517

ALLISON v. TRUSTEES OF NEW YORK & BROOKLYN BRIDGE.

Circuit Court, S. D. New York.

December 23, 1886.

PATENTS FOR INVENTIONS—NO. 105,290—PIPE COUPLINGS—SCOPE OF CLAIM-INFRINGEMENT.

The claim of letters patent No. 105,290, granted July 12, 1870, relating to an improvement in pipe couplings, is for rods or tubes “having tapering ends, and tapering threads upon the same, in combination with a sleeve having tapering sockets, and threads corresponding to those of the rods.” Held, that the terms “tapering ends” and “tapering sockets,” considered in connection with the descriptive part of the specification, are to be interpreted as describing a rod with a tapering screw, and a socket with a tapering chamber, and that the patent is not infringed by a coupling using rods in which the threads of the screw surround a cone-shaped stem, but the exterior lines of the threads form a cylinder, and not a cone-shaped or tapering end or screw, and in which the exterior lines of the sleeve form a cylindrical chamber, and not a cone-shaped or tapering chamber.

Suit for Infringement of Patent.

George Harding, for complainant.

Bergen & Dykman and Witmore & Jenner, for defendants.

WALLACE, J. The only issue between the parties is whether the rod coupling of the defendants is an infringement of letters patent No. 105,290, 518granted to the complainant, July 12, 1870, for an improvement in pipe couplings. The object of the invention described in the letters patent is to effect a perfect and secure junction of tubes, pipes, rods, etc., with a socket or sleeve designed to receive and retain them when the ends of two rods or pipes are brought into connection in the socket. The specification states that the invention “consists of a coupling in which tapering and vanishing screw-threads on the ends of the tubes, pipes, rods, etc., to be coupled together, are combined with a socket having internal vanishing and tapering screw-threads corresponding to those on the tubes, rods,” etc.

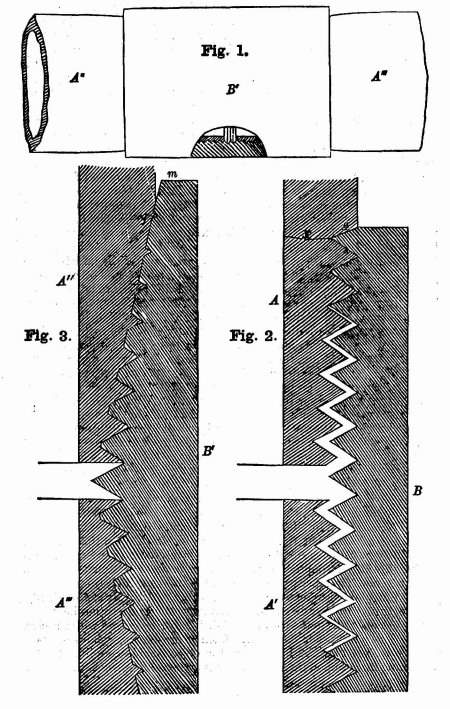

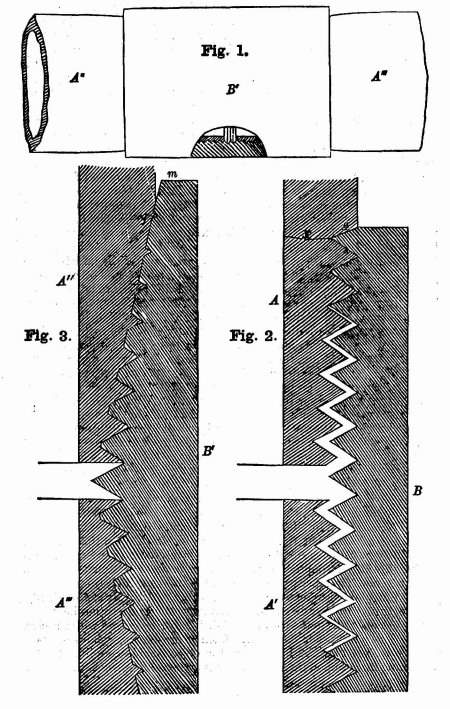

In the accompanying drawings, Fig. 1 represents an exterior view, partly in section, of the ends of two pipes coupled together according to the invention; Fig. 2 represents the ordinary mode of coupling pipes together; and Fig. 3 illustrates the advantages of the invention.

