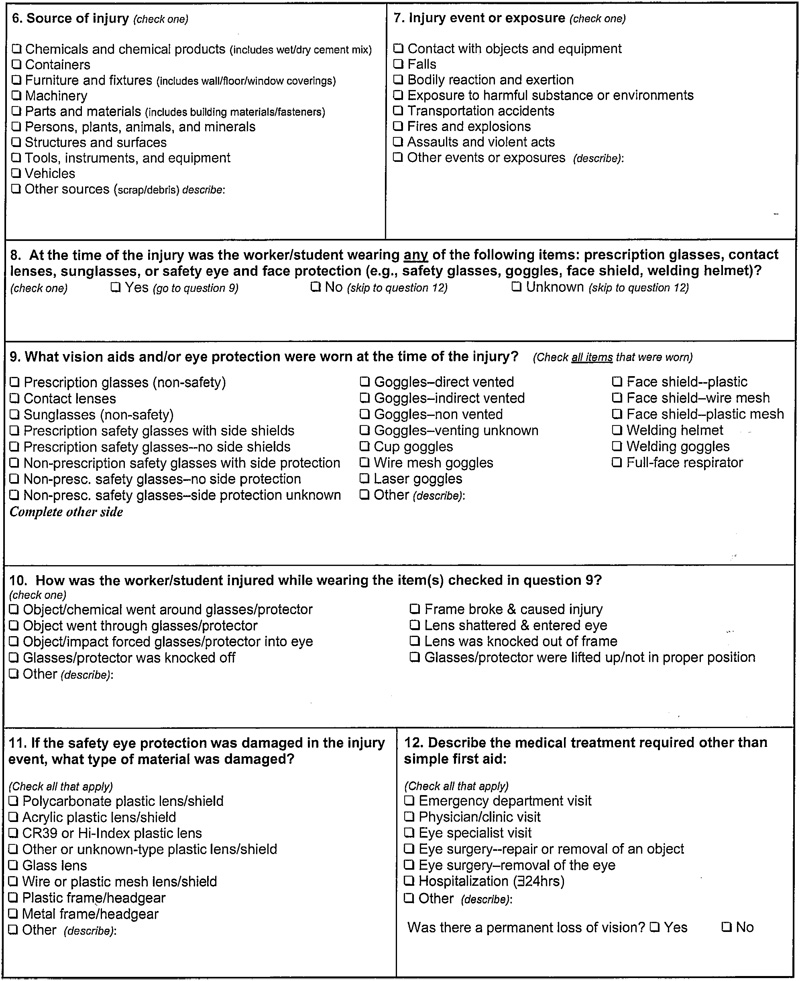

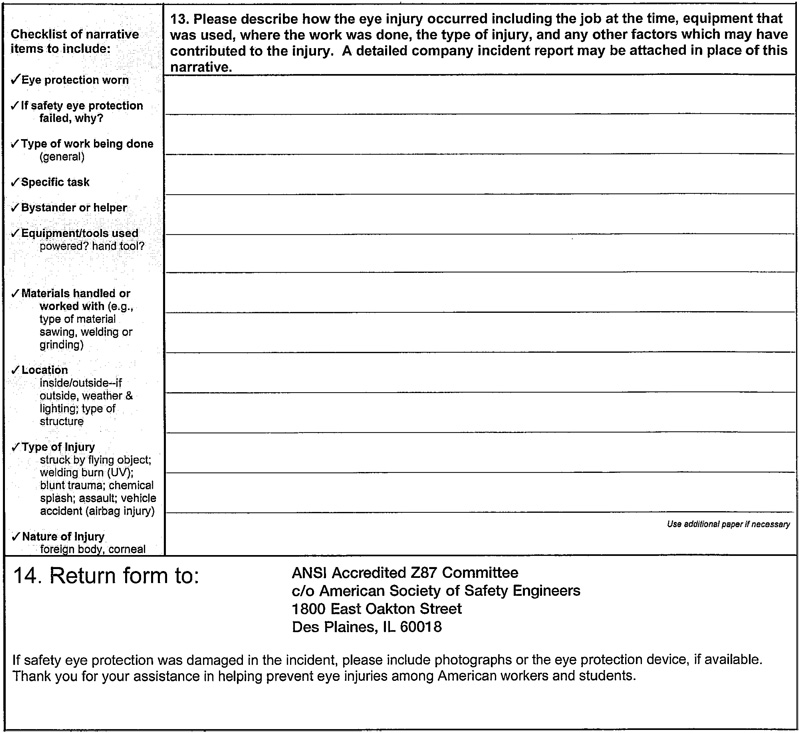

| Annex H – Eye Injury Report Form (informative) | 64 | |

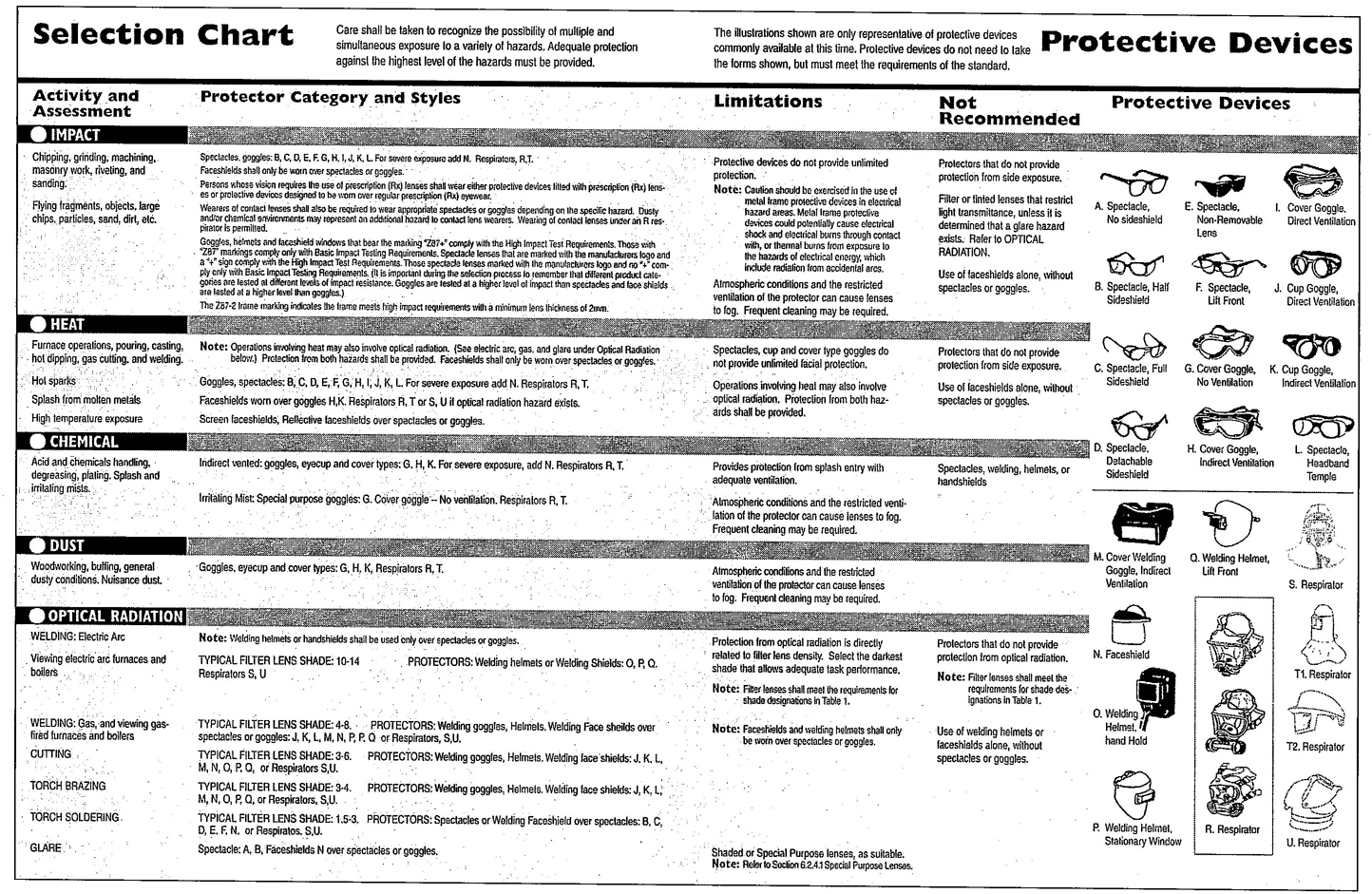

| Annex I – Selection Chart | 67 | |

American National Standard Z87.1-2003 uses a column format to provide both specific requirements and supporting information.

