Case No. 17,634.

29FED.CAS.—75

WILBUR v. BEECHER.

[2 Blatchf. 132; Merw. Pat. Inv. 203; 1 Fish. Pat. Rep. 401.]1

Circuit Court, N. D. New York.

Oct. 20, 1850.

PATENTS—UTILITY AND INVENTION—CONSTRUCTION OF SPECIFICATIONS—INFRINGEMENT—MEASURE OF DAMAGES—BARK GRINDING MILLS.

1. The invention covered by Montgomery and Harris' patent of the 12th of August, 1840, for an “improvement in the mill for breaking and grinding bark,” is a multiplication of the grinding chambers and apparatus in a mill of a given size, and which may still be driven by the same power as a mill of a single chamber.

2. It appearing that a mill constructed according to the specification of the patent, with three grinding chambers, would grind, when not in very rapid operation, say at a speed of 50 or 60 revolutions in a minute, a cord of bark an hour through the day, being double the quantity ground by the old single-chambered mill: Held, that that was evidence enough of the utility of the invention.

3. On the point of the utility of an invention, the question is not, whether the machine invented is the best one known to the community, nor whether it does its work better or faster than any other machine in the same department of labor, but whether it is, to a certain degree, useful.

[Cited in Hoffheins v. Brandt, Case No. 6,575; Stimpson v. Woodman, 10 Wall. (77 U. S.) 125; Gibbs v. Hoefner, 19 Fed. 324.]

11824. In this case, the thing discovered and described was the formation of grinding-chambers, by the combination of movable conical rings with stationary cylinders, these two pans being severally brought together and fastened by cross-bars; the particular description in the specification showed a mill with three grinding-chambers; but the claim was to the combination of stationary cylinders with one or more movable conical rings, thus allowing both cylinders and rings to be multiplied to any extent, or the mill to be limited to two cylinders and one ring: Held, that any further particular description in the specification was unnecessary, in order to enable a mechanic of ordinary skill to make a mill with more chambers than three.

5. A bark-mill that multiplies the grinding-chambers by a combination of movable conical rings with stationary cylinders is an infringement of Montgomery and Harris' patent.

6. The shape of the grinding-chambers and the form of the teeth in the mill are no part of the patented combination, and, therefore, although the defendant' mill, by a change in those points, grinds better and faster than the patented mill, yet, if it contains the combination of the movable conical nuts with the stationary cylinders, it is still an infringement.

7. The case of Parkhurst v. Kinsman [Case No. 10,757], cited and applied.

8. The plaintiff, in a patent suit for making and selling, is entitled to the actual damages he has sustained by the infringement, or, in other words, to the profits the defendant has made thereby; for the law presumes, that if the defendant had not put his machines into the market, the demand would have been for the plaintiffs, and he would have received the profits.

9. The difference between the actual cost of making a machine and its sale price is not all nominal profit; but the jury must take into account the interest on capital, the risk of bad debts and the expenses of selling, in arriving at the defendant's profits.

This was an action on the case [by Erastus Wilbur against Mather Beecher], tried before NELSON, Circuit Justice, for the infringement of letters patent granted to Richard Montgomery and Lewis W. Harris, of Sangerfield, Oneida county, New York, on the 12th of August, 1840, for an “improvement in the mill for breaking and grinding bark.” The plaintiff was the assignee of the patent for the state of New York.

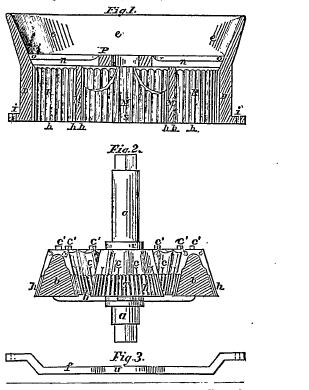

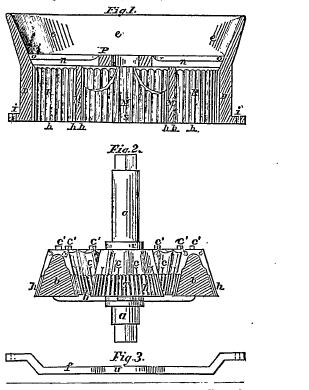

At the trial, the plaintiff gave in evidence the patent, with the specifications and drawings thereto annexed, from which it appeared that the bark-mill described and claimed in the specification was composed of alternate stationary and movable rings, placed concentrically, the opposing surfaces of the rings being provided with teeth; that the movable rings were connected together, and to a central shaft with which they revolved, by transverse arms or cross-bars; and that the stationary rings were also connected to each other by transverse arms. The rings, as connected and combined, formed a community of grinding chambers, consisting of two or any greater number, an increase in the number of chambers to any extent being effected by multiplying the number of rings, and connecting and combining them in the manner described in the specification.

