Case No. 10,051.

17FED.CAS.—78

NATIONAL SPRING CO. v. UNION CAR SPRING MANUF'G CO.

[12 Blatehf. 80; 1 Ban. & A. 240; 6 O. G. 224; Merw. Pat. Inv. 451.]1

Circuit Court, S. D. New York.

May 20, 1874.

PATENTS—REISSUE—RUBBER AND STEEL SPRING—INTERPOLATION—INVENTION REDUCED TO PRACTICE PRIOR TO FOREIGN PATENT.

1. The reissued letters patent granted to the National Spring Company, as assignees of Erastus T. Bussell, December 13th, 1870, for an “improvement in combined India rubber and steel springs,” the original patent having been granted to Bussell, as inventor, November 29th, 1853, and extended for seven years from November 29th, 1867, are valid.

2. The original specification, drawings, and model exhibit fully what the reissue claims, and what the original fails to claim.

3. The original specification contains, on its face, sufficient evidence that there was inadvertence and mistake of some kind in preparing it.

4. The reissued patent is not open to the objection that it is not for the same invention as that embodied in the original patent, or that the specifications of the two patents are repugnant to each other.

5. The original specification states the invention of Bussell to be a combination of vulcanized India rubber with spiral steel, so arranged, with the spiral steel on the outside of the rubber, that each sustains the other, when they are both under longitudinal pressure, the result being independent of any fluting of the rubber. Therefore, although the claim of the original patent was, “The fluting a column of vulcanized India rubber longitudinally, and then so surrounding it with the helical spring, mine being an improvement upon Ray's spring,” it was proper to claim, in the reissue, “The combination of a column of rubber, or its equivalent, whether solid or hollow, with a spiral metallic spring, when the said spring is arranged external to and surrounding the rubber, substantially as and for the purposes specified.”

6. The original specification shows that Bussell supposed that a patent had been granted to Ray for surrounding a column of vulcanized India rubber with a helical spring; whereas, in fact, Ray had no such patent, and no specification of any patent to Ray disclosed such an arrangement, and all that any patent to Ray disclosed was a column of rubber with a spiral metal spring in its centre, such spring surrounding a bolt extending the length of the column of rubber, and there being detached rings of metal surrounding on the outside the column of rubber.

7. When the specification of the reissue speaks of a “solid” column of rubber, it means one which is not hollow, as distinguished from Ray's arrangement, in which the column of rubber is hollow.

8. The claim of the reissue, in speaking of a column of rubber, “whether solid or hollow,” means only, a column of rubber, whether hollow or not hollow.

9. The reissued patent is infringed if the column of rubber is combined with a spiral metallic spring arranged external to and surrounding tie rubber, whether there be or be not a longitudinal hole in the centre of the rubber, or whether there be or be not flutes in the rubber, or other provision for the vent of the rubber, under pressure.

10. The language of the specification of the reissue, that “any other material that is, for the purpose of a spring, the equivalent of India rubber, such as compressed animal and vegetable fibre, gutta percha, &c., may be employed in place of the rubber,” when the original specification made no mention of such equivalents, is not to be regarded as an interpolation, or as determining that any particular thing is an equivalent, but is to be interpreted only as meaning, that, if the articles named be, for the purposes of a spring, the equivalents of India rubber, they may, when in a condition to be such equivalents, be employed in the place of the rubber.

11. The complete application for the reissue was filed March 12th, 1870, the fee or duty having been previously paid. The petition and specification were not signed by Bussell, although he was living, but were signed by the assignees, to whom the reissue was granted, and the oath was not made by Bussell. These proceedings were in conformity with the statutes in force when the 33d section of Act July 8, 1870 (16 Stat. 202), was enacted, requiring, in case of a reissue to an assignee, that the application be made, and the specification be sworn to by the inventor, if he be living. The 111th section of the latter act, while repealing the prior acts, provides that such repeal shall not take away any right existing under any of the prior laws, and that all applications for patents pending at the time of the passage of the act of 1870, “in cases where the duty has been paid, shall be proceeded with and acted on in the same manner as though filed after the passage thereof:” Held, that the application was to be proceeded with, and acted on, on the merits, in like manner as though filed after the passage of the act of 1870, with the requirements complied with which the 33d section of that act prescribes.

