Case No. 12,370.

SARVEN v. HALL et al.

[11 Blatchf. 295; 4 O. G. 666; 6 Fish. Pat Cas. 495.]1

Circuit Court, D. Connecticut.

Sept. 23, 1873.

PATENTS—CARRIAGE WHEEL—INFRINGEMENT—DEVICES.

1. The second claim of the reissued letters patent granted to James D. Sarven, September 6, 1870, for an “improvement in carriage wheels,” and extended for seven years from June 9, 1871 (the original patent having been granted to him June 9, 1857) namely, “a carriage wheel constructed with a mortised wooden hub, with tenoned spokes, and with flanges which embrace the faces of the spokes in the immediate vicinity of the hub, and are connected together so as to form a metallic band through which the spokes extend into the mortices in the wooden hub, substantially as before set forth,” does not require that the tenoned spokes should have shoulders bearing on the wooden hub.

2. Such claim is infringed, if, with the other features of the claim, the wheel has tenoned spokes with shoulders which sustain the spokes against endwise pressure, by bearing on the tapering sides of metallic mortices.

[This was a bill in equity by James D. Sarven against Elihu Hall & Co.]

2 [Motion for preliminary injunction. Suit brought on letters patent No. 17,520, for “an improved carriage-wheel,” granted to complainant June 9, 1857, reissued August 11, 1868, and again reissued September 6, 1870, No. 4,116, and extended for seven years from June 9, 1871. The validity of the patent was established in the case of Sarven v. Hall [Case No. 12,369]. The claims of the patent were:

[”A carriage-wheel constructed with the spokes, combined with the wooden hub, by tenons entering mortises in said hub, and with each other, in such manner that a solid belt is formed around the said hub, substantially as before set forth. Also, a carriage-wheel, constructed with a mortised wooden hub, with tenoned spokes and with flanges, which embrace the faces of the spokes in the immediate vicinity of the hub, and are connected together so as to form a metallic band, through which the spokes extend into the mortises in the wooden hub, substantially as before set forth. Also, a carriage-wheel, constructed with a mortised wooden hub, with 521tenoned spokes combined with each other, so that a solid belt is formed around the hub, and with metallic flanges, which embrace the faces of the spokes in the immediate vicinity of the hub, and are connected together so as to form a metallic band, through which the spokes extend into the mortises in the wooden hub, substantially as set forth.”

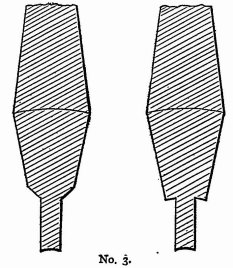

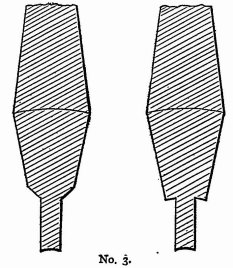

[The above engravings shows the Sarven wheel, as described in the patent. The defendants first made the Warner wheel, patented to Almon Warner, February 5, 1867, shown in the following engraving, No. 2.3 After the first decision, owing to the fact that complainant's counsel and experts had insisted at the hearing, as one of the reasons of infringement, that the Warner wheel had shoulders on the spokes, bearing against the wooden hub, defendant cut away the shoulders, and proceeded to manufacture wheels, in other respects, the same as before. This present suit and motion were brought to prevent the manufacture of the wheel thus changed. The engravings below show the spoke as originally used by defendants, and the spoke as changed by them, with the shoulders cut away.]2

No. 3.

John S. Beach, Samuel S. Fisher, and Keller & Blake, for complainant.

Chas. R. Ingersoll and Benj. F. Thurston, for defendants.

