Case No. 9,599.

MILLER'S FALLS CO. v. IVES et al. (two cases).

[14 Blatchf. 169; 2 Ban. & A. 574; 14 O. G. 203.]1

Circuit Court, D. Connecticut.

March 23, 1877.

PATENTS—REISSUE—BRACE FOR TOOLS.

1. The invention set forth in reissued letters patent granted to the Miller's Falls Manufacturing Company. November 29th, 1870, for an improvement in instruments for operating tools such as augers, bits, &c., the shanks of which are of variable sizes (the original patent having been granted to James M. Horton, July 8th. 1862) defined.

2. The invention set forth in letters patent granted to Charles H. Amidon, January 14th, 1868, for an improvement in bit-stocks, defined.

3. The claims of the patents construed, and the patents held to be valid.

4. The construction of devices which infringe the patents, set forth.

[These were suits by the Miller's Falls Company against W. A. Ives & Co. to restrain the infringement of letters patent No. 35,856, granted to J. M. Horton, July 8, 1862 (reissued No. 4,187, November 29, 1870), and No. 73,279, granted to C. H. Amidon, January 14, 1868.]

Charles E. Mitchell, for plaintiffs.

Benjamin F. Thurston, for defendants.

SHIPMAN, District Judge. These are two bills in equity, each of which is brought to restrain the defendant corporation from an alleged infringement of letters patent granted to James M. Horton, on July 8th, 1862, and reissued for the second time to the Miller's Falls Manufacturing Company, on November 29th, 1870, and also from an infringement of letters patent granted to Charles H. Amidon, on the 14th of January, 1868. Each patent is now owned by the plaintiffs. The Horton patent was for an improvement in instruments for operating tools, such as augers, bits, &c., the shanks of which are of variable sizes. The Amidon patent was for an improvement in bit-stocks. The infringement complained of in the first suit was the making and selling by the defendants of bit-braces, known in the market as the “Ives Brace” and the “Ives Novelty.” The second suit was brought to restrain the defendants from making the “Centennial” and the “Centennial Novelty” braces, the manufacture of which last named tools was commenced after the first suit had been brought. The two bills of complaint may be treated as substantially one action. The principal defence as against the Horton patent is non-infringement, 371and as against the Amidon patent is want of novelty.

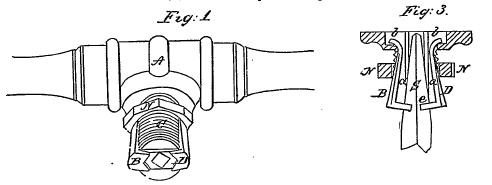

The Horton device was an auger handle, provided with a metal band, called in the patent a barrel, around its centre, the lower portion of which barrel is formed into a projecting cylinder or socket, recessed or slotted upon its opposite sides. The recesses receive two jaws, the ends of which are curved so as to lie loosely in the recesses, and act as fringes upon which the jaws swing. Along the centre axis of the cylinder there is a rectangular tapering bore, large enough to receive the shank of the boring tool. A revolving nut, which forces the jaws together, is fitted upon the screw threads which are cut upon the periphery of the cylindrical portion of the cylinder. When the nut is near the handle, the lower parts of the jaws swing upon their hinged parts, so as to receive the shank of the tool to be used. When the nut is screwed up, the curved ends of the jaws enclose the shoulder of the auger shank.

[Drawings of patent No. 35,856, granted July 8, 1862, to J. M. Horton, published from the records of the United States patent office.]

The claims are: “(1) The combination of the barrel A, provided with a socket C, jaws B and D and nut N, working on a screw for holding a boring tool, substantially in the manner described and specified. (2) The socket C of the barrel A, having cavities bb, in combination with the jaws B D having curved ends to fit therein, to allow the necessary lateral movement in the socket without falling out, substantially as described and specified.”