11. Observations on an attempt to impeach, by the testimony of the inventor, the validity of the reissue to his assignees.

12. An invention reduced to practice in the United States, prior to the granting of an English patent, sustained as against such patent.

In equity.

George Gifford and Josiah P. Fitch, for plaintiffs.

Charles H. Woodruff, for defendants.

BLATCHFORD, District Judge. This suit is brought on reissued letters patent [No. 4,202], granted to the plaintiffs, December 13th, 1870, as assignees of Erastus T. Bussell, for an “improvement in combined India rubber and steel springs,” the original patent [No. 10,280] having been granted to Bussell, as inventor, November 29th, 1853, and extended for seven years from November 29th, 1867. The specification of the reissued patent is signed by the plaintiffs, who are a corporation, by their president, and is not signed by Bussell. It states that Bussell “invented a new and improved combination of vulcanized rubber and steel, forming thereby a spring useful for railroad cars, carriages, buggies, &c., of which the following is a specification:

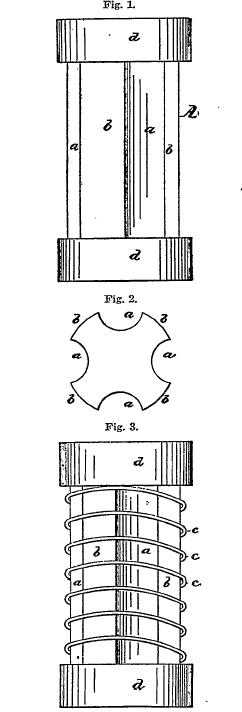

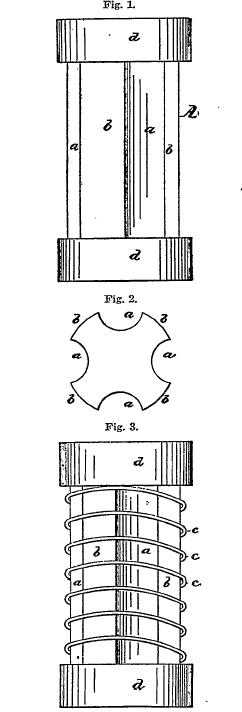

“Figure 1 represents a column of vulcanized rubber, showing, also, metal caps on each end, such as may be used for bearings.

1233[Drawings of reissued patent No. 4,202. granted to B. T. Bussell, December 13, 1870, published from the records of the United States patent office.]

