In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

ANSI Z245.2-1997

American National Standard

for Equipment Technology and

Operations for Wastes and

Recyclable Materials —

Stationary Compactors —

Safety Requirements

WASTE EQUIPMENT TECHNOLOGY ASSOCIATION

A PART OF THE

ENVIRONMENTAL INDUSTRY ASSOCIATIONS

4301 CONNECTICUT AVENUE, NEW • SUITE300 • WASHINGTON, DC 20008

TELEPHONE: 202-244-4700 • FAX: 202-966-4824

ANSI®

Z245.2-1997

Secretariat

Environmental Industry Associations

Approved October 14, 1997

American National Standards Institute, Inc.

American National Standard

Approval of an American National Standard requires verification by ANSI that the requirements for due process, consensus, and other criteria for approval have been met by the standards developer.

Consensus is established when, in the judgment of the ANSI Board Of Standards Review, substantial agreement has been reached by directly and materially affected interests. Substantial agreement means much more than a simple majority, but not necessarily unanimity. Consensus requires that all views and objections be considered, and that a concerted effort be made toward their resolution.

The use of American National Standards is completely voluntary; their existence does not in any respect preclude anyone, whether he has approved the standards or not, from manufacturing, marketing, purchasing, or using products, processes, or procedures not conforming to the standards.

The American National Standards Institute does not develop standards and will in no circumstances give an interpretation of any American National Standard. Moreover, no person shall have the right or authority to issue an interpretation of an American National Standard in the name of the American National Standards Institute. Requests for interpretations should be addressed to the secretariat or sponsor whose name appears on the title page of this standard.

CAUTION NOTICE: This American National Standard may be revised or withdrawn at any time. The procedures of the American National Standards Institute require that action be taken periodically to reaffirm, revise, or withdraw this standard. Purchasers of American National Standards may receive current information on all standards by calling or writing the American National Standards Institute, 11 W. 42nd Street, New York, 10036, Phone: 212-642-4900, Fax: 212-398-0023.

Published by

Waste Equipment Technology Association

(An Environmental Industry Association)

4301 Connecticut Ave., N.W., Washington, D.C. 20008

Copyright © 1997 by the Environmental Industry Associations

All rights reserved

No part of this publication may be reproduced in any

form, in an electronic retrieval system or otherwise,

without prior permission of the publisher.

Printed in the United States of America

E| Page | ||

| Foreword | iii | |

| 1 | Scope and purpose | 1 |

| 1.1 | Scope | 1 |

| 1.2 | Purpose | 1 |

| 1.3 | Effective date | 1 |

| 2 | Normative references | 2 |

| 3 | Definitions | 2 |

| 4 | Construction, installation, reconstruction, and modification | 12 |

| 4.1 | Design | 12 |

| 4.2 | Installation of stationary compactors | 12 |

| 4.3 | Reconstruction | 12 |

| 4.4 | Modification | 12 |

| 5 | Operating and maintenance instructions | 12 |

| 5.1 | Operating instructions | 12 |

| 5.2 | Reconstruction and modification | 12 |

| 5.3 | Maintenance | 12 |

| 5.4 | Lockout procedures | 12 |

| 6 | Operational requirements | 13 |

| 6.1 | Employer responsibility for stationary compactors | 13 |

| 6.2 | Operator/employee responsibility for stationary compactors | 15 |

| 7 | Stationary compactor safeguards and features | 16 |

| 7.1 | Access covers | 16 |

| 7.2 | Access doors interlock | 16 |

| 7.3 | Compactor and container mechanism | 16 |

| 7.4 | Compactor-container and self-contained compactor tailgates | 16 |

| 7.5 | Controls | 16 |

| 7.6 | Container dumping systems | 17 |

| 7.7 | Electrical systems | 17 |

| 7.8 | Guarding | 17 i |

| 7.9 | Locking system | 17 |

| 7.10 | Safety signs | 17 |

| 7.11 | Service openings | 19 |

| 7.12 | Continuously operating stationary compactors – additional safety features | 19 |

| Figures | ||

| 1 | Apartment/institutional stationary compactor | 7 |

| 2 | Commercial/industrial stationary compactor | 8 |

| 3 | Self-contained compactor-container | 9 |

| 4 | Continuously operating stationary compactor (as used in typical waste processing facility operations) | 10 |

| 5 | Transport equipment for compactor-containers | 11 |

| Annex | ||

| A | Bibliography | 20 |

(This foreword is not part of American National Standard Z245.2-1997)

This American National Standard is applicable to the construction, reconstruction, modification, care, maintenance, operation, and use of stationary refuse compacting equipment. This American National Standard gives guidance on safety requirements for on-site waste and recycling equipment used in apartment, institutional, commercial, and industrial locations, including transfer stations and recycling facilities. This American National Standard shall not apply to compactors commonly referred to as domestic or household compactor appliances. This American National Standard specifies the characteristics of stationary compactors into a distinctly identifiable standard for ease in identification and the process of revision. This standard is a revision of ANSI Z245.2 –1992. Stationary compactors also have been addressed previously in ANSI Z245.1 (1978 and 1984 editions), Mobile Refuse Collection and Compaction Equipment, Safety Requirements. For mobile collecting and compacting equipment, refer to the ANSI Z245.1 standard.

