In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

ANSI-

M-29-01 B7.1-1970

SUPERSEDED

Approved December 29, 1970

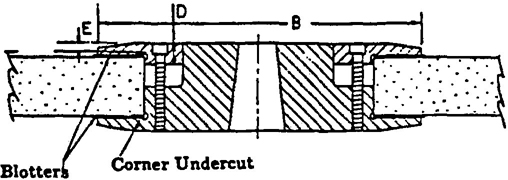

SPONSORS

International Association of Governmental Labor Officials

Grinding Wheel Institute

American National Standard

An American National Standard implies a consensus of those substantially concerned with its scope and provisions. An American National Standard is intended as a guide to aid the manufacturer, the consumer, and the general public. The existence of an American National Standard does not in any respect preclude anyone, whether he has approved the standard or not, from manufacturing, marketing, purchasing, or using products, processes, or procedures not conforming to the standard. American National Standards are subject to periodic review and users are cautioned to obtain the latest editions.

CAUTION NOTICE: This American National Standard may be revised or withdrawn at any time. The procedures of the American National Standards Institute require that action be taken to reaffirm, revise, or withdraw this standard no later than five years from the date of publication. Purchasers of American National Standards may receive current information on all standards by calling or writing the American National Standards Institute.

DATES OF PREVIOUS REVISIONS

Originally issued as a Tentative American Standard in 1922.

Revised and issued as an American Standard in 1926.

Revised in 1930, 1935, 1943, 1947, 1956, 1964 and 1970.

Copyright 1970 by the American National Standards Institute, Inc.

C| SECTION 1—SCOPE AND DEFINITIONS | Page | ||||

| 1.1 | Scope | 1 | |||

| 1.2 | Definitions | 1 | |||

| 1.2.1 | Shall and Should | 1 | |||

| 1.2.2 | Abrasive Wheel | 1 | |||

| 1.2.3 | Organic Bonded Wheels | 1 | |||

| 1.2.4 | Inorganic Bonded Wheels | 1 | |||

| 1.2.5 | Reinforced Wheels | 2 | |||

| 1.2.6 | Grinding Surface or Face | 2 | |||

| 1.2.7 | Safety Guard | 2 | |||

| 1.2.8 | Wheel Speed | 3 | |||

| 1.2.9 | Revolutions Per Minute | 3 | |||

| 1.2.10 | Surface Feet Per Minute | 3 | |||

| 1.2.11 | Flanges | 3 | |||

| 1.2.12 | Steel Rings | 3 | |||

| 1.2.13 | Threaded Bushings | 4 | |||

| 1.2.14 | Reducing Bushings | 4 | |||

| 1.2.15 | Tape or Wire Winding | 4 | |||

| 1.2.16 | Chuck | 4 | |||

| 1.2.17 | The Wheel Manufacturer | 4 | |||

| 1.2.18 | The Machine Builder | 5 | |||

| 1.2.19 | The User of Wheels and Machines | 5 | |||

| 1.3 | Usage Definitions | 5 | |||

| 1.3.1 | Centerless O.D. Grinding | 5 | |||

| 1.3.2 | Coping | 5 | |||

| 1.3.3 | Cutting Off | 6 | |||

| 1.3.4 | Cylindrical O.D. Grinding | 6 | |||

| 1.3.5 | Internal Grinding | 6 | |||

| 1.3.6 | Off-Hand Grinding | 6 | |||

| 1.3.7 | Portable Grinding | 6 | |||

| 1.3.8 | Precision Grinding | 6 | |||

| 1.3.9 | Saw Gumming | 7 | |||

| 1.3.10 | Slotting | 7 | |||

| 1.3.11 | Snagging | 7 | |||

| 1.3.12 | Surface Grinding | 7 | |||

| 1.3.13 | Tool Grinding | 7 | |||

| 1.3.14 | Tuck Pointing | 7 | |||

| 1.4 | Definitions and Limitations of Wheel Shapes | 7 | |||

| 1.4.1 | Type 1 Straight Wheels | 8 | |||

| 1.4.2 | Type 2 Cylinder Wheels | 8 | |||

| 1.4.3 | Abrasive Disc Wheels | 8 | |||

| 1.4.4 | Type 4 Taper Sided Wheels | 8 | |||

| 1.4.5 | Type 5 Recessed One Side Wheels | 9 | |||

| 1.4.6 | Type 6 Straight Cup Wheels | 9 | |||

| 1.4.7 | Type 7 Double Recessed Wheels | 9 | |||

| 1.4.8 | Type 11 Flaring Cup Wheels | 10 | |||

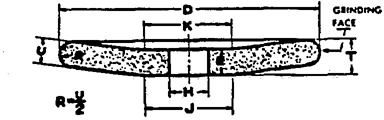

| 1.4.9 | Type 12 Dish Wheels | 10 | |||

| 1.4.10 | Type 13 Saucer Wheels | 10 | |||

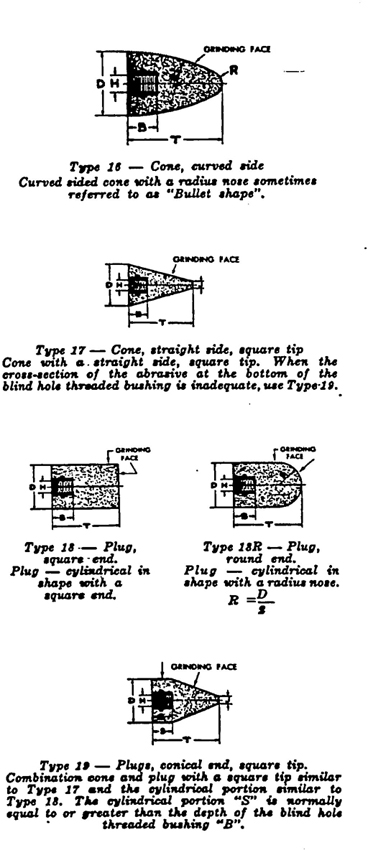

| 1.4.11 | Types 16, 17, 18, 18R and 19 Cone and Plug Wheels | 11 | |||

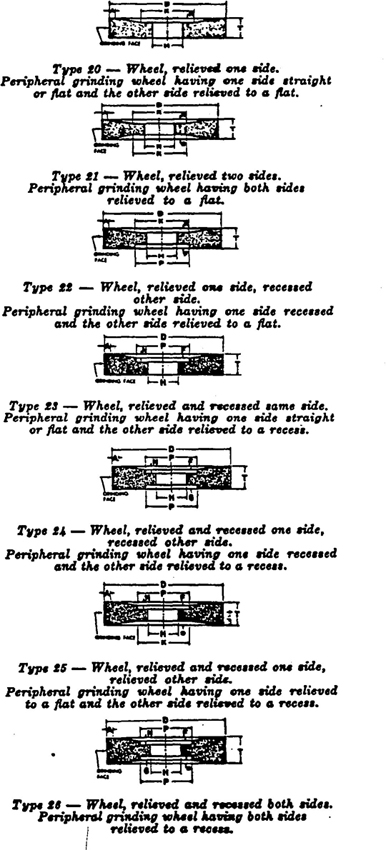

| 1.4.12 | Types 20, 21, 22, 23, 24, 25, 26 Relieved and/or Recessed Wheels | 12 | |||

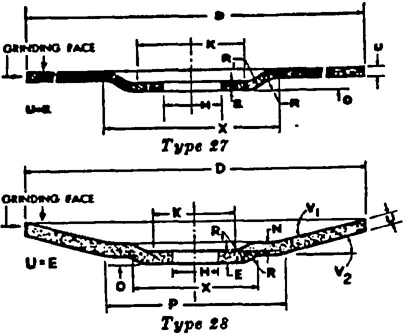

| 1.4.13 | Types 27 and 28 Depressed Center Wheels | 13 | |||

| 1.4.14 | Types 27A Depressed Center Wheels | 13 | |||

| 1.4.15 | Cutting Off Wheels | 14 | |||

| 1.4.16 | Coping Wheels | 14 | |||

| 1.4.17 | Tuck Pointing Wheels | 14 | |||

| 1.4.18 | Mounted Wheels | 15 | |||

| 1.4.19 | Threaded Hole Cup Wheels | 15 | |||

| 1.4.20 | Modified Types 6 & 11 Wheels (Terrazzo) | 15 | |||

| SECTION 2—HANDLING, STORAGE AND INSPECTION | |||||

| 2.1 | Handling | 16 | |||

| 2.2 | Storage | 16 | |||

| 2.3 | Inspection | 18 | |||

| SECTION 3—GENERAL MACHINE CONDITIONS | |||||

| 3.1 | Machine Design and Maintenance | 20 | |||

| 3.2 | Safety Guards | 20 | |||

| 3.3 | Power | 20 | |||

| 3.4 | Exhaust Provision | 20 | |||

| 3.5 | Diameter of Spindle | 21 | |||

| 3.6 | Flanges | 21 | |||

| 3.7 | Work Rests | 21 | |||

| 3.8 | Limiting Wheel Diameter | 21 | |||

| 3.9 | Direction of Machine Spindle Thread | 23 | |||

| 3.10 | Length of Machine Spindle Thread | 23 i | |||

| 3.11 | Size of Spindle or Mount | 24 | |||

| 3.12 | Threaded Hole Wheels | 24 | |||

| 3.13 | Mounting of Abrasive Discs (Inserted Nut, Inserted Washer and Projecting Stud Type) | 25 | |||

| 3.14 | Mounting of Plate Mounted Type Wheels | 26 | |||

| SECTION 4—SAFETY GUARDS | |||||

| 4.1 | General Requirements | 27 | |||

| 4.2 | Cup Wheels | 27 | |||

| 4.3 | Guard Exposure Angles | 28 | |||

| 4.3.1 | Bench and Floor Stands | 28 | |||

| 4.3.2 | Cylindrical Grinders | 29 | |||

| 4.3.3 | Surface Grinders and Cutting-off Machines | 29 | |||

| 4.3.4 | Swing Frame Grinders | 29 | |||

| 4.3.5 | Automatic Snagging Machines | 30 | |||

| 4.3.6 | Top Grinding | 30 | |||

| 4.3.7 | Portable Grinders | 30 | |||

| 4.3.7.1 | Right Angle Head or Verticle Portable Grinders—Type 27 and 28 Wheel | 30 | |||

| 4.3.7.2 | Other Portable Grinders | 30 | |||

| 4.4 | Exposure Adjustment | 31 | |||

| 4.5 | Enclosure Requirement | 32 | |||

| 4.5.1 | Safety Guard | 32 | |||

| 4.5.2 | Additional Enclosure | 32 | |||

| 4.6 | Material Requirements and Minimum Dimensions | 33 | |||

| 4.6.1 | For Speeds Up to 8,000 S.F.P.M. | 33 | |||

| 4.6.2 | For Speeds Up to 16,000 S.F.P.M. | 33 | |||

| 4.6.3 | Optional Materials | 33 | |||

| 4.6.4 | Exceptions | 33 | |||

| 4.7 | Material Specifications | 34 | |||

| 4.8 | Construction Guide for Fabricated Guards | 34 | |||

| 4.9 | Specifications for Rivets, Bolts, Welds and Studs for Fabricated Guards | 34 | |||

| 4.10 | Construction Guide for Drawn Steel Guards | 37 | |||

| 4.11 | Band Type Guards—General Specifications | 40 | |||

| 4.12 | Construction Guide for Band Type Guards | 40 | |||

| SECTION 5—FLANGES | |||||

| 5.1 | General Requirements | 42 | |||

| 5.1.1 | Type 1 Cutting-Off Wheels | 42 | |||

| 5.1.2 | Type 27A Cutting-Off Wheels | 42 | |||

| 5.1.3 | Flange Types | 43 | |||

| 5.2 | Design and Material | 43 | |||

| 5.3 | Finish and Balance | 43 | |||

| 5.4 | Uniformity of Diameter | 43 | |||

| 5.5 | Recess and Undercut | 44 | |||

| 5.6 | Contact | 44 | |||

| 5.7 | Driving Flange | 45 | |||

| 5.7.1 | Flanges, Multiple Wheel Mounting | 45 | |||

| 5.8 | Dimensions | 45 | |||

| 5.8.1 | Straight Flanges, Relieved and Unrelieved | 45 | |||

| 5.8.2 | Straight Adaptor Flanges Heavy Duty Grinding | 45 | |||

| 5.8.3 | Sleeve Flanges | 46 | |||

| 5.9 | Repairs and Maintenance | 46 | |||

| SECTION 6—MOUNTING | |||||

| 6.1 | Inspection | 52 | |||

| 6.2 | Arbor Size | 52 | |||

| 6.3 | Surface Condition | 52 | |||

| 6.4 | Bushing | 52 | |||

| 6.5 | Blotters | 53 | |||

| 6.6 | Flanges | 53 | |||

| 6.7 | Multiple Wheel Mounting | 53 ii | |||

| 6.8 | Tightening of the Mounting Nut | 54 | |||

| 6.8.1 | Single End Nut | 54 | |||

| 6.8.2 | Multiple Screws | 54 | |||

| 6.9 | Direction and Length of Thread on Machine Spindle | 54 | |||

| 6.10 | Threaded Hole Wheels | 54 | |||

| 6.11 | Mounting of Abrasive Discs (Inserted Nut, Inserted Washer and Projecting Stud Type) | 55 | |||