Operating rules (safe practices) are not included, unless they are of such a nature as to be vital safety requirements, equal in weight to other requirements, or guides to assist in compliance with the standard.

The information and materials contained in this publication have been developed from sources believed to be reliable. However, the American Society of Safety Engineers (ASSE) as secretariat of the ANSI accredited Z87 Committee or individual committee members accept no legal responsibility for the correctness or completeness of this material or its application to specific factual situations. By publication of this standard, ASSE or the Z87 Committee does not ensure that adherence to these recommendations will protect the safety or health of any persons, or preserve property.

8American National Standard Occupational and Educational Personal Eye and Face Protection Devices

This standard for personal eye and face protective devices (hereinafter referred to as protectors) is, as far as possible, designed to be performance oriented. Every effort was made to develop requirements that are consistent with, or more stringent than, ANSI Z87.1-1989(R-1998). This standard recognizes the Bureau of Labor Statistics1 study that revealed the need for angular protection, in addition to frontal protection, in eye and face protectors worn in the occupational setting.

Protectors do not provide unlimited protection. In the occupational and educational environment, protectors are not substitutes for machine guards and other engineering controls. Protectors alone should not be relied on to provide complete protection against hazards, but should be used in conjunction with machine guards, engineering controls, and sound safety practices. Every effort should be made to eliminate eye and face hazards in occupational and educational settings.

In 1992, the Occupational Safety and Health Administration began regulating occupational exposure to bloodborne pathogens and, as a result, now require employers to provide personal protective equipment (PPE) including eye and face protection for employees exposed to these hazards. At the time of the publication of this standard, no standards existed for eye and face protection intended to provide protection from bloodborne pathogens. Nevertheless many employers have elected to provide their employees with PPE conforming to the requirements of ANSI Z87. These products may or may not provide adequate protection against bloodborne pathogens.

Extreme caution must be exercised in the selection and use of personal protective equipment in applications for which no performance requirements or standardized testing exists.

This standard sets forth criteria related to the description, general requirements, testing, marking, selection, care, and use of protectors to minimize or prevent injuries, from such hazards as impact, non-ionizing radiation and chemical type injuries on occupational and educational environments including, but not limited to, machinery operations, material welding and cutting, chemical handling, and assembly operations.

This standard provides minimum requirements for protectors including selection, use, and maintenance of these protectors as devices to minimize or prevent eye and face injuries.

2.3.1 The requirements of this standard apply to protectors when first placed in service.

2.3.2 Protectors bearing the marking Z87 or represented in any way as being in compliance with this standard, shall meet all requirements of this standard in their entirety. All components of eye and face protective devices shall comply with the requirements of this standard.

2.3.3 Compliance with this standard cannot always be assured when replacement components are used. End users shall exercise extreme care in the selection and installation of replacement components to ensure compliance with this standard.

1 “Accidents Involving Eye Injuries,” U.S. Department of Labor, Bureau of Labor Statistics, April 1980, Report 597.

92.3.4 Components bearing the marking Z87 shall not be used with non- complying components.

2.3.5 The use of a device that is not in compliance with this standard or the use of a protector in applications outside its scope, may result in serious injury or death.

2.4.1 This standard does not apply to hazardous exposure to bloodborne pathogens, X-rays, high-energy particulate radiation, microwaves, radio-frequency radiation, lasers, masers, and sports, nor does it address comfort and/or appearance features.

2.4.2 This standard, by setting forth its requirements, points out the need to exercise caution in the selection and use of protectors where no performance requirements or standardized testing exist. For example, these protectors may not provide adequate protection against bloodborne pathogens.

Request for interpretations of this standard shall be in writing and addressed to the secretariat of this accredited standards committee.

End users are encouraged fill out an injury report form (Annex H), if there is an incident involving an eye injury. Filling out and submitting the report will enable the committee to build a history, identify potential opportunity areas for standard revisions and increase protection. The report should be sent to American Society of Safety Engineers (ASSE) 1800 East Oakton Street Des Plaines, IIIinois 60018.

For purposes of this standard, the following definitions shall apply:

astigmatism. A condition in a lens of a protector in which there is a difference in refractive power in one meridian from that in another meridian.

Basic Impact Protectors /Lenses. Protectors that are used only in an environment where the known or presumed hazards are of low impact nature.

blue-light transmittance. Transmittance of optical radiation weighted by its ability to cause photochemical damage to the retina.

chin protector. That portion of a device that offers protection to a wearer's chin, lower face and neck.

cleanability. The ability to be made readily free of dirt or grime without being damaged.

cover lens/plate. See “lens/plate, cover”

crown protector. That portion of a device that offers protection to a whearer's forehead.

crown strap. That portion of a headgear that rests on the top of the head.

dark state. The lowest operating luminous transmittance of an automatic darkening filter lens.

diopter (D). A unit of measurement (plus or minus) used to express the power of a lens. It is expressed as the reciprocal of the focusing distance given in meters. The diopter is also used to express the curvature of surfacing tools and the refracting power of curved surfaces.

effective far-ultraviolet transmittance. Transmittance of optical radiation weighted by its ability to damage the cornea with wavelengths from 200 to 315 nanometers.

10faceshield. A protective device commonly intended to shield the wearer's face, or portions thereof, in addition to the eyes, from certain hazards, depending on faceshield type. Faceshields shall be used only in conjunction with spectacles and /or goggles.

faceshield, wedding. A faceshield intended for limited welding applications. Faceshields shall be used only in conjunction with spectacles and/or goggles.

filter lens. See “lens, filter”.

fracture. A lens will be considered to have fractured if it cracks through its entire thickness into two or more separate pieces, or if any lens material visible to the naked eye becomes detached from the inner surface.

frame. A device, which holds the lens or lenses on the wearer.

front. The part of a spectacle or goggle frame that is intended to contain the lens or lenses.

glare. Uncomfortably bright light without hazardous levels of ultraviolet or infrared radiation.

goggle. A protective device intended to fit the face surrounding the eyes in order to shield the eyes from certain hazards, depending on goggle type.

goggle, welding. A goggle intended for limited welding applications.

handshield. A hand-held welding helmet. See “welding helmet”.

haze. The percent of incident light that is not transmitted in a straight line through the lens but forward scattered, greater the 2.5° diverging.

headgear. That part of a protective helmet, hood, or faceshield that supports the device on the wearer's head.