WOODRUFF, Circuit Judge. This suit is brought to restrain an alleged infringement of letters patent for an “improvement in carriage wheels,” reissued to the plaintiff, September 6, 1870, and, on the 8th of June, 1871, extended for the term of seven years from the 8th of June, 1871, on which day his original patent, granted June 9, 1857, expired. In a former suit between the same parties, in this court, decided in April, 1872 [Case No. 12,369], it was held, that the plaintiff's patent was infringed by a carriage wheel which the defendant, a corporation, was then and theretofore manufacturing, and a decree was entered in favor of the complainant against the defendant, for an injunction and an account of profits, &c. A change was thereupon made in the construction of the carriage wheels manufactured by the defendant, which, on its behalf, is claimed to avoid the decree in the former case and the patent itself, and to relieve the defendant from the charge of infringement. The plaintiff, on the other hand, insists, that notwithstanding such change, the wheel which the defendant is now manufacturing infringes his patent, and, upon that ground, he has filed the present bill, and moves for an injunction to restrain the manufacture of such wheel.

In the former suit, the defendant's wheel was held to infringe the second claim in the plaintiff's reissued patent, which is in these words: “Also, a carriage wheel constructed with a mortised wooden hub, with tenoned spokes, and with flanges which embrace the faces of the spokes in the immediate vicinity of the hub, and are connected together so as to form a metallic band, through which the spokes extend into the mortices in the wooden hub, substantially as before set forth.” The plaintiff was not held to have an exclusive right to the use of either of the distinct devices mentioned in this claim. Each was held, upon the evidence, to be old, that is to say, a carriage wheel with a wooden hub, a carriage wheel with a wooden hub and tenoned spokes, a carriage wheel with flanges on each side of the spokes, bolted together, to assist in resisting lateral strain, and connected together by bolts, so as to form a metallic ring, through which the spokes passed, were neither of them new. But, it was found and held, upon the evidence, that a carriage wheel combining all these was the invention of the complainant, and was embraced within the above recited second claim of his patent. In respect to this combination, the wheel of the defendant differed from the plaintiff's only in this—that, instead of flanges placed separately upon each side of the spokes, and bolted together through or between the spokes, the flanges used by the defendant were cast in one piece, the annular sides being connected by cross pieces, which passed between each two spokes, thus forming what was appropriately termed a mortised annulus, through the mortices of which the spokes were driven, and into the mortices of the hub; and it was insisted that, thus constructed, the double flange or mortised annulus, by means of the tapering sides of the mortices therein, which firmly grasped the spoke, served to bear the pressure or thrust endwise upon the spoke, relieved the shoulder bearing on, or adapted to bear on, the hub, and so constituted a distinct device from the mere flanges bolted together for resisting lateral pressure. In relation to this point, expert witnesses were examined on the behalf of the complainant, and their testimony 522mony went very far to show, that, if the defendant's wheel had been constructed without shoulders on the spokes, bearing, or which, in use, might be brought to bear, upon the wooden hub, the wheel would not infringe the complainant's patent, as, for example, if the end of the spoke entering the hub were uniformly tapering; and, on the argument of the cause, much stress was laid, by the complainant's counsel, on the fact, that the spokes in the defendant's wheel had, like those of the plaintiff, shouldered tenons, the shoulders passing through the metallic mortices and bearing on the wooden hub. The court were of opinion, that the circumstance that the sides of the openings in the mortised annulus were tapering, so as to furnish an endwise bearing to the spokes, did not render it a distinct device, in such sense as to relieve the defendant from the charge of using the patented combination; that, in their use, and for the purpose for which the plaintiff's flanged collars are useful, the sides of the mortised annulus are identical, in the office they perform, viz., to sustain the spokes against lateral strain; that, in the mechanical construction of the parts that perform that office, they are substantially the same; that the crosswise partitions and form of tapering mortices may be improvements upon the plaintiff's flanged collars bolted together; but that the mortised collars do, nevertheless, operate, for all the purposes for which flanged collars are used, in precisely the same way. Conceding, for the purposes of the case, that the tapering sides of the mortices formed by the cross pieces enabled the mortised collar to perform a function of which the plaintiff's collars were incapable, viz., to grasp firmly the end of the spoke and sustain it against the endwise pressure, it was none the less an equivalent of the plaintiff's flanged collar, in all the functions, mode of operation, and construction of the latter, although, by an additional feature, it had, also, a further useful function, and, as an equivalent in the combination, it did not relieve the defendant from the charge of infringement. Possibly, this holding may be deemed in conflict with some observations in the opinion delivered, in the supreme court, in Rees v. Gould, 15 Wall. [82 U. S.] 187, but it is, certainly, in no conflict with the actual decision made in that case, which involved no such question; and the opinion of this court in the former suit will govern the decision of the present motion.