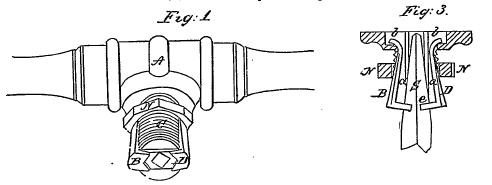

The Amidon brace consists, as described in the patent, “first, in the construction and use of two jaws, which conform to the taper of the bit shank, and are forced equally upon said shank at both ends, by a screw nut or other device; second, in the special construction of the end of the bit stock to hold said jaws and retain them always in place; third, in the formation of the groove in the edge of each jaw, so that the shoulders of the bit shank are enclosed, and the accidental withdrawal of the bit prevented;” and, fourth, in a particular not material to the present case. The bit stock has at one end the ordinary swivelled head, and at the other the clamping mechanism which is the subject of the invention. The end of the stock which receives the shank, and is called the foot, is cylindrical, and has a male screw thread cut upon its outer surface. A slot is cut vertically through the foot, and within this slot rest the jaws which seize and hold the shank. At the bottom of the slot is bored a cylindrical cavity with an enlarging orifice. A thimble or nut is constructed with a female screw thread corresponding at its lower portion with the thread on the foot, while the upper part is protuberant and contracted towards the mouth at the upper end. This nut screws upon the foot, and forces the jaws upon the shank. These jaws are in thickness suitable to fill loosely the slot. Their lower ends are attached to each other by a curved wire, which is rigidly set in one part, and projects loosely through the other part. The upper and lower ends of the jaws are bevelled, so that they may be forced together by the inclined surfaces of the nut and the cavity at the bottom of the slot, when the nut is screwed upon the foot. In the opposing surfaces of the jaws are formed grooves, which, when the jaws are in position, form a recess of square section. This recess is made tapering, so as to correspond with the taper of the bit shank, and is largest at the outer end, so that the shoulders of the bit shank may be enclosed within the jaws and the removal of the bit be prevented, except by relaxing the pressure of the jaws. As the jaws are loosely connected at the lower ends by the wire, they may either move apart, as on a pivot at that end, or they may be moved bodily away from each other, so as to accommodate a bit shank of any size or taper.

The three claims which are material to this case are: “(1) In combination with the jaws G, G, or their equivalents, constructed to move away from or towards each other in the manner described, so that they may conform to the taper of the bit-shank, the screw thimble F, or its equivalent, to force the said jaws upon said shank, as and for the purpose 372set forth. (2) The jaws G, G, constructed with the groove, formed substantially as set forth, so as to enclose the taper sides and the shoulders of the shank, as and for the purpose described. (3) The cavity D, formed with a bevelled orifice, as shown, in combination with the jaws G, G, constructed with correspondingly bevelled ends, as and for the purpose shown and described.”

The Ives brace is substantially like the Amidon. The Novelty brace differs from the Ives mainly in the fact that, in the thimble, the threaded portion is separated from the swell portion, and the nose or head of the thimble is attached fixedly to the socket. The lower portion of the thimble revolves towards the foot, and, by its revolution, produces the same effect as if the whole thimble revolved.

1. As to the character of the Horton invention, and the construction of the Horton patent. Devices for holding tools or articles which have shanks of variable sizes and tapers were known prior to the date of the Horton patent, and consisted broadly of clamping jaws and a nut which caused the jaws to effect a gripe upon the tool to be held. Thus, the clamp described in the Mechanics' Magazine (volume 14, p. 116) consisted of two jaws, with a recess in them to hold whatever was placed therein. The jaws are forced together by a dome-headed nut acting upon their noses. The “Stever Chuck” had a slotted socket with a screw thread, and two jaws, which clamp the tool by a screw nut or sleeve acting upon the jaws. The “Meriden Cutlery Chuck” had a slotted socket, with a round tapering bore at the bottom of the chuck, and two jaws forced together by a collar or sleeve, which moves forward upon the socket without any screw-thread, and is retained in its place by friction. The D. H. Chamberlain awl holder, patented in 1854, which will be more particularly considered hereafter, has a socket, and a dome-headed nut moving upon the screw on the socket, which nut acts upon two jaws, which approach each other and grasp the shank of an awl or other similar instrument.

The peculiar features of the Horton handle consisted in combining with the handle or stock of a boring tool, a slotted cylinder, provided with a rectangular tapering bore for holding firmly the shank of a boring tool, and hinged jaws working in the slot, having the necessary lateral movement to receive, without displacement, variable sizes of tools, and a nut moving on the screw thread upon the circumference of the cylinder, which nut clamps the jaws together so as to hold the shank. The shank is held firmly in place by the tapering bore and by the jaws which seize the angular portion of the bit, and serve not only to draw out the auger from the wood, but also help to prevent the auger shank from being twisted in its place as the bit enters the wood. The nut wedges the swinging jaws against the edges of the shank of the tool, and binds the projecting noses of the jaws against the upper end of the shank, so as to hold the tool firmly in position as it advances in the wood, and so as to draw it back as it is endeavored to be pulled out. Neither of the pre-existing devices had this combination of barrel, slotted socket with threaded outer surface, tapering bore, hinged jaws and nut. It is not claimed by the learned expert of the defendants that the Horton invention was antedated by any of the devices placed in evidence. The patent was for a handle of a boring tool having these described elements in combination, which several elements are formed substantially as described in the specification. The first claim was for the entire combination of the several elements. The second claim omitted the encircling nut, and made prominent the shape of the jaws by which lateral movement was permitted in the socket, without the jaws falling out.