High Impact Protectors/Lenses. Protectors that are used in an environment where the known or presumed hazards are of high velocity of high mass or a high impact nature.

hood. A device that completely covers the head, neck, and portions of the shoulders.

infrared radiation (IR). As related to this standard, electromagnetic energy with wavelengths from 780 to 2000 nanometers.

interpupillary distance (PD). The distance in millimeters between the centers of the pupils of the eyes.

lens. The transparent part of a protective device through which the wearer sees, also referred to as a plate or window for some devices.

lens, automatic darkening welding filter. A filter lens, which automatically switches from a light state to a dark state in response to a change of light intensity.

lens, cover. An expendable lens used to protect another lens surface from damage.

lens, filter. A lens that attenuates specific wavelengths of ultraviolet, visible, and infrared radiation.

lens, impact-resistant. A lens capable of withstanding the appropriate impact tests of this standard.

lens, non-removable. A lens and holder that are homogeneous and continuous.

lens, photochromic. A lens, which darkens when exposed to, and fades when removed from, ultraviolet radiation and/or sunlight.

lens, non-plano. Lenses made to an individual prescription (Rx/prescription ophthalmic) or lenses using non-prescription, non-plano lenses for magnifying purposes.

11lens, plano (non-Rx). A lens that does not incorporate a corrective prescription; this lens is not necessarily flat. A plano lens is sometimes called afocal.

lens, polarizing. A lens, which transmits light preferentially in particular planes of orientation.

lens, prescription (Rx). A lens manufactured to the wearer's individual corrective prescription.

lens, tinted. A lens with color such as amber, smoke, or cobalt, which does not meet the requirements of Table 1.

lens, welding filter. A lens specified for use for welding or brazing.

lift-front. A type of supplementary lens and holder that covers the viewing area of a protector immediately in front of the wearer's eyes and that can be positioned outside the line of sight.

light. Optical radiation weighted by its ability to cause visual sensations.

light state. The highest operating luminous transmittance of an automatic darkening welding filter lens.

luminous transmittance (TL). The fraction of light (380-780 nm) passing through a medium.

lux (lx). A unit of measurement of illuminance equal to one lumen per square meter of the illuminated surface.

millisecond (ms). One thousandth of a second; 10−3 second.

nanometer (nm). A unit of measurement of wavelength equal to one billionth of a meter; 10−9 meter.

NIOSH. National Institute for Occupational Safety and Health, the federal agency responsible for, among other things, certifying the respiratory protective properties of respirators.

optical density. A measure of the transmittance of an optical device.

optical radiation. As related to this standard, that portion of the electromagnetic spectrum ranging in wavelength from 200 nm to 2000 nm, having the nominal sub-intervals: UV-C (200-280 nm), UV-B (280-315 nm), UV-A (315-380 nm), VISIBLE (380-780 nm), IR-A (780-1400 nm), IR-B (1400-3000 nm), and IR-C (3000 nm-1 mm).

plano. See “lens, plano”.

power. See “refractive power”, “resolving power”, and “prismatic power.”.

prismatic power, “prism”. A measure of the angular deviation expressed in prism diopters(Δ) of a light ray after passing along the viewing path through a lens. (One prism diopter equals deviation of 1 cm per meter of path length.)

protective device, “protector”. A complete product meeting the requirements of this standard.

protective helmet. Headwear conforming to ANSI Z89.1-1997, or the latest revision thereof; also known as a “hard that”.

refractive power, “power”. A measure of the ability of a lens to focus light rays, expressed in diopters (D).

resolving power, “definition”. The measure of the ability of a lens to form separate distinct images of two objects close together.

respirator, full facepiece. A tight fitting respirator that covers the nose, mouth and eyes from approximately the hairline to below the chin.

12respirator, loose fitting. A respiratory inlet covering that is designed to form a partial seal with the face, or that completely covers the head and neck, and may cover portions of the shoulder.

respirator, welding. A respirator intended to provide optical radiation protection for welding operations.

retained. In this standard, the use of the word “retained” means that the lens does not separate from the frame by more the 25% of its periphery.

shall. In this standard, the use of the word “shall” indicates a mandatory requirement.

should. In this standard, the use of the word “should” indicates a recommendation.

sideshield. A part of, or attachment to, a spectacle that provides side impact resistance.

spectacles. A protective device intended to shield the wearer's eyes from certain hazards, depending on the spectacle type.

switching index. The response time of an automatic darkening welding filter lens.

temple. That part of a spectacle frame commonly attached to the front and generally extending behind the ear of the wearer.

type tests. One or more tests performed on an item to approve a material, construction, model or design to determine if it is capable of meeting the requirements of a product standard.

ultraviolet radiation (UV). In this standard, electromagnetic energy with wavelengths from 200 to 380 nanometers.

welding goggle. See “goggle, welding”.

welding faceshield. See “faceshield, welding”.

welding faceshield. A protective device intended to provide protection for the eyes and face against optical radiation and weld spatter, which shall be worn only in conjunction with spectacles or goggles.

window. The lens portion of a faceshield (see “lens”).

window, non-removable. A window and holder that are homogeneous and continuous.

The following standards contain provisions, which, through reference in this text, constitute mandatory provisions, of this standard. Other reference materials, which do not contain mandatory provisions, are listed in Annex F.

American Conference of Governmental Industrial Hygienists - ““Relative Spectral Effectiveness by Wavelength”- 1993-1994.

ANSI Z80.1-1999, American National Standard for Opthalmics - Prescription Opthalmic Lenses - Recommendations.

ANSI Z80.5-1997, American National Standard Requirements for Dress Ophthalmic Frames.

ASTM D635-1998, Test Method for Rate of Burning and/or Extent and Time of Burning of Self-Supporting Plastics in a Horizontal Position.

ASTM D1003-00, Standard Test Method for Haze and Luminous Transmittance of Transparent Plastics.

ASTM D2240-2002, Standard Test Method for Rubber Property - Durometer Hardness.

ASTM D412-1998a, Standard Test Method for Vulcanized Rubber and Thermoplastic Rubbers and Thermoplastic Elastomers - Tension.

NBS Special Publication 374.

13Protectors are personal protective devices designed to protect the wearer from potential hazards that could adversely affect a person's eyes and/or face. Depending on the potential hazard, the protector may be designed to block flying objects or hazardous liquids, filter optical radiation, or enhance the wearer's vision for performing certain visual tasks. It is also important to realize that different categories are tested at different levels of impact resistance. There are three categories of protector lenses based on transmittance: clear, filter and special purpose (tables 1 and 2). There are many types of protectors available. In the following sections, illustrations of various types of devices used to protect the eyes and face are provided for guidance only; they are not intended to show every type of device available.

6.1.1 Spectacles and Spectacle Components

Spectacles are protective devices designed to shield the wearer's eyes from various impact, or impact and optical radiation hazards. A spectacle commonly consists of the following components: a front, a lens or lenses, a pair of temples, and side protection (figure 1). Spectacle components can be assembled in various combinations to make a complete protector to provide the user with a wide selection of suitable equipment for differing applications.

Figure 1 - Spectacles

6.1.1.1 Temples

A temple (figure 2) is that component of a spectacle that extends from the front to just behind the wearer's ear or continues completely around the wearer's head and is used to secure the frame in its proper use position. Temples are usually hinged at the front to permit easy storage when not in use and they are commonly available in the following three types: (1) spatula temples, (2) cable temples, and (3) headband temples. To properly fit the wide variety of wearers, temples are adjustable and/or available in various lengths.

Figure 2 - Temples: spatula, cable and headband

6.1.1.2 Fronts

The front (figure 3) is that component of a spectacle that retains the lens or lenses in the proper orientation for viewing. The front can be a separate part from the lens (removable lens type) or can be molded as an integral part of the lens (non-removable lens type). Frames for prescription lenses usually incorporate the removable type lens front. Cover spectacles are typically the non-removable lens type.