Inquiries, requests for interpretation, and suggestions for the improvement of this standard should be directed to the Secretary, Accredited Standards Committee Z245, c/o Environmental Industry Associations, 4301 Connecticut Ave., NW, Suite 300, Washington, D.C. 20008.

This standard was processed and approved for submittal to ANSI by the Accredited Standards Committee Z245 on Equipment Technology and Operations for Wastes and Recyclable Materials. Committee approval of this standard does not necessarily imply that all members of the committee voted for its approval. At the time it approved this standard, the Z245 Committee had the following members:

Chris Voell, Chairman

John A. Legler, Vice-Chairman

Richard B. Curtis, Secretary

| Organization Represented | Name of Representative |

|---|---|

| AIG Risk Management | Margaret Corda Joe Karch (Alt.) |

| American Federation of State, County and Municipal Employees | Gilbert Escudero Steve Fantuzzo (Alt.) iii |

| Allied Waste | Pete Bihl |

| Browning Ferris Industries | Al Dibens |

| City of Greensboro | Donald C. Inman Elizabeth Treadway (Alt.) |

| City of Rochester | Lou Guilmette |

| SACOM (Consumer) | Jerry Van Beek |

| Vital Safety Services (Consumer) | Wes Beitl (Alt.) |

| Environmental Industry Associations | Jack Legler Richard Curtis (Alt.) |

| Institute of Scrap Recycling Industries | Mike Mattia Cheryl Ann Spector (Alt.) |

| Solid Waste Association of North America (SWANA) | Chris Voell John Skinner (Alt.) |

| State of Pennsylvania | William LaCour Carl Hursch (Alt.) |

| Waste Equipment Technology Association (WASTEC) Baler Committee | Sidney Wildes Kent Spiers (Alt.) |

| Compactor Committee | Denny Pool John Richardson (Alt.) |

| Container Committee | Denny Gill |

| Distributor Committee | Skip Berg |

| Mobile Equipment Committee | Larry Horning Jerry Zanzig (Alt.) |

| Residential Container Committee | Larry Hawkins |

| WMX Technology | Jim McHenry Heather Lawton (Alt.) |

The Z245.2 Standard Development Subcommittee, which drafted this standard, had the following members:

| Denny Pool, Chairman | Susan Eppes |

| Richard Curtis, Secretary | Larry Hanska |

| Larry Horning | |

| Shannon Harrop | |

| Dave Malter | |

| Tim Monaco | |

| John Richardson | |

| Bob Riethmiller | |

| Kevin Riordan | |

| Jim Roseberry | |

| Kent Spiers | |

| Jerry Van Beek |

AMERICAN NATIONAL STANDARD ANSI Z245.2-1997

American National Standard

for Equipment Technology and Operations

for Wastes and Recyclable Materials—

Stationary Compactors—

Safety Requirements

1.1 Scope

This American National Standard is applicable to all persons engaged in the manufacture, modification, operation, cleaning, maintenance, service, or repair of stationary compacting equipment, and makes an attempt to distinguish between persons who may be the legal owner, lessor, lessee, or who are otherwise contracted with or hired to become involved with the equipment. This standard shall not apply to compactors intended for use in private homes, which are specifically excluded from the requirements of this standard.

1.2 Purpose

The purpose of this standard is to establish safety requirements with respect to the manufacture, reconstruction, modification, maintenance, service, operation, and installation (where applicable) of stationary compacting equipment.

1.3 Effective date

This standard revises the stationary compactor requirements found in ANSI Z245.2-1992. Provisions of that standard remain in effect. In order to enable manufacturers reasonable time to incorporate the provisions that are either new or are revisions of ANSI Z245.2-1992, the following guidelines have been selected by the Accredited Standards Committee Z245 as to effective dates:

-for all new stationary compacting equipment manufactured twelve (12) months after the approval date, the provisions of this revised standard, ANSI Z245.2-1996, shall apply, except that the provisions of 4.3, 4.4, 5.2, 6.1 and 6.2 of this American National Standard shall apply for all stationary compacting equipment, regardless of the date of manufacture, as of six months after the approval date of this standard;

-for all stationary compacting equipment manufactured from July 3, 1993 until 12 months after the approval date of this standard, the provisions of ANSI Z245.2 - 1992 shall apply;

-for all stationary compacting equipment manufactured from November 3, 1985 until July 2, 1993, the provisions of ANSI Z245.1 - 1984 shall apply;

1-for all stationary compacting equipment manufactured from March 16, 1977 to November 2, 1985, the provisions of ANSI Z245.1-1975 shall apply;

The following standards contain provisions which, through reference in this text, constitute provisions of this American National Standard. At the time of publication, the editions indicated were valid. All standards are subject to revision, and parties to agreements based on this American National Standard are encouraged to investigate the possibility of applying the most recent editions of the standards indicated below.

ANSI A1264.1-1989, Safety Requirements for Workplace Floor and Wall Openings, Stairs, and Railing Systems.

ANSI Z535.1-1991, Safety Color Code.

ANSI Z535.2-1991, Environmental and Facility Safety Signs.

ANSI Z535.3-1991, Criteria for Safety Symbols.

ANSI Z535.4-1991, Product Safety Signs and Labels.

ANSI Z535.5-1991, Accident Prevention Tags.

ANSI Z245.1-1975, Safety Requirements for Refuse Collection and Compaction Equipment.

ANSI Z245.1-1984, Refuse Collecting and Compacting Equipment–Safety Requirements.