On such former trial, however, the claim in behalf of the defendant was urged, that the tapering sides of the mortices in the mortised collars were not merely auxiliary to the shoulders near the end of the spokes, in resisting the endwise bearing, but that, in fact, such shoulders were unnecessary, and that the mortices in the metallic ring in fact sustained all of that pressure; and examples in which some of the spokes were not driven in so far that their shoulders reached the wooden hub, were exhibited in proof thereof. This was strenuously denied by the complainant and his witnesses, who claimed and testified that shrinkage of the spoke would render the support derived from the bearing of the shoulder upon the wooden hub indispensable, and that the instances in which the shoulder did not, in the examples produced, reach so far, were exceptional and, in fact, merely occasional imperfections in the manufacture, otherwise, why did the defendant make all his spokes with shouldered tenons? It will be thus seen, that, on such former trial, the question whether the defendant's wheel had tenoned spokes, with shoulders thereon bearing upon the wooden hub, to give greater strength to the spoke, and sustain, or assist in sustaining, the endwise thrust or bearing, when in actual use, was made to assume great apparent importance; and, in view of the testimony of the complainant's experts above mentioned, and the apparent concessions of his counsel, it is not at all strange that the defendant was led to the belief, that, if it should construct spokes so that their shoulders should not bear on the wooden hub, and practically illustrate and verify, in its new manufacture, its claim that its mortised collar, by the tapering sides of the mortice, so grasped and held the spokes as in fact to sustain all of the endwise bearing or thrust, it would avoid any infringement of the complainant's patent. I cannot resist the impression, that, for this belief of the defendant the complainant and his witnesses and counsel are largely responsible. The defendant, therefore, after the decree, cut away, in part, the shoulders of the spokes thereafter used, by rounding off the corners, so that, as is now claimed, there is no shoulder, at the head of the tenon, which rests on the wooden hub. The complainant, however, still insists that what remains constitutes a shoulder, which, though it may be less effective, does, nevertheless, perform the office of a shoulder at the head of the tenon, whenever, and so soon as, by very slight shrinkage, or for any other reason, the spoke, by force, acting endwise thereon, is driven, in the slightest degree, inward toward the centre of the wheel. The defendant, on the other hand, with its witnesses, deny that the spoke can be driven in so as to produce such bearing, the tapering sides of the mortices in the metallic collar being absolutely and invariably sufficient, as its wheels are constructed, to sustain the spoke against such force or pressure.