Figure 3 - Fronts: Spectacles with non-removable lenses

146.1.1.3 Lenses

Lenses are that component of a spectacle through which the wearer sees and which provides a protective barrier. Lenses are available in various materials, shapes, thicknesses, shades and tints depending on their particular application. Lenses also can be made to refract or bend light to magnify an object or provide corrective vision to a wearer's individual prescription (Rx). Lenses that do not refract light are considered “plano” and do not provide corrected vision.

6.1.1.4 Bridges/Nose Piece

A bridge or nose piece (figure 4) is that component of a spectacle, which supports the front on a wearer's face and typically rests on the bridge of the wearer's nose. Bridges are commonly available in three types: (1) fixed bridge (non-adjustable), (2) universal/saddle, and (3) adjustable nose pad. Bridge sizes are expressed in millimeters and measured as the distance between lenses (DBL).

Figure 4 - Bridges: fixed and adjustable nose pad

6.1.1.5 Side Protection

Side protection (Figure 5) is that component of a spectacle that extends from the front to some distance between the front and the wearer's ear and provides limited protection to the wearer's eyes from lateral hazards. Side protection may be an integral part of the frame or lens, a separate sideshield that is permanently attached to the frame, or a removable part of the frame. The function and coverage of side protection are defined by the high velocity impact test (section 14.2).

Figure 5 - Side Protection: flatfold sideshields and detachable sideshields

6.1.1.6 Special Purpose Spectacles

Special purpose spectacles are those which use lenses designed for a specific application. Examples of products for such applications include, but are not limited to, sunglasses, notch filters (e.g. - didymium containing), and furnace glasses. Special purpose spectacles use lenses that meet the requirements of table (2).

6.1.1.7 Lift-Front Spectacles

A lift-front spectacle (figure 6) is a spectacle conforming to the requirements of this standard that has an additional permanent or removable front attached, that can be raised or lowered to the wearer's line of sight. The lift-front component is typically used to provide additional protection, as needed, from glare, optical radiation, or both, or is used for special viewing tasks, such as magnification, and is marked accordingly. Lift-front spectacles are

15evaluated for impact and optical performance with the lift-front in the up position. The lift-front lens is evaluated for optical performance requirements of 7.4 or 7.5.

Figure 6 - Lift-front spectacles

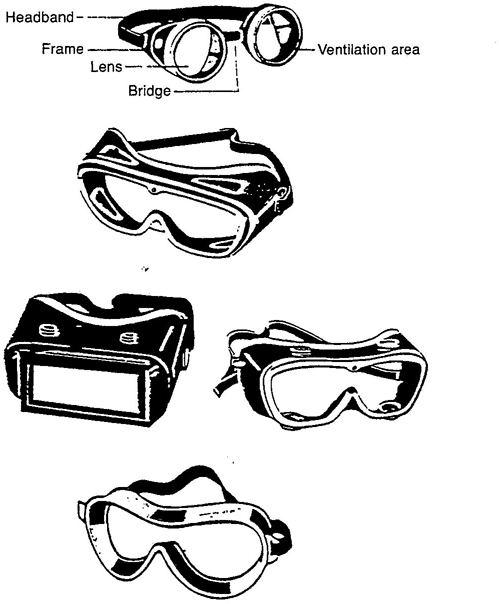

6.1.2 Goggles and Goggle Components

Goggles are protective devices designed to fit snugly but not necessarily seal completely to a wearer's face surrounding the wearer's eyes in order to shield the eyes. Goggles provide more protection than spectacles from impact, dust, liquid splash and optical radiation hazards. A goggle commonly consists of the following components: a frame, a lens or lenses, ventilation area and headband.

Goggles (figure 7) are commonly available in two styles: (1) eyecup goggles that cover the eye sockets completely; and (2) cover goggles, which may be worn over spectacles. Goggles are commonly available with rigid or flexible frames and are usually ventilated to minimize fogging. Three different types of ventilation are available: (1) direct ventilation, (2) indirect ventilation, and (3) goggles with no ventilation provision. Direct ventilated goggles permit the direct passage of air from the work environment into the goggle and are not recommended for use in protection against liquid splash hazards. Indirect ventilated goggles permit the passage of air and may prevent the direct passage of liquids and/or optical radiation. Goggles with no provision for ventilation minimize passage of dusts, mist, liquid splash and vapor. Goggles are available in many configurations to provide the user with a wide selection of suitable equipment.

Figure 7 - Goggles: eyecup goggle (showing components), cover goggles with direct ventilation, and indirect ventilation, and non-ventilated goggles

6.1.2.1 Side Protection

Side protection is that component of a goggle that extends from the front to some distance between the front and the wearer's ear and provides limited protection to the wearer's eyes from lateral hazards. Side protection in goggles is commonly an integral part of the frame or lens. The function and coverage of side protection are defined by the high velocity impact test (section 14.2).

6.1.2.2 Lift Front

A lift-front goggle is a goggle conforming to the requirements of this standard that has an additional permanent or removable front attached, that can be raised or lowered to the wearer's line of sight. The lift-front-component is typically used to provide additional protection, as needed, from glare, optical

16radiation, or both, or is used for special viewing tasks, such as magnification, and is marked accordingly. Lift-front goggles are evaluated for impact and optical performance with the lift-front in the up position. The lift front lens is evaluated for optical performance requirements of 8.4 or 8.5

6.1.2.3 Special Purpose Goggles

Special purpose goggles are those which use lenses designed for a specific application. Examples of products for such applications include, but are not limited to, notch filters (e.g.-didymium containing) and furnace goggles. Special purpose goggles use lenses that meet the requirements of table 2.

6.1.3 Faceshields and Faceshield Components

Faceshields are protective devices designed to shield the wearer's face, or portions thereof, in addition to the eyes, from various hazards. Facesheilds shall be used only in conjunction with spectacles and/or goggles and provide a higher level of protection than spectacles or goggles alone. Faceshields are used to provide protection from impact, dust, liquid splash and optical radiation hazards. Facehields (figure 8) may be used with a headgear assembly designed to suspend a transparent window that surrounds and shields the wearer's face. Faceshields may be incorporated with head protection. Faceshields also may provide neck and chin protectors. The assembled devices are available in many combinations of the various component types to provide the user with a wide choice of suitable equipment.

Figure 8 - Faceshield

6.1.3.1 Faceshield Windows

Faceshield windows provide a protective barrier between the work environment and the wearer's eyes and face. Faceshields are available in various materials, shapes, thickness, shades and tints depending on their particular application. Commonly available windows are plastic, plastic with a glass insert, or a wire screen.

6.1.3.2 Special Purpose Facehields

Special purpose faceshields are those which use windows designed for a specific application. Special purpose faceshields may provide limited protection from impact hazards, optical radiation, or both. Special purpose faceshields meeting certain light transmittance requirements are marked as “light”, “medium”, or “dark” (section 9.4.5) or meet the requirements of table 2.

6.1.4 Welding Helmets and Handshields

Welding helmets and handshields are protective devices designed to provide protection to a wearer's eyes, face, ears, and front of the neck against optical radiation and weld spatter. Welding helmets and handshields shall be used only in conjunction with spectacles, goggles, or both. There are three types (figure 9) commonly available: (1) helmet with stationary lens, (2) lift-front helmet; and (3) handshield. A welding helmet may be mounted on a protective helmet with special accessories. A welding helmet may be the respiratory inlet covering of a loose fitting facepiece respirator.

17Figure 9 - Welding helmets: helmet with stationary lens, lift-front helmet and handshield

6.1.4.1 Special Purpose Lenses and Windows

Special purpose lenses are designated as such because they do not meet the transmittance requirements of table 1, but do meet the transmittance requirements of table 2. A typical example is a cobalt furnace lens.

Special purpose lenses and windows are further classified and marked in accordance with the requirements of section 10.11. Only devices meeting the applicable sections of this standard shall be used with special purpose lenses. (For additional information, see ANSI Z49.1-1999.)