| 6.12 | Mounting of Plate Mounted Type Wheels | 55 | |||

| 6.13 | Safety Guards | 55 | |||

| 6.14 | Mounted Wheels | 55 | |||

| 6.15 | Type 27 and Type 28 Wheels | 56 | |||

| 6.16 | Type 27A Wheels | 56 | |||

| 6.17 | Type 2 Cylinder Wheels | 57 | |||

| 6.18 | Segments | 57 | |||

| SECTION 7—SPEEDS | |||||

| 7.1 | Standard Speeds | 58 | |||

| 7.1.1 | Standard Maximum Speeds | 58 | |||

| 7.1.2 | Machine Builder’s Responsibility | 58 | |||

| 7.1.3 | Wheel User’s Responsibility | 58 | |||

| 7.1.4 | Wheel Manufacturer’s Responsibility | 60 | |||

| 7.2 | Speed Check of Machines—User’s Responsibility | 61 | |||

| 7.3 | Speed Adjustment Control—User’s Responsibility | 61 | |||

| SECTION 8—SPECIAL SPEEDS | |||||

| 8.1 | Introduction | 62 | |||

| 8.2 | Requirements for Special Speeds | 62 | |||

| 8.2.1 | Condition A—The Wheel Manufacturer | 62 | |||

| 8.2.2 | Condition B—The Machine Builder | 63 | |||

| 8.2.3 | Condition C—The User | 63 | |||

| 8.3 | Wheel Manufacturer’s Responsibility | 63 | |||

| 8.3.1 | Manufacturer’s Test | 63 | |||

| 8.3.2 | Identification | 63 | |||

| 8.4 | Machine Builder’s Responsibility | 63 | |||

| 8.4.1 | General Machine Conditions | 64 | |||

| 8.4.2 | Safety Guards | 64 | |||

| 8.4.3 | Flanges | 64 | |||

| 8.5 | User Responsibility | 64 | |||

| 8.5.1 | Handling, Storage and Inspection | 65 | |||

| 8.5.2 | General Machine Conditions | 65 | |||

| 8.5.3 | Safety Guards | 65 | |||

| 8.5.4 | Flanges | 65 | |||

| 8.5.5 | Mounting | 65 | |||

| 8.5.6 | General Operating Rules | 65 | |||

| SECTION 9—GENERAL OPERATING RULES | |||||

| 9.1 | User’s Responsibility | 66 | |||

| 9.2 | Investigation After Breakage | 66 | |||

| 9.3 | Wheel Speed | 66 | |||

| 9.4 | Replacing Safety Guard | 66 | |||

| 9.5 | Starting the Wheel | 66 | |||

| 9.6 | Balance | 66 | |||

| 9.7 | Truing and Dressing | 67 | |||

| 9.8 | Wet Grinding | 67 | |||

| 9.9 | Side Grinding | 67 | |||

| 9.10 | Lubrication | 67 | |||

| 9.11 | Check for Wear | 68 | |||

| 9.12 | Work Rests | 68 | |||

| 9.13 | Large Hole Inorganic Bonded Wheels | 68 | |||

| SECTION 10—MOUNTED WHEELS | |||||

| 10.1 | Maximum Safe Operating Speed | 69 | |||

| 10.2 | Special Maximum Operating Speed | 70 | |||

| 10.3 | Work Pressure | 70 | |||

| TABLES OF MAXIMUM OPERATING SPEEDS FOR MOUNTED WHEELS | 71—85 | ||||

| CONVERSION TABLE—WHEEL SPEEDS (SFPM) | 86 | ||||

| APPENDIX A | 87 | ||||

| KEY WORD INDEX | 88 | ||||

(This Foreword is not a part of the American National Standard Safety Code

For the Use, Care and Protection of Abrasive Wheels, B7.1-1970)

In 1917 the Grinding Wheel Manufacturers and the Machine Tool Builders began to recognize a need for codification and standardization of the basic requirements of safe operation of abrasive grinding wheels. By 1922 these two groups had completed a tentative draft of requirements for an American Standard. It was reviewed, revised, and subsequently published in 1926 under the auspices of the American Standards Association (now the American National Standards Institute) as the “American Standard Safety Code For the Use, Care and Protection of Abrasive Wheels.” The Code has been revised in 1930, 1935, 1943, 1947, 1956, 1964 and 1970.

The two groups which initiated the Code in 1917 have been expanded into a Standards Committee representing nationally recognized engineering, safety, abrasive wheel and grinding machine fabricators and user associations, labor organizations, insurance underwriter groups, and several interested government agencies.

Safety is indeed everybody’s business in the “Use, Care and Protection of Abrasive Wheels.”

Basic to a proper understanding of the Code is a thorough knowledge of the nature and characteristics of a abrasive wheels and the grinding machines on which they are used. Their safety and protection devices can and must be used to limit, if not eliminate, injury or damage in case of accidental wheel breakage. Constant educational programs at all levels are the best insurance against those unforseen conditions or circumstances which result in an industrial accident.

This Code outlines the best known practices, tests, and safety devices for the protection of all personnel and equipment from injury or damage in case of accidental wheel breakage. USE THEM.

This, the “American National Standards Institute Safety Code For the Use, Care and Protection of Abrasive Wheels,” is specifically dedicated to vigilant safety practice and education.

ivMembers who compose the Standards Committee and the organizations they represent are as follows:

STANLEY W. GERNER, Chairman

National Bureau of Standards

ALLEN P. WHERRY, Secretary

Grinding Wheel Institute

| Organization Represented | Name and Business Affiliation |

|---|---|

| American Federation of Labor & Congress of Industrial Organizations | Charles F. West, Jr., International Association of Machinists |

| American Foundrymen’s Society | Herbert J. Weber |

| American Insurance Association | Lee Murphy, Employers-Commercial Union Companies |

| American Iron & Steel Institute | R. G. Dettmar, Interlake Steel Corporation |

| American Mutual Insurance Alliance | Joseph W. Hart, Liberty Mutual Insurance Co. Frederick H. Deeg (Alt.) |

| American Society of Mechanical Engineers | H. J. Eierman, Royal Globe Insurance Cos. |

| American Society of Safety Engineers | H. Stanley Tabor, American Mutual Insurance Companies |

| Compressed Air & Gas Institute | W. B. Fleischer, Air Tool Div., Dresser Industries, Inc. R. H. Oatley (Alt.), Stanley Air Tools Div. of The Stanley Works |

| Department of Health, Education and Welfare Public Health Service | Jeremiah R. Lynch |

| Grinding Wheel Institute | J. R. Gregor, General Grinding Wheel Corp. J. C. Arndt, Simonds Abrasive Div., Wallace-Murray Corp. G. R. Blake, Norton Company Norman Kendall, Cortland Div., American Abrasive Corp. W. G. Pinkstone, A. P. de Sanno & Son, Inc. A. A. Russ, National Grinding Wheel Div., Federal-Mogul Corp. R. A. Beebe (Alt.), Acme Abrasive Company R. J. Gandy, Jr. (Alt.), The Carborundum Co. R. O. Lane (Alt.), Abrasives Div., The Bendix Corp. E. G. Rieker (Alt.), Precision Grinding Wheel Co., Inc. L. C. Seelye (Alt.), Avco Bay State Abrasives Div. |

| Industrial Safety Equipment Association, Inc. | John I. Junkin, Junkin Safety Appliance Co., Inc. Charles N. Sumwalt, Jr. (Alt.) |

| International Association of Governmental Labor Officials | Frank W. Marcaccio, Div. of Industrial Inspection, Rhode Island Dept. of Labor Harold C. Barringer, Maryland Dept. of Labor and Industry William Dailey (Alt.), Rhode Island Dept. of Labor James A. Underwood (Alt.), Colorado Industrial Commission |

| National Bureau of Standards, U. S. Department of Commerce | Stanley W. Gerner |

| National Machine Tool Builders Association | Harold S. Sizer, Brown & Sharpe Mfg. Co. W. Atkinson, Jr. (Alt.), NMTBA |

| National Metal Trades Association | Emile Couture, Brown & Sharpe Mfg. Co. |

| National Safety Council | E. O. Kumler, TRW Inc. Joseph VanSickle (Alt.) |

| Power Tool Institute, Inc. | J. L. Bennett, The Black & Decker Mfg. Co. Peter Rebechini (Alt.), Skil Corp. |

| U. S. Department of Labor | Stanley J. Butcher, Bureau of Labor Standards James M. Meagher, Jr. (Alt.) |

This 1970 revision of the B7 Safety Code continues the two-column format to provide supporting information for the regulations.

The material in the left column is confined to code regulations only and is so captioned. These regulations are printed in distinctive bold type to indicate their authority without question. Where a condensed document is required (e.g. for State Code adoption), the material in the left column together with supporting tables and sketches can be used as a complete code.

The right column, captioned “Explanatory Information,” offers basic reasons for each rule to encourage compliance. Material appears in this second column only when it clarifies the regulation. This column should not be construed as being a part of the American National Standard Safety Code For The Use, Care And Protection of Abrasive Wheels B7.1-1970.

Operating rules (safe practices) are not included in either column of this Safety Code unless they are of such nature as to be vital safety requirements, equal in weight to other requirements included in the Code.

viThis code sets forth rules and specifications for safety in the use of abrasive wheels, excluding natural sandstone, including specifications for safety guards, flanges, chucks and rules for the proper storage, handling, mounting and use of grinding wheels.

Metal, wooden, cloth or paper discs, having a layer of abrasive on the surface, are not included.

Explanatory Information

(NOT PART OF ANSI CODE)

This column will offer reasons for the rule, to encourage compliance. Material will appear in this column only when it will clarify the regulations. (Not including tables or sketches.)

The word “shall” where used is to be understood as mandatory and “should” as advisory.

Explanatory Information

(NOT PART OF ANSI CODE)

The sketches and photographs used in this publication are classified as “Figures” or “Illustrations.” The items listed as “Figures” are applicable to the code regulations, while those listed as “Illustrations” apply to the explanatory information.

An abrasive wheel is a cutting tool consisting of abrasive grains held together by organic or inorganic bonds. Diamond and reinforced wheels are included.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 1

Examples of the various types of abrasive wheels included in this Code.

Organic wheels are wheels which are bonded by means of an organic material such as resin, rubber, shellac or other similar bonding agent.

Inorganic wheels are wheels which are bonded by means of inorganic material such as clay, glass, porcelain, sodium silicate, magnesium oxychloride, or metal. Wheels bonded with clay, glass, porcelain or related ceramic materials are characterized as “vitrified bonded wheels”.

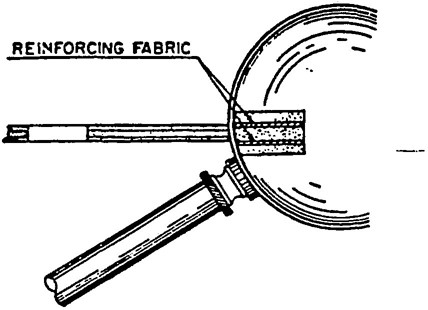

1The term “Reinforced” as applied to grinding wheels shall define a class of organic wheels which contain strengthening fabric or filament.

The term “Reinforced” does not cover wheels using such mechanical additions as steel rings, steel cup backs or wire or tape winding. (See appendix A page 87 for additional protection devices.)

Explanatory Information

(NOT PART OF ANSI CODE)

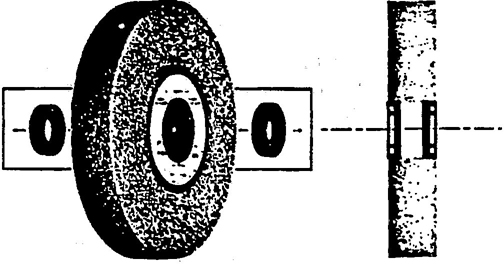

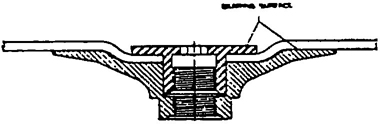

ILLUSTRATION No. 2.

Cross Section View One method of reinforcing organic bonded wheels.

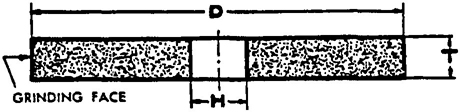

The grinding surface or face is the surface of the grinding wheel upon which grinding is performed.

Explanatory Information

(NOT PART OF ANSI CODE)

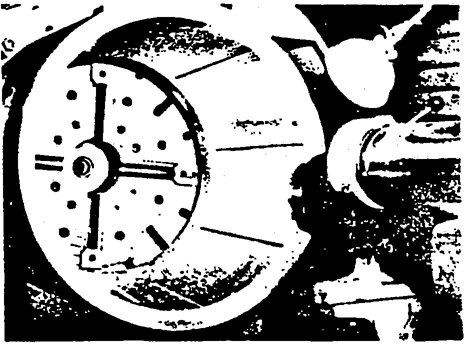

ILLUSTRATION No. 3

Arrow indicates grinding face.

A safety guard is an enclosure designed to restrain the pieces of the grinding wheel and furnish all possible protection in the event that the wheel is broken in operation. See section 4 page 27 for full description.

Explanatory Information

(NOT PART OF ANSI CODE)

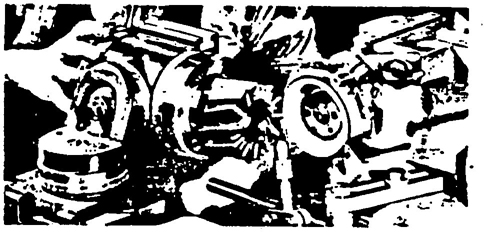

ILLUSTRATION No. 4

The safety guard affords operator protection in case of accidental breakage.

Wheel speed shall be computed from the free running speed of the machine spindle.