2 [The specification and claims of the patent were as follows:

[“To all whom it may concern: Be it known that we, Richard Montgomery and Lewis W. Harris, of Sangerfield, in the county of Oneida and state of New York, having invented a new mode of breaking and grinding bark and other substances of a similar character, and we, do hereby declare that the following is a full and exact description thereof:

[“The nature of our invention consists in providing a mode of breaking and grinding bark and other substances of a like character, by means of hollow stationary cylinders, and one or more revolving conical nuts, placed concentrically in connection with teeth and pickers, the whole constructed, arranged, and combined, as hereinafter particularly described, the machine operating with the like facility and with the same effect, whether its revolutions are performed forward, or in a counter direction.

[“To enable others skilled in the art to which our invention appertains, or with which it is most nearly connected to make and use such invention, we will proceed to describe its construction and operation. The material parts of our machine are as follows, viz.: (1) A cylinder D, Fig. 1, which is hollow, the sides, within and without, are perpendicular to the base, the interior surface being provided with teeth. This cylinder is stationary. (2) Another cylinder M, Fig. 1, which is also hollow. Its sides, like those in the cylinder D, Fig. 1. are also perpendicular to the base, within and without, and are provided with teeth. This cylinder is also stationary. (3) A conical nut b, Fig. 2, which is hollow. The sides within and without, incline upward, each toward the other, at a corresponding angle. The sides within and without, are provided with teeth. (4) Another conical nut T, Fig. 2, which is solid, and through the center and axis of which a shaft passes. The exterior surface of this nut inclines equally on all sides upward toward the shaft a, Fig. 2, and is provided with teeth. The nuts b and T, revolve with the shaft a, to which they are attached. (5) Fluted teeth h, h, h, Figs. 1. and 2, upon the internal surface of the stationary cylinder D, Fig. 1, and upon the internal and external surfaces of the stationary cylinder M, Fig. 1, and upon the external and internal surface of the revolving nut b, Fig. 2, and upon the external surface of the revolving nut T, Fig. 2. (6) Larger teeth c, c, c, c, Fig. 2, upon the external and internal surface of the revolving nut b, Fig. 2, and upon the external surface of the revolving nut T, Fig. 2. (7) Square teeth c, c, c, c, Fig. 2, with a flat top, called pickers, standing upon the upper end of the large teeth on the revolving nut b, Fig. 2. (8) Stationary tranverse arms n, n, n, Fig. 1, to which the cylinders & and M, Fig. 1, are attached, and which hold these cylinders in their proper position. (9) Transverse arms 1183to which the revolving nuts b and T, Fig. 2, are attached, and which secure to these nuts a corresponding motion. (10) The shaft a, Fig. 2, which passes through the center and axis of the revolving nut T, Fig. 2, and to which it is secured. (11) A hopper e, Fig. 1, for holding the substance to be ground, and which is attached to the outside cylinder D, Fig. 1. (12) A cross-bar f, Fig. 3, with a socket n, in its center, in which the end of the shaft a, Fig. 2, turns. (13) Ears i, i, i, i, Fig. 1, upon the cylinder D, Fig. 1, through which bolts or screws are passed, to secure the machine in a fixed and permanent position.