2. The next question is whether the Ives and the Novelty braces infringe the Horton patent. These braces, which are substantially a reproduction of the Amidon brace, are manifestly an improvement upon the Horton invention, but have its leading features. These features, in the defendants' braces, are a threaded and slotted cylinder, which loosely holds a pair of movable jaws pivoted at the foot, or secured by a projection at the bottom of the slot, and enclosing a bit shank which they are made to clamp firmly by the action of an encircling nut, which is forced upon the shank at both ends, and closes the noses of the jaws over the top of the shank, so that the tool is held and retained in its proper position. The tapering bore of the Horton patent is transferred, in the defendants' braces, to the faces of the jaws, and becomes the tapering grooves which enclose the shank as the jaws are pressed against it by the action of the nut or thimble. The defendants insist that the jaws of the Ives braces and of the Horton patent are not the same, because they say that the only office of the Horton jaws is to prevent the auger bit from being withdrawn from the handle, and are a substitute for the nut or rivet which secures the handle of an old-fashioned auger, while the Ives jaws gripe the shank and prevent its turning around in the handle. But, the Horton jaws do not merely hold the auger bit in the handle. They also resist any tendency to turn around or to be twisted in the handle. Arguing upon this idea, that the office of the jaws in the two devices is different, the defendants easily prove that the respective jaws are radically different from each other, and that the grooved jaws of the Amidon bit holder, which grasp the shank so that it cannot turn, perform a different office from the jaws of the Horton handle, which, they say, serve merely to withdraw the auger bit; but, the premises being unsatisfactory, I am of opinion that the conclusion is also untenable. The principle of the Horton invention is reproduced in the Amidon and the defendants' 373bit stock, and, while that principle is developed so as to make a more perfect instrument, it is developed in substantially the same way, and by the same general mechanical means. The lateral movement which is mentioned in the second claim of the Horton patent, is produced, in the Novelty brace, by the jaws being loosely pivoted together in the bottom or foot of the cylinder, instead of swinging in recesses or cavities of the cylinder, as in the Horton patent, and is produced, in the Ives brace, by the movement of the jaws in a projection substantially similar to the arrangement in the Horton cylinder. The hinge-like movement of the jaws is substantially alike in each brace.

3. Is the Amidon patent invalid for want of novelty? That the Ives and Novelty braces infringe the Amidon patent, is not practically denied, and the principal question which remains as to these two braces is the validity of the patent. The Amidon bit stock is an improvement upon the Horton handle, and it becomes important to ascertain wherein the improvements consist. They are found in the shape of the jaws, and of the nut or thimble, and in the cavity at the bottom of the socket. These jaws are bevelled at the upper and lower ends, so that they are forced together by the surfaces of the thimble and of the cavity at the foot of the cylinder. The grooves of the jaws are so tapered as to fit the edges and shoulders of the shank, and the protuberant portion of the sleeve gives the jaws such a capacity of movement that they can take in a bit shank beyond the end of its shoulder, and the jaws will conform to the shape of the shank. The bevel of the jaws at their upper and lower ends, whereby the jaws are forced together, and the taper of the grooves in the jaws, are the peculiar and distinguishing features of the jaws. The protuberant swell of the thimble, whereby the jaws have greater capacity of adjustment to the taper and shoulder of the bit shank, and the contracting mouth of the thimble, which draws the noses of the jaws together over the top of the shank, are the peculiar features of the thimble. The recess at the bottom of the slot, formed with a bevelled orifice, has its office to force the lower ends of the jaws together, as they are forced by the pressure of the thimble against the walls of the cavity. In the peculiar formation of these parts of the combination consist the patentable features of the Amidon patent.

The question of novelty depends materially upon the construction which is given to the patent and to its first claim, which is as follows: “In combination with the jaws G, G, or their equivalents, constructed to move away from or toward each other in the manner described, so that they may conform to the taper of the bit shank, the screw thimble F, or its equivalent, to force the said jaws upon said shank, as and for the purpose set forth.” If this claim means the jaws G, G, or any jaws constructed so as to move away from or towards each other, in the general manner described, so that they may conform to the taper of a bit shank, in combination with the screw thimble F, or any thimble which forces the jaws upon the shank, the claimed invention was probably well known. Such a construction would limit the patentable part of the invention to the third claim, and would make it consist of the recess at the bottom of the slot in combination with bevelled jaws; but such a construction is not in accordance with the actual invention or with the specification. The peculiarities of the jaws G, G, are minutely described, and stress is laid upon the peculiar shape of the jaws, which evidently constituted, in the mind of the patentee, the distinctive feature of his invention. The protuberance and convergence of the screw thimble are described, though the same prominence is not given to the thimble as to the jaws. The first claim specifies the peculiarly shaped jaws G, G, or jaws which are substantially formed like the jaws G, G, in the following particulars, viz., which are constructed to loosely fill the slot, and so that they may move apart on a pivot, or may be moved bodily away from or towards each other in the described manner, and thus conform to the taper of different bit shanks, in combination with the peculiarly shaped screw thimble F, or a thimble which is so constructed as to allow, by its protuberance, the range of movement of the jaws which thimble F permits, and also to bind the heels and noses of the jaws upon the shank. This claim has special reference to jaws pivoted and bevelled, which have the range of movement between the laterally supporting walls of a slotted cylinder which the jaws G, G, have, in combination with the encircling thimble, which, by its protuberant shape, also gives the jaws their capacity of movement, and, by its convergence, clamps the noses of the jaws. The grooves are particularly specified in the second claim, which is for the peculiarly shaped jaws G, G, with tapered and grooved faces. The third claim is for the cavity D, in the bottom of the slot, with a bevelled orifice, in combination with the jaws G, G, which combination permits a lateral movement of the jaws within the cylinder, and the closing of the heels of the jaws within the cylinder, and the closing of the heels of the jaws when acted upon by the thimble.

