Case No. 7,911.

KNOX v. MURTHA et al.

[9 Blatchf. 205; 5 Fish. Pat. Cas. 174; Merw. Pat. Inv. 104.]1

Circuit Court, E. D. New York.

Nov. 28, 1871.

PATENTS—SMUT-MILL—CONSTRUCTION OF CLAIM—PATENTABILITY.

1. The third claim of the reissued letters patent, No. 3,794, granted to Daniel Shaw, January 11th, 1870, for an improved smut-mill and separator, (the original patent having been granted to him April 6th, 1852, and reissued November 3d. 1863, and extended April 6th, 1866,) namely, “In combination with a smutter or scourer, and a suction fan, both arranged on and driven by the same shaft, and an air-trunk for directing the course of the blast, a regulator, for changing the force or volume of the current of air, without changing the speed or motion of the smutting or scouring cylinder, substantially as described,” is limited to a combination in which a tight smutter or scourer is employed, and does not cover a combination in which an open scourer is employed.

2. The general words of the claim are to be construed as limited by any particular description found in the specification.

3. Reasons stated why such third claim is, probably, invalid.

4. The fifth claim of the patent, namely, “The arranging of the smutter or scourer and the suction separating fan within or between the legs of the blast or air-trunk, in which the entire separation is made, and which passes over or around them, for the purpose of economizing space, and cheapening the construction of the machine, substantially as described,” is void, as covering no patentable invention.

[Cited in Smith v. Thomson, 38 Fed. 606.]

2 [Final hearing upon pleadings and proofs. Suit brought upon letters patent for an “improved smut-mill and separator,” granted to Daniel Shaw, April 6, 1852; reissued November 3, 1863; extended for seven years from April 6, 1866; again reissued January 11, 1870, as reissue No. 3794, and assigned to complainant.

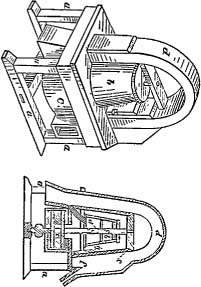

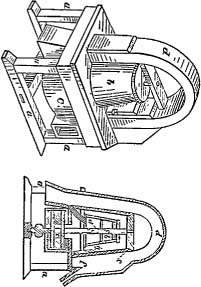

[The above engraving illustrates the Shaw machine. The specification states:

[“Figure 1 represents, in perspective, an external view of the combined smut-mill and grain-separator; and figure 2 represents a vertical section through the same. Previous to my invention, the smutting and scouring of grain were done in one machine, and the separating of the grain into qualities, according to the specific gravity, and further separating of grain from the screenings of lighter impurities, and from the dust, chaff, etc., were done in another machine, thus requiring two machines, two handlings, and two operations. I lay no claim to any such 823separated machines or operations. Nor do I claim any machine where a separation is attempted through the smutting-cylinder, or wherein less than three distinct and separate divisions of the material, according to their values and specific gravities, are made, and separately deposited in separate places. The object and purpose of my invention are to so devise, as, that by one machine, one handling of the grain, and one operation, the grain shall be divested of the smut, or scoured, separated into qualities of heavy and lighter grain, and separated from the dust, chaff, and light impurities, by once passing through such machine; and, secondly, my object and purpose are to so construct such a machine as that it would be simple in its construction, not liable to get out of order, efficient in its operation, and, from its cheapness of construction, within the reach of any one.”