Explanatory Information

(NOT PART OF ANSI CODE)

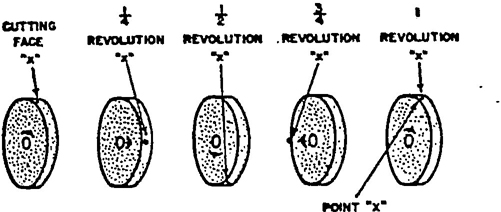

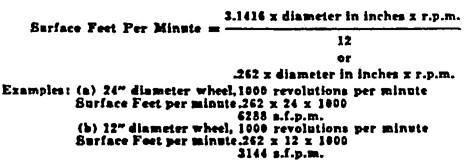

In Table 20 page 59, wheel speeds are classified in surface feet per minute (sfpm). Machine spindle speeds, however, are usually indicated in revolutions per minute. Therefore, one must have a clear understanding of how these two are related.

ILLUSTRATION No.5

Point ‘x’ has traveled a distance equal to the circumference of the wheel. (3.1415 x diameter)

Revolutions per minute (rpm) is the number of complete turns that a grinding wheel makes in one minute.

Surface feet per minute (sfpm) is the distance in feet any one abrasive grain on the peripheral surface of a grinding wheel travels in one minute.

Explanatory Information

(NOT PART OF ANSI CODE)

Surface feet per minute (sfpm) is the distance in feet any one abrasive grain on the cutting face travels in one minute. In Illustration No. 5 the point “x” on the cutting face travels, for every complete turn, a distance equal to the circumference, (3.1416 x diameter). Since the diameter of a grinding wheel is usually indicated in inches, it is necessary to divide the result by 12 in order to obtain the number of “surface feet per minute”.

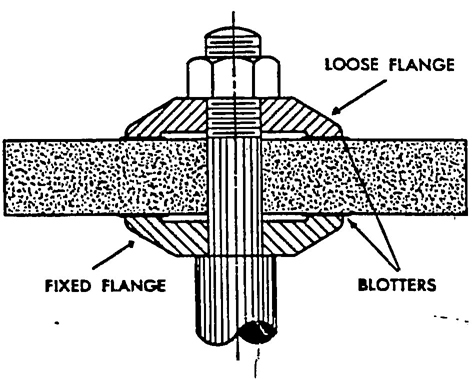

Flanges are collars, discs or plates between which wheels are mounted and are referred to as adaptor, sleeve, or back up type. See section 5 page 42 for full description.

Steel rings may be molded into certain organic bonded grinding wheels in manufacture. Where used, such rings act mainly to add rigidity to the wheel as it approaches discard size and to help retain the pieces of the wheel should accidental breakage occur at stub size. See Appendix A page 87.

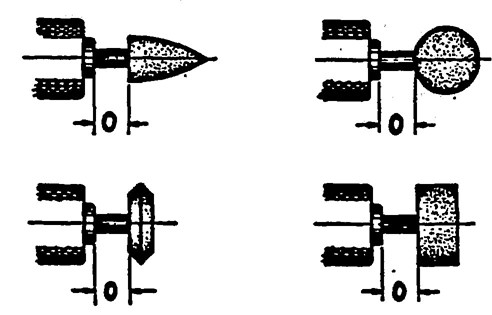

3Cup back, inserted type, round knurled and prong anchor bushings as shown in Illustration 6 are generally molded on types 6 and 11 organic bonded cup wheels.

Bushings of round, hexagonal, square or similar designs may be cemented or molded into the wheel holes. Including cone and plug wheels.

Adequate safety guards shall always be used with these wheels unless specifically excepted, by the code. See section 4 page 27 and Appendix A page 87.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 6

Hexagonal, prong anchor, round knurled and cup back bushings.

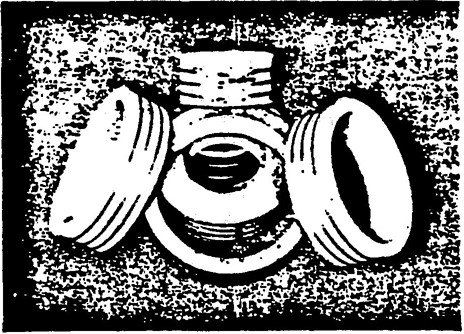

Reducing bushings are inserts or devices used to reduce the hole size in a grinding wheel so that it can be mounted correctly on a smaller diameter spindle. Reducing bushings shall be specifically designed, properly manufactured and fitted for use in grinding wheels as specified in paragraph 3.11, page 24. Minimum hole size as shown in Table 1 page 22 should not be violated nor should the bushing ends interfere with proper seating of the mounting flange or flanges. (See section 6 page 52.) Reducing bushings shall not be used to permit the operation of a grinding wheel in excess of its maximum operating speed.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 7

One type of reducing bushing commonly used to reduce a grinding wheel hole size.

Tape or wire winding as used on the periphery of cylinder, cup or segmented disc wheels helps to retain the pieces of the wheel should accidental breakage occur. See Appendix A page 87.

A chuck is a fixture designed to hold abrasive segments or certain types of grinding wheels and is mounted on a machine spindle or machine face plate.

Any individual, partnership, corporation or other form of enterprise which manufactures any kind of a abrasive wheel.

4Any individual, partnership, corporation or other form of enterprise which uses abrasive wheels and machines.

The precision grinding of the outer surface of any cylindrical work piece which is rotated by a regulating wheel and supported by a work blade.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 8

Typical through feed centerless grinding operation.

The sawing or grooving of any non-metallic material with an abrasive wheel.

5The slicing or parting of any material or part.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No.9

Cutting ordinary bar stock, using a resinoid bonded cutting-off wheel mounted on a dry, chopper type cutting-off machine.

The precision grinding of the outer surface of any cylindrical work piece which is supported at one or both ends.

The precision grinding of the inside surface of the hole in a work piece.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No.10

Internal grinding of a large bore cylinder.

The grinding of any material or part which is held in the operator’s hand.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 11

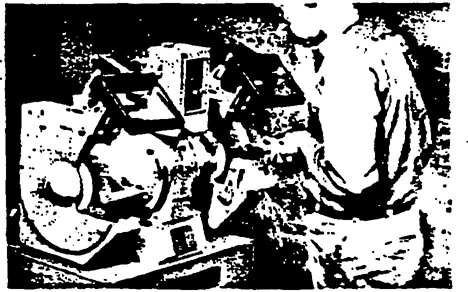

Off hand grinding on a double end pedestal grinder.

A grinding operation where the grinding machine is designed to be hand held and may be easily moved from one location to another.

Grinding operations performed by machines used to finish work parts to specified dimensions and finish requirements.

The shaping and/or sharpening of saw teeth by grinding.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 12

Sharpening the teeth (Saw Gumming) on a large band saw.

The grinding of a slot or groove in any material or part.

Grinding which removes relatively large amounts of material without regard to close tolerances or surface finish requirements.

The precision grinding of a plane surface.

The precision grinding or sharpening of various types of cutting tools.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 13

Grinding a shell end mill.

Removal, by grinding, of cement, mortar or other non-metallic jointing material.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 14

Tuck pointing using a reinforced organic bonded grinding wheel.

The following wheel shape definitions and limitations are safety code recommendations for general use and should be used wherever possible. Wheel dimensions or shapes differing from the standard recommendations below may be used on specific machines with the approval of the wheel manufacturer.

Explanatory Information

(NOT PART OF ANSI CODE)

When using non-standard wheels, it is often advisable for the user to consult the machine builder concerning special problems in mounting and guarding.

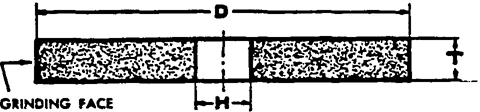

7Definition:

Type 1 straight wheels have diameter, thickness and hole size dimensions and should be used only on the periphery. Type 1 wheels shall be mounted between flanges, see section 5 page 42.

Limitation:

Hole dimension (H) should not be greater than two-thirds of wheel diameter dimension (D) for precision, cylindrical, centerless or surface grinding applications. Maximum hole size for all other applications should not exceed one-half wheel diameter. Inorganic wheels used in snagging operations should have a maximum hole size of not more than one quarter of the wheel diameter.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 15

Type I — Straight Wheels Peripheral grinding wheel having a diameter, thickness and hole.

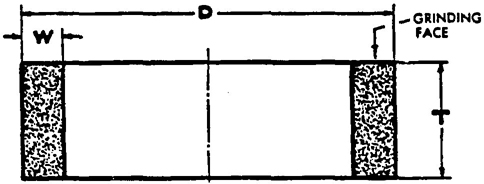

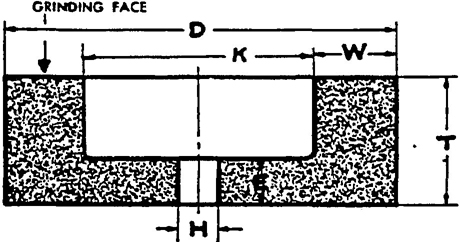

Definition:

Type 2 cylinder wheels have diameter, wheel thickness and rim thickness dimensions. Grinding is performed on the rim face only, dimension W. Cylinder wheels may be plain, plate mounted, inserted nut or of the projecting stud type.

Limitation:

Rim height, T dimension, is generally equal to or greater than rim thickness, W dimension.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 16

Type 2 Cylinder Wheel Side girnding wheel having a diameter, thickness and wall — wheel is mounted on the diameter

Definition:

Abrasive discs have diameter, thickness and hole size dimensions. They are used in a manner similar to type 2 cylinder wheels. (See section 3.13 page 25 and 3.14 page 26.)

Limitation:

Wheel thickness, T dimension, must be less than rim thickness, W dimension.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 17

Typical example of the various abrasive disc wheels

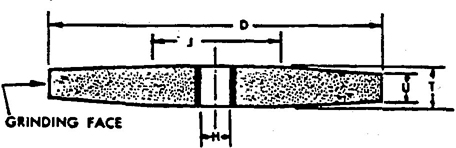

Definition:

Type 4 taper sided wheels have diameter, wheel thickness, grinding face thickness and hole size dimensions. Type 4 wheels have the same limitations on hole size and usage as type 1 wheels, definition 1.4.1 page 8.

Limitation:

Grinding face, thickness dimension U, must be equal to or greater than one half T dimension. J dimension shall be large enough to accommodate suitable flanges. If tapered safety flanges are used, J dimension and degree of taper required shall be determined by the wheel manufacturer.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 18

Type 4 — Taper Sided Wheels Peripheral grinding wheel having a diameter, wheel thickness grinding face thickness and hole size dimensions

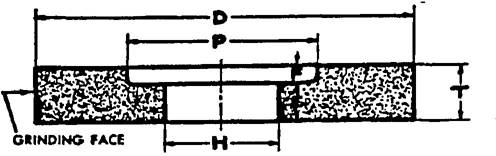

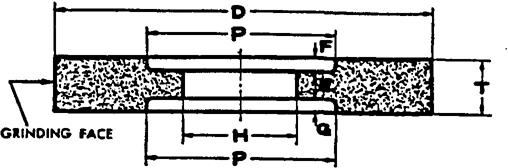

Definition:

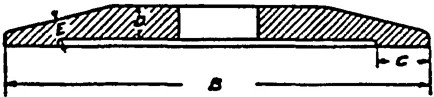

Type 5 recessed one side wheels have diameter, thickness and hole size dimensions and in addition also have a recess diameter and depth dimension. Type 5 wheels are subject to the same limitations of use and mounting as type 1 wheels definition 1.4.1 page 8 and section 6 page 52.

Limitation:

Type 5 wheels are subject to the same limitation of hole size as type 1 wheels definition 1.4.1 page 8. In addition recess depth, F dimension, should not exceed 50% of wheel thickness, T dimension, and diameter of recess, P dimension, shall be large enough to accommodate a suitable flange as recommended in section 5 page 42.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 19

Type 5 — Wheel, recessed one side Peripheral grinding wheel having one side straight or flat and the opposite side recessed. Recessed wheels allow a wider faced grinding wheel to be used when the available mounting thickness (E) is less than the required overall thickness (T). The recess allows grinding clearance for the nut and flange.

Definition:

Type 6 cup wheels have diameter, thickness, hole size, rim thickness and back thickness dimensions, Grinding is always performed on rim face, W dimension.

Limitation:

Minimum back thickness, E dimension, should not be less than ¼ T dimension. In addition, when unthreaded hole wheels are specified, the inside flat, K dimension, must be large enough to accommodate a suitable flange, see flange recommendations, section 5 page 42.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 20

Type 6 — Straight-cup Wheel Side grinding wheel having a diameter, thickness and hole with one side straight or flat and the opposite side recessed. This type, however, differs from Type 5 in that the grinding is performed on the wall of the abrasive created by the difference between the diameter of the recess and the outside diameter of the wheel. Therefore, the wall dimension “W” takes precedence over the diameter of the recess as an essential intermediate dimension to describe this shape type.

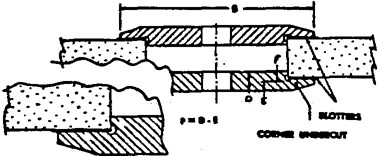

Definition:

Type 7 double recessed wheels have diameter, thickness and hole size dimensions and in addition also have recess diameters and depth dimensions. Type 7 wheels are subject to the same limitations of use and mounting as type 5 wheels, definition 1.4.5 page 9 and section 6 page 52.

Limitation:

Type 7 wheels are subject to the same limitation of hole size as type 1 wheels, section 1.4.1 page 8. In addition the combined depths of recess, F and G dimensions, should not exceed 50% of wheel thickness, T dimension.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 21

Type 7 — Wheel, recessed two sides Peripheral grinding wheels having both sides recessed to allow grinding clearance for both flanges or recessed so that unusually wide faced wheels may be mounted when the available mounting thickness (E) is less than the overall thickness (T)

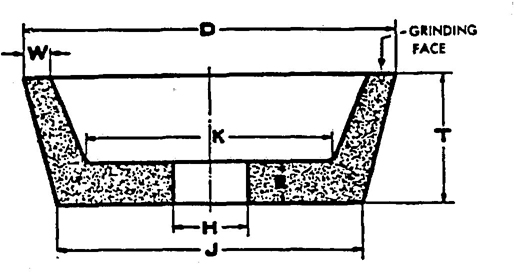

Definition:

Type 11 flaring cup wheels have double diameter dimensions D and J, and in addition have thickness, hole size, rim and back thickness dimensions. Grinding is always performed on rim face, W dimension. Type 11 wheels are subject to all limitations of use and mounting listed for type 6 straight sided cup wheels definition 1.4.6 page 9 and section 6 page 52.