ANSI Z245.1-1992, Refuse Collection, Processing and Disposal Equipment–Mobile Refuse Collection and Compaction Equipment–Safety Requirements.

ANSI Z245.30-1994, Refuse Collection, Processing and Disposal Equipment–Waste Containers–Safety Requirements.

ANSI/NFPA 70-1993, National Electrical Code.

U.S. Code of Federal Regulations (CFR), Title 29, U.S. Occupational Safety and Health Administration Part 1910.

For the purposes of this American National Standard, the general definitions in 3.1 through 3.17 and the equipment definitions in 3.18 through 3.48 shall apply, unless the context clearly indicates otherwise.

3.1 caution signs: CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury; or it may be used to alert against unsafe practices.

3.2 danger signs: DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. It is limited to the most extreme situations.

23.3 employee: An individual hired by an employer to work for compensation.

3.4 employer: A person who hires one or more individuals to work for compensation.

3.5 hazard: A condition of such a nature that it may precipitate an accident or injury.

3.6 loader: A person who is authorized by the employer to place materials in the loading hopper of a compactor, but not to operate the equipment.

3.7 maintenance personnel: Employees who are trained and authorized by the employer to service, inspect, clean, or maintain equipment.

3.8 maintenance testing: Functional and operational checks that may be performed on equipment and systems by authorized employers and qualified maintenance personnel before, during, or after maintenance and before placing equipment back in regular service.

3.9 manufacturer: The term manufacturer includes any intermediate or final-stage manufacturer, re-manufacturer, or modifier, prior to the compactor being offered for sale.

3.10 modification: Any change, alteration, addition to or removal from the original equipment or component, made in such a manner that the changed or altered portions or function of the equipment or component are different than the manufacturer's original design, specification, or use.

3.11 operator (authorized): An individual, 18 years old or older, who is trained and authorized by the employer to control the operation of the equipment, and who may clean the equipment other than in the course of servicing, maintenance, or repair.

3.12 person: An individual, corporation, partnership, legal entity, or business.

3.13 pinch point: A point at which it is possible to be caught between moving parts, or between moving and stationary parts, of a piece of equipment.

3.14 reconstruction: The disassembly and reassembly of equipment, generally for the purpose of placing the equipment back into full operation and substantially extending the service life beyond the normal life cycle contemplated at the time of original manufacture. Reconstruction can result in the equipment being repaired, rebuilt, or overhauled to the original equipment manufacturer's specifications.

3.15 refuse: Any type of solid waste (except human wastes), including garbage, rubbish, ashes, incinerator residues, street cleanings, plant trimmings, and residential, commercial, and industrial solid wastes, including recyclable materials.

3.16 safety factor: The ratio of the breaking strength of a component (for example, a winch cable) to the maximum designed load or stress when used in accordance with the manufacturer's instructions.

33.17 warning signs: WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

3.18 access cover or door: A panel covering an opening that is designed to permit access to the interior of the equipment.

3.19 automatic start control: A control that uses an automatic actuator or sensor to start the operation of the equipment.

3.20 chute: An enclosure connected to the equipment and an adjacent structure that funnels material into the loading chamber.

3.21 compactor-container: A container specially designed to be compatible with the compactor to which it is attached. It is used to receive, contain, store, and transport the compacted material.

3.22 compactor-container attaching mechanism: The system that couples and secures the compactor-container to the compactor.

3.23 compactor frame: The structural assembly of a stationary compactor that encloses the loading chamber and ram components.

3.24 control panel: The panel that contains the controls for operating the stationary compactor. It can be mounted on the compactor frame or located remotely at the control station.

3.25 container: A receptacle (also referred to as a bin) that receives and holds refuse for lifting, unloading, or transportation by mechanical means. Containers are specially designed for use with certain types of equipment. Containers used with rear-loading compacting equipment may incorporate features that differ from containers used with front-loading compacting equipment. Containers used in conjunction with tilt-frame and hoist-type equipment are designed to be picked up, transported, unloaded, and set off by that equipment. These containers receive, store, and transport compacted or loose refuse, and are hoisted onto the tilt-frame or hoist-type equipment (commonly referred to as roll-offs, luggers and hook-lifts). Carts are typically two-wheeled containers used in residential collection systems and facilities in conjunction with mechanized lifting systems.

3.26 container-lifting mechanisms: The component mechanisms, such as (but not limited to) lifting arms, forks, and hydraulic cylinders, cables, and winches and reeving cylinders that are used to lift containers other than two-wheeled containers.

3.27 container lifting mechanism - point of operation: The immediate area surrounding the container-lifting mechanism(s) when it is used for elevating and unloading the container.

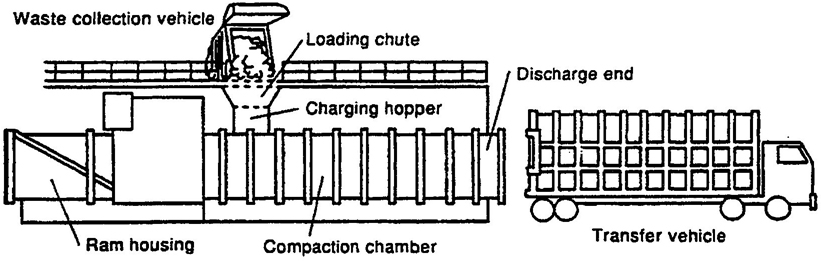

3.28 continuously operating stationary compactors: Stationary compactors where the main motor remains in continuous operation.