Figure 2 is a cross section of the same. Figure 3 is a view of the column of rubber surrounded by a spiral metal spring, showing, also, the before mentioned caps.” The drawing designates the three figures on it as follows: “Fig. 1. Fluted column of vulcanized rubber, with the metallic caps on each end. Fig. 2. Transverse section of rubber column. Fig. 3. Compound vulcanized rubber and steel spring, with the metallic caps on each end.” The drawing bears the signature, “Inventor, E. T. Bussell, by J. P. Fitch, his Att'y.” The drawings show the column of rubber as being fluted by four flutes or grooves running lengthwise of it and equidistant from each other, the flutes being marked a, and the unfluted spaces being marked b. The specification says: “This invention consists in surrounding a column of India rubber, or its equivalent, by a spiral metallic spring, so arranged that each sustains the other, whereby a more perfect and serviceable spring for the purposes specified is produced than by any combination of rubber and metal hitherto known. A column of vulcanized rubber, A, is surrounded with a spiral metallic spring, c, c, c. Fig. 3, the two springs being of equal length, so as to have the same bearings at the ends, and the relative diameters of the two being such that the steel or metal spring will fit snugly on to the rubber column. The column of rubber may be fluted, as shown in the drawing, by several concavities running longitudinally, a, a, a. This construction is regarded as a desirable one, as it allows the rubber, when pressure is applied to the spring, to expand laterally into the said concavities, thus preventing it, to a degree, from being pressed outward between the coils of the metal spring, where it is liable to be chafed and worn. Any other material that is, for the purpose of a spring, the equivalent of India rubber, such as compressed animal and vegetable fibre, gutta percha, &c., may be employed in place of the rubber. The combination of spiral metallic springs with rubber, or its equivalents, for the purpose here described, is not new. Ray, in the year 1848, obtained a patent for such a combination. But he described and claimed a spiral metallic spring placed within a hollow rubber column or tube, and then supported the rubber externally by detached metal rings. The arrangement and combination of Bussell, here claimed, is distinct and different from, and is thought superior to, Ray's, both for the reason that it permits the use of a solid column of rubber, or its equivalent, which Ray's does not, and because the spring, when placed exterior to the rubber or its equivalent, performs alone the combined offices of both the spiral spring and the detached rings in Ray's, thus rendering Bussell's arrangement much the more simple and cheaper of the two. Another objection to arranging the spiral within the rubber tube is, that either the rubber tube has to be made objectionably large in diameter, or the spiral objectionably small. This difficulty is obviated in Bussell's combination, as is evident. It is not intended here to claim, broadly, the combination of rubber, or its 1234equivalent, with a spiral spring, for the purposes indicated; nor the combination of a spiral spring with a hollow cylinder of rubber, when the spring is placed within the cylinder. Neither is claimed the supporting of a column of rubber, or its equivalent, when used as a spring, by detached metallic rings arranged externally to the rubber.” The claim is, “The combination of a column of rubber, or its equivalent, whether solid or hollow, with a spiral metallic spring, when the said spring is arranged external to and surrounding the rubber, substantially as and for the purposes specified.”