6.1.5 Respirators

Full facepiece respirators are NIOSH-approved, tight fitting respirators designed to provide a complete seal with the face and to provide protection to the wearer's eyes from impact hazards in addition to eye irritants. Loose fitting respirators are NIOSH-approved respirators designed to provide a partial seal with the face and to provide protection to the wearer's eyes from impact hazards in addition to eye irritants. Welding respirators are NIOSH-approved respirators designed to provide protection to the wearer's eyes from impact and optical radiation hazards in addition to eye irritants. Depending on the type of welding, the respirator may be designed to provide protection to the face, ears and front of the neck against optical radiation and weld spatter.

6.2.1 General Requirements

Protectors shall be required where there is a reasonable probability of an eye or face injury that could be minimized or prevented by the use of such protection. In such cases, employers and educational authorities shall make eye and face protectors conveniently available to employees and students for their use in the work environment, per applicable federal and state regulations. The employees and students shall use such devices. Where there is a reasonable probability of impact from flying objects, a protector with side protection shall be required.

Protectors are not substitutes for engineering controls and sound safety practices. Protectors alone should not be relied upon to provide the sole means of protection against eye and face hazards. Protectors shall be used in conjunction with engineering controls and sound safety practices. Known hazards should be removed or minimized to the extent possible.

Employers and employees should consult their federal, state and local safety and health regulatory authorities to become knowledgeable of the legal requirements applicable to their area. Under the Department of Labor, the Federal Occupational Safety and Health Administration (Fed OSHA) has codified in 29 Code of Federal Regulations (CFR) 1910 Occupational Safety and Health Standards for General Industry, and 29 CFR 1926 Occupational Safety and Health Standards for the Construction Industry specific legal requirements and guidelines that employers must follow to protect their employees adequately (see specifically 29 CFR 1910.133

18and 29 CFR 1926.102). By law, state and local government authorities can implement their own safety and health regulations if they are at least as protective as the federal regulations.

6.2.2 Hazard Assessment

It is necessary to consider certain general guidelines for assessing the eye and face hazard situations that exist in the work environment and to match the protective device to the particular hazard. The person directly responsible for a safety program should apply common sense and fundamental technical principles to accomplish these tasks. This process is subjective by nature because of the infinite variety of situations where face and eye protection may be required. At a minimum, the following recommended hazard assessment procedure should be followed in order to assess the need for eye and face protective equipment.

(1) Survey the Work Area. Conduct a walk-through survey of the area. The purpose of the survey is to identify sources of potential eye and face hazards. Consideration should be given to the six hazard categories addressed by this standard:

Impact

Heat

Chemical (Liquid Splash)

Dust

Glare

Optical Radiation(2) Identify Sources of Hazards. During the walk-through survey observe:

(a) Sources of motion; i.e., machinery or processes where any movement of tools, machine elements or particles could exist, or movement of personnel that could result in collision with stationary objects.

(b) Sources of high temperatures that could result in facial burns, eye injury or ignition of protective equipment, etc.

(c) Types of chemical exposures.

(d) Sources of dust.

(e) Sources of optical radiation, i.e., welding, brazing, cutting, furnaces, heat treating, high intensity light sources and ultraviolet lamps.

(f) Layout of workplace and location of other personnel.

(g) Any electrical hazards.(3) Organize Data. Following the walk-through survey, organize the data and information for use in the assessment of hazards. The objective is to prepare for an analysis of the hazards in the environment to enable proper selection of protective equipment.

(4) Analyze Data. Having gathered and organized data on a workplace, make an estimate of the potential for eye and face injury. Each of the basic hazards should be reviewed and a determination made as to the type and level of each of the hazards found in the area. The possibility of exposure to several hazards simultaneously should be considered.

(5) Selection. Specify the protector(s) suitable for the hazards identified (see Selection Chart, Annex I-Attached at the end of the standard).

(6) Reassessment of Hazards. A periodic reassessment of the work area should be performed on a regular basis to identify changes in the hazard situation that could affect the level of protection required. Reassess the workplace hazard situation by identifying and evaluating new equipment and processes, reviewing accident records, and reassessing the suitability of previously selected eye and face protection.

6.2.3 Protector Selection

After completing a thorough hazard assessment of the environment such as recommended in section 6.2.2, the general procedure for selection

19of protective equipment is as follows:

(1) Become familiar with the Selection Chart (Annex I - Attached at the end of the standard), the types of protective equipment that are available, their capabilities and limitations.

(2) Compare the hazards associated with the environment, i.e., impact velocities, masses, projectile shape, radiation intensities, etc., with the available protective equipment.

(3) Make a judgment in selection of the appropriate protective equipment so that the protection is consistent with the reasonably probable hazard.

(4) Basic impact protectors (lenses) may be used only in an environment where the known or presumed hazards are of low velocity, low mass and low impact nature. High impact protectors shall be used in an environment when the known or presumed hazards are of a high velocity, high mass or high impact nature.

(5) Provide and fit the user with the protective device and provide instruction on its care, use and limitations as recommended in sections 6.2.4 and 6.2.6.

(Note: Be aware that spectacles, goggles, and face shields are tested with different impact criteria so the protector selection should be consistent to the testing.)

The Selection Chart (Annex I - Attached at the end of the standard) is intended to aid in identifying and selecting the types of eye and face protectors that are available. The capabilities and limitations for the hazard “source” operations are listed in this guide. This guide is not intended to be the sole reference in selecting the proper eye and face protector.

6.2.4 Product Use and Limitations

Protectors are a personal item. They should be issued for exclusive use by a particular individual. However, in circumstances where protectors are reissued, the protectors shall be maintained in a sanitary and reliable condition as described in section 6.2.6.

Employers and educational authorities should train their employees and students in the proper use, care, application, inspection, maintenance, storage, and limitations of protective devices and provide them with all warnings, cautions, instructions and limitations.

included with the protector by the manufacturer. The wearer should follow all instructions provided by the manufacturer.

Caution shall be exercised to ensure that the level of protection provided by any protector is adequate for its intended purpose.

See the Selection Chart (Annex I - Attached at the end of the standard), for information on specific applications.

For more information regarding training please review the American National Standard, Z490. 1-2001, “Criteria for Accepted Practices in Safety, Health, and Environmental Training”.

6.2.4.1 Special Purpose Protectors and Lenses

Special purpose protectors and lenses are those which meet the requirements of table 2, but do not meet the requirements of table 1. They are designed for specific applications. They might not provide adequate ultraviolet protection, infrared protection, or ultraviolet and infrared protection when used for applications for which they are not designed. Therefore, special purpose protectors and lenses shall be used only after a complete hazard assessment and at the discretion of the individual responsible for the selection of protectors.

206.2.4.2 Prescription (Rx) Eyewear

Wearers of prescription (Rx) eyewear shall wear eye protection that incorporates the prescription in its design or that can be worn over prescription lenses without disrupting either the prescription eyewear or the protective eyewear.

Contact lens wearers should recognize that dusty and/or chemical environments may represent an additional hazard. Contact lenses are not protective devices. Wearers of contact lenses shall wear appropriate protectors in hazardous environments.

6.2.4.3 Filter Lenses and Windows

A filter lens meets the ultraviolet, luminous and infrared transmittance requirements of table 1 and is marked with a shade number that indicates its transmittance levels in accordance with table 1. Filter lenses of an appropriate shade are suitable for protection from sources of very high radiance, such as welding arcs. Filter lenses are also suitable for protection from sources of low radiance, provided that they are not so dark as to interfere with normal visual performance of the task.