43.29 cycle: The operation of a mechanism to perform one complete operation having a definite beginning and end. An interrupted cycle is one in which the operation of a mechanism stops automatically before completion of the cycle.

3.30 dock ramp: A structural platform for walking on or driving a vehicle on that provides access from an adjacent structure or area to the equipment.

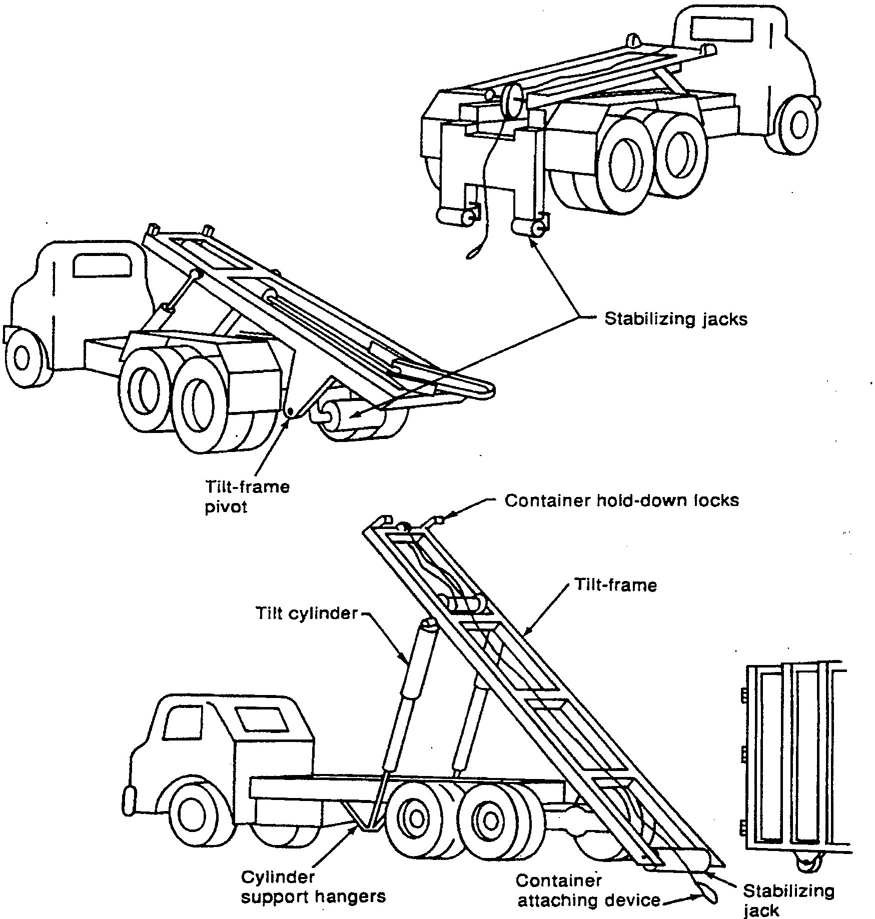

3.31 hoist-type equipment or hoist equipment: The hoist arms, chains, and frames used to elevate, support, transport, dump, and unload compatible containers or equipment. Hoist-type equipment is utilized with an engine-powered cab and chassis. (See figure 5).

3.32 installer: A company or person in control of putting equipment in place, activating it, and performing initial equipment operation.

3.33 integrated power unit: A power unit that is contained within the body/frame work of the equipment.

3.34 interlock: A device or mechanism used to connect individual components together so that the action of one part of the equipment is constrained by, or dependent upon, another.

3.35 loading chamber: The opening within the structural configuration of the machine in which the material is loaded prior to compression by the ram.

3.36 load hopper: An enclosure mounted on the equipment that serves to direct the flow of material into the loading chamber.

3.37 loading height: The vertical distance between the loading sill and working surface.

3.38 loading sill: The ledge over which material is deposited into the equipment.

3.39 point of operation: The area of the equipment where work is actually performed upon the material.

3.40 ram: The powered component of a stationary compactor that moves the refuse from the loading chamber to the compactor-container where it is compacted.