* * * * * * * *

[“a, a, etc., represent a main frame for containing and supporting the entire machine. Upon this main frame is supported a vertical shaft, which may be driven by a belt from any first moving-power, and upon the lower end of this shaft is arranged a fan, c, and upon the upper end thereof a smutting or scouring-cylinder, b, both the fan and the smutting-cylinder being arranged within suitable cases, that have proper inlet and exit-openings, as will be explained. Over the smutter and fan-cases passes an inverted bow or U-shaped wind-trunk, d, which is common to the smutter by the pipe or passage d', and to the fan by or through a passage underneath the smutter-case, that leads into the eye of the fan. A sliding regulator, g, commands the passage leading from the wind-trunk to the eye of the fan, so that, without interfering with the speed of the smutter-cylinder or the fan, the force of the blast or current of air through the wind-trunk to the fan may be regulated. Within the wind-trunk is arranged a screen, e, where a separation of the lighter grains or impurities may be made from the smut, dirt, chaff, etc., said lighter grains dropping from the edge of the screen into the opening at f, and thence passing out of the machine, while the smut, dirt, and chaff are drawn into and through the fan, and driven out through the trunk (Fig. 1) leading from the fan-case out of the building, if necessary. The heavy wheat, or that which is fully cleaned and divested of all its impurities, when, or the instant after, it is passed from the smutter through the passage into the wind-trunk, falls out of the open end of said trunk, while all the remaining particles of light grain, chaff, short straw, smut, dirt, etc., are taken by the ascending current of air, and carried up and over to where the succeeding separation takes place, as above mentioned. The grain, with all the impurities mixed with it, as it comes from the thresher, or in a partially-screened state, is thrown into the smutter, through an opening in its top, where the smut-balls are broken or loosened, and the grain scoured by attrition, and by the beater-arms throwing it against the enclosing-case or shell. No separation takes place in the smutter, as there is no operative-blast within the outer case. The whole contents of the smutter, including the dirt shoveled in with the grain, and everything loosened from the grain, pass from the smutter or scourer into the wind-trunk, and the moment they enter the wind-trunk, then the separating begins; the heavy wheat, by its specific gravity, dropping down and out of the wind-trunk, while all the lighter particles are carried up and over to the final separation. There are three different places of deposit for the three different things separated from each other, viz., the heavy, plump, cleaned wheat, at the end of the wind-trunk, where the air enters; the lighter grains and particles are carried out through f; and the dirt, smut, and chaff are drawn through the fan, and out through the trunk or passage leading therefrom, and out of the building, if necessary. Having thus fully described my invention, and shown how it is operated, what I claim therein as new, and desire to secure by letters patent, is: 1. The combination of a smutter or scourer, with an independent suction separating fan-blast or current of air, so that the separation of the dust, chaff, and other impurities from the grain, shall take place after the grain has been scoured, and after leaving the scouring-cylinder, and the dust separated from the lighter impurities, and deposited apart from the chaff and other impurities, and independent of any action of the smutter, substantially as described. 2. In combination with a smutter or scourer and a separating suction-blast, the separating and depositing in separate places of, first, the heavy or very clean wheat; second, the lighter grains or screenings, freed from dust; and third, the smut, dust, and chaff, substantially as described. 3. In combination with a smutter or scourer and a suction-fan, both arranged on and driven by the same shaft, and an air-trunk for directing the course of the blast, a regulator for changing the force or volume of the current of air, without changing the speed or motion of the smutting or scouring-cylinder, substantially as described. 4. The combination of a smutter or scourer and a suction separating-fan, with a wind or air-trunk, common to both the smutter and the fan-blast, and so that the contents of the smutter may pass into the column of air that rushes through the trunk to the fan, and the entire separation take place therein by the action of the fan-blast alone, after leaving the scourer, substantially as described. 5. The arranging of the smutter or scourer and the suction separating-fan within or between the legs of the blast or air-trunk in which the entire separation is made, and which passes over or around them, for the purpose of economizing 824space and cheapening the construction of the machine, substantially as described.”]3

Keller & Blake, for complainant.

Sprague & Hyatt, for defendants.

BENEDICT, District Judge. This is a suit in equity brought by John M. Knox, the assignee of a patent for an improved smut mill and separator, reissued to one Daniel Shaw, on the 11th of January, 1870, to obtain a decree for an injunction and account against Terance J. Murtha and Richard P. Charles, because of an alleged infringement of said patent in the use of a grain scourer and separator manufactured by Howes, Babcock & Co., of Silver Creek, in this state. The defendants deny the infringement and also deny the validity of the Shaw patent as reissued.