6.2.4.4 Tinted Lenses and Windows

Lenses having low luminous transmittance should not be worn indoors, except when needed for protection from optical radiation. Care should be exercised in conjunction with wearing such lenses for driving vehicles with tinted windshields or for night driving. Some polarized lenses may present viewing problems when reading liquid crystal displays. Some tinted lenses may absorb certain wavelengths of visual displays or signs, rendering them unreadable.

6.2.4.5 Photochromic Lenses

Photochromic lenses darken when exposed to, and fade when removed from, ultraviolet radiation or sunlight. They are frequently used to provide comfortable vision for a wide range of ambient illumination. They should be used with care where the wearer passes from outdoors to indoors in the course of the job. Photochromic lenses that do not meet the transmittance requirements of table 1 and the switching index requirements of table 3 are not suitable for protection from direct exposure to high radiance sources (e.g., welding arcs and unshielded high intensity lamps). Photochromic lenses that do not meet the switching index requirements in table 3 are not automatic darkening welding filters. Photochromic lenses shall be used only after a complete hazard assessment and at the discretion of the person responsible for the selection of protectors, (See the Selection Chart, Annex I - Attached at the end of the standard.)

6.2.4.6 Protection from Low Radiance Sources of Ultraviolet and Visible Radiation

Some lenses that comply with the transmittance requirements of table 2, but not with all of the requirements of table 1, can provide sufficient ultraviolet attenuation to be used for protection from direct exposure to ultraviolet sources of low radiance and from indirect exposure (i.e., scattered radiation) to properly shielded ultraviolet sources of high radiance. Lenses that have some attenuation of visible light may also be suitable for protection from scattered light from properly shielded high radiance sources of visible light, (See Selection Chart, Annex I - Attached at the end of the standard.)

6.2.5 Fitting the Device

Careful consideration should be given to comfort and fit. Protectors that fit poorly will not afford the protection for which they were designed. Protectors should be fitted by qualified personnel. Continued wearing of protectors is more likely when they fit the wearer comfortably. Protectors are generally available in a variety of styles and sizes and care should be taken to ensure that the right size is selected for a particular person. For devices with adjustable fitting features, adjustments should be made on a regular and individual basis for a

21comfortable fit, which will maintain the protective device in its proper wearing position.

Some protectors may not be compatible with other personal protective equipment when worn together, such as goggles with faceshields, goggles with respirators and spectacles with goggles. The end user should carefully match protectors with other personal protective equipment to provide the protection intended. Because of individual facial characteristics, care must be exercised in fitting goggles to ensure that a snug fit around the face is achieved in order to provide adequate protection.

6.2.6 Inspection, Care and Maintenance

Wearers shall perform a visual inspection of their protectors prior to each use. Protective devices that are distorted, broken or excessively scratched or pitted are not suitable for use and shall be discarded.

Reasonable care shall be taken during the use and storage of protectors so that they are not subject to unnecessary abuse.

Protectors shall be maintained in a usable condition in accordance with manufacturer's instructions. When one protector is being used by more than one person, it is recommended that it be cleaned and disinfected prior to being used by a different individual.

Spectacles are protective devices designed to shield the wearer's eyes from certain hazards. Spectacles may be available in basic impact and high impact classes. Spectacles may in many cases be used alone. When faceshields or welding helmets are required, spectacles, goggles, or both shall be worn in conjunction with them (see Selection Chart, Annex I - Attached at the end of the standard).

Spectacle frame tests are designed to test the ability of the frame to retain a lens upon impact and to evaluate the strength of the temples and/or sideshields. For the purpose of these tests, frames shall be equipped with test lenses. The test lenses for frames designed for non-plane spectacles shall be 2.0mm, + 0.2mm, −0.0mm (0.079 in, +0.008 in, −0.0 in) thick. A test lens shall be capable of withstanding the following test criteria without failure. All spectacle frames shall meet the high mass and high velocity impact requirements of 7.2.1 and 7.2.2.

7.2.1 High Mass Impact

Spectacle frames shall be capable of resisting an impact from a pointed projectile weighing 500 g (17.6 oz) dropped from a height of 127 cm (50.0 in). The spectacles shall be tested in accordance with section 14.1. No piece shall be detached from the inner surface of any frame component, and the test lens shall be retained in the frame.

7.2.2 High Velocity Impact

Spectacle frames shall be capable of resisting impact from a 6.35 mm (0.25 in) diameter steel ball traveling at a velocity of 45.7 m/s (150 ft/s). The spectacles shall be tested in accordance with section 14.2. No piece shall be detached from the inner surface of any frame component, and the test lens shall be retained in the frame.

Basic impact spectacle lenses shall comply with all subparagraphs of this section.

7.3.1 Drop Ball Impact

Basic impact spectacle lenses shall be capable of resisting impact from a 25.4 mm (1 in) diameter steel ball dropped from a height of 127

22cm(50.0 in). The lens shall be tested in accordance with section 14.4. The lens shall not fracture as a result of this test.

Glass lenses shall be individually tested. Statistical sampling is an acceptable means of demonstrating compliance for plastic lenses. An example of an acceptable plan is in ANSI/ASQC Z1.4-1993, Sampling Procedures and Tables for Inspection by Attributes.

7.3.2 Minimum Thickness

Basic impact spectacle lenses shall be not less than 3.0 mm (0.118 in) thick, except those lenses having a plus power of 3.00 D or greater in the most plus meridian in the distance portion of the lens which shall have a minimum thickness no less than 2.5mm (0.098 in).

7.3.3 Plastic Lens Penetration Test

Basic impact plastic spectacle lenses shall be capable of resisting penetration from a weighted projectile weighing 44.2 gm (1.56 oz) dropped from a height of 127 cm (50.0 in) when tested in accordance with section 14.5. The lens shall not fracture or be pierced through as a result of this test.

7.4.1 Basic Impact Testing Requirements

Plano lens products designed to meet basic impact requirements shall comply with section 7.3.

7.4.2 High Impact Testing Requirements

7.4.2.1 Spectacle Product Tests

The spectacle product test is designed to test the capability of the complete product, both removable and non-removable lens products, to meet the requirements of this standard. For purposes of product testing, spectacles shall be tested as a complete device.

7.4.2.1.1 High Mass Impact

High impact spectacles shall be capable of resisting an impact from a pointed projectile weighing 500 g (17.6 oz) dropped from a height of 127 cm (50.0 in). The spectacles shall be tested in accordance with section 14.1. No piece shall be detached from the inner surface of any spectacle component and the lens shall be retained in the frame. In addition, the lens shall not fracture.

7.4.2.1.2 High Velocity Impact

High impact spectacles shall be capable of resisting impact from a 6.35 mm (0.25 in) diameter steel ball traveling at a velocity of 45.7 m/s (150 ft/s). The spectacles shall be tested in accordance with section 14.2. No contact with the eye of the headform is permitted as a result of impact. No piece shall be detached from the inner surface of any spectacle component and the lens shall be

retained in the frame. In addition, the lens shall not fracture.

7.4.2.1.3 Penetration Test (For Plastic lenses only)

High impact plano spectacle lenses shall be capable of resisting penetration from a weighted projectile weighing 44.2 gm(1.56 oz) dropped from a height of 127 cm(50.0 in) when tested in accordance with section 14.5. The lens shall not fracture or be pierced through as a result of this test. No piece shall be detached from the inner surface of any spectacle component and the lens shall be retained in the frame.

7.4.2.2 Thickness

When used in a frame marked Z87-2, the lenses, shall be not less than 2.0 mm (0.079 in) thick.

7.4.3 Optical Requirements

When tested alone, lens/plate shall meet all optical requirements for plano spectacles.

237.4.3.1 Optical Qualities

The lenses shall be free of striae, bubbles, waves and other visible defects and flaws which would impair their optical quality per the specifications and test methods in ANSI Z80.1 - 1999.