[“The drawings which accompany this specification represent different parts of our machine, and the proper position in the machine of the several parts represented will appear from the description and references. The stationary cylinders & and M, Fig. 1, are provided with low fluted teeth of equal length, depth, and sizes, extending longitudinally along and entirely across the inner surface of the cylinder D, and the outer and inner surfaces of the cylinder m, and disposed at equal distances entirely around them. They are arranged in perpendicular lines, parallel to each other, and to the upright shaft a, Fig. 2, and are formed and separated by a narrow concave groove extending the entire length of each tooth, and on both sides of it. The revolving nut T, Fig. 2, which is attached to the shaft a, Fig. 2, is in the form of a truncated cone, its sides retreating upward toward the shaft a. The form of the revolving nut b, Fig. 2, is that of a hollow truncated cone retreating without on all sides alike upward toward the shaft a. The interior surface of this nut and the teeth thereon, converge on all sides from the top downward toward the lower end of the shaft a, at an angle corresponding with that of the slope externally. The revolving-nuts T and b, Fig. 2, are provided with low fluted teeth, of an equal depth and size, and differing from each other only in length. They are like the small teeth in the cylinders & and M, Fig. 1, and are situated upon the external side of the revolving-nut T, Fig. 2, and upon the external and internal sides of the revolving-nut b, Fig. 2. They begin at the lower termination of the sides, and extend longitudinally along, but not entirely across them, and are formed and separated from each other by a concave groove, in like manner with those in the cylinders & and M, Fig. 1, above described, and are disposed, at equal distances from each other, entirely around these sides. They are grooved out of the lower circular portion of the nuts longitudinally, and, as far as they extend, slope with them. Those upon the external side of the revolving-nut T, Fig. 2, incline toward the upper portion of the shaft a, Fig. 2, and those upon the internal side of the nut b, Fig. 2, incline toward the lower end of this shaft. The revolving-nuts T and b, Fig. 2, are also each of them provided, in addition to the small teeth above described, with a row of larger teeth, arranged upon the external sides of the revolving-nut T, Fig. 2, and upon the external and internal sides of the revolving-nut b, Fig. 2. Each tooth extends from the lower termination of these sides upward longitudinally entirely across to the upper termination thereof, and is a mere continuation of some of the small teeth above described extended and gradually increased in depth and size from the point of extension toward the top of the nuts respectively. The large teeth upon the nut T, Fig. 2, and upon the external sides of nut b, Fig. 2, incline with the surfaces upon which they are situated toward

2 [Richard Montgomery and Lewis W. Harris.

[Bark Mill.

Patented August 12, 1840.]

the shaft a, Fig. 2, like the small teeth thereon, and at a corresponding angle, whilst the large teeth upon the interior surface of the revolving-nut b, Fig. 2, incline, like the small teeth, upon this surface toward the lower portion of the shaft (a), and at the same angle with the small teeth last mentioned. The back of each of the large teeth, on the exterior surface of the revolving-nut b, Fig. 2, joins at the top of this nut with a large tooth of the same dimension, the interior surface of this nut, the backs coinciding, and the edges facing in opposite directions. Upon the top of each of the large teeth thus united is a square tooth or picker, standing parallel to the shaft (a, Fig. 11842), which, and in breaking the bark or other substance to be ground against the stationary arms n, n, n, Fig. 1, as the nuts revolve. The stationary arms (n, Fig. 1) are attached to the cylinder in at n, and to the cylinder & at O. In the center of the arm n, at P, is a socket, in which the shaft a, Fig. 2, turns. The lower circumference of the hopper e, Fig. 1, corresponds in size with the cylinder D, Fig. 1, over which it is placed, and to which it is permanently secured. Fig. 1 represents the stationary cylinders & and M', and the hopper e, and the stationary arms n', in an inverted position. R, Fig. 1, is the space filled by the revolving-nut b, Fig. 2, and S, Fig. 1, that filled by the revolving-nut T, Fig. 2. When placed in their proper positions in the machine, g, g, Fig. 1, are ears upon the stationary cylinders D, to which the cross-bar f, Fig. 3, is secured. The nuts b and T, Fig. 2, are firmly secured at the base to transverse arms which revolve with them. These revolving-arms are like the stationary arms n, n, n, Fig. 1, and connect the nuts b, and T with each other in the same manner, that the stationary arms n, Fig. 1, connect the cylinders D, and M, Fig. 1. The lower end of the shaft a, Fig. 2, is firmly secured to the center of the revolving-arms where these arms intersect each other. A revolution of the shaft therefore, carries the revolving-arms and the nuts b and T around with it. c, c, c, c, Fig. 2, are rows of pickers and large teeth upon the nuts b and T, extending entirely around them. As the nuts revolve under the stationary arms n, Fig. 1, the bark, or other substance to be ground, is broken by them against the stationary arms and the surrounding teeth, and sides of the cylinders & and M, into pieces of a proper size, to be acted on by the small teeth in the cylinders and nuts, h, h, h, Figs. 1 and 2, are fine teeth upon the inner surface of the cylinder D, and upon the external and internal surface of the cylinder M, and upon the external and internal surfaces of the nut b, and upon the surface of the nut T. The nut b performs its revolutions between the cylinders & and M. The nut T is surrounded by the cylinder M, within which it revolves. The small teeth in the cylinders are of a corresponding size with the small teeth, in the nut opposed to them, and in connection with which they are designed to act. The teeth in the cylinders are perpendicular to the base of the cylinders, and surround the shaft a, in lines parallel to the shaft and to each other. Those in the revolving-nuts surround the shaft a, in lines inclining toward it as hereinbefore mentioned, but which are in the same plane with the axis of the shaft a. The machine, therefore, grinds with the like facility, whether the nuts revolve forward, or in a contrary direction. The bark or other substance to be ground is placed in the hopper e; the moving-power is applied to the shaft a, which, in revolving takes with it the nuts b and T, together with the arms, which secure and connect them to each other. The substance is broken by the large teeth and pickers c, c, c, c, Fig. 2, against the stationary arms n, n, n, Fig. 1, and the surrounding teeth and sides of the stationary cylinders, and, falling down between the small teeth in the cylinders, and those in the nut opposite, is there ground, and is then discharged through the small teeth, from the base of the machine. The revolving-nuts being of a conical shape as above described, and the teeth thereon inclining with the cone upon which they are situated, as above mentioned, may be brought nearer to those in the cylinders by raising the shaft a, to which they are attached, or may be removed farther from them by lowering the shaft, and, in this manner, the machine may be made to grind coarse or fine as occasion may require.