Limitation:

Minimum back thickness, E dimension, should not be less than ¼ T dimension. In addition when unthreaded hole wheels are specified the inside flat, K dimension, shall be large enough to accommodate a suitable flange, see flange recommendations section 5 page 42.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 22

Type 11 — Flaring-cup Wheel Side grinding wheel having a wall flared or tapered outward from the back. Wall thickness at the back is normally greater than at the grinding face (W).

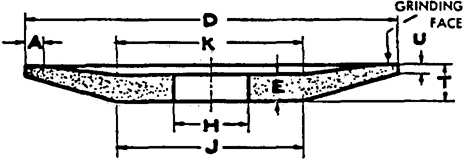

Definition:

Type 12 dish wheels have diameter, thickness, rim thickness and back thickness dimensions. In addition type 12 wheels always have a face thickness, U dimension. Grinding may be performed on both A and U dimensions.

Limitation:

Minimum back thickness, E dimension, should be equal to or greater than ½ wheel thickness, T dimension. If unthreaded hole wheels are specified K dimension shall be large enough to accommodate a suitable flange, see flange recommendations section 5 page 42.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 23

Type 12 — Dish Wheel Side grinding wheel known as a dish, differing from a Type 12 always has a “U” dimension. The “W” dimension of a type 11 becomes that “A” of a type 12. The grinding may be performed on the “U” face.

Definition:

Type 13 saucer wheels have diameter, thickness, hole size and back thickness dimensions. Grinding shall be performed on wheel periphery, U dimension, only.

Limitation:

Where unthreaded hole wheels are specified, J and K dimensions shall be large enough to accommodate suitable flanges, see section 5 page 42. In addition, wheel thickness shall be uniform throughout, U dimension should always equal E dimension.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 24

Type 13 — Saucer Wheel Peripheral grinding wheel known as a saucer, differing from a Type 12 in that the cross-section is equal throughout (U = E).

The face is always half-round with

Definition:

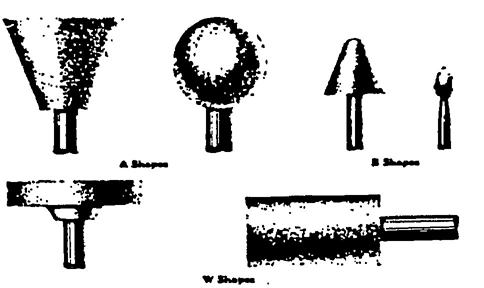

Type 16 cones have a curved side with a nose radius. Type 17 cones have straight sides with or without a nose radius. Types 18 and 18R plug wheels are cylindrical in shape with either a square or curved grinding end. Type 19 cone wheels are a combination of cone and plug type shapes and are usually specified where base dimension D in a type 17 cone would not provide an adequate cross section of abrasive. All types of cone and plug wheels are manufactured with blind hole threaded bushings and may be used on all surfaces except that flat mounting surface D.

Limitation:

Cone and plug type wheels are mounted by being screwed onto a threaded machine spindle so that surface D seats firmly against an unrelieved, flat back-up flange. (See section 3.12 page 24.) It is recommended that the maximum size or mass of the above cones and plugs be not greater than that of a 3” diameter by 5” long type 18 plug wheel.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 25

Various types of cone and plug wheels.

Definition:

[Illegible Text Omitted on Page 12] 20 through 26 relieved and/or recessed [Illegible Text Omitted on Page 12] have diameter, thickness, hole size, re-[Illegible Text Omitted on Page 12] diameter and depth dimensions and in [Illegible Text Omitted on Page 12] may be concaved on one or both sides. [Illegible Text Omitted on Page 12] 20 through 26 wheels are subject to the [Illegible Text Omitted on Page 12] limitations of use and mounting as type [Illegible Text Omitted on Page 12] definition 1.4.5 page 9 and section 6 [Illegible Text Omitted on Page 12] 52.

Limitation:

[Illegible Text Omitted on Page 12] relief depths shall be considered as [Illegible Text Omitted on Page 12] and added to straight recess depth or [Illegible Text Omitted on Page 12] for determination of total wheel recess [Illegible Text Omitted on Page 12]. Total recess depths should not exceed [Illegible Text Omitted on Page 12] of wheel thickness, T dimension.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 26

Various types of relieved and/or recessed wheels.

Definition:

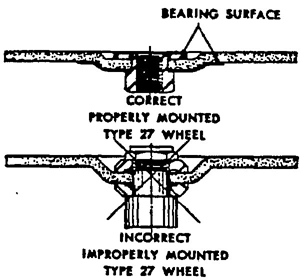

Types 27 and 28, depressed center wheels, have diameter, thickness and hole size dimensions. Both types are reinforced, organic bonded wheels having off-set hubs which permit side and peripheral grinding operations without interference with the mounting. Type 27 wheels are manufactured with flat grinding rims permitting notching and cutting operations. Type 28 wheels have saucer shaped grinding rims.

Limitation:

Special supporting, back adaptor and inside flange nuts are required for the proper mounting of these types of wheels, see section 6.15 page 56.

Mounts which are affixed to the wheel by the manufacturer may not require and inside nut and shall not be reused.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION NO. 27

Types 27 and 28 — Wheels, depressed center. Peripheral grinding wheel having an offset center and used on right angle head portable grinders. Grinding may also be done on the side of the wheel.

ILLUSTRATION NO. 28

Type 27A wheel showing typical mounting details.

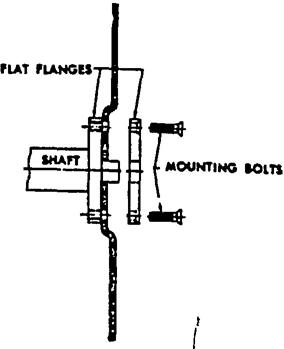

Type 27A depressed center, cutting-off wheels have diameter, thickness and hole size dimensions. They are reinforced, organic bonded, off-set hub type wheels, usually 16” diameter and larger, specially designed for use on cutting-off machines where mounting nut or outer flange interference cannot be tolerated.

Limitations

See section 5.1 page 42 and illustration 28 for mounting details.

13Definition:

Cutting off wheels have diameter, thickness and hole size dimensions and are subject to all limitations of mounting and use listed for type 1 wheels, definition 1.4.1 page 8 and section 6 page 52. They may be steel centered, diamond abrasive or organic bonded abrasive of the plain or reinforced type.

Limitation:

Cutting off wheels are recommended only for use on specially designed and fully guarded machines and are subject to the following maximum thickness and hole size limitations.

| Wheel Diameter | Max. Thickness |

|---|---|

| 6" and smaller | 3/16 " |

| Larger than 6" to 12" | ¼" |

| Larger than 12" to 23" | 3/8 " |

| Larger than 23" | ½" |

Maximum hole size for cutting-off wheels should not be larger than ¼ wheel diameter.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 29

A wet machine with horizontal movement for slabbing.

Definition:

Coping wheels are peripheral cutting wheels, and have diameter, thickness and hole size dimensions. They may be metal or organic bonded, solid or steel centered, and are subject to the same limitations of use and mounting as type 1 wheels, definition 1.4.1 page 8 and section 6 page 52.

Limitation:

Coping wheels are recommended for use only on specially designed and fully guarded machines.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 30

Slotting a block of marble to contour using a coping wheel.

Definition:

Tuck pointing wheels, usually type 1, reinforced organic bonded wheels have diameter, thickness and hole size dimension. They are subject to the same limitations of use and mounting as type 1 wheels definition 1.4.1 page 8 and section 6 page 52.

Limitation:

Wheels used for tuck pointing should be reinforced, organic bonded, (See paragraph 4.5.1, Exception B, page 32.)

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 31

Tuck pointing granite using a straight resinoid reinforced wheel.

Definition:

Mounted wheels, usually 2" diameter or smaller, and of various shapes, may be either organic or inorganic bonded abrasive wheels. They are secured to plain or threaded steel mandrels.

Limitation:

See section 10 page 69 for safe operation and speeds for mounted wheels.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 32

Typical examples of grinding wheels knows as mounted wheels.

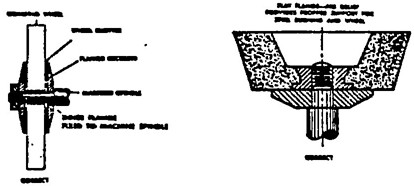

Threaded hole cup wheels types 6 and 11 are designed for use on vertical, right angle head, or flexible shaft portable grinders. They have one central threaded bushing, securely anchored in place. They are mounted by being screwed onto a threaded machine spindle so that the wheel back seats firmly against an unrelieved flat back flange.

Limitation:

Threaded hole cup wheel mounting should not be used with wheels larger 6” diameter. Back fianges used in mounting threaded hole cup wheels shall be flat and unrelieved.

Explanatory Information

(NOT PART OF ANSI CODE)

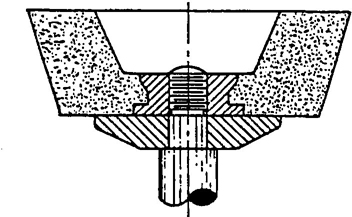

ILLUSTRATION NO. 33

A cup wheel with an inserted bushing. Note the bushing and abrasive are in uniform contact with the back flange.

ILLUSTRATION NO. 33A

A cup wheel with a prong anchor bushing. Note the bushing and abrasive are in uniform contact with the back flange.

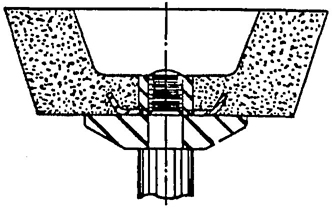

ILLUSTRATION NO. 34

Typical examples of modified types 6 and 11 wheels (terrazzo) showing taperred K dimensions.

Some type 6 & 11 cup wheels used in the terrazzo trade have tapered K dimensions to match a special tapered flange furnished by the machine builder.

Limitation:

These wheels shall be mounted only with a special tapered flange.

15All grinding wheels are breakable and therefore care shall be exercised in handling and storage to prevent damage. The following rules, which are based on experience, shall always be observed.

(a) Handle wheels carefully to prevent dropping or bumping.

(b) Do not roll wheels (hoop fashion).

(c) Use trucks or other suitable conveyances, which provide support and protection in transporting all wheels which cannot be carried by hand.

(d) Place wheels carefully on a shelf or rack or in bins, boxes or drawers.

Explanatory Information

(NOT PART OF ANSI CODE)

All grinding wheels must be handled carefully.

It should be realized that grinding wheels are necessarily manufactured in varying strengths to grind properly.

Some grinding wheels are stronger than others, but all grinding wheels can be broken by mishandling.

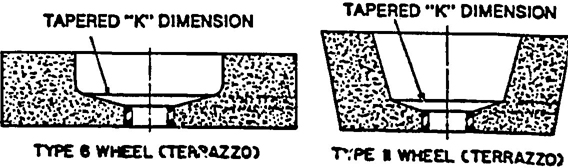

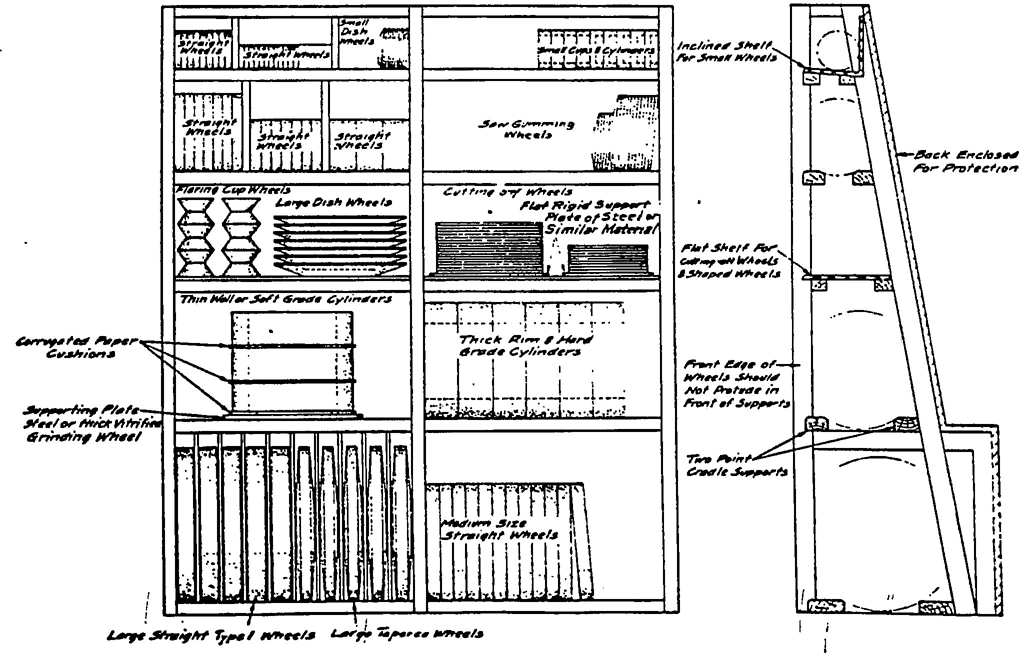

Suitable racks, bins, drawers or boxes shall be provided to store the various types of wheels used. (See Fig. 1,2 and 3 pages 17–18.)