I shall not, on this motion, attempt to settle this disputed question. I thought, when considering the former case, and I now think, that undue prominence was given to the subject of the bearing of the shoulders of the spokes on the wooden hub, as compared with their bearing, whether more or less completely, upon the tapering sides of the mortices in the metallic ring. That prominence arises chiefly out of the fact, that the patented combination, as described in the second claim of the complainant's patent, is “a mortised wooden hub, with tenoned spokes, and with flanges which embrace the faces of the spokes 523* * * so as to form a metallic band through which the spokes extend into the mortices in the wooden hub, substantially as before set forth,” and out of the suggestion thereupon, that there are no tenoned spokes, in any proper sense, unless there be a shoulder at the head of the tenon, bearing upon the substance or object in which the mortice is made, to receive the tenon. That this suggestion gives the ordinary meaning of the term “tenoned” is unquestionable, although the word “tenon” has not, derivatively, any such necessary inherent meaning. But, let it be assumed, that, in mechanics, the word “tenoned” imports not merely a tenon to be inserted in a mortice, but, as a correlative or adjunct, a shoulder to sustain the thing tenoned against endwise pressure, as illustrated in tenoned posts inserted in the sill of a building, tenoned braces to strengthen an angle in a frame, and the like. There is no necessary or prescribed form either to the tenon or to the shoulder. The tenon may be straight, curved or dovetailed; the shoulder may be rounded or square; it may be at a right angle with the tenon or at an acute or oblique angle. Let it, then, be further assumed, that the defendant has done that which the complainant denies, viz., so constructed the spokes in the new manufacture, that their shoulders do not now bear on the exterior surface of the wooden hub. What has the defendant done? The defendant's spokes have still both shoulders and tenons, in the literal sense of the word. The shoulders are made not at right angles to the tenon; they do not bear directly on the wooden hub, but they do bear, and do sustain the spokes against endwise pressure—the very office claimed for the shoulder of a tenon. They bear upon the superimposed metallic collar, and yet are within that collar and receive the same support against lateral strain which the flanged sides of that collar give, and are intended to give, and as the flanged collars do, in the complainant's wheel. True, the defendant, if it has, in fact, made the whole bearing shoulder of its spokes bear on the tapering sides of the metallic mortices, has created a difference between its wheel and that of the complainant, but not a difference in office or in mode of operation. It has still tenoned spokes, within the literal reading of the complainant's specification and claim, and tenoned spokes within the substance of the complainant's invention. True, they are not specifically like the spokes shown in the complainant's drawings, nor are they specifically like the tenoned spokes in an ordinary wheel. But, in considering the validity of the reissued patent, the court did not, on the former trial, deem the plaintiff, in the use of flanges in the combination in question, confined to spokes tenoned as in the ordinary wheel, as seemed, on this argument, to be assumed by the defendant's counsel. The language of the opinion may have tended to mislead, but the ordinary wheel was only mentioned for illustration. The original patent declared that the patentee claimed the use of the flanged collars, when used in connection with a wooden hub, if the spokes are arranged as therein set forth, or in any other manner—a claim, doubtless, too broad, but corrected, in that respect, in the reissue.

I cannot, therefore, resist the conclusion, that, within the substance of the plaintiff's second claim, the defendant's spokes are tenoned spokes, and, therefore, as truly within this second claim of the complainant's patent, whether the endwise pressure upon the spokes is received and borne upon the tapering sides of the metallic mortices, or on the exterior surface of the wooden hub.

There is another view of the subject, which involves the doctrine of equivalents in a combination, which tends to the same conclusion, unless the observations made in the case of Rees v. Gould, above cited, be deemed to impair its force. The complainant is entitled to the exclusive use of the combination described in his second claim. The several devices combined by him were, as heretofore held, none of them new. Among those devices are tenoned spokes. And let it be conceded that, by tenoned spokes, he must be deemed to mean spokes having a shoulder at the head of the tenon, resting on the wooden hub; and that the defendant places the shoulder of its spokes on the inclined or tapering sides of the metallic mortices—it might place the shoulder on a distinct projection within those mortices. Is it not obvious, that, having regard to the purpose of a shoulder on the spoke, the function it performs, the mode of its operation, to receive and sustain the endwise pressure, which are claimed to be the sole purpose, function and operation of the shoulder, the defendant's construction is a precise equivalent of that described and claimed in the patent? If a spoke tenoned into a wooden hub, and having a shoulder resting on the surface of the hub, were new, and were patented, it is not possible that one who should place a metallic band around a wooden hub, and make a mortice therein, and a mortice in the wooden hub beneath, and insert the tenon in the mortice, so that the shoulder should bear either squarely or obliquely on the metal, could escape the charge of infringing such patent.