[“What we claim as our invention, and desire to secure by letters patent, is: The combination of the conical nuts, one or more, with the cylinders placed concentrically, as herein mentioned and described, and constructed, arranged, and connected in the manner herein described, and provided with teeth and pickers, arranged as is also herein mentioned and set forth. Richard Montgomery.

[“Lewis W. Harris.”]2

The plaintiff also gave evidence tending to show the novelty and utility of the invention, the sufficiency of the specification, and the manufacture and sale by the defendant, in the state of New-York, of a large number of bark-mills alleged to be an infringement. The bark-mills made and sold by the defendant were constructed, some with four, but most of them with six grinding chambers, formed by alternate stationary and movable rings, arranged and combined in the manner described in the said specification; but the teeth in the defendant's mills varied in some particulars from the teeth described in the specification, and the chambers and stationary rings in the defendant's mills differed somewhat in shape from those in the patented mill.

The defendant introduced evidence designed to show that the specification did not sufficiently describe the manner of constructing a bark-mill with any other number of grinding-chambers than three. So much of the specification as is material, and the principal points made and evidence given, are stated in the charge to the jury.

Samuel Stevens, Samuel Blatchford, and Levi D. Carpenter, for plaintiff.

Joshua A. Spencer and William Baker, for defendant.

In charging the jury, NELSON, Circuit Justice, remarked as follows:

The improvement which has been patented to Montgomery and Harris has been described in the specification which accompanies the patent, and it is necessary for us to look into that, in the first instance, with a view to ascertain, 1185as nearly as possible, the thing which has been discovered, and the property in which is secured to the patentees. The law requires that the applicant for a patent shall set forth in his specification a description of his invention, sufficiently full and particular to enable any intelligent mechanic to make a machine from such description.

The patentees in this case begin by stating in their specification, in very general terms, the nature of the improvement which they have discovered. They say: “The nature of our invention consists in providing a mode of breaking and grinding bark and other substances of a like character, by means of hollow, stationary cylinders, and one or more revolving conical nuts, placed concentrically, in connection with teeth and pickers, the whole constructed, arranged and combined as hereinafter particularly described.” They then go on in their specification and describe the material parts of the machinery of the mill, First, the outer cylinder or shell of the mill; next, another cylinder, which is also stationary, and is the second in the models which have been shown, there being teeth on the inside of the outer cylinder, and on the inside and outside of the inner cylinder; next, a movable conical nut or ring, with teeth on the outside and inside; and then another conical nut, which is solid, and has teeth on its outside, and through the centre of which a shaft passes, which is connected with the driving power. The patentees then give a description of the teeth which are used on these stationary cylinders, and on the movable conical rings. They also describe the cross-bars or pieces that hold firmly together the stationary cylinders, and the cross-bars that hold together firmly the movable conical grinders. All this, taken together, perfects the mill, and produces the combination which the patentees allege they have discovered, and which they design to describe in their specification.