Wheels shall not be stored subject to:

(a) Exposure to high humidity, water or other liquids.

(b) Freezing temperature.

(c) Any temperature low enough to cause condensation on the wheels when moving them from storage to an area of higher temperature.

Explanatory Information

(NOT PART OF ANSI CODE)

Grinding wheels must be protected while awaiting use. Wheel storage should be arranged to allow for removal of wheels without disturbing or damaging other wheels. Storage and records should also be set up to allow for wheel use on a rotational basis so that wheels will be in storage a minimum length of time. This minimizes the possibility of damage from lengthy storage. Such suitable storage should be available for partly used wheels as well as new wheels.

162.2 Storage

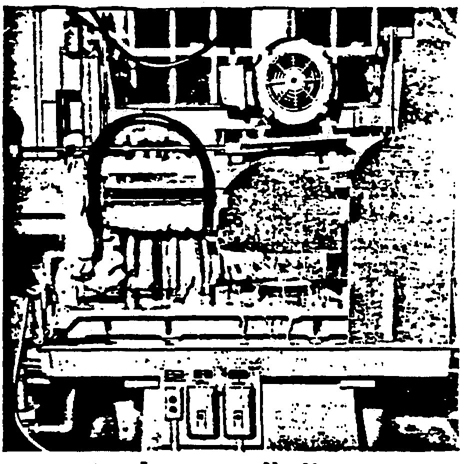

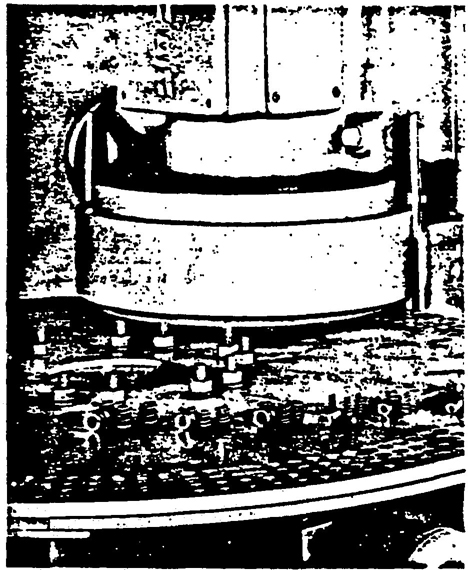

FIGURE NO. 1

A well-designed grinding wheel storage area used by a large industrial plant.

Explanatory Information

(NOT PART OF ANSI CODE)

Grinding wheel storage racks should be designed, constructed and located to fit the needs of the user. The following factors should be considered:

Location

All grinding wheels should be stored in a dry area in rooms not subject to extreme temperature changes since some bonds may be affected by excessive humidity, dampness and extreme temperature differentials. Racks should be located as near as practical to the grinding location, but never where there is danger of damage from passing trucks, crane handling or excessive vibration.

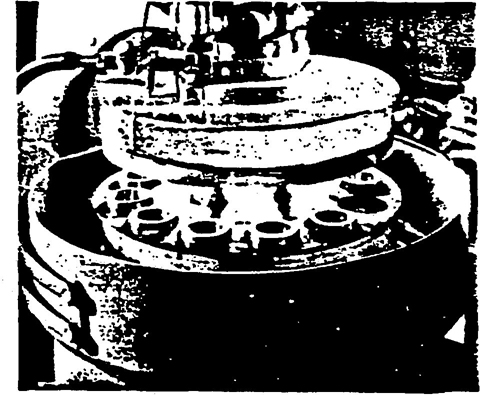

FIGURE NO. 2

This drawing illustrates a rack design which is suitable for handling a wide variety of grinding wheels.

2.2 Storage

FIGURE NO. 3

The various sizes and shapes of wheels are located in the racks so that they are easily accessible and protected from damage.

Explanatory Information

(NOT PART OF ANSI CODE)

Storage Methods

The racks, bins or drawers should be constructed so that each of the various types of wheels can, be stored in an orderly and safe manner. (See Fig. 2 page 17.) Wheel selection should be possible with a minimum of handling.

The selection of racks, bins, boxes or drawers for storage depends on the size and type of wheels. The following suggestions should be considered.

Thin organic bonded wheels such as those used for cutting-off should be laid flat on a flat surface of steel or similar rigid material away from excessive heat or moisture to prevent warpage. Not even blotters should be allowed between stacked thin wheels. If thin wheels are supplied with blotters attached, suitable separators should be used to preserve flatness.

Straight or tapered wheels (Types 1, 4, 5, 7, 13, 20, 21, 22, 23, 24, 25 and 26) of appreciable thickness are best supported in racks (see Fig. 2 page 17). Preferably the racks should provide a cushioned two-point cradle support to prevent the wheels from rolling. Partitions are helpful in facilitating wheel selection with a minimum of handling.

Cylinder wheels (Type 2), large straight cup wheels (Type 6), large dish wheels (Type 12) and large saucer wheels (Type 13) may be stacked on flat sides with some form of cushioning material between them; or they may be stored on edge like large straight wheels.

Flaring cup wheels (Type 11) are best stored as Illustrated in Fig. 2 page 17 to prevent chipping of edges.

Small wheels (approximately 4 inches or less in diameter). except flaring cup wheels (Type 11), are often stored in boxes, bins, or drawers.

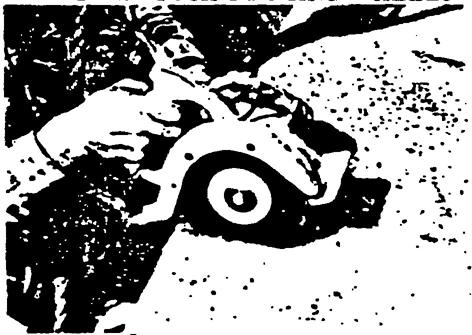

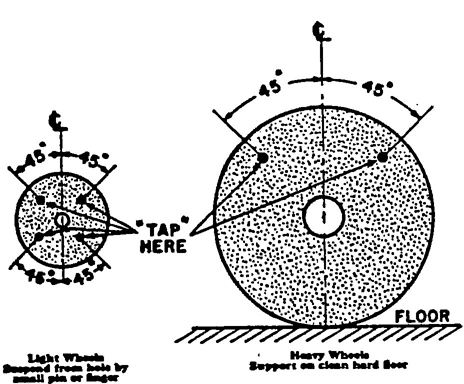

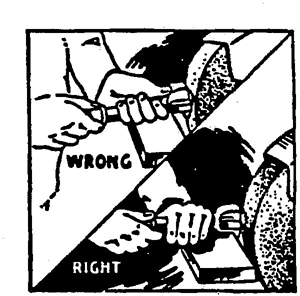

Immediately after unpacking, all wheels shall be closely inspected to make sure that they have not been damaged from handling, shipping or other causes. As an added precaution, wheels should be tapped gently with a light non-metallic implement, such as the handle of a screw driver for light wheels, or a wooden mallet for heavier wheels. If they sound cracked (dead), they shall not be used. This is known as the “Ring Test”. (see Figs. 4 and 5 page 19.)

Explanatory Information

(NOT PART OF ANSI CODE)

The first inspection should be made on the original shipping container. If there is visible evidence of damage to the container, special care must be used in the inspection of the wheels.

182.3 Inspection

Wheels must be dry and free from sawdust when applying the ring test, otherwise the sound will be deadened. It should also be noted that organic bonded wheels do not emit the same clear metallic ring as do vitrified and silicate wheels.

FIGURE NO. 4 FIGURE NO. 5

“Tap” wheels about 45 degrees each side of the vertical center line and about 1 or 2 inches from the periphery as indicated by the spots in Fig. 4 and Fig. 5.

Then rotate the wheel 45 degrees and repeat the test.

A sound and undamaged wheel will give a clear metallic tone. If cracked, there will be a dead sound and not a clear “ring.”

Explanatory Information

(NOT PART OF ANSI CODE)

“Ring Test”

If the wheel is not too heavy, it may be suspended from the hole on a small pin or the finger. (See III. No. 35.) Heavier wheels may be allowed to rest in a vertical position on a clean, hard floor.

“Tap” the wheel gently with a non-metallic implement such as a wooden screw driver handle for light wheels and a wooden mallet for heavy wheels. The best spot to “tap” a wheel for the ring test is about 45 degrees either side of the vertical center line and about 1 or 2 inches from the periphery. (See Figs. 4 and 5.)

ILLUSTRATION NO. 35

If struck directly along the vertical center line, the “ring,”, even in a sound wheel, is sometimes muffled and may give the erroneous impression that the wheel is cracked. This is especially true with large wheels which are supported on the floor when conducting this test. (See Fig. 5.) It is sometimes noticeable also when the wheel is suspended from the hole. It is recommended that the test be repeated after rotating the wheel 45 degrees to the right or left.

Repeat this “ring test” immediately before mounting-either a new or used wheel on a machine, especially if the wheel has been in storage or out of service for a considerable time. In making this test it must be realized that wheels bonded with organic material do not give forth the same clear metallic sound as do vitrified and silicate wheels. Also wheels must be dry and free from sawdust when applying the test, otherwise the sound will be deadened.

Comparison of the sound with other wheels of the same lot and specification will allow rejection of any wheel with a suspiciously different ring before use.

19It shall be the machine manufacturer’s responsibility to design, and the user’s responsibility to maintain, his machines for safe operating condition.

The following areas are important to fulfill these obligations.

Explanatory Information

(NOT PART OF ANSI CODE)

Grinding is a safe operation under normal conditions. Severe stresses can be set up in the wheel if established safe operating practices are not maintained. Only machines designed for the required spindle speed with suitable bearings to take the pressure and thrust of the grinding operation are recommended.

Proper maintenance of grinding machines is very important to insure safe operation. Grinding machine maintenance should be performed only by qualified personnel.

Grinding machines shall be equipped with safety guards in conformance with the requirements covered in section 4 page 27.

Explanatory Information

(NOT PART OF ANSI CODE)

Safety guards must be used on grinding machines to insure protection in case of an accidental wheel breakage. (See section 4.1 page 27 for exceptions.)

Grinding machines should be supplied with sufficient power to maintain the rated spindle speed under all conditions of normal operation.

Explanatory Information

(NOT PART OF ANSI CODE)

If the grinding wheel speed is reduced materially under normal grinding pressure, its cutting ability is decreased and excessive heat and pressure often result. Adequate power will avoid this hazard.

Stationary machines used for dry grinding should have provision made for connection to an exhaust system.

For detailed recommendations. Reference is made to “American National Standard For Ventilation Control of Grinding, Polishing and Buffing Operations (Z43.1).” Copies may be obtained from The American National Standards Institute.

Explanatory Information

(NOT PART OF ANSI CODE)

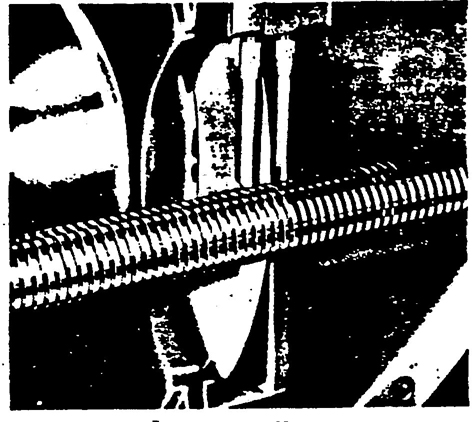

ILLUSTRATION No. 36

Note the excellent provisions employed to exhaust grinding dust.

Table 1 page 22 shows the minimum diameters of spindles which should be used for wheels of various sizes. It applies to machines where wheels are not mounted between bearings. The use of heavier spindles than those listed in this table is often desirable.

Explanatory Information

(NOT PART OF ANSI CODE)

Standard machine design generally conforms to the minimum spindle diameter requirements in Table 1 page 22. Investigation has shown that requests for wheels with undersize holes often result from the desire to use larger diameter wheels than were originally intended for the machine.

Grinding machines shall be equipped with flanges in accordance with the requirements listed in section 5 page 42.

Explanatory Information

(NOT PART OF ANSI CODE)

Proper selection, use and maintenance of flanges are all essential factors in the safe use of grinding wheels. See section 5 page 42.

On offhand grinding machines (see section 1.3.6 page 6), work rests shall be used to support the work. They shall be of rigid construction and designed to be adjustable to compensate for wheel wear.

Work rests shall be kept adjusted closely to the wheel with a maximum opening of ⅛ʺ to prevent the work from being jammed between the wheel and the rest, which may cause wheel breakage. The work rest shall be securely clamped after each adjustment. The adjustment shall not be made with the wheel in motion.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 37

This floor stand grinder has a work rest which is properly adjusted. Note the provisions for work-rest adjustment.

Grinding machines should be provided with a means of limiting the diameter of wheel which can be mounted. The safety guard is generally satisfactory for this purpose on single speed machines.

On variable speed machines, the speed shifting device should be connected with an adjustable guard or another diameter limiting device to prevent the mounting of a wheel which might run at higher than the recommended surface speed.

Explanatory Information

(NOT PART OF ANSI CODE)

On variable speed machines, a positive mechanical or manual regulation check should be maintained to avoid overspeeding another or full size wheel after the original wheel stub has been removed.