I shall first consider the question of infringement. There is no dispute as to the description of machine which the defendants use; and whether they infringe or not depends upon the construction given to the Shaw patent. This patent [No. 8,861] was originally issued to Daniel Shaw on the 6th of April, 1852, and reissued on the 3d of November, 1863. On the 6th of April, 1866, an extension of the patent was granted for seven years, and the patent was again reissued to Shaw, on the 11th of January, 1870. It is designated in this case as the Shaw reissue No. 3,791. It contains five claims; but, since the commencement of this suit, a disclaimer has been made of the first, second and fourth claims, leaving only the third and fifth claims to be considered here.

The third claim is as follows: “In combination with a smutter or scourer, and a suction fan, both arranged on and driven by the same shaft, and an air trunk for directing the course of the blast, a regulator for changing the force or volume of the current of air, without changing the speed or motion of the smutting or scouring cylinder, substantially as described.” This is a claim for a combination only; and one of the questions raised is, whether the combination secured by it is limited to the use of a tight smutter or scourer, or whether it covers the use of any form of smutter or scourer in combination with the other elements described. If, as the defendants insist, it be construed so as to confine the patent to a combination in which one element is a tight smutter or scourer, this action must fail; for, the combination employed in the machine used by the defendants contains an open scourer, and does not contain a tight smutter or scourer. Much importance has been attached to this question by the counsel, and I have considered it with care. My conclusion is, that the construction contended for by the defendants is the true construction to be placed upon the third claim.

An examination of the patent will, as I think, render apparent the correctness of this conclusion. In the claim itself, which designates the combination sought to be secured, no description is given of the scourer which is stated to be an element of the combination sought to be secured. The words are, “in combination with a smutter or scourer;” and these words, it is said, are sufficient to include any form of scourer then known. But, effect must be given to the words, “substantially as described,” which are used in the claim, and their effect is to refer to the specification for the description of the elements of the combination which is wanting in the claim. The general words of the claim in respect to the scourer are, therefore, to be construed as limited by any particular description found in the specification. The specification first recites, that, “previous to the invention of Shaw, smutting and scouring of grain were done in one machine; and the separating of the grain into qualities, according to its specific gravity, and further separating of grain from the scourings or lighter impurities, and from the dust and chaff, were done in another machine, thus requiring two machines, two handles, and two operators.” The specification then declares: “I lay no claim to any such separated machines or operations, nor do I claim any machine where a separation is attempted through the smutting cylinder, or wherein less than three distinct and separate divisions of the material, according to their values and specific gravities, are made, and separately deposited in separate places.” The specification further states, that “the invention consists in the combination of a smutter or scourer with a suction separating fan-blast or current of air, so that a separation of the dust, chaff, and other impurities from the grain shall take place after the grain has been scoured; and after leaving the scouring cylinder;” and, again, that “the invention further consists of a combination of a smutter or scourer, and a suction separating fan, with a wind or air trunk common to both the smutter and the fan-blast, and so that the contents of the smutter may pass into the column of air that rushes through the trunk to the fan, and be separated therein;” and, again, that “the grain, with all the impurities mixed with it, as it comes from the thresher, or in a partially screened state, is thrown into the smutter, through an opening at its top, where the smut balls are broken or loosed, and the grain scoured by attrition and by the beater arms throwing it against the enclosing case or shell. No separation takes place in the smutter, as there is no operative blast within the outer case. The whole contents of the smutter, including the dirt shoveled in with the grain, and every thing loosened from the grain, pass from the smutter or scourer into the wind trunk, and, from the moment they enter the wind trunk, then the separation begins, the heavy wheat, by its specific 825gravity, dropping down, and out of the wind trunk, while all the lighter particles are carried up and over to the final separation.” This description of the invention cannot be misunderstood, when taken in connection with the state of the art at the time. At the time of the invention of Shaw, two forms of machines called “smutters” or “scourers” were well known. The form called here a “tight” scourer has a tight cylinder or enclosing case, within which the grain, as it comes from the thresher, is beaten about by arms and scoured, and then the mass discharged, to be thereafter separated by a separator. The other form, here called an “open” scourer, has, instead of a tight cylinder, an enclosing case with numerous perforations in it, through which dust and dirt can be driven by the blast caused by the beaters, or by an operative blast introduced from a fan. The difference between these two machines is radical. If grain, as it comes from the thresher, be submitted to the action of a tight scourer, while useless portions are loosed from the kernels of grain and the kernels scoured, they are, by the same operation, smeared with any smut or adhesive dirt set free by the action of the beaters, and this to an extent, as the evidence shows, which renders the machine comparatively valueless where smutty wheat is present. But, if an open scourer, with an operative blast, be used, the smut and a large portion of the dirt and dust, as fast as loosed, are driven through the perforations in the enclosing case, and thus an important separation is effected, simultaneously with the loosening of the particles and by the same operation. The one form of machine loosens and separates; the other loosens and combines. Of these two forms, only the tight scourer will answer to construct the machine or combination described in the Shaw patent; and by the use of that form of scourer alone can the result be obtained which the patent declares to be the result sought by the invention, namely, the accomplishment of the entire separation in the air trunk.