They next set out their claim, which is the most material part of the specification, especially when taken in connection with the particular description previously given. The claim, in the language of the patentees themselves, is as follows: “What we claim as our invention, and desire to secure by letters patent, is the combination of the conical nuts, one or more, with the cylinders, placed concentrically as herein mentioned and described, and constructed, arranged and connected in the manner herein described, and provided with teeth and pickers arranged as is also herein mentioned and set forth.” The claim in substance is this—the combination of the conical nuts, one or more, with the cylinders, placed concentrically as described in the specification, and furnished with teeth and pickers on their surfaces.

Now, the first question is—what is the thing that has been invented by the patentees? Because, unless we ascertain intelligibly what the machine is which it is claimed has been discovered, we shall be altogether disqualified for determining whether or not it has been infringed or violated by the operation of the defendant's mill. The claim is exceedingly plain, and is very distinctly and clearly expressed. It is simply the combining together of the stationary cylinders and the movable conical rings, there being teeth on the sides of both, and that combination being sustained by the cross-bars to which the movable parts and the stationary parts are severally attached, so that, on applying the driving power to the shaft, the grinding is effected in the grinding chambers formed by the surfaces of the nuts and cylinders.

It is proper to inquire what the purpose is of this combination, and what useful object was intended to be obtained by it. Obviously, it seems to me, to increase the grinding apparatus in a machine of a given size, and which may still be driven by the same power as before. This is the new and valuable idea which has occurred to the patentees, which they have reduced to practice, and which is, in their description, embodied in a working machine. This is manifest on looking at the old mill, and comparing it with the new mill of the patentees. There was but one grinding chamber in the old mill, while one of the simplest forms of the mill discovered and reduced to practical operation by the patentees, contains two grinding-chambers, which are formed by inserting a movable conical nut between an outer and an inner stationary cylinder. It was the multiplication of these chambers and of the grinding apparatus or machinery, that was discovered by the patentees, and which it is agreed was never before known or put in practice.

As to the utility of the invention, I do not understand that it is called seriously in question. An invention must not only be one that can be reduced to practice, but it must be one of some utility. It appears, from the testimony in this case, that the mill of the patentees, formed by the multiplication of the grinding-chambers, particularly the mill with the three chambers, described in the specification and shown in the drawings, will grind, when not in very rapid operation, say at a speed of fifty or sixty revolutions in a minute, a cord of bark an hour through the day; and the witness did not doubt, that with an increased velocity, it would grind more. It grinds, moreover, double the quantity ground by the old mill. This is evidence enough of the utility of the invention. The question is not, whether the machine invented is the best one known to the community, nor whether it does its work better or faster than any other machine in the same department of labor. But, if it be to a certain degree useful, and be original with the patentee, it belongs to him alone, whether it does less or more work.

It has been insisted, on the part of the defendant, and that view was taken by some of the experts whom he called, that the specification in question here is not sufficiently full 1186and particular to enable a mechanic of ordinary skill to make a mill with grinding-chambers multiplied beyond the number particularly enumerated in the specification, which is limited to three. But several of the experts who have been examined on the part of the plaintiff say, that there is no difficulty in constructing a mill with any number of grinding-chambers, from the description in the specification. Some of the witnesses for the defendant, who were examined particularly in respect to this point of the case, obviously labored under a misapprehension as to the extent of the questions that were put to them. They failed to comprehend the principle on which these questions are put to experts, and they, therefore, failed to respond intelligibly. Mr. Pond, a witness for the defendant, of great intelligence, and of long practical experience in this branch of business, would not say that, after reading the specification, he could not make a mill with the grinding chambers multiplied to any given number. But he undertook to give a legal construction to the specification for himself, and, assuming his construction to be sound, and predicating upon it the answer he gave, he said he could not make such a mill if he were to follow, throughout its structure, the particular and identical description in the specification; and this was the view taken by another witness. The point is thus made one of some importance.