21| Thickness of Wheel, Inches | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diam- eter of Wheel |

Less Than 1/4″ |

¼ | ⅔ | ½ | ⅝ | ¾ | 1 | 1¼ | 1½ | 2 | 2¼ | 2½ | 2¾ | 3 | 3¼ | 3½ | 4 | 5 | 6 |

| ←Diameter of Spindle — Inches→ | |||||||||||||||||||

| 2 3 4 5 |

⅛ ¼ [Illegible Text Omitted on Page 22] ⅜ |

⅛ ¼ [Illegible Text Omitted on Page 22] ⅜ |

[Illegible Text Omitted on Page 22] ¼ ⅜ ⅜ |

[Illegible Text Omitted on Page 22] ⅜ ⅜ ½ |

¼ ⅜ ⅜ ½ |

¼ ⅜ ⅜ ½ |

⅜ ⅜ ⅜ ½ |

⅜ ⅜ ½ ½ |

⅜ ⅜ ½ ½ |

⅜ ½ ½ ½ |

⅜ ½ ½ ⅝ |

½ ½ ½ ⅝ |

½ ½ ⅝ ⅝ |

½ ½ ⅝ ⅝ |

½ ½ ⅝ ⅝ |

½ ½ ⅝ ¾ |

½ ⅝ ⅜ ¾ |

⅝ ⅝ ¾ ¾ |

⅜ ⅜ ¾ ¾ |

| 6 7 8 |

½ ½ ½ |

½ ½ ½ |

½ ½ ½ |

½ ½ ½ |

½ ½ ½ |

½ ½ ⅝ |

½ ½ ⅝ |

½ ⅝ ⅝ |

½ ⅝ ⅝ |

⅝ ⅝ ¾ |

¾ ¾ ¾ |

¾ ¾ ¾ |

¾ ¾ ¾ |

¾ ¾ 1 |

¾ ¾ 1 |

¾ ¾ 1 |

¾ 1 1 |

¾ 1 1 |

1 1 1 |

| 9 10 12 |

⅝ ⅝ ⅝ |

⅝ ⅝ ¾ |

⅝ ⅝ ¾ |

⅝ ⅝ ¾ |

⅜ ⅝ ¾ |

⅝ ¾ ¾ |

⅝ ¾ ¾ |

¾ ¾ ¾ |

¾ ¾ 1 |

¾ ¾ 1 |

1 1 1 |

1 1 1 |

1 1 1 |

1 1¼ 1¼ |

1 1¼ 1¼ |

1 1¼ 1¼ |

1¼ 1¼ 1¼ |

1¼ 1¼ 1½ |

1¼ 1¼ 1½ |

| 14 16 18 |

¾ ⅞ ⅞ |

¾ 1 1 |

¾ 1 1 |

¾ 1 1 |

¾ 1¼ 1¼ |

1 1¼ 1¼ |

1 1¼ 1¼ |

1 1¼ 1¼ |

1 1¼ 1¼ |

1 1¼ 1¼ |

1 1¼ 1½ |

1¼ 1¼ 1½ |

1¼ 1¼ 1½ |

1¼ 1½ 1½ |

1¼ 1½ 1½ |

1¼ 1½ 1½ |

1½ 1½ 1¾ |

1½ 1½ 1¾ |

1½ 1¾ 1¾ |

| 20 24 26 |

1 1 1 |

1 1 1 |

1 1 1 |

1 1 1 |

1¼ 1¼ 1¼ |

1¼ 1¼ 1¼ |

1½ 1½ 1½ |

1½ 1½ 1½ |

1½ 1½ 1½ |

1½ 1½ 1½ |

1½ 1½ 1¾ |

1½ 1½ 1¾ |

1½ 1½ 1¾ |

1½ 1¾ 1¾ |

1¾ 1¾ 2 |

1¾ 1¾ 2 |

1¾ 2 2 |

1¾ 2 2 |

2 2 2 |

| 30 36 |

1 1½ |

1½ 1¾ |

1½ 1¾ |

1½ 1¾ |

1½ 1¾ |

1½ 1¾ |

1½ 2 |

1½ 2 |

1¾ 2 |

1¾ 2 |

1¾ 2 |

1¾ 2 |

2 2¼ |

2 2¼ |

2 2¼ |

2 2½ |

2¼ 2½ |

2¼ 2¾ |

2¼ 2¾ |

| 40 44 48 |

1¾ 2 2¼ |

2 2½ 2¾ |

2 2½ 2¾ |

2 2½ 2¾ |

2 2½ 2¾ |

2 2¾ 2¾ |

2¼ 2¾ 2¾ |

2¼ 2¾ 3 |

2¼ 2¾ 3 |

2¼ 3 3 |

2½ 3 3½ |

2½ 3 3½ |

2½ 3 3½ |

2½ 3 3½ |

2¾ 3½ 3½ |

2¾ 3½ 3½ |

2¾ 3½ 3½ |

2¾ 3½ 3½ |

2¾ 3½ 4 |

| 53 60 72 |

2½ 2¾ 3 |

3 3½ 3½ |

3 3½ 3½ |

3 3½ 3½ |

3 3½ 3½ |

3½ 3½ 3½ |

3½ 3½ 3½ |

3½ 4 4 |

3½ 4 4 |

3½ 4 4 |

3½ 4 4½ |

3½ 4 4½ |

3½ 4 4½ |

3½ 4 4½ |

4 4 4½ |

4 4½ 5 |

4 4½ 5 |

4 5 6 |

4½ 5 6 |

| NOTE: For speeds exceeding those listed in Table 20 page 59, for unusually severe operations and for wheels with heavy mountings (such as bolted-on abra-[Illegible Text Omitted on Page 22]), the spindle sizes shown in the above table may not be [Illegible Text Omitted on Page 22] asmuch as the proper spindle size is dependent upon many factors, [Illegible Text Omitted on Page 22] design of the machine, type of bearings, quality of materials, [Illegible Text Omitted on Page 22] and application of wheel, a simple table is not practicable. [Illegible Text Omitted on Page 22] larger than specified by the machine manufacturer should not be used. | |||||||||||||||||||

If wheels or flanges are secured by means of a central spindle nut, the direction of the thread shall be in such relation to the direction of rotation that the nut will tend to tighten as the spindle revolves. The following rule will assist in determining the proper relationship:

“To remove the nut it must be turned in the direction that the spindle revolves when the wheel is in operation.”

Explanatory Information

(NOT PART OF ANSI CODE)

On double-end floor stands and bench grinders one end of the spindle must therefore have a right hand thread and the other a left hand thread. When re-assembling such machines after repairs, care shall be used to properly replace the spindle, with respect to direction of threads.

ILLUSTRATION No. 38

The direction of rotation of the cutting-off wheel is indicated by the arrow on the guard. This is also the direction the nut must be turned for removal.

If wheels are mounted by means of a central spindle nut and flanges, two conditions shall be maintained:

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 39

The spindle is of sufficient length to accommodate the wheel and flanges.

Grinding wheels shall fit freely on the spindle (wheel sleeves or adaptors) and remain free under all grinding conditions.

To accomplish this, the spindle or wheel mount shall be made to nominal (standard) size plus .000 minus .002 inches. The wheel hole shall be made suitably oversize to assure safety clearance under the conditions of operating heat and pressure.

Explanatory Information

(NOT PART OF ANSI CODE)

To avoid rupturing pressure in the wheel hole, the diameter of the spindle or wheel mount shall be kept within the limits of plus zero, minus. .002 inches. The hole in the wheel must be suitably oversize so that the wheel fits freely but not loosely under all operating conditions, to allow for expansion of the wheel spindle or mount caused by the heat of operation.

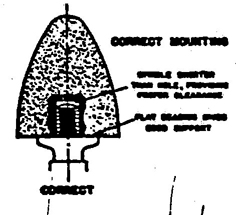

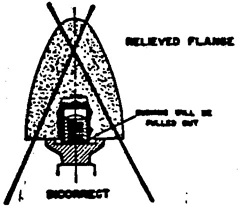

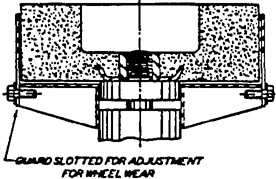

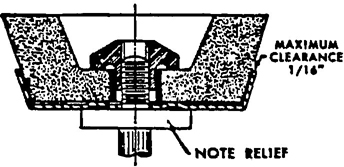

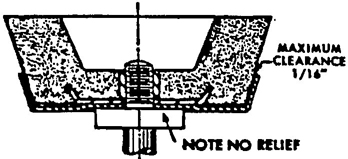

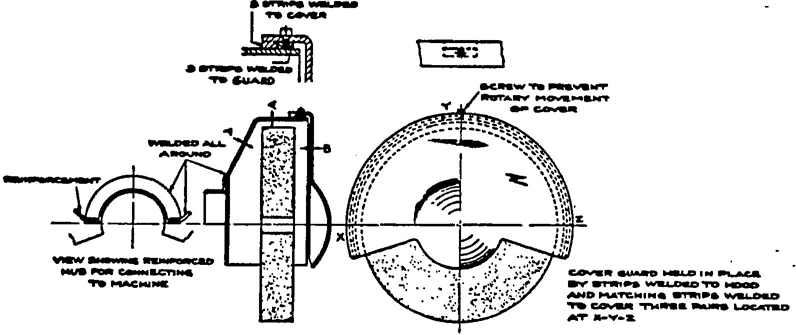

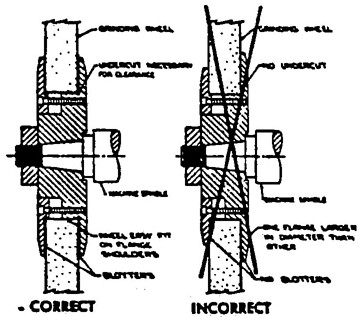

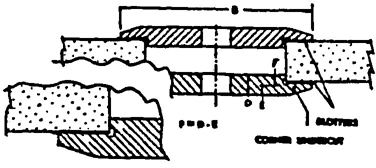

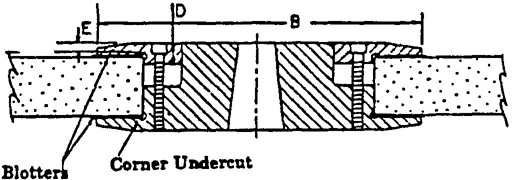

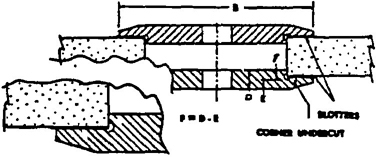

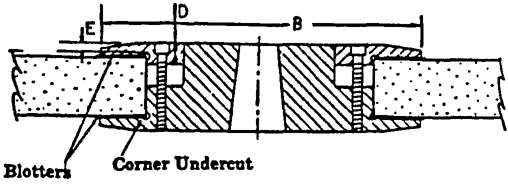

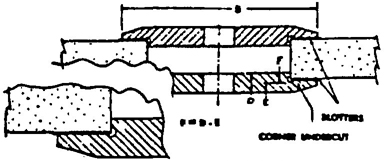

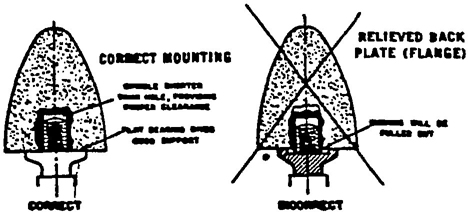

Machines on which threaded hole wheels are mounted shall be provided with spindles which are so threaded as to allow the wheel to be screwed firmly and flat against the back flange. (See Figs. 6 and 7.)

The back flange shall be flat, unrelieved, securely fastened and square to the spindle axis. (See III. 40.) The fixed back flange shall be of sufficient diameter to insure proper support to the wheel. (See Table 13 page 48.)

The direction of the thread shall be such that to remove the wheel it must be turned in the same direction that it rotates when in use.

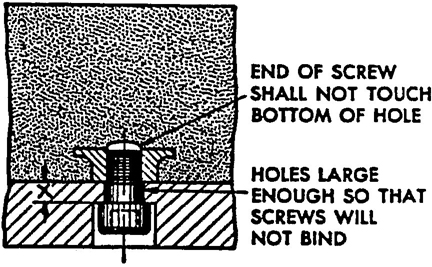

If threaded hole wheels are of cone or plug shape with blind holes, the length of the spindle and the depth of the hole shall be such that the end of the spindle shall not touch the bottom of the wheel hole.

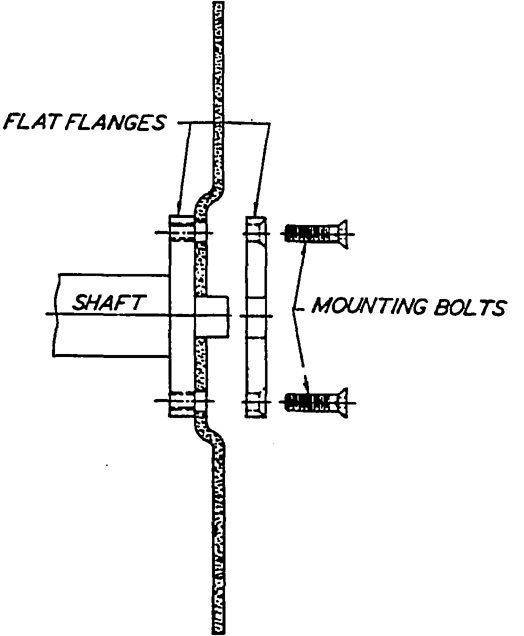

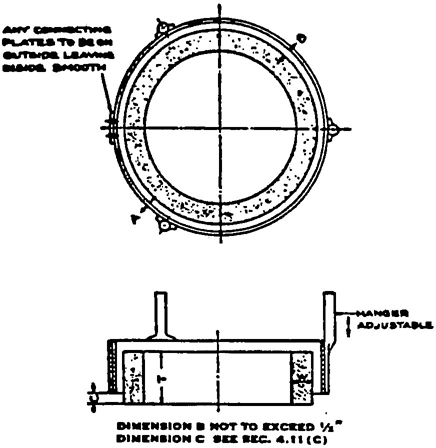

FIGURE No. 6

FIGURE No. 7

Explanatory Information

(NOT PART OF ANSI CODE)

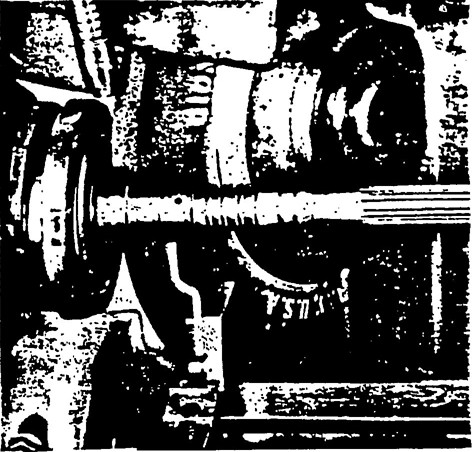

A relieved back flange shall not be used. If made with a relief, the flange will cause the bushing to be pulled out of the wheel, as shown in Illustration 40.