The specification of the Shaw patent, although it does not, in so many words, say that the smutter or scourer used is a tight scourer, does state that no claim is made to a machine wherein a separation is attempted through the smutting cylinder. This is equivalent to describing the smutter or scourer as tight, and without an operative blast; and, accordingly, the specification must be understood as excluding from the combination an open scourer with an operative blast.

There was a reason for thus limiting the claim of the patent. At that time, there were in use three combined separating machines, which made three separations, or, more properly, delivered their contents in three divisions, and used open scourers, wherein a part of the separation was accomplished, namely, Torrey's, Ashley's and Johnston's; and there is no evidence of the prior existence of any machine making three separations which used a tight scourer. Shaw, therefore, would naturally be expected to limit his claim to a combination in which a tight scourer formed one of the elements, as he has done by the reissue in question.

I have not overlooked the suggestion, that the use of an open scourer, instead of a tight scourer, is but adapting an improvement to the combination claimed by Shaw. The answer is, that an open scourer is not an improved tight scourer, but a different device, producing a different result, as is shown by the fact, that the defendants' machine will clean and separate smutty wheat, which the Shaw machine will not do. Shaw's patent is for a combination of elements acknowledged to be old, which are arranged in a certain way, in order to accomplish a stated result, namely, the separation of the threshed grain into three divisions in the air-trunk alone. One of these elements he has, by his claim, taken in connection with his specification, described as a tight scourer. The defendants do not infringe upon his patent, because their machine does not contain any tight scourer, or its equivalent, but does contain another element, having a different function, and producing, in combination, a different result Even if the result attained by the defendants' machine be considered as similar to that sought to be accomplished by the Shaw machine, because, in addition to the separation effected by the open scourer, it also effects three separations of the remainder in the air-trunk, still, the defendants cannot be held to be infringers on the Shaw patent, for, the combination which they use is not Shaw's combination. It discards one of Shaw's elements, as he has described them, and includes a device not found in Shaw's combination, which performs, in the defendants' machine, a function not performed by any device in Shaw's machine, whereby the material to be separated in the air-trunk is changed in character, being free from smut, and having a different proportion of dust; and, in such added device, as the evidence shows, nearly three-quarters of the separation takes place. I am, therefore, of the opinion, that the plaintiff has failed to prove the infringement charged.