What is the thing discovered and described? It is the formation of grinding chambers, by the combination of movable conical rings with stationary cylinders, these two parts being severally brought together and fastened by cross-bars. The description in the specification shows a mill with three grinding chambers. How will you add another chamber? The patentees evidently had in their minds the idea of multiplying the chambers, because they suggest the use of stationary cylinders and one or more movable conical rings, thus allowing both cylinders and rings to be multiplied to any extent, or the mill to be limited to two cylinders and one ring. Where was the necessity of their adding the description of another stationary cylinder just like the one described in the specification, and of another conical ring just like the one they have described, and directing the ring and cylinder to be put into the mill concentrically, so as to obtain two more grinding chambers? There would be nothing new in such a description. The specification already directs how to make the cylinder and the ring, and how to combine them in order to produce grinding chambers. A ring between two cylinders produces two chambers, and two more are made by the addition of another ring and another cylinder. This is a mere duplication of parts, and there is nothing new in the multiplication of the parts. By taking the description of what has already been put together to form grinding-chambers, and by putting the same together again, and adding it to the mill by the same connection of cross-bars, you have a multiplication of the grinding-chambers.

If I have been fortunate enough to communicate to you my ideas in respect to the thing really invented and put into practical operation by the patentees, you will be prepared to take up the next subject of inquiry, and that is, whether the defendant has been guilty of an infringement; or, in other words, whether he has appropriated to his own use and for his own benefit, this new machine constructed and put in operation by the patentees. As I have already stated, the object and effect of the invention are, an increase of the grinding apparatus by a multiplication of the grinding-chambers. Has the defendant appropriated to himself this idea? Has he increased the grinding apparatus in his mill, by using the combination of the movable, conical rings with the stationary cylinders? Both parties must start with the old machine, the Gale mill, which was the only mill in operation at the time of the invention by the patentees. Montgomery and Harris being the first in point of time, made the improvement which I have been explaining; that is, they increased and multiplied the number of the grinding-chambers by a combination of rings and cylinders. They thus made an advance on the old machine. Instead of only one grinding-chamber in the mill, you have two, three, four or five, or any number you see fit to make, by a multiplication of the parts. Has the defendant appropriated this combination, in the mill which he has constructed? Has he formed grinding-chambers by combining movable conical rings with stationary cylinders? If he has, he has appropriated and adopted the combination invented, described, claimed and patented by Montgomery and Harris. The defendant has a mill of six grinding-chambers and twelve grinding surfaces. Has he obtained that by a multiplication of the chambers, according to the combination of the patentees? If he has, then he has been guilty of an infringement.

It is urged, on the part of the defendant, that the shape of the grinding chambers in the defendant's mill is different from the shape of the chambers in the plaintiff's mill, and that, consequently, the combination in the defendant's mill of the running parts and the stationary parts which form the chambers, is different from the combination of those parts in the plaintiffs mill. It will be quite obvious, however, to any person of ordinary understanding, who will look at these various mills, and at the principle on which they are constructed, that this grinding chamber, though made of various shapes, will still produce a useful result. A particular shape may and probably will enable one machine to operate more advantageously than another. A mill with grinding surfaces of one particular shape may grind faster and better than a mill with surfaces of another shape. But a mill that does not grind so fast or so well as another, because it has chambers of a different shape, 1187will not, therefore, cease to be useful. This is demonstrated by the evidence in this case. The chamber in the plaintiffs mill has one receding side formed by the movable conical nut, and one upright side formed by the stationary cylinder. The evidence shows that the mill thus constructed is a useful and valuable mill. In the defendant's mill, both the surfaces of the chamber are receding, as well that of the cylinder as that of the ring. Thus, a larger opening is made to let in the bark, and it is very likely that this is an improvement, and that its effect is to and in feeding the mill and in increasing its grinding capacity. In every new invention, the particular machine, when first reduced to practice, is measurably in an imperfect state. But the idea of the inventor is complete. There is, however, in the execution and mechanical construction, which go to embody the original idea in a machine for practical use, a degree of imperfection which, from a want of experience, always attends the first construction. In the two machines in question here, the shape of the grinding-chamber is different in this respect only that in the plaintiff's one of its sides is upright and one recedes, while in the defendant's both of its sides recede. A person using the combination discovered and put into use by the patentees, may, by experience in its practical operation, see where it can be altered, and may call in a mechanic and have the alteration made, which may improve the machine. This is a necessary consequence of the practical use of the machine by a man of ordinary skill and judgment. But there is no novelty or invention in such alteration.