The fixed back flange should be perfectly flat and heavy enough to prevent distortion.

ILLUSTRATION No. 40

Unrelieved and relieved flange

If the spindle stops quickly when power is shut off, the energy stored in the spinning wheel may cause the wheel to unscrew from the spindle and “Spin Off” the machine.

To help prevent “spinning off” the threads on the machine spindle should be maintained in good condition and the wheel should be held in contact with the work piece until the wheel has stopped.

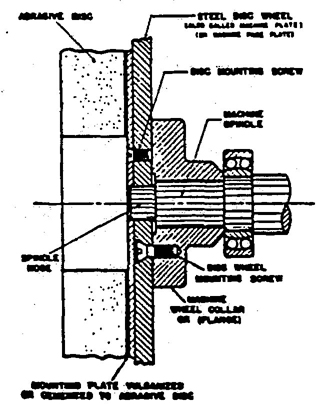

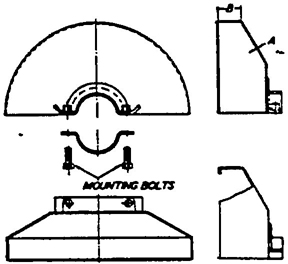

24Machines on which inserted nut wheels are mounted shall be provided with a steel disc wheel (machine face plate) of approximately the same diameter as the wheel, and of sufficient thickness to provide necessary support. Minimum steel disc wheel (machine face plate) thickness for disc grinders are shown in Table 2.

| Diameter Inches | Minimum Thickness Inches |

|---|---|

| 8 to 14 inclusive | ½ |

| 15 to 18 inclusive | ½ |

| 19 to 26 inclusive | ¾ |

| 27 to 36 inclusive | ⅞ |

| 37 to 40 inclusive | 1 |

| 41 to 72 inclusive | 1 ¼ |

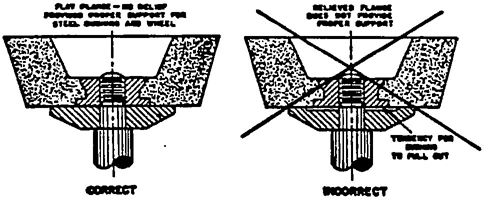

Screw holes in steel disc wheel (machine face plate) should be accurately located to match the threaded holes in the inserted nuts in the wheel, and shall be large enough so that the screws will not bind.

Dimension X (Fig. 8) shall be uniform for all holes so that screws can be used interchangeably.

FIGURE NO.8

Screws shall be of sufficient length to properly engage the threads in the inserted nuts, yet not so long that there will be any possibility of the ends touching bottom.

Explanatory Information

(NOT PART OF ANSI CODE)

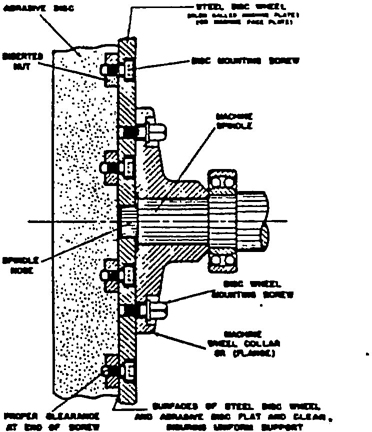

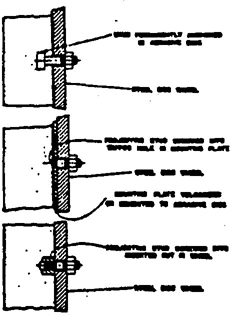

The following illustrations (Nos. 41, 42 and 43) will serve to clarify the differences which exist between the three types of mountings for abrasive discs, i.e. the inserted nut type, the inserted washer type, and the projecting stud type.

ILLUSTRATION No. 41

Inserted nut type abrasive disc

ILLUSTRATION No. 42

Inserted washer type abrasive disc.

3.13 Mounting of Abrasive Discs (Inserted Nut, Inserted Washer and Projecting Stud Type)

Steel disc wheels (machine face plates) shall be flat concentric and at a 90° angle as mounted to the machine spindle.

Explanatory Information

(NOT PART OF ANSI CODE)

Machine face plate and the mounting surface of the abrasive disc shall be maintained true, flat and clean. This is the user’s responsibility.

ILLUSTRATION No. 43

Various methods of mounting projecting stud or stud mounted type abrasive discs.

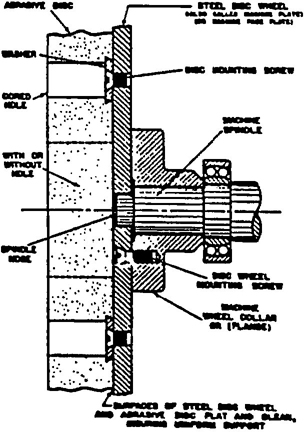

If the plates attached to the wheel are as thick or thicker than shown in Table 2 page 25, there are no special requirements as to the diameter and thickness of the steel disc wheel (machine face plate) on the machine.

If the plates attached to the wheel are thinner than shown in Table 2 page 25, the machine shall be equipped with a steel disc wheel (machine face plate) of sufficient diameter and thickness to provide adequate additional support. Minimum specifications are given in Table 3 for disc grinders.

| Abrasive Disc Diameter D (Inches) | Minimum Thickness Pt (Inches) |

|---|---|

| 12 and smaller | ¾ |

| 14 to 16 inclusive | ½ |

| 17 to 18 inclusive | ⅝ |

| 19 to 26 inclusive | ½ |

| 27 to 36 inclusive | ⅞ |

Explanatory Information

(NOT PART OF ANSI CODE)

A typical method of mounting a plate mounted type wheel is shown in Illustration No. 44. Note the additional reinforcement given the abrasive disc and the mounting plate by the steel disc wheel (machine face plate).

Even when plate mounted wheels are used, the machine face plate (steel disc wheel) should be the full diameter of the wheel where possible. The original thickness of the machine face plate should be thicker than minimum in Table 3 to allow for remachining to correct for wear.

ILLUSTRATION No. 44

Plate mounted type wheels.

All abrasive wheels shall be used only on machines provided with Safety Guards as defined in the following paragraphs of this section.

Exceptions: This requirement shall not apply to the following classes of wheels and conditions.

(1) Wheels used for internal work while with in the work being ground.

(2) Mounted wheels used in portable operations (see definition Sec 1.4.18 page 15) 2 inches and smaller in diameter.

(3) Types 16, 17, 18, 18R and 19 cones and plugs and threaded hole pot balls where the work offers protection.

Note: For additional forms of operator protection see Appendix A page 87.

Explanatory Information

(NOT PART OF ANSI CODE)

Exceptions to the use of safety guards are based on the impossibility of using these classes of wheels with conventional guards in place. In these cases, the work often forms a guard and the mass of the wheel is small. Face protection is particularly important when using this class of wheel.

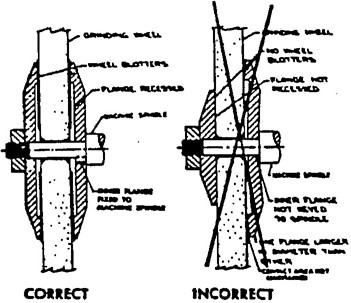

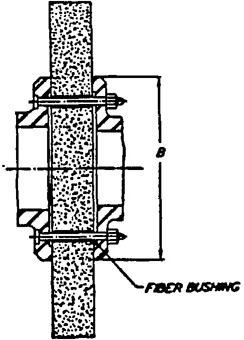

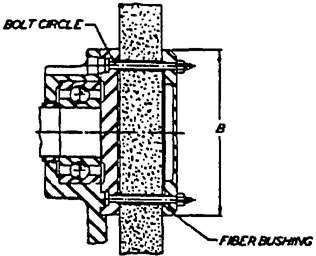

Cup wheels (Types 6 and 11) shall be protected by

(a) Safety Guards as specified in Sections 4.1 page 27 to 4.10 page 37 inclusive or

(b) Band Type Guards as specified in Sections 4.11 page 40 and 4.12 page 40 or

(c) Special “Revolving Cup Guards” which mount behind the wheel and turn with it. They shall be made of steel or other material with adequate strength and shall enclose the wheel sides upward from the back for ⅓ of the wheel thickness. The mounting features shall conform with all Code regulations. (See section 6 page 52.)

It is necessary to maintain clearance between the wheel side and the guard. This clearance shall not exceed 1/16 inch.

(d) Some other form of guard that will insure as good protection as that provided by the guards specified in (a) and (b) and (c).

Explanatory Information

(NOT PART OF ANSI CODE)

Cup wheels are available with either a threaded or unthreaded hole. Guards are available for each of these types. The following illustrations Nos. 45, 46 and 47, show the typical types manufactured. Each is shown mounted in conjunction with a guard.

ILLUSTRATION No. 45

Type 6 cup wheel showing band type guard.

ILLUSTRATION No. 46

An unthreaded hole cup wheel and revolving cup guard assembly. Note relief in guard which acts as a flange.

ILLUSTRATION No. 47

Type II cup wheel showing threaded prong-anchor bushing molded into back, and revolving cup guard. Note there is no relief between guard and wheel bushing.

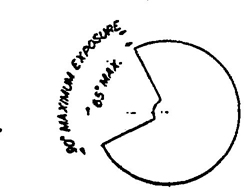

The maximum exposure angles specified in the following paragraphs shall not be exceeded.

Visors or other accessory equipment shall not be include as a part of the guard when measuring the guard opening, unless such equipment has strength equal to that of the guard.

Explanatory Information

(NOT PART OF ANSI CODE)

Maximum guard openings are based on the fact that the line of flight of broken wheel pieces will be tangential in the direction of rotation of the wheel. The maximum exposure angles must not be exceeded.

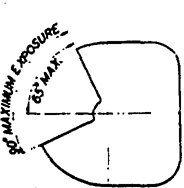

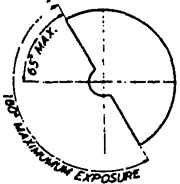

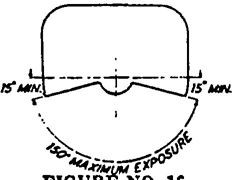

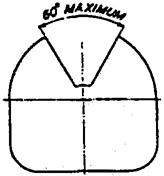

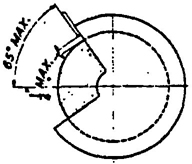

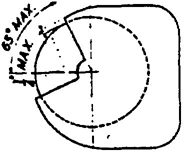

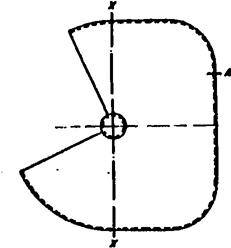

The angular exposure of the grinding wheel periphery and sides for safety guards used on machines known as bench and floor stands should not exceed 90 degrees or one-fourth of the periphery. This exposure shall begin at a point not more than 65 degrees above the horizontal plane of the wheel spindle. (See Figs. 9 and 10 and section 4.4 page 31.)

FIGURE NO. 9

FIGURE NO. 10

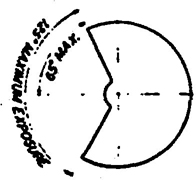

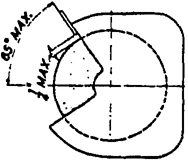

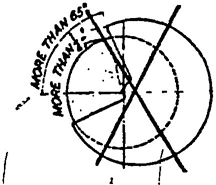

Wherever the nature of the work requires contact with the wheel below the horizontal plane of the spindle, the exposure shall not exceed 125 degrees. (See Figs. 11 and 12.)

FIGURE NO. 11

FIGURE NO. 12

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION NO. 48

An example of a well-designed guard for a bench grinder. Note that exposure does not exceed the 90° maximum stipulated.

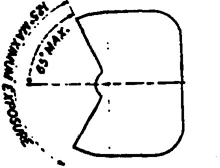

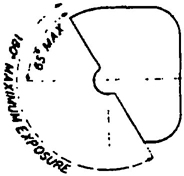

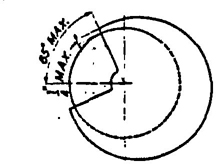

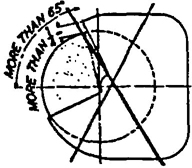

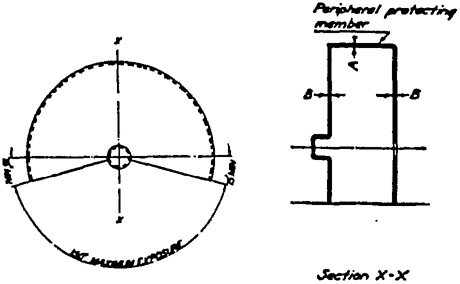

The maximum angular exposure of the grinding wheel periphery and sides for safety guards used on cylindrical grinding machines shall not exceed 180 degrees. This exposure shall begin at A point not more than 65 degrees above the horizontal plane of the wheel spindle. (See Figs. 13 and 14 and section 4.4 page 31.)