7.4.3.2 Prismatic Power

Complete devices shall be tested in accordance with section 14.9. The prismatic power shall not exceed 0.50 Δ in any direction. Vertical prism imbalance shall not exceed 0.25 Δ, and horizontal prism imbalance shall not exceed 0.25 Δ “Base In” or 0.50 Δ “Base Out”.

7.4.3.3 Refractive Power

Complete devices shall be tested in accordance with section 14.10. The refractive power, in any meridian, shall not exceed +/− 0.06 D. The maximum astigmatism (the absolute difference in power measured in the two extreme meridians) shall not exceed 0.06 D.

7.4.3.4 Resolving Power

Lenses shall be tested for resolving power in accordance with section 14.10. All lines in both orientations of NBS Pattern 20 shall be clearly resolved.

7.4.3.5 Haze

Clear plano lenses shall exhibit not more than 3% haze when tested in accordance with section 14.11.

7.4.3.6 Transmittance

Plano lenses shall comply with the requirements specified in table 1 for clear or filter lenses, or table 2 for special purpose lenses.

Measurements shall be taken in accordance with section 14.12.

7.5.1 Basic Impact

Basic impact non-plano lenses shall satisfy all the requirements of sections 7.3.1, and 7.3.2.

7.5.2 High Impact

High impact non-plano spectacle lenses shall comply with all subparagraphs of this section.

7.5.2.1 High Velocity Impact

High impact non-plano lenses shall be capable of resisting an impact from a 6.35 mm (0.25 in) diameter steel ball traveling at a velocity of 45.7 m/s (150 ft/s). The lenses shall be tested in accordance with section 14.3. No piece shall be detached from the inner surface of the lens. In addition, the lens shall not fracture.

7.5.2.2 Minimum Thickness

High impact non-plano lenses shall be not less than 2.0 mm thick. This requirement is in recognition of the thickness needed to maximize lens retention in the frame in a high velocity impact.

7.5.3 Optical Qualities

Non-plano spectacle lenses shall comply with the optical quality requirements of ANSI Z80.1-1999.

7.5.4 Transmittance

Non-plano lenses shall comply with the requirements specified in table 1 for clear lenses or table 2 for special purpose lenses.

Measurements shall be taken in accordance with section 14.12.

The front, temple, lens and removable sideshields shall be tested in accordance with section 14.6. The material shall not burn at a rate greater than 76 mm (3 in) per minute.

24Spectacles shall be tested in accordance with section 14.7. Metal components used in spectacles as utilized on the device shall be corrosion resistant to the degree that the function of the spectacles shall not be impaired by the corrosion. Lenses and electrical components are excluded from these requirements.

Spectacles shall be capable of being cleaned in accordance with section 14.8. The function and markings of the spectacles shall not be impaired by the cleaning process.

Since this standard allows for a great variety of spectacle lens shapes, sizes, and retention systems, compliance with this standard cannot always be assured when replacement lenses are used. Users shall exercise extreme care in the selection and installation of replacement lenses. To ensure compliance with this standard all replacement lenses shall be capable of meeting the same performance requirements as the replaced lenses. Only those replacement lenses designated by the lens manufacturer to be compatible with a particular spectacle model shall be used as a component of that spectacle, This information shall be supplied with the replacement lenses.

All markings shall be permanent, legible, and placed so that interference with the vision of the wearer is minimal. For a summary table of required markings see Annex G.

7.10.1 Frame Marking for Products with Removable Lenses

Spectacle frames including the front, both temples, and removable sideshields shall be marked with the manufacturers mark or symbol and “Z87”. If the frame is intended for non-plano lenses, the front and both temples shall be marked with the manufacturers mark or symbol and “Z87-2”.

In addition, the components of frames that are intended for non-plano use shall be marked for size in accordance with the system described in ANSI Z80.5-1997. Fronts shall be marked with the A-dimension (eye size) and DBL (distance between lenses). Temples shall be marked with their overall length.

7.10.2 Removable Lens Marking

Removable lenses shall be marked as follows:

| Mark | Indication |

|---|---|

| Mark or Logo | Identification of manufacturer. |

| Complies with Basic Impact Testing Requirements of sections 7.4.1 or 7.5.1. | |

| Mark or Logo | Identification of manufacturer. |

| + | Complies with High Impact Testing Requirements of sections 7.4.2 or 7.5.2. |

| Shade Number | Filter lens which complies with table 1. |

| S | Special purpose lens, complies with table 2, but not with table 1. |

| V | Photochromic lens. |

7.10.2.1 Examples of Lens Marking

Assume that manufacturer “K” makes a Special Purpose lens which meets basic impact requirements. That lens would be marked as follows:

25KS

Assume that manufacturer “W” makes a lens which meets the table 1 requirements of a shade 2.5 filter and meets high impact testing requirements. That lens would be marked as follows:

W + 2.5

Assume that manufacturer “Y” makes a clear lens, which meets table 1 and high impact testing requirements. That lens would be marked as follows:

Y+

7.10.3 Marking for products with Non-removable Lenses

Spectacles with non-removable lenses shall require only one marking. This marking may be placed on the front or one of the temples and shall consist of the manufacturer's identifying mark or symbol, “Z87” indicating compliance with this standard, a shade number if applicable and a “+” indicating that it meets the high impact testing requirements.

Goggles are protective devices intended to fit the face immediately surrounding the eyes in order to shield the eyes from a variety of hazards. While goggles may be used alone, they may also be used in conjunction with other protectors.

8.2.1 Goggle Frame Tests

For the purpose of these tests, goggle frames shall be equipped with test lenses. A test lens shall be capable of withstanding the specified test criteria without failure.

8.2.1.1 High Mass Impact

Goggle frames shall be capable of resisting an impact from a pointed projectile weighing 500 g (17.6 oz) dropped from a height of 127 cm (50.0 in). The goggle shall be tested in accordance with section 14.1. No piece shall be detached from the inner surface of any goggle component and the lens shall be retained in the frame. If the goggle uses only one lens, then it shall not separate from the frame along more than 25% of its periphery.

8.2.1.2 High Velocity Impact

Goggle frames shall be capable of resisting impact from a 6.35 mm (0.25 in) diameter steel ball traveling at a velocity of 76.2 m/s (250 ft/s). The goggles shall be tested in accordance with section 14.2. No contact with the eye of the headform is permitted as a result of impact. No piece shall be detached from the inner surface of any goggle component and the lens shall be retained in the frame. If the goggle uses only one lens, then it shall not separate from the frame along more than 25% of its periphery.

8.2.2 Basic Impact Lens Tests

For the purposes of these tests, goggle lenses shall be tested individually.

8.2.2.1 Drop Ball Impact

Basic impact goggle lenses shall be capable of resisting the impacts specified below. The lens shall be tested in accordance with section 14.4. The lens shall not fracture as a result of this test.

Round, removable lenses that are clear or that have shade numbers 1–3 shall be capable of resisting impact from a 25.4 mm (1 in) diameter steel ball, weighing 68 g (2.4 oz), dropped from a height of 127 cm (50.0 in). For shades higher than shade 3, round removable lenses shall be capable of resisting impact from a 22 mm (7/8 in) diameter steel ball, weighing 44.2 g (1.56 oz), dropped from a height of 1.0 m (39 in).

268.2.2.2 Minimum Thickness

Basic impact goggle lenses shall be not less than 3.0 mm (.118 in) thick at their thinnest point, except plastic, which shall be not less than 1.27 mm (.050 in) thick at its thinnest point.

8.2.2.3 Plastic Lens Penetration Test

Basic impact plastic goggle lenses shall be capable of resisting penetration from a weighted projectile weighing 44.2 g (1.56 oz) dropped from a height of 127 cm (50.0 in) when tested in accordance with section 14.5. The lens shall not fracture or be pierced through as a result of this test.