An illustration of this is to be found in a case recently tried before me in the city of New York, involving the title to a most useful machine called a burring machine, for the purpose of cleaning wool or cotton, and separating the dirt and foul stuff from the fibre. This had before been done by hand, at great expense. But a machine was invented whereby the whole operation was performed by covering a cylinder with a common card of leather, furnished with teeth formed with a hook on the outside and a slot below. As the cylinder revolved, the wool or cotton being brought close to it, was caught by the hooked teeth and drawn into the slot, in such manner that the fibre went to the bottom of the slot, while the dirt remained on the top of the tooth. There was then a beater, which rubbed along the surface of the cylinder and brought off the dirt, and the operation was complete. There was such demand for the machines that the business of constructing them became extensively profitable. In the suit of which I have spoken, the defendant had originally been in partnership with the inventor in constructing the machines, and, after the partnership expired, continued to construct them without any right or license. When prosecuted by the inventor, he set up, among other things, by way of defence, that he had changed the form of the hooked teeth, and had altered the shape of the slots between the teeth. This, he insisted, was a great improvement. He had taken the whole of the patentee's machine, and, slightly altering it, claimed the right to use it, and thus to absorb the whole of the invention. The case referred to is that of Parkhurst v. Kinsman [Case No. 10,757]. But, if any such doctrine were to be incorporated into the patent law, and to be administered by courts and juries, as that such an alteration would be a defence to a charge of infringement, no patent of any machine, however useful, would be worth the parchment on which it is written. But this is not the law. A difference merely in shape is a difference in degree only, and not in the thing itself. In this case, the grinding chamber—the space through which the bark enters—is more open in one mill than in the other. But there is nothing new in this particular shape, because the shape of the grinding chamber is no part of the combination patented.

The same observations are equally applicable to the shape of the teeth. Their shape, whether they be straight or slanting, is no part of the patented combination. Either form will work very well, though the one may be better and more perfect than the other. But the form of the teeth, whether straight or slanting, is not new. Teeth of both shapes are found in many grinding mills, and neither party can claim either form as new.

The novelty of the patentee's machine consists, then, in the combination of the movable conical nuts with the stationary cylinders, by which means the patentees are enabled to multiply the grinding chambers in a mill to any given number. The teeth were old. The mere form of the grinding surfaces was not new. But this multiplication of the grinding chambers, in the manner described, appears to have been never before known. That is the novelty and all the novelty there is in the matter. As to the subsidiary parts, such as the peculiar shape of the chambers and the peculiar form of the teeth, they are incidental. But no one has a right, without the authority of the patentees, to use the combination of the two parts that go to form the grinding chambers. If you shall think that that combination is incorporated in the machine of the defendant, the plaintiff will be entitled to your verdict. But if you shall think otherwise, your verdict will be for the defendant.

If the defendant has been guilty of violating the plaintiff's rights, the rule on the question of damages is, that the plaintiff is entitled to all the actual profits which the defendant has made by the use of the principle of the plaintiff's combination. In other words, the plaintiff is entitled to all the damages which he has sustained by reason of the use which the defendant has made of the plaintiff's property. This is, in effect, the same thing, because the law presumes that if the defendant had not put his machines into the market, the demand would have been for the plaintiff's, and that 1188he would have received the profits on the machines which have been made and sold by the defendant. Vindictive or exemplary damages are not allowed. The jury are confined to the actual damages, and the law has provided that the court may increase those damages in proper cases.

There are some data in this case which you can take as guides to the amount of damages. It is stated by one witness, that from the year 1843 to this time, a period of some seven years, the defendant has cast six hundred and thirty-two mills; that the average cost of those mills to the defendant was $20 apiece; and that they sold at retail for $45 each, and at wholesale for $37 and $40 each. But the difference between $20 and $45 on each mill is not all of it nominal profit. The interest on capital, the risk of bad debts and the expenses of selling the mills, are all to be taken into account in arriving at the profits which the defendant has made. The right of the plaintiff accrued in August, 1845, and the suit was commenced in June, 1849. The jury should confine their inquiry on the subject of damages to that period, about four years, and to the profits which the defendant derived from sales of his mills within that period.

The jury found a verdict for the plaintiff for $7,200, which was reduced by the court, by consent of the plaintiff to $6,000.

The defendant afterwards moved, on a case, for a new trial, on the ground of errors in the charge of the court, and of the excessiveness of the damages. But the motion was denied.

1 [Reported by Samuel Blatchford, Esq., and here reprinted by permission. Merw. Pat. Inv. 203, contains only a partial report.]

2 [From Fish. Pat. Rep. 401.]

2 [From 1 Fish. Pat. Rep. 401.]

2 [From 1 Fish. Pat. Rep. 401.]

This volume of American Law was transcribed for use on the Internet

through a contribution from Google.