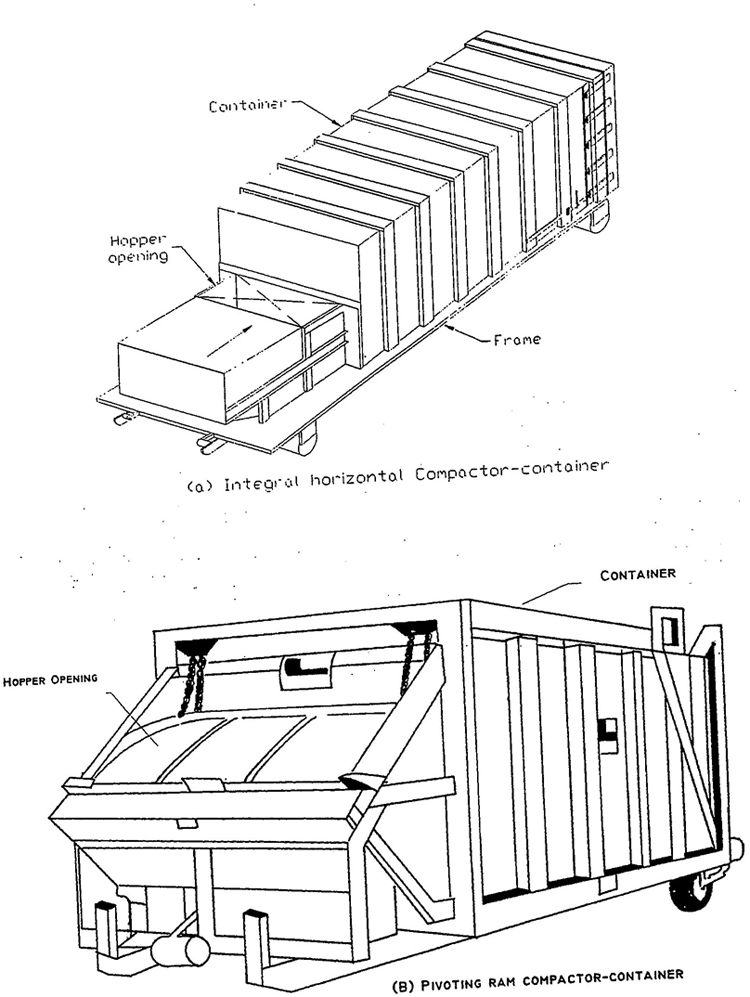

3.41 self contained compactor-container: A powered machine that remains stationary during operation, designed to compact refuse into an integral container. The entire unit is moved for placement and unloading of refuse (see figure 3).

3.42 service opening: An opening into the interior of stationary compacting equipment that is designed to permit access to the interior for the purpose of service or maintenance, but not of a size to permit a person to pass through.

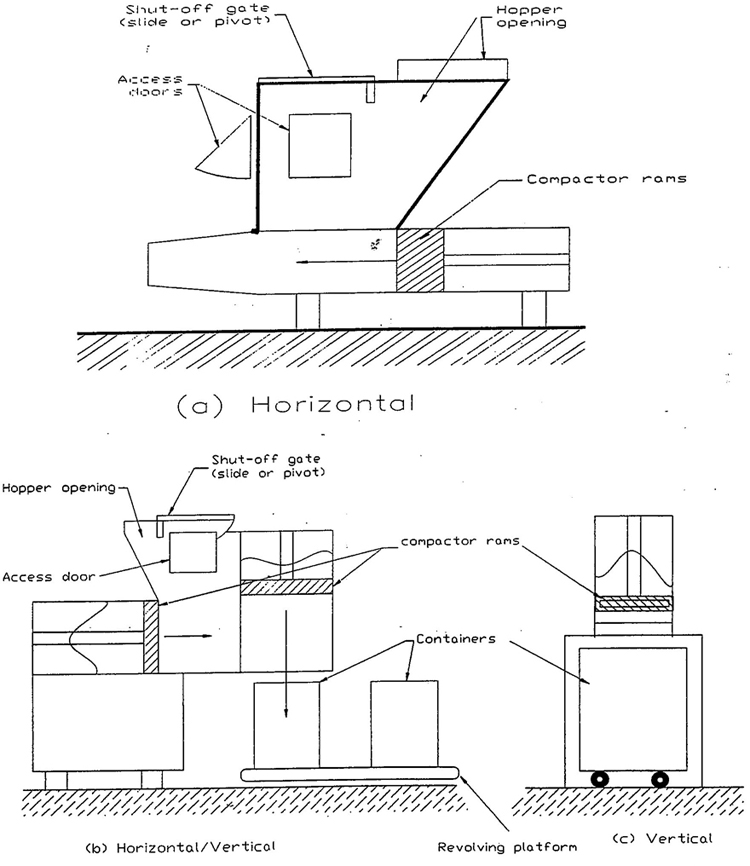

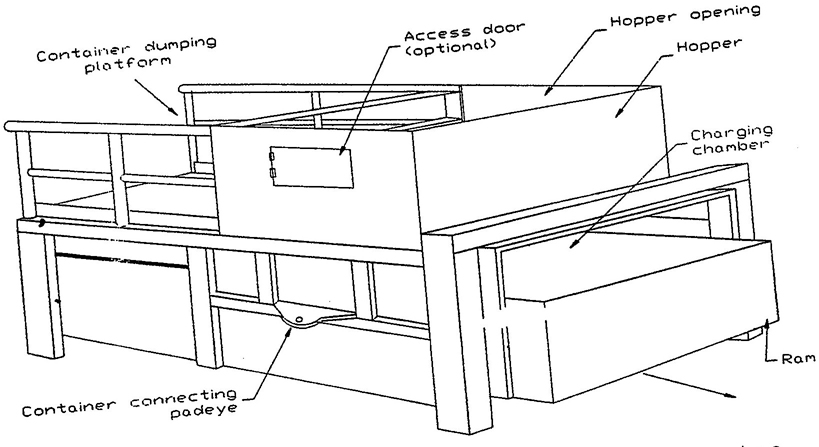

53.43 stationary compaction equipment and self contained compactor-container equipment: (Hereinafter referred to as stationary compaction equipment or stationary compactors) Powered machines that remain stationary when in operation, and are designed to compact refuse into a container. Apartment/institutional stationary compactors are stationary compactors used in apartment complexes or institutions (see figure 1). Commercial/industrial stationary compactors are stationary compactors used in commercial businesses, industrial plants, or waste processing, disposal, transfer and recycling facilities, (see figures 2, 3 and 4).