The drawing annexed to the original patent is, in its three figures, and in the designation of them, and in the lettering of them, the same as the drawing of the reissue. The specification of the original states that Bussell has invented “a new and improved combination of vulcanized India rubber and steel forming thereby a useful spring for railroad cars, carriages, buggies, &c., &c. * * * Fig. 1 is the fluted column of vulcanized rubber, with the metallic caps on each end; Fig. 2 is a transverse section of this column of rubber; and Fig. 3 is a view of the compound spring with the metallic caps on each end. My invention consists in a combination of vulcanized India rubber with spiral steel, so arranged that each sustains the other, and the good qualities of both are combined, so as to make a most perfect spring for elasticity and durability, which is applicable to railroad cars, carriages, buggies, &c. * * * Owing to many contingencies, that require springs to be of various degrees of stiffness, the diameter of my compound springs must necessarily vary much, but their length is to be graduated by the amount of motion desirable in a spring. For springs for railroad cars I take a fluted column of vulcanized India rubber, A, Fig. 1, about eight inches in diameter, and about eight inches long, these conditions depending upon the desirable strength of the spring and the amount of motion required. The column of rubber is fluted by four semi-concavities running longitudinally at equal distances from each other, a, a, a, a, the concavities leaving each intermediate point, b, b, b, b, equal to the span of each concavity. The depth of each one of these concavities is about one-fifth the diameter of the column of India rubber. For carriage springs the diameter of the rubber is about two inches. I then surround this fluted column of vulcanized rubber with a spiral steel spring, c, c, c, Fig. 3, the diameter of the wire constituting the spiral spring being about one-twentieth that of the column of rubber. I make the spiral spring to touch the points of rubber, b, b, b, b, thus serving as a self-adjusting base upon which the rubber can act centrifugally, each point, b, b, b, b, being a base to each rubber arch, a, a, a, a. By this arrangement and combination of vulcanized India rubber and steel, several important desideratums are filled, that have not hitherto been attained by any other spring, namely, it makes, 1st, a sprightly spring, one that responds quickly to any impression made upon it, steel being much more sprightly, in its movements, than vulcanized India rubber, and this element being incorporated into the compound spring; 2d, a durable spring, capable of sustaining burdens to an indefinite length of time, the rubber, in this shape maintaining and resuming its normal shape better than in any other, the integrity of the elastic arches, a, a, a, Fig. 2, being most perfect; 3d, a strong spring, one that cannot be crushed by any reasonable weight, the steel effectually guarding the rubber against any such calamity, for, as the external surface of the rubber is shortened under compression, the resisting surface of the spiral steel, in its self-adjusting integrity, gathers and concentrates its coils around the compressed rubber, thus setting up a herculean barrier, circumscribing the bounds of the rubber within it; and, 4th, a sprightly, durable, and strong spring, that will admit of any desirable amount of motion, each concavity, a, a, a, a, serving as a vacuum for its elasticity and contracting volume to find vent in. Vulcanized India rubber being a durable substance, I thus have, in this arrangement, a combination of elements, in such a way as to make a spring possessing all the good qualities that can reasonably be expected. The rubber sustains the steel from any violence to its molecules from severe flexion, whilst the steel affords a self-adjusting base upon which the rubber can act at proper intervals, it yielding its sprightliness to the rubber at the same time, and the points, b, b, b, b, fig. 2, being in constant contact with the steel, serves to equalize the power of the rubber, whilst the concavities, a, a, a, a, give vent to and equalize its elasticity. * * * I do not claim the surrounding of columns of vulcanized India rubber with detached bands of metal at the ends, or any point between the ends, for springs, nor do I claim originality in the combination of metallic springs with vulcanized India rubber, as these are the subjects of patents heretofore granted to Fowler M. Ray, but, as well known forms of such springs and combinations, are liable to the following objections: 1st, an incapacity for great motion, this depending upon their outer surface being regular and surrounded by bands of metal whose diameters are unvarying, together with the incorporating into the centre of said rubber springs, helical or spiral springs of metal, whose diameters increase with their compression, causing them thus to encroach upon the rubber centrifugally; 2d, the liability of such springs losing their elasticity and becoming worthless from the unequal exercise of their different parts, the stretching to their utmost extent the fibres at the circumference, and this at the expense of their vitality, while the centrifugal action of the helical spring within serves further to embarrass it in its movements, so that a large mass of the rubber is 1235rendered partially Inert by being confined between the almost lifeless circumferal rubber and the centrifugally acting helical spring—the rubber thus circumstanced may properly be compared to an elastic arch with the burden or force applied to its concave side, without any base upon which to rest that of its own external fibres; and, 3d, their great liability of being crushed by an overload, for the want of a continuous metallic support externally; and, inasmuch as fluting a column of vulcanized India rubber longitudinally on its external surface and surrounding it by a spiral steel spring, substantially as above described, produces a spring susceptible of much greater motion and much greater freedom in all its movements than any of the foregoing forms, the fluted concavities giving vent to the compressed rubber, and the diameter of the spiral spring increasing with its compression, thus yielding to and allowing the greater freedom to the expanding rubber within, the circumference of the rubber mass, being a series of elastic arches, brings the radial points of expansion almost equally near the surface in every direction, and the self-adjusting base afforded to each arch in the spiral spring that surrounds them, gives to them the capacity of multiplying strength in use, and of promptly resuming their normal shape—the rubber thus circumstanced, in contrast with other forms of rubber car springs, is a series of elastic arches, with the force applied to their convex sides, whilst their bases rest upon an accommodating metallic surface, which enables them to endure, without loss of vitality, almost indefinitely; and finally, inasmuch as the continuous coil of steel on the outside of the rubber approximates a solid broad band, when an overload is put upon the springs, thus guarding the rubber effectually against any mishap that other rubber springs are liable to, therefore, what I claim as my invention is not the surrounding a column of vulcanized India rubber with a helical spring, as that is the subject of a patent granted to F. M. Ray, but what I claim and desire to secure by letters patent is, The fluting a column of vulcanized India rubber longitudinally, and then so surrounding it with the helical spring, mine being an improvement upon Bay's spring.”