The specification states that—

“It has been usual to cut a slightly tapering screw on the ends of the adjoining tubes, while an internal screw or thread, without any taper, was formed in the socket; hence but a portion of this internal thread of the socket was in proper binding contact with the threads of the pipes, as is clearly shown in figure 2; the greater portion of the threads, both on the tubes and in the socket, being of no avail as a medium of effecting a tight junction of the tubes.”

After pointing out the defects in and objections to such screw couplings, the patentee proceeds in the specification as follows:

“In order to obviate these objections, I cut on the ends of the pipes, A´´ and A´´´(Figure 3.) a tapering screw. Instead of cutting the thread of this screw to one uniform depth, however, I so cut it that it shall gradually vanish until it disappears at the exterior of the tube as shown at Y, figure 3. It should be understood, however, that the thread of the screw does not vanish so abruptly as is shown in that figure, which is exaggerated, with the view of rendering more apparent the advantages of my invention. The socket, B, figure 3, instead of having a screw-thread cut through it as in figure 2, has two screw-threads, tapering, one in one direction for receiving the end of one tube, and the other in another direction for receiving the end of the other tube, the tapers of each screw corresponding with that of the tube which it has to receive, and the screw-thread vanishes to correspond with the vanishing thread of the tube, as clearly indicated in the drawing.”

The claim of the patent is as follows:

“The rods or tubes, A, A', having tapering ends and tapering threads upon the same, in combination with a sleeve having tapering sockets and threads corresponding to those of the rods, as set forth.”

The defendants contend that their coupling does not infringe this claim, because, although their tube is cut with a vanishing thread, and their sleeve has a vanishing thread to correspond to that of the tube, their coupling does not have a rod with a tapering end or screw, or a tapering socket. In their rods the threads of the screw surround a cone-shaped stem, but the exterior lines of the threads form a cylinder, and not a cone-shaped or tapering end or screw; and the exterior lines of their sleeve form a cylindrical chamber, and not a cone-shaped or tapering chamber.

519

520 The case turns wholly on the meaning of the term “tapering ends” and “tapering sockets,” as used in the claim. If these terms are to be interpreted as describing a rod with a tapering screw and a socket with a tapering chamber, the defendants do not infringe. If they describe a rod with a tapering stem having vanishing threads cut upon it, and a socket to correspond, infringement is established. It is entirely clear that the “tapering threads” of the claim are synonymous with the “vanishing threads” of the specification.

520 The case turns wholly on the meaning of the term “tapering ends” and “tapering sockets,” as used in the claim. If these terms are to be interpreted as describing a rod with a tapering screw and a socket with a tapering chamber, the defendants do not infringe. If they describe a rod with a tapering stem having vanishing threads cut upon it, and a socket to correspond, infringement is established. It is entirely clear that the “tapering threads” of the claim are synonymous with the “vanishing threads” of the specification.