3.44 stationary compactor-point of operation: The area of a stationary compactor where loading of material occurs.

3.45 sustained-manual-pressure control: A control that requires continuous pressure by the operator.

3.46 tailgate: The hinged gate or door(s) that closes the rear of the compactor container.

3.47 tilt-frame or roll-off equipment: The tilt-frame, tilt-frame support equipment, hoisting devices, tilt cylinders, and controls for operating the tilt-frame and hoisting devices for loading, dumping, and unloading containers or stationary compactors (see figure 5). Tilt-frame equipment can be mounted on an engine-cab and chassis or on a trailer chassis.

6

Figure 1 - Apartment/institutional stationary compactor

7

Figure 2 -Commercial/Industrial Stationary Compactor

8

FIGURE 3 SELF-CONTAINED COMPACTOR CONTAINER

9

Figure 4 -Continuously operating stationary compactor (as used in typical waste processing facility operations)

10

Figure 5 — Typical transport equipment for compactor-containers

114.1 Design

Stationary compactors shall be designed and constructed in accordance with the appropriate sections of this standard. Equipment shall be permanently identified with the name of the manufacturer, the date of manufacturer or a code traceable to the date of manufacture, and a statement attesting to compliance with this standard.

4.2 Installation of stationary compactors

The installer shall install stationary compactors in accordance with the appropriate sections of this American National Standard, applicable codes, local ordinances, and the manufacturer's recommendations, and shall affix to such equipment the date of installation, installer's name and a statement attesting to compliance with this standard.

4.3 Reconstruction

Any person (see clause 3.14) reconstructing (including where modifications occur) stationary compactors after the effective date of this standard shall do so in accordance with all clauses of this standard and shall affix to such equipment his or her name, the date of reconstruction, and a statement attesting to compliance with this standard.

4.4 Modification

Any person (see clause 3.10) modifying stationary compactors after the effective date of this standard shall do so in accordance with the appropriate clauses of this standard and shall affix to such equipment his or her name, the date of the modification, and a statement attesting to compliance with this standard.

5.1 Operating instructions

Manufacturers shall develop and provide operating instructions establishing guidelines for the appropriate installation, use, cleaning, and care of the unit. Such instructions shall include precationary notices associated with the operation of the unit.

5.2 Reconstruction and modification

Any person modifying stationary compactors shall furnish appropriate operating instructions establishing guidelines for the use, cleaning, and care of the unit or component associated with the reconstruction (where modifications occur) or modifications. Instructions shall include precautionary notices associated with the reconstruction or modification.

5.3 Maintenance

The manufacturer shall develop and provide a guideline for maintenance, including a periodic or regular inspection schedule, of all stationary compactors for the employer/owner to perform.

5.4 Lockout procedures

The manufacturer shall provide instructions for a lockout procedure. The lockout procedure shall isolate and render safe all energy sources, including electrical, hydraulic, potential, and kinetic. These procedures shall be compatible with the U. S. Code of Federal Regulations, Title

1229, the requirements of Occupational Safety And Health Administration regulation, 29 CFR Part 1910.147 for lockout/tagout of energy sources.

6.1 Employer responsibility for stationary compactors

The employer shall provide properly maintained stationary compactors that meet all applicable regulatory safety standards and shall be responsible for all of the following:

a) Ensuring that the installation of stationary compactors conforms with local codes, ordinances, and manufacturer's recommendations;

b) Providing to employees instruction and training in safe work methods before assigning them to operate, clean, service, maintain, modify, or repair the equipment. Such instruction and training shall include procedures provided by the manufacturer. The employer will maintain records as to the names of employees and the dates of training;

c) Monitoring the employee's operation of stationary compactors and taking appropriate action to ensure proper use of the equipment, including adherence to safe practices;

d) Repairing, prior to placing the stationary compactor into service, any mechanical malfunctions or breakdowns that affect the safe operations of the equipment;

e) Establishing and following a program of periodic and regular inspections of all stationary compactors to ensure that all parts, component equipment, and safeguards are in safe operating condition, and adjusted, in accordance with the manufacturer's recommended procedures and this standard. This shall include keeping all malfunction reports and records of inspections and maintenance work performed;

f) Protecting any person by one of the following methods:

1) the installation of a guard, loading hopper, or enclosure with a minimum loading height of 106.7 cm (42 in), that shall prevent entry into the loading chamber, prevent any person being caught between moving parts of the equipment or between the material being processed and moving parts of the equipment; which in itself creates no hazard between the protective guard and moving parts, is consistent with other requirements of this standard, is interlocked in such a manner that the equipment cannot be operated if the guard is not in place, and is accessible for inspection and maintenance, or;

132) sustained-manual-pressure controls located in such a way that the operator cannot reach the point of operation and within an area fully visible to the operator of the complete point-of-operation area when a guard is not used.

g) For stationary compactors fed by means of a loading pit conveyor, reciprocating floor, or push pit that is flush with or below the facility floor, providing:

1) protection for employees by means of:

i) limiting access within 183 cm (6 ft) of the edge of the pit to authorized employees;

ii) training authorized employees to recognize and avoid the hazards associated with the pit area;

iii) requiring that others whose employees use the pit area provide assurance of such training; and

iv) limiting access by unauthorized persons by installing signs, such as:

RESTRICTED AREA, AUTHORIZED EMPLOYEES ONLY

2) providing a device, to the extent practicable, which prevents trucks or other motor vehicles which unload directly into the loading pit from rolling into the pit;

h) When stationary compactors equipped with automatic cycling controls are provided, allowing their use only in locations where the loading chamber is not accessible while the compactor is cycling automatically;

i) Providing guard railings for dock ramps in accordance with ANSI A1264.1. These shall be located around the loading chamber opening if walk-on ramps are used to deposit refuse into the loading chamber. Guard railings and toeboards shall be provided on the sides of docks and ramps;

j) Using the manufacturer's recommended procedures for the lockout/tagout of hazardous energy sources (see clause 5.4). (See OSHA 29 CFR 1910.147, Appendix A, for recommended lockout/tagout procedures.)

k) Providing for an adequate work area around the stationary compactor for safe maintenance, servicing, and cleaning procedures (see OSHA 29 CFR 1910.303 for electrical equipment);

l) Keeping all surrounding walking areas and floors free from obstructions, and accumulations of waste matter, grease, oil, and water.

m) Maintaining records or employee reports of malfunctions required in clause 6.2(c);

n) Specifically inspecting safety interlocks, switches, and other protective devices to ensure that these devices are not disabled or bypassed, and not to permit the stationary

14compactor to be operated unless these devices are fully functional. These inspections shall be in accordance with clause 6.1(e);

o) Ensuring that containers supplied are capable of withstanding the maximum forces generated by the compacting system.

p) Ensuring that only authorized employees (18 years old or older) operate, inspect, or maintain compacting equipment.

6.2 Operator/employee responsibility for stationary compactors

Operators/employees who work on and around stationary compactors shall be responsible for the items listed below:

a) Using all applicable safety features provided on stationary compactors;

b) Using stationary compactors only after receiving instruction in accordance with clauses 6.1 and 6.2;

c) Reporting any damage to, or malfunction of, stationary compactors by submitting a report to the employer or responsible authority when the damage or malfunction occurs;

d) Ensuring that access doors and service opening covers are in place, secure, and/or locked before operations begin;

e) Ensuring that the area of operation around container lifting systems and the container is clear of persons during all phases of the dumping operation prior to energizing the dumping system;

f) Ensuring that all persons are clear of the compactor point of operation before actuating any compaction cycle controls or container dumping controls and shall be ready to stop the compaction cycle or container dumping operation if necessary;

g) Ensuring that all persons are clear of the tailgate (on compactor-container combinations so equipped) before the tailgate is opened or shut. The operator shall warn all persons not to cross behind or under an open tailgate;

h) Using all compacting equipment in accordance with this standard and the manufacturer's instructions, including ensuring the proper position of all locks, doors, guards, etc;

i) Ensuring that no one disables or bypasses safety interlocks, switches, or other protective devices and that the stationary compactor is not operated unless these devices are fully functional;

j) Locking out (see clause 6.1(j)) the unit when inspecting malfunctions, jams, or other problems arising from daily operations; servicing; or performing maintenance (except maintenance testing). The affected employee shall identify the type and magnitude of the energy that the equipment uses, shall understand the hazards, and know the methods to control the energy.

15k) Coupling and securing a container to a compactor frame as specified by the compactor and container manufacturer(s).

l) Operating, inspecting, and maintaining a compactor only if 18 years old or older and after being properly instructed and trained in accordance with the instructions given in clause 6.1(p).

7.1 Access covers

Access covers shall be interlocked, secured by a lockable device, or removable by hand tools only.

7.2 Access doors interlock

Any loading chamber access door(s) shall have an interlock system that prevents cycling motion while the access door(s) is/are open.

7.3 Compactor to container attachment mechanism

The compactor and container mechanism should be capable of withstanding more than the manufacturer's specified maximum force that is exerted by the ram on the refuse in the container. Maximum force rating (force in pounds) shall be stated on the compactor manufacturer's nameplate affixed to the compactor.

7.4 Compactor-container and self contained compactor tailgates

On all compactor-containers and self contained compactors equipped with tailgates, a sign shall be located on the sides of the body at the rear, such as:

WARNING-STAND CLEAR WHEN TAILGATE OR CONTAINER IS IN MOTION AND DURING LOADING AND UNLOADING

7.4.1 Tailgate latching and locking devices

7.4.1.1 The tailgate locking mechanism used to secure the tailgate to the body shall be capable of withstanding the maximum design forces for this area. The tailgate locking mechanism shall be designed to prevent sudden opening as it is unlatched.

7.4.1.2 On units equipped with side-hinged tailgates, latching devices shall be provided to hold the tailgates(s) open when refuse is being unloaded.

7.5 Controls

7.5.1 Each control shall be conspicuously labeled as to its function.

7.5.2 Operating controls shall be designed and located to prevent unintentional activation.

7.5.2.1 Electric start buttons shall be designed to prevent unintentional activation.

7.5.2.2 Electric stops buttons, including emergency stop buttons, shall be red, distinguishable from all other controls by size and color, and shall not be recessed.

7.5.3 Security switch

7.5.3.1 A key-lock on-off switch, or similarly functioning security, switch, shall be provided by

16the manufacturer as a means to disconnect power to the operating controls and lock these controls in the off position.