This florid and ambitious original specification contains, on its face, sufficient evidence that there was inadvertence and mistake of some kind in preparing it. In one part of it, it speaks of patents having been theretofore granted to Ray, containing, as subjects, the surrounding of columns of vulcanized India rubber with detached bands of metal at the ends, or any point between the ends, for springs, and the combination of metallic springs with vulcanized India rubber, and says that the resulting springs have bands of metal of unvarying diameters surrounding the outer surfaces of the India rubber and helical or spiral springs of metal in the centre of the India rubber. In another part of it, it speaks of a patent granted to Ray as having for its subject the surrounding a column of vulcanized India rubber with a helical spring. Now, it is shown, that, in point of fact, Ray had no patent for surrounding a column of vulcanized India rubber with a helical metal spring, and that no specification of any patent to Ray disclosed such an arrangement. The only combination of a spiral metal spring with a column of rubber, disclosed in any patent to Ray, was one where the spiral metal spring was in the centre of the column of rubber, and surrounded a bolt extending the length of the column of rubber; and in connection with such arrangement there were detached rings of metal surrounding on the outside the column of rubber. The original specification states the invention of Bussell to be, a combination of vulcanized India rubber with spiral steel, so arranged that each sustains the other. This results from placing the spiral steel on the outside of the rubber. In such position each does sustain the other, when they are both under longitudinal pressure. When the steel is on the inside, they do not sustain each other. Again, in detailing the advantages of the arrangement of a spiral steel spring outside of and surrounding a column of rubber, the original specification sets forth, as an advantage, the strength of the spring, in that the steel prevents the rubber from being crushed, because, as the external surface of the rubber is shortened by compression, the coils of steel form a resisting surface against the rubber. This is independent of any fluting of the rubber, and is in contrast with the effect when the spiral steel is on the inside of the rubber. In another place, the original specification, speaking of the existing springs, with spiral springs of metal in the centre of the rubber, and detached bands of metal surrounding the rubber, in contrast with the arrangement of Bussell, points out, as an objection to the former, their liability to be crushed by an overload, for the want of a continuous metallic support externally. This, too, is a result independent of any fluting of the rubber. Then, as to fluting the column of rubber, the original specification points out that the rubber, when compressed, will find vent in the concavities.

The objection is taken to the reissued patent, that it is not for the same invention as that embodied in the original patent, and is, therefore, void; and, to maintain this, it is contended, that, on their faces, the two specifications are repugnant to each other. The argument is based on the view, that the original specification throughout speaks of the invention of Bussell as being one in which a fluted column of rubber is a constituent, and in which no column of rubber that is not fluted is spoken of as being a constituent, and that the claim is one to fluting a column of vulcanized India rubber longitudinally, and then surrounding it with a helical spring. But, the inference naturally to be drawn 1236from the language of the original specification, that Bussell does not claim, as his invention, “the surrounding a column of vulcanized India rubber with a helical spring, as that is the subject of a patent granted to F. M. Ray,” is, that, as such original specification exhibits the surrounding a column of vulcanized India rubber with a helical spring, and points out the advantages of such an arrangement, Bussell would, but for his idea, now shown to have been a mistaken one, in regard to Ray's patent, have claimed, in such original specification, the surrounding a column of vulcanized India rubber with a helical spring. If so, why should it not be claimed in a reissue? It would seem that there could not be found any more proper occasion for the office of a reissue. The original specification, drawings, and model exhibit fully what the reissue claims, and what the original fails to claim.