FIGURE NO. 13

FIGURE NO. 14

Explanatory Information

(NOT PART OF ANSI CODE)

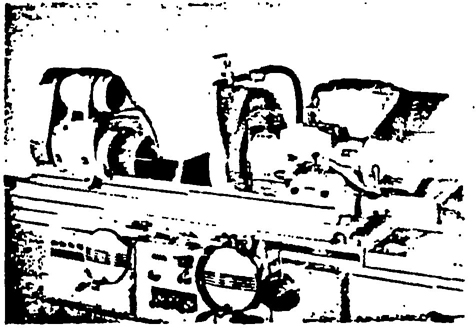

ILLUSTRATION No. 49

A Cylindrical grinding machine employing a well-designed guard.

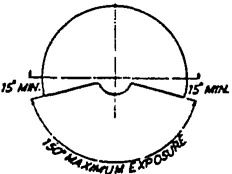

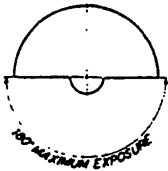

The maximum angular exposure of the grinding wheel periphery and sides for safety guards used on cutting-off machines and on surface grinding machines which employ the wheel periphery shall not exceed 150 degrees. This exposure shall begin at a point not less than 15 degrees below the horizontal plane of the wheel spindle. (See Figs. 15 and 16.)

FIGURE NO. 15

FIGURE NO. 16

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 50

This surface grinder has a well-designed guard conforming to basic requirements. The guard is so designed as to allow easy access to the wheel.

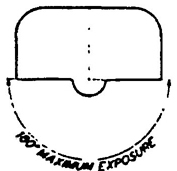

The maximum angular exposure of the grinding wheel periphery and sides for safety guards used on machines known as swing frame grinding machines shall not exceed 180 degrees, and the top half of the wheel shall be enclosed at all times. (See Figs. 17 and 18.)

FIGURE NO. 17

FIGURE NO. 18

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 51

This swing frame grinder has an excellent guard. Note that the guard encloses at least 180° of the wheel.

The maximum angular exposure of the grinding wheel periphery and sides for safety guards used on grinders known as automatic snagging machines shall not exceed 180 degrees and the top half of the wheel shall be enclosed at all times. (See Figs. 17 and 18.)

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No.52

The operator of a semi-automatic snagging machine easily controls movement of the grinder in all direction

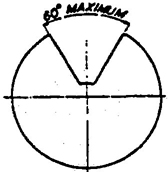

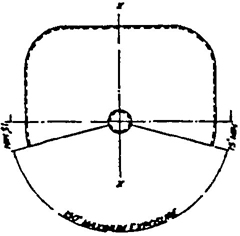

Where the work is applied to the wheel above the horizontal center line, the exposure of the grinding wheel periphery shall be as small as possible and shall not exceed 60 degrees. (See Figs 19 and 20.)

FIGURE NO. 19

FIGURE NO. 20

Safety guards used on machines known as right angle head or vertical portable grinders shall have a maximum exposure angle of 180 degrees, and the guard shall be so located so us to be between the operator and the wheel during use. Adjustment of guard shall be such that pieces of an accidentally broken wheel will be deflected away from the operator. (See Fig. 39 page 39.)

The maximum angular exposure of the grinding wheel periphery and sides for safety guards used on other portable grinding machines shall not exceed 180 degrees and the top half of the wheel shall be enclosed at all times. (See Figs. 17 and 18.)

Explanatory Information

(NOT PART OF ANSI CODE)

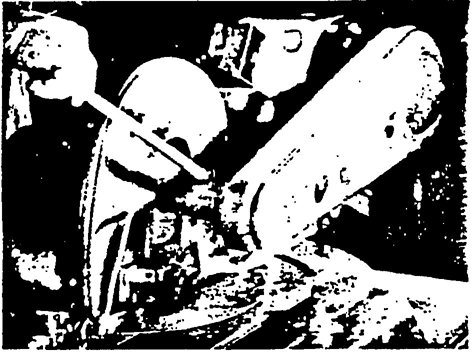

ILLUSTRATION No.53

A Type 27 reinforced wheel properly mounted and guarded on a vertical portable grinder.

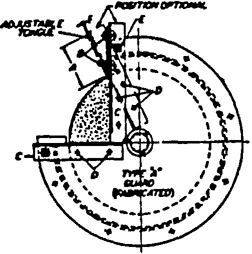

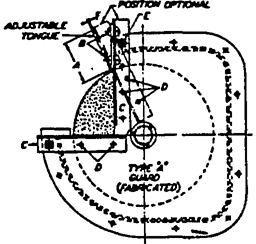

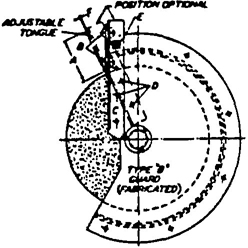

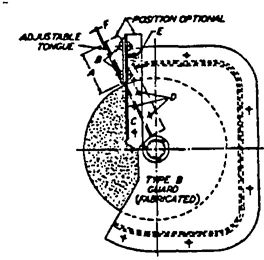

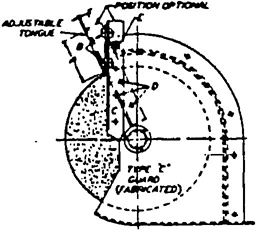

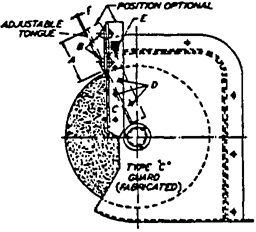

Safety guards of the types described in Rules 4.3.1 page 28 and 4.3.2 page 29 where the operator stands in front of the opening, shall be constructed so that the peripheral protecting member can be adjusted to the constantly decreasing diameter of the wheel. The maximum angular exposure above the horizontal plane of the wheel spindle as specified in Rules 4.3.1 page 28 and 4.3.2 page 29 shall never be exceeded, and the distance between the wheel periphery and the adjustable tongue or the end of the peripheral member at the top shall never exceed ¼ inch. (See Figs. 21, 22, 23, 24, 25 and 26.)

FIGURE NO. 21

FIGURE NO. 22

CORRECT

Showing adjustable tongue giving required angular protection for all sizes of wheel used.

FIGURE NO. 23

FIGURE NO. 24

CORRECT

Showing movable guard with opening small enough to give required protection for smallest size wheel used.

FIGURE NO. 25

FIGURE NO. 26

INCORRECT

Showing movable guard with size of opening correct for full size wheel but too large for smaller wheels.

Explanatory Information

(NOT PART OF ANSI CODE)

Figures 21, 22, 23 and 24 show two satisfactory methods of accomplishing exposure adjustment. These sketches are for purposes of illustration only. Other methods that agree with the basic rule are also acceptable. Figures 25 and 26 show a condition that does not comply with the requirements.

31The safety guard shall cover, the spindle end, nut, and flange projections. The safety guard shall be mounted so as to maintain proper alignment with the wheel, and the strength of the fastenings shall exceed the strength of the guard.

Exception A — Safety guards on all operations where the work provides a suitable measure of protection to the operator, may be so constructed that the spindle end, nut, and outer flange are exposed; and where the nature of the work is such as to entirely cover the side of the wheel, the side covers of the guard may be omitted.

Exception B — The spindle end, nut and outer flange may be exposed on machines designed as portable saws. (See paragraph 1.4.17, page 14.)

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 54

An example of a well-designed guard for a bench grinder. Note the side member of the guard is readily removed for access to wheel.

The nature of many operations requires that adjacent personnel other than the operator be afforded protection.

Such protection should take the form of an enclosure which isolates the operation from the remaining working area.

Heavy wire screen, corrugated iron, steel sheet or other suitable material may be used in its construction.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION No. 55

Notice the protective screen placed around the grinding area. This auxiliary enclosure isolates the grinding area from the remainder of the plant.

See Figures 33 and 34 and Table 5 page 36 for minimum basic thickness of peripheral and side members for various types of safety guards and classes of service.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION NO. 56

This cutting-off machine is employing a wheel less than is inches in diameter and is operating at a speed less than 16,000 surface feet per minute Note excellent case iron guard.

ILLUSTRATION NO. 57

This cutting-off machine has a wheel larger than 16 inches diameter and is operating at a speed less than 14,200 surface feet per minute. Note complete enclosure of wheel by the fabricated safety guard.

ILLUSTRATION NO. 58

Note the heavy cast iron safety guard completely enclosing the cutting-off wheel.

If operating speed does not exceed 8,000 surface feet per minute cast iron safety guards, malleable iron guards or other guards as described in paragraph 4.6.2. shall be used.

Cast steel, or structural steel, safety guards as specified in Table 5 page 36 shall be used where operating speeds of wheels are faster than 8,000 surface feet per minute up to a maximum of 16,000 surface feet per minute.

If materials other than those listed in Table 5 page 36 are used, the thickness of the peripheral and side members shall be such that the resultant safety guard will be as strong or stronger than a similar guard constructed according to Table 5 page 36.

1. For cutting-off wheels* 16 inches diameter and smaller and where speed does not exceed 16,000 surface feet per minute, cast iron or malleable iron safety guards as specified in Table 5 page 36 or other safety guards providing equal or better protection shall be used.

2. For cutting-off wheels* larger than 16 inches diameter and where speed does not exceed 14,200 surface feet per minute, fabricated safety guards as specified in Table 6 page 37 or other safety guards providing equal or better protection shall be used.

3. For thread grinding wheels not exceeding 1 inch in thickness cast iron or malleable iron safety guards as specified in Table 5 page 36 or other safety guards providing equal or better protection shall be used.

*See section 1.4.15 page 14 for cutting-off wheel definition.

33The minimum thickness specifications shown in Tables 5 page 36 and 6 page 37 are based on the following material specifications of the American Society for Testing Materials.

(Excluding specifications for rivet steel.)

Note: Copies of the above listed specifications may be procured at a nominal price from the American Society for Testing Materials, Philadelphia, Pennsylvania.

Other materials having at least equal strength properties and which lend themselves equally well to the desired type of construction may also be used.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION NO. 59

Close-up view of thread grinding wheel. Note the excellent safety guard.

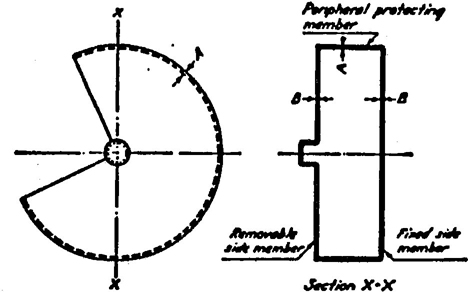

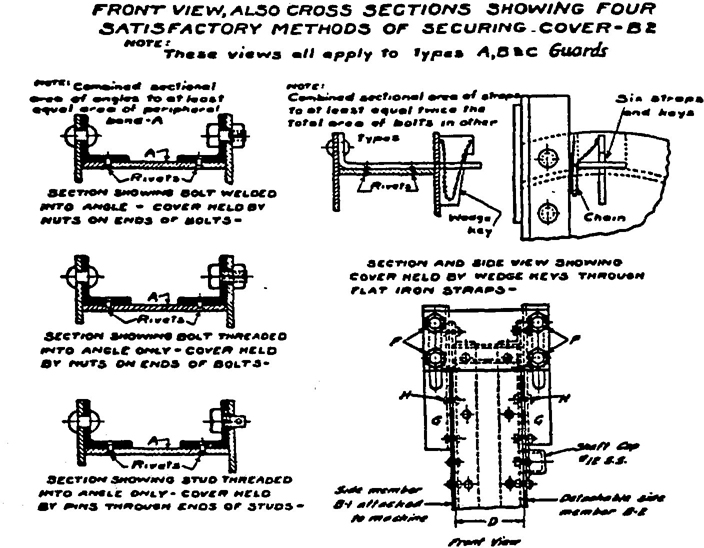

Guides for the construction of fabricated guards of structural steel are shown in Figs. 27 to 32 inclusive and in Table 4 page 35. Two designs are shown. Other designs affording equal or better protection are also acceptable.

The requirements given in Column A of Table 4 page 35 shall apply also to cast guards and in such cases, where the tongue is held by bolts, Column B shall also apply.

Table 7 page 38 may be used as a guide in determining the spacings and size of rivets, bolts and studs to provide satisfactory connections. Any means of fastening shall be considered satisfactory if, when assembled, it has strength at least equal to the tensile strength of the members being joined.

Explanatory Information

(NOT PART OF ANSI CODE)

ILLUSTRATION NO. 60

The fabricated safety guards is easily identifiable by the rivets, bolts and welds used in its assembly.

FIGURE NO. 27

FIGURE NO. 28

FIGURE NO. 29

FIGURE NO. 30

FIGURE NO. 31

FIGURE NO. 32

See Section 3-4 page 20 for Exhaust Provision.

| A | B | C | D | E | F | G* | H* | |

|---|---|---|---|---|---|---|---|---|

| Diameter of wheel Inches |

Length of Tongue Inches |

Diameter of Bolts Medium-Carbon Queeched & Tempered Inches |

Size of Angle Supports Tongue and Rest Inches |

Diameter of Rivets for Supports Inches |

Diameter of End Connected Bolts Inches |

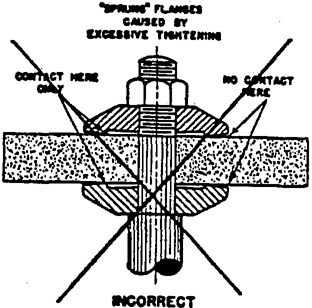

Thickness of Tongue Inches |