The patentee was the first to combine in a coupling a sleeve and screw in which a vanishing male and female thread were made to correspond with each other. By doing this, he effected a more perfect metallic contact throughout between the socket and the screw, and made a more perfect and secure, joint than had been done before. The expert for the defendants admits that he knew of no instance in the state of the art in which a vanishing screw-thread cut upon a tapering mandrel or cone was combined with a tapering female thread cut upon the surface of a hollow cone prior to the date of the patent in question. The patentee was therefore entitled to claim broadly a sleeve or socket and screw in which a vanishing male and female thread were made to correspond with each other. But the question in this case is whether the terms of his claim, when interpreted, as they must be, by the specification, are not narrower than the real invention, and such as to enable the defendants to deny infringement. The claim by itself, so far as it relates to the rods, is capable of an interpretation which would fully cover the real invention. If a rod with a tapering end is to be regarded as a rod in which the stem of the screw is tapering, the claim is ample, and embraces the rod of the defendant. On the other hand, if the term “tapering end” is intended to describe a rod with a tapering screw,—that is, a rod in which the exterior lines of the screw-threads form a tapering end:,—the coupling of the defendant is not an infringement. A rod with a tapering end may mean a rod in which the stem, mandrel, or solid part of the end tapers, or it may mean one in which the end, screw-thread included, as adapted to be fitted into a sleeve or recess, is tapering. The term, as used in the claim, is therefore capable of two meanings; and, being ambiguous, the true meaning must be ascertained by resort to the descriptive part of the specification in order to discover what the patentee describes as new, and what the public have a right to understand was intended to be claimed.

An examination of the specification denotes quite plainly that the patentee supposed that the gist of his improvement upon the couplings previously in use consisted in substituting a tapering screw having vanishing threads, in conjunction with a sleeve or socket adapted to receive such a screw, for tapering screws without the vanishing thread, and a socket not adapted to receive a tapering screw. The drawings distinctly denote this. In describing the advantages of his invention he dwells upon the objections to the use of a “slightly tapering screw” with a socket which does not taper to receive it. Each of the drawings shows a tapering screw, but Fig. 2, which shows the objectionable coupling, has no vanishing thread upon the screw, and has no tapering recess in the socket, 521while Fig, 3, which illustrates the improvement, shows a tapering screw with a vanishing thread, and a tapering recess with a vanishing thread. Nevertheless, the inquiry is not what the patentee may have supposed, but what he has described, his invention to be. He states, in the general statement of the nature of his invention, that the tubes are to have “tapering and vanishing screw-threads,” not “tapering or vanishing.” He points out the objections to the use of a “slightly tapering screw” on the ends of the tubes in the old coupling, with a socket which did not taper to receive it. Then, in describing the difference between his coupling and the old one, he says that he cuts a “tapering screw” on the end of his tube; but, instead of cutting his threads at a uniform depth, he cuts them so that the thread shall vanish gradually until it disappears. He thus declares unequivocally that what he has done which is new is to make a tapering screw with a peculiar form of thread. The specification contains no suggestion to indicate that a rod having a tapering stem, but not a tapering screw, could be employed. Such a stem could not be employed with the socket described in the specification. The specification requires the ends, of the rod to be adapted to fit into a tapering recess, “as clearly indicated in the drawing.” The claim itself makes a sleeve having a tapering socket an element. A tapering socket is one adapted to receive a tapering screw. Read by the aid of the context, it does not seem open to fair doubt that the rods with tapering ends and tapering threads specified in the claim are rods with a tapering screw and vanishing threads upon the ends. Some significance should also be attached to the description of the rods in the claim by a reference to the drawings, which shows a rod with a tapering screw.

It follows that the bill must be dismissed.

This volume of American Law was transcribed for use on the Internet

through a contribution from Google.

520 The case turns wholly on the meaning of the term “tapering ends” and “tapering sockets,” as used in the claim. If these terms are to be interpreted as describing a rod with a tapering screw and a socket with a tapering chamber, the defendants do not infringe. If they describe a rod with a tapering stem having vanishing threads cut upon it, and a socket to correspond, infringement is established. It is entirely clear that the “tapering threads” of the claim are synonymous with the “vanishing threads” of the specification.

520 The case turns wholly on the meaning of the term “tapering ends” and “tapering sockets,” as used in the claim. If these terms are to be interpreted as describing a rod with a tapering screw and a socket with a tapering chamber, the defendants do not infringe. If they describe a rod with a tapering stem having vanishing threads cut upon it, and a socket to correspond, infringement is established. It is entirely clear that the “tapering threads” of the claim are synonymous with the “vanishing threads” of the specification.