Much criticism is made on the specification of the reissue, because it makes prominent the column of rubber, merely as a column, without calling it, as the original specification always does, a fluted column, and because it only says that it may be fluted, as a desirable construction, to allow the expansion of the rubber, under pressure, into the concavities. But, when it was to claim, as it lawfully might, the column of rubber, as a column, with the spiral metallic spring arranged external to and surrounding the column, it was entirely proper that it should describe it as a column. It is none the less a column because it is fluted. The fluting introduces provision for vent. The advantages of the columnar structure bound tightly in the grasp of the surrounding helix of metal exist independently of provision for vent. As has been shown, both of these features exist in the arrangement shown in the drawings and specification of the original patent. Bussell, in his original patent, limited his claim to an arrangement combining both features. He might have claimed therein the features of the column and the outside spiral metallic spring, leaving out the feature of the fluting, although his structure contained the fluting. This has now been done by the reissue.

It is also objected, that the specification of the reissue contains an interpolation, in saying that Bussell's arrangement is different from Ray's, because it “permits the use of a solid column of rubber,” which Ray's does not It is undoubtedly true, that Bussell's arrangement does permit the use of a column of rubber which has not a longitudinal hole in its centre, and that Ray's arrangement requires that there shall be a longitudinal hole in the centre of the column of rubber. In the connection in which the specification of the reissue thus speaks of a “solid” column of rubber, it speaks of one which is not hollow, Ray's being hollow. Bussell's drawing shows a column of rubber which has no longitudinal hole in its centre, and, therefore, shows a column which is solid, in the sense intended. To state this self-evident circumstance in the specification of the reissue is no interpolation, when the drawings of the original patent show clearly that the remark is a true one. So, too, the words of the claim, “whether solid or hollow”—“the combination of a column of rubber, or its equivalent, whether solid or hollow, with a spiral metallic spring, &c.”—must be read with reference to the previous observation in the specification, that Ray's arrangement does not permit the use of a column of rubber which is not hollow, while Bussell's arrangement does. So read, the claim is one to the combination of a column of rubber, whether hollow or not hollow, with a spiral metallic spring. This claim means nothing different from what it would mean if the words “whether solid or hollow” were entirely omitted from it. The column of rubber, and the advantages resulting from combining it with a spiral metallic spring arranged external to and surrounding the rubber, exist as fully whether there is a longitudinal hole in the centre of the rubber or not. The advantages of a provision for vent, resulting from fluting the column, or from having a longitudinal hole in its centre, or longitudinal holes elsewhere in it, or spiral recesses in it, are a different thing. The reissued patent claims nothing in respect of such latter advantages, and does not claim any provision for vent. Its claim has reference solely to the embrace between the surrounding spiral metallic spring and the interior column of rubber. It may be that such embrace is more or less effective when it is spirally continuous, and not broken by recesses or flutes, and when there is no provision for vent. That is a question of degree of effectiveness of embrace. If, in the use of the embrace, it is made spirally continuous, it is none the less used. If, in the use of the embrace, provision is made for vent, in any of the ways above referred to, the embrace is none the less used. This view disposes of the criticisms, that Bussell did not invent a column of rubber having a spirally continuous embrace between the rubber and the external metallic spring, and did not invent a column of rubber having a longitudinal hole in its centre, or any provision for vent except by means of flutes. He invented what the reissued patent claims, as above explained, and if, in using that, an additional feature is added by the user, still the invention claimed is used.