8.3.1 Goggle Product Tests

For purposes of product testing, goggles shall be tested as a complete device. Goggles with lift fronts shall be tested for impact resistance and optical requirements with the lift front in the “up” position.

8.3.1.1 High Mass Impact

High impact goggles shall be capable of resisting an impact from a pointed projectile weighing 500 g (17.6 oz) dropped from a height of 127 cm (50.0 in). The goggles shall be tested in accordance with section 14.1. No piece shall be detached from the inner surface of any goggle component and the lens shall be retained in the frame. If the goggle uses only one lens, then it shall not separate from the frame along more than 25% of its periphery. In addition, the lens shall not fracture.

8.3.1.2 High Velocity Impact

High impact goggles shall be capable of resisting impact from a 6.35 mm (0.25 in) diameter steel ball traveling at a velocity of 76.2 m/s (250 ft/s). The goggles shall be tested in accordance with section 14.2. No contact with the eye of the headform is permitted as a result of impact. No piece shall be detached from the inner surface of any goggle component and the lens shall be retained in the frame. If the goggle uses only one lens, then it shall not separate from the frame along more than 25% of its periphery. In addition, the lens closest to the eye shall not fracture.

8.3.1.3 Penetration Test

High impact goggle lenses shall be capable of resisting penetration from a weighted projectile weighing 44.2 gm (1.56 oz) dropped from a height of 127 cm (50.0 in) when tested in accordance with section 14.5. The lens closest to the eye shall not fracture or be pierced through as a result of this test. No piece shall be detached from the inner surface of a goggle component and the lens shall be retained in the frame.

When tested alone, the lens/plate shall meet all optical requirements.

8.4.1 Optical Qualities

The lenses shall be free of striae, bubbles, waves and other visible defects and flaws which would impair their optical quality.

8.4.2 Prismatic Power

Complete devices shall be tested in accordance with section 14.9. The prismatic power shall not exceed 0.25 Δ in any direction. Vertical prism imbalance shall not exceed 0.125 Δ, and horizontal prism imbalance shall not exceed 0.125 Δ “Base In” or 0.50 Δ “Base Out”.

8.4.3 Refractive Power

Complete devices shall be tested in accordance with section 14.10. The refractive power, in any meridian, shall not exceed +/− 0.06 D. The maximum astigmatism, the absolute difference in power measured in the two extreme meridians, shall not exceed 0.06 D.

278.4.4 Resolving Power

Lenses shall be tested for resolving power in accordance with section 14.10. All lines in both orientations of NBS Pattern 20 shall be clearly resolved.

8.4.5 Haze

Clear plano lenses shall exhibit not more than 3% haze when tested in accordance with section 14.11.

8.4.6 Transmittance

Plano lenses shall comply with the requirements specified in table 1 for clear lenses or table 2 for special purpose lenses. Measurements shall be taken in accordance with section 14.12.

8.5.1 Optical Requirements

Non-plano lenses shall comply with the optical requirements of ANSI Z80.1-1999.

8.5.2 Transmittance

Non-plano lenses shall comply with the requirement specified in table 1 for clear or filter lenses, or table 2 for special purpose lenses. Measurements shall be taken in accordance with section 14.12. Note: Most non-plano lenses do not comply with the requirements of table 1.

The frame, lens and lens housing or carrier shall be tested in accordance with section 14.6. The material shall not burn at a rate greater than 76 mm (3 in) per minute.

Goggles shall be tested in accordance with section 14.7. Metal components used in goggles shall be corrosion resistant to the degree that the function of the goggles shall not be impaired by the corrosion. Lenses and electrical components are excluded from these requirements.

Goggles shall be capable of being cleaned in accordance with section 14.8. The function and markings of the goggles shall not be impaired by the cleaning process.

When goggles are provided with openings to allow circulation of air, venting shall be consistent with the intended application of the goggles.

8.9.1 Direct Ventilation

The vented portion of a goggle shall be such that openings shall exclude spherical objects 1.5 mm (0.059 in) in diameter or larger.

8.9.2 Indirect Ventilation

The vented portion of a goggle shall be such that no direct, straight line passage from the exterior to the interior of the goggle exists.

When tested in accordance with section 14.12, non-lens areas of welding goggles with removable lenses shall transmit no more optical radiation than that permitted by table 1 for shade number 8. Non-lens areas of welding goggles with non-removable lenses shall transmit no more optical radiation than that of their lens.

Since this standard allows for a great variety of goggle lens shapes, sizes, and retention systems, compliance with this standard cannot always be assured when replacement lenses are used. Users shall exercise extreme care in the selection and installation of replacement lenses. To ensure compliance with this standard all replacement lenses shall be capable of

28meeting the same performance requirements as the replaced lenses. Except for 50 mm (1.97 in) round and 51 × 108 mm (2.00 × 4.25 in) rectangular lenses, only those replacement lenses designated by the manufacturer to be compatible with a particular goggle model shall be used as a component of that goggle. This information shall be supplied with the replacement lens(es).

50 mm (1.97 in) round and 51 × 108 mm (2.00 × 4.25 in) rectangular lenses shall have dimensional tolerances of: Round +/-0.2 mm (0.008 in) and Rectangular +/-0.8 mm (0.031 in).

All markings shall be permanent, legible, and placed so that interference with the vision of the wearer is minimal. For a summary table of required markings see Annex G.

8.12.1 Frame Marking

Goggles, including the frame and lens housing or carrier, shall bear the manufacturer's identifying mark or symbol and shall be marked “Z87” indicating compliance with this standard.

8.12.2 Removable Lens Marking

Lenses shall be marked as follows:

| Mark | Indication |

|---|---|

| Manufacturer | Manufacturers mark. |

| Z87 | Complies with Basic Impact Testing Requirements of section 8.2.2. |

| Z87+ | Complies with High Impact Testing Requirements of section 8.3. |

| Shade Number | Filter lens which complies with table 1. |

| S | Special Purpose lens, complies with table 2, but not with table 1. |

| V | Photochromic lens. |

8.12.2.1 Examples of Lens Marking

Assume that manufacturer “K” makes a Special Purpose lens which meets basic impact requirements. That lens would be marked as follows:

K Z87 S

Assume that manufacturer “W” makes a lens which meets the table 1 requirements of a shade 2.5 filter and meets high impact testing requirements. That lens would be marked as follows:

W Z87+ 2.5

Assume that manufacturer “Y” makes a clear lens which meets table 1 and high impact testing requirements. That lens would be marked as follows:

Y Z87+

8.12.3 Marking for products with Non-removable Lenses

Goggles with non-removable lenses shall require only one marking. This marking may be placed on the lens housing or the lens and shall consist of the manufacturer's identifying mark or symbol, “Z87” indicating compliance with this standard, a shade number if applicable and a “+” indicating that it meets the high impact testing requirements.

Faceshields are protective devices designed to shield the wearer's face, or portions thereof, in addition to the eyes, from certain hazards. Faceshields shall be worn only in conjunction with spectacles or goggles.

299.2.1 Faceshield Frame/Crown Tests

For the purpose of these tests, faceshield frames or crowns shall be equipped with test windows. A test window shall be capable of withstanding the specified test criteria without failure.

9.2.1.1 High Mass Impact

Faceshield frames or crowns shall be capable of resisting an impact from a pointed projectile weighing 500 g (17.6 oz) dropped from a height of 127 cm (50.0 in). The faceshield shall be tested in accordance with section 14.1. No piece shall be detached from the inner surface of any faceshield component and the window shall be retained in the frame.

9.2.1.2 High Velocity Impact