On the argument of the motion, I was much impressed by still another view of the subject. Looking at the whole specification, and construing the claims of the patentee by aid thereof, it will be seen, that the invention had reference to improving the carriage wheel in two important particulars, viz., strengthening the wheel so as to resist lateral strain, and strengthening it against force or strain in the direction of its plane. The patentee did not profess to have improved its capacity to resist the bearing or thrust endwise of the spokes; this was no part or purpose of his invention. By means of the circular flanges, bolted together, the increased strength to resist lateral strains was to be 524effected, and by these metallic circular bands, made fast to the hub and bolted to the spoils, and by making the spokes to form a solid or continuous belt of wood around the exterior of the wooden hub, the greater power to resist a strain in the direction of the plane of the wheel was to be secured. In reference to either result, tenons inserted in mortices in the wooden hub were of essential importance. By his arrangement, no strain, either laterally or in the direction of the plane of the wheel, could be made to act on the tenon of one spoke only, but by the joint power or efficiency of the metallic bands and tenons, several tenons acted together to resist any force, jar or shock from any direction. When, therefore, the patentee had described his invention and made his second claim, including tenoned spokes, the claim should be construed with reference to the office or function which entered into his improvement, and with reference to the service done by the tenon in its relation to the parts which constituted an improvement and enabled the wheel better to resist force applied laterally or in the direction of the plane of the wheel. This was all he professed to have improved. For that purpose, it was the tenons entering the hub, and made fast therein, that entered into his combination, as rendering service towards effecting his improvement. The endwise thrust was not in his contemplation, or the shoulders at the head of the tenon, as pertaining to any improvement made by him. True, there must be capacity to resist such end thrust. One mode of constructing a wheel, which would give it greater power in that respect, he had very prominently, and, as suggested in the former opinion, I think, chiefly in view, viz., increasing the number of spokes. But, as to the matter of tenoning the spokes, the point was to so unite the spokes as that any strain upon one, instead of acting on one alone, should, through the tenons inserted in the hub, and the circular flanges, bolted to all, be resisted by the joint power of several or all of the tenons. Hence, his improvement was applicable to any wheel having spokes tenoned into the hub, entirely irrespective of the question whether the shoulders at the head of the tenon rested on the surface of the wooden hub, or whether any other provision was made to sustain the endwise pressure. The hold of the spokes in the hub was the efficient means of making his improvement practically useful, and constituted the marked distinction between his wheel and the wheel described in the Smith and Parfrey patent, in which there were no spokes inserted in mortices in the hub. In this view of the proper meaning of “tenoned spokes,” in the claim of the patentee, there remains no question that the defendant's present manufacture is an infringement. The tenons at the end of the defendant's spokes are identical in form with the tenons in the wheel of the complainant, they are secured in the mortices in the wooden hub in the same manner, and, in their action conjointly with the circular metallic band, they perform precisely the same office or function, in resisting strains either laterally or in the direction of the plane of the wheel. The particular mode in which the shoulder above is formed, or how it is sustained, is, with reference to that which constitutes the substance and gist of the complainant's invention, immaterial, so long as the rings or flanges are made to bear upon or against the body of the spoke, and bind it so as to effect the objects the patentee disclosed and secured.

These reasons all concur in the result, that the complainant's motion should be granted. The question of costs is not very important, but, in view of the manner in which I think the defendant has been misled into the situation in which I deem him now placed, which, in my judgment, falls but little short of estopping the complainant to allege that a wheel without tenons having shoulders bearing on the surface of the wooden hub infringes his patent, I cannot charge the defendant with costs.

1 [Reported by Hon. Samuel Blatchford, District Judge, and by Samuel S. Fisher, Esq., and here compiled and reprinted by permission. The syllabus and opinion are from 11 Blatchf. 295, and the statement is from 6 Fish. Pat. Cas. 495.]

2 [From 6 Fish. Pat. Cas. 495.]

3 [For drawings of these patents, see Case No. 12,369.]

This volume of American Law was transcribed for use on the Internet

through a contribution from Google.