7.5.4 For emergencies, a safety retract feature such that whenever the unit is shut off and started again, the ram will always retract to its rear position, or a means of stopping and controlling the movement of the ram at any point shall be provided. Emergency stop controls shall be readily accessible to the operator or shall be located within 91.4 cm (3 ft) of the point of operation, the material feed area, or if chute fed, within 91.4 cm (3 ft) of the access door. An electrical disconnect shall be located within sight of the operating control panel and no more than 1,524 cm (50 ft) away from the operations control panel.

7.6 Container dumping systems

7.6.1 General

Container dumping systems for stationary compactors shall be installed in accordance with the manufacturer's instructions. Controls shall be of the sustained-manual-pressure type, and located outside the area of operation of the dumping system and container, and in direct line of sight of the dumping operation.

7.6.2 Two-wheeled container lifters

Lifters for two wheeled container shall conform to the requirements of ANSI Z245.30-1994, Refuse Collection, Processing and Disposal Equipment-Waste Containers-Safety Requirements.

7.6.3 Trunnion bar type container dumpers

Dumping systems for trunnion bar type containers shall conform to the requirements for rear-loader container systems specified in ANSI Z245.1-1992, Refuse Collection, Processing and Disposal Systems - Mobile Refuse Compaction Equipment - Safety Requirements.

7.6.4 Automatic container dumping systems

Automatic container dumping systems may be used if an emergency stop control is provided and the point of operation as well as the area through which the container moves is either:

1) completely enclosed by guards, a cage, or other similar devices which prevent entry, or

2) equipped with a means of sensing the presence of individuals in this area and immediately stopping the movement of the dumping mechanism.

7.7 Electrical systems

Electrical systems furnished as part of the stationary compactor, or for the installation thereof, shall be in accordance with ANSI/NFPA 70 and national, state, and local codes.

7.8 Guarding

Moving components of the stationary compactor frame and ram shall be enclosed, guarded, or both.

7.9 Locking system

A locking device shall be provided on operating controls to prevent unauthorized operation.

7.10 Safety signs

All safety signs shall be color coded and manufactured in accordance with ANSI Z535

17series standards. Also, the ANSI Z535 standards series should be consulted for examples of alternate wording of these signs.

7.10.1 A sign shall be located on or immediately next to each automatic sensing device, and at the point of operation, such as:

WARNING – THIS COMPACTOR STARTS AUTOMATICALLY

7.10.2 Where voltage exceeds 120 volts, a sign shall be located on each control panel and power unit, such as:

DANGER – 440 VOLTS (or appropriate voltage)

7.10.3 A sign shall be located on each access cover, such as:

WARNING – DO NOT REMOVE ACCESS COVER EXCEPT FOR SERVICING;

FOLLOW LOCKOUT/TAGOUT PROCEDURES

7.10.4 A sign shall be located on each access gate that prohibits access to the loading chamber from a walk-on ramp, such as:

WARNING – GATE MUST BE CLOSED BEFORE OPERATING COMPACTOR

7.10.5 A sign shall be located on the inside face in the loading hopper, such as:

DANGER – DO NOT ENTER

7.10.6 A sign shall be located on each outside face of the loading hopper, such as:

WARNING – KEEP OUT

7.10.7 On commercial/industrial stationary compactors without a loading hopper, a sign shall be located at the loading sill(s) such as:

DANGER –DO NOT ENTER

This sign shall be visible from both sides of the compactor.

7.10.8 Apartment/Institutional stationary compactors operated by employees

7.10.8.1 A sign shall be located on each loading hopper access door or access cover, such as:

WARNING – BEFORE OPENING DOOR (or COVER, as appropriate), TURN CONTROL PANEL KEY SWITCH TO OFF POSITION, REMOVE KEY, AND BLOCK OFF TRASH CHUTE

7.10.9 Compactors equipped with discharge end lockout devices (See 7.12.2.)

7.10.9.1 A sign shall be located near the device, such as:

WARNING –WHEN CHANGING CONTAINERS OR REPOSITIONING TRANSFER VECHICLES, TURN KEY SWITCH TO OFF POSITION AND REMOVE KEY

187.10.10 Container dumping systems

7.10.10.1 A sign shall be located in the vicinity of the dumper controls, such as:

OPERATOR–BEFORE OPERATING DUMPER, CLEAR AREA OF ALL INDIVIDUALS

7.10.10.2 A sign shall located in clear view of the dumper system and container, such as:

DANGER – STAY CLEAR OF DUMPER AND DUMPING AREA

7.11 Service openings

Service openings that expose pinch points shall be protected by a removable cover.

7.12 Continuously operating stationary compactors – additional safety features

7.12.1 Start-up alarms

A start-up alarm shall be provided, which is audible and visible for 5 seconds, and with a minimum delay of 15 seconds after the starting control is activated before the main motor starts. All non-adjustable audible alarm signals must provide a pulsing or intermittent signal of at least 100 db A of be pre-set to at least 10 db A above the ambient noise level. Automatic adjustment types must be able to generate a signal at least 10 db A above the ambient noise level.

7.12.2 Discharge lockout device

A key lock switch shall be provided within sight of the discharge end to prevent the inadvertent activation of the compaction cycle when the discharge end is not visible from the operator station.

19ANSI/NFPA 82 - 1994, Standard on Incinerators and Waste and Linen Handling Systems and Equipment

20