It is also objected, that the specification of the reissue, in its body and in the claim, not only speaks of rubber “or its equivalent,” but contains, in its body, this language, not found in the original specification: “Any other material that is, for the purpose of a spring, the equivalent of India rubber, such as compressed animal and vegetable fibre, gutta percha, &c., may be employed in place of the rubber.” It is conceded, that the patent would cover any equivalent for the rubber, even if the words “or its equivalent” were 1237not found in the claim. But, it is objected, that the specification of the reissue undertakes to say what are equivalents, when the original specification made no mention of such equivalents, and that, therefore, the things mentioned are interpolations into the specification of the reissue. Certainly, any other material that is, for the purpose of a spring, the equivalent of India rubber, may be employed in place of the rubber. The employment of such other material would be within the patent, if nothing were said on the subject. Saying so does no harm. The point of the objection is, that it is asserted that the specification of the reissue points out “compressed animal or vegetable fibre, gutta percha, &c.,” as being, necessarily, for the purpose of a spring, the equivalent of India rubber; that no such statement is found in the original specification; and that Bussell, when he took out his original patent, did not contemplate the use of compressed animal or vegetable fibre. But, I think the body of the specification of the reissue can fairly be interpreted only as meaning, that if “compressed animal or vegetable fibre, gutta percha, &c.,” be, for the purpose of a spring, the equivalent of India rubber, it may, when in a condition to be such equivalent, be employed in place of the rubber. Under the claim, what is an equivalent is left to be determined in each case, as it arises; and the specification cannot properly be construed as determining that any particular thing is an equivalent.

The petition, oath and specification, on the application for the granting of the reissued patent sued on in this case, were filed in the patent office on the 7th of March, 1870. The fee or duty of $30 was paid on that day. A third drawing, completing the application, was filed on the 12th of March, 1870. The petition was not signed by Bussell, but was signed, “National Spring Company, by Rich'd Vose, President.” It set forth, that the National Spring Company, who are the plaintiffs in this suit, and the grantees of the reissue, were the owners, by assignment, of the entire interest in the original patent, and stated that the company thereby appointed Josiah P. Fitch its attorney to prosecute the application. The specification was signed, “National Spring Company, by Richard Vose, President.” It was not signed by Bussell. The oath to the specification was made on the 5th of March, 1870, by Richard Vose, and no oath thereto was made by Bussell. The 33d section of the act of July 8, 1870 (16 Stat. 202), provides, that “patents may be granted and issued or reissued to the assignee of the inventor or discoverer, the assignment thereof being first entered of record in the patent office, but, in such case, the application for the patent shall be made and the specification sworn to by the inventor or discoverer, and, also, if he be living, in case of an application for reissue.” This provision requires that, when an application for a reissue is made, the inventor, if living, shall make the application and swear to the specification, and then the patent may be reissued to the assignee of the inventor, if the assignment be first entered of record in the patent office. The 111th section of the same act provides for the repeal of prior patent acts, including the acts of July 4, 1836, and March 3, 1837 (5 Stat. 117, 191), and then proceeds: “Provided, however, that the repeal hereby enacted shall not affect, impair or take away any right existing under any of said laws; * * * and provided, also, that all applications for patents pending at the time of the passage of this act, in cases where the duty has been paid, shall be proceeded with and acted on in the same manner as though filed after the passage thereof.” The 13th section of the act of July 4th, 1836, provided for the reissue of a patent to the assignee of the original patent, but it did not require that the application should be made by the inventor, or that the new specification should be sworn to by him; and, although the 6th section of the act of March 3, 1837, providing for the issuing of a patent to the assignee of the inventor, enacted that the application therefor should be made by the inventor, and the specification should be sworn to by the inventor, yet it was never held by the courts, or by the patent office, that this provision of the act of 1837 applied to the case of the reissue of a patent. Hence, the provision of the 33d section of the act of 1870 was entirely new, so far as it required that, in case of a reissue to an assignee, the application therefor should be made by, and the new specification be sworn to by, the inventor, if living.

In the present case, the new specification was sworn to, and the application for the reissue was made, and the duty was paid, before the 8th of July, 1870. Such application was an application for a patent, within the meaning of the 111th section of the act of 1870, and was pending when that act passed, and the duty had been paid. It was, therefore, to be proceeded with and acted on in the same manner as though filed after the passage thereof. This means, that it was to be regarded as having been filed before the passage of the act, when filed in a complete form, before such passage, so as to be a pending application, with the duty paid, and then it was to be proceeded with and acted on, on the merits, in like manner as though filed after such passage, with the requirements complied with which the 33d section of the act of 1870 prescribes. To say, that the second proviso to the 111th section of the act of 1870 means, as is contended for by the defendants, that a pending application, made in conformity with the previous repealed laws, is to be filed anew and made to conform to the provisions of the new law found in section 33 thereof, and in the other sections relating to applications for patents, is to give no meaning whatever to such proviso, for, without such proviso, section 33 and such other sections would require that 1238the application should be made in conformity with the new law, as a prerequisite to the granting of the patent.