This statement of the invention and this construction of the patent excludes from the consideration of anticipatory devices, the Stackpole brace of 1862, the Stackpole patent of 1867, the Goodell brace, and the Bartholomew brace of 1867. The jaws of neither of these braces have tapering ends or noses which are closed over the shoulders of the bit shank, and which are acted upon by a protuberant and convergent sleeve or thimble. These devices were not, however, mainly relied upon by the defendants, who chiefly urged, as an anticipatory invention, the Dexter 374H. Chamberlain awl holder, patented in 1854. This tool is a useful one for holding the shanks of awls, or other similar small tools, but could not be relied upon to endure the strain and twist which necessarily comes upon an auger or bit, whose radially cutting edges are forced by successive revolutions into the wood. The tool consists of a pair of clamps, each one of which is cylindrical upon the outside. The upper and lower ends are conical, which ends are cut off and do not run to a point. Through the centre of the inside of each one of the clamps, is cut a triangular groove from top to bottom, so that, when the clamps are placed together, the triangles face each other, and make a uniform, straight, square groove throughout the extent of the clamps or jaws. These jaws enclose the shank of an awl, and are screwed together and kept in place by a dome-shaped screw nut. These jaws are not like the Amidon jaws, loosely placed in a slotted socket, to give lateral motion, nor are they so constructed as to accommodate themselves to bit shanks of varying taper, nor is the dome-shape sleeve the equivalent of the protuberant and converging sleeve of the Amidon patent. In brief, the Chamberlain holder has neither the movable nor tapered jaws, nor the thimble, of the Amidon stock.

On February 16th, 1871, the plaintiffs, or their predecessors, licensed the defendants to make two thousand braces of their patent, No. 111,649, dated February 7th, 1871, for a royalty of ten per cent, on the net prices for which the defendants sold the braces. They did not manufacture the precise invention represented in their patent, but made a quantity of the braces known as the “Ives Brace,” and which are made according to the Amidon patent. I have not seen the Ives patent, and therefore do not understand precisely the difference between the two articles, but understand, from the testimony of the defendants' expert, that there is less capacity of lateral movement in the jaws at the foot of the brace in the Ives patent, than in the Amidon, and that the elder patent is broader than the Ives patent. The defendants were licensed only to make the article which was shown in their patent. On December 30th, 1875, the defendants, by agreement, submitted to a preliminary injunction against manufacturing the Ives brace, and conceded that it was an infringement of the Amidon patent, without conceding any other questions in the case, in regard to other braces. It was further agreed, that, in any accounting, the defendants shall account for all Ives braces, in accordance with the terms of said agreement of February 11th, 1871. Upon this state of facts, I think that the Ives brace is not protected by the license, and it is also true that the plaintiffs have agreed that the infringement is to be paid for as if it was so protected.

The questions in regard to the Centennial and Centennial Novelty braces only remain. These two braces differ from the Ives and the Novelty mainly in this, that the jaws are attached to the side walls of the bevelled cavity in the foot, and that these side walls move on a pivot towards each other, when operated upon by the screw thimble, and so pinch the jaws together. This accomplishes the same result, in substantially the same way in which it is accomplished in the Amidon patent, where the heels of the jaws are forced together in the bevelled orifice by the screw thimble acting directly upon the jaws, or, as it is expressed in the patent the jaws are “forced together by the inclined surfaces of the thimble F and the cavity D, when the said thimble is screwed on the foot.” It is not material whether the walls of the orifice pinch the jaws, or the jaws are pinched against the walls. These two braces, differing from the other braces of the defendants only in the particular which has been named, infringe also the third claim of the Amidon patent, and, equally with the other braces, infringe the first and second claims of that patent, and also of the Horton patent.

There should be a decree for an injunction against the four braces of the defendants, and for an accounting.

1 [Reported by Hon. Samuel Blatchford, Circuit Judge; reprinted in 2 Ban. & A. 574; and here republished by permission.]

This volume of American Law was transcribed for use on the Internet

through a contribution from Google.