The enactment of the proviso was reasonable and proper, and the spirit and purpose which prompted it were still further carried out by the enactment of the act of March 3, 1871 (16 Stat. 583), providing that that part of section 33 of the act of July 8th, 1870, which requires that, in the case of an application by an assignee for the reissue of a patent, the application shall be made, and the specification be sworn to, by the inventor, if living, shall not be construed to apply to patents issued and assigned prior to July 8th, 1870. The view was, that an assignee who had, before July 8th, 1870, under the laws as they were before that date, purchased a patent, should have his rights in respect to obtaining a reissue measured by the former laws, and not affected by the new law. If he should become assignee on or after July 8th, 1870, he would do so with the knowledge that, in respect to a reissue, he must obtain the inventor, if living, to mate and swear to the application for the reissue, and he could take steps, in becoming assignee, to secure that end, or, failing that, could refrain from becoming assignee. On any other view, an assignee who became such before July 8th, 1870, might be deprived practically of a substantial right.

In this connection it is proper to refer to the attempt made by the defendants to impeach the validity of the reissue, on the testimony of Bussell. Much criticism might be made on the degree of reliance which ought to be attached to the evidence of Bussell, in view of the attitude in which he presents himself on the record in this case; and a court would hesitate to allow him, by his evidence, to render valueless a patent which he had assigned and given credit to, with the invention shown by it, and the right of reissue appurtenant to it. But, an examination of his testimony, in view of the observations before made on the original and reissued specifications, will show that he states nothing which can affect the validity of the reissue. The point of his testimony, is that he had not, when he applied for his original patent, designed to use an externally plain cylinder, or a hollow cylinder, in combination with a surrounding metallic spiral spring, and he assumes that the claim of the reissue covers and claims the feature of having the external surface of the column of rubber a plain cylindrical surface, and also covers and claims the feature of having a longitudinal hole or holes in the column of rubber. But, as has been shown, the claim of the reissue does not claim either of these features. It may be an infringement of the claim to use, in combination with an external spiral metallic spring, a column of rubber having either of these features; but that is a totally different question. The infringement would arise from the use of a column of rubber, in the combination, and not from the use of either of the special features referred to. If a patent should be granted claiming the special feature of a longitudinal hole or holes in a column of rubber surrounded by an external spiral metallic spring, such patent would find no anticipation, in respect to such special feature, in the original patent to Bussell or in its reissue.

In regard to the alleged prior invention by Ray, the evidence shows, that whatever he did, in the way of making a structure containing the combination of the plaintiffs' patent, was wholly experimental and fruitless, and was abandoned. The evidence fails to establish that any car spring containing such combination was used before Bussell made his invention, or before the date of his original patent I refer to the alleged use on the Naugatuck Railroad, the Housatonic Railroad, and the New Jersey Railroad. The temporary arrangement made by Kirtland on cars on the Housatonic Railroad was not the use of an organized combination or structure like the plaintiffs' spring, but was an incomplete and abandoned invention. In regard to the English patent to Asbury, the testimony shows that Bussell invented and reduced to practice the combination covered by the claim of the plaintiffs' patent prior to the granting of the patent to Asbury.

As it is admitted that the defendants have made and sold springs composed of a column of rubber surrounded by a spiral metallic spring, there must be a decree for the plaintiffs.

1 [Reported by Hon. Samuel Blatchford, District Judge, and Hubert A. Banning, Esq., and Henry Arden, Esq.; and here republished by permission. Merw. Pat. Inv. 451, contains only a partial report.]

This volume of American Law was transcribed for use on the Internet

through a contribution from Google.