There is another aspect of this case, which I will also notice. The defendants have put in evidence a grain separator, well known, and in use prior to the date of the Shaw invention, which had been invented by one Sanders, and is known as Sanders' separator. This machine consists of an air-trunk, through which an air current is created by a suction fan, and the same regulated by a regulator. In this trunk, the current first ascends through an ascending leg. At the top of the ascending leg, the air-trunk turns 826at right angles, and gives to the air current a horizontal direction. This horizontal portion of the air-trunk is enlarged, and its lower surface given the form of a capacious hopper, with a slide-valve at the bottom. After passing the hopper, the air-trunk turns down again, and into the eye of the fan. In this machine, material coming from a scourer is spouted into the ascending leg, where the heavy grain is separated from the rest of the mass by gravity, precisely as in the Shaw machine. This separation effected, the remainder of the mass passes into the horizontal part of the air-trunk, where the current is weakened by the enlargement of the trunk, and, by means of the depression of the bottom of the air-trunk, to form the deep hopper, the force of gravity is again rendered effective. Here, therefore, while the dirt, dust and chaff are carried on, by the air current, to the eye of the fan, the screenings are carried, by their gravity, out of the air current, to the bottom of the hopper, and thence removed by the slide-valve. The dust and dirt, thus separated from the screenings, pass out of the machine through the fan. The Shaw machine, according to the testimony of Mr. Renwick, an expert called by the plaintiff, differs from the Sanders machine only in that it contains a separator combined with a scourer driven by the same shaft. If this opinion be correct, the Shaw patent must fail, so far as the third claim is concerned, for want of novelty, because, it has been proved, that the combination of a scourer and a separator driven upon the same shaft, was in use before the Shaw invention. It would, also, be open to the objection, that no invention was required to attach a scourer to the shaft of Sanders' separator. But this conclusion of the expert is not agreed to by the plaintiff, who insists that another and a material difference exists between Sanders' separator and Shaw's machine. At first, it was said, that, in the Sanders machine, the screenings fall into the hopper simply by reason of the enlargement of the air-trunk, which reduces the speed of the current, and then nothing but the dust passes with the air current, in the descending leg, to the eye of the fan, while, in the Shaw machine, the screenings, as well as the dust, pass into the descending leg, and there, while the screenings are descending by the force of gravity, as well as by the force of the current of air, the current of air is forced to take a lateral direction away from the force of gravity, and is aided by an ancillary upward current of air, admitted through the spout F, the place of exit for the screenings, which operates against the descending force of the screenings, and thus the separation is completed. But, it is manifestly no substantial change in the air-trunk, to place the enlargement on the descending leg, instead of on the horizontal portion, as in Sanders' separator. In both cases, the air current is weakened by an enlargement of the trunk, and, in both cases, the separation is effected by the air current being forced to take a lateral direction, away from the force of gravity. If there be any difference, then, between the two machines, sufficient to support the patent, it must arise solely from the existence, in the Shaw machine, of an ancillary current, admitted through the spout F. This was finally conceded on the argument, and the opening at the spout F, for the incoming of the opposite current of air, was pointed out as constituting the only substantial difference between the two air-trunks. But no such feature as an ancillary current admitted into the air-trunk at the spout F, is alluded to in the Shaw patent. It does not appear either in the original patent, or in either of the reissues, and it seems impossible to say that these descriptions convey the idea that an ancillary upward current of air, admitted through the spout F, is an element in the machine. In the third claim of the reissue, the air-trunk is described simply as “an air-trunk for directing the course of the blast.” But this description, to render it effective for any purpose, must be held to be qualified by the description given in the specification; and there, while the spout F is mentioned, it is only spoken of as used for receiving and carrying out the scourings from the air-trunk. It is true, that, in the drawings, the spout F is open, and it is spoken of in the description as an opening, but no one could gather, from either the description or the drawings that the machine was to be so constructed and the size of the opening at the spout F so proportioned, that, while the scourings should there pass out, an ancillary current of air was, at the same time, to be there admitted, to perform a characteristic part in effecting the separation within the air-trunk. No witness is called to show that such an idea would be conveyed by the specification and drawings, and the contrary seems proved by the fact, that no such idea was conveyed to Mr. Renwick, the plaintiff's expert, who has made this patent a study. My conclusion upon this branch of the case, therefore, is, that, if the only difference between Shaw's machine and Sanders' separator is that stated by the plaintiff's expert, the Shaw patent must fail, so far as the third claim is concerned, for want of novelty, and, also, of invention; and that, if there exists the further difference claimed by the plaintiff, that an ancillary current of air is admitted to the air-trunk through the spout F—a position not easy to maintain upon the evidence—then the Shaw patent must fail, so far as the third claim is concerned, because it does not contain a sufficient description of the invention sought to be secured.

Entertaining these views in respect to the third claim of the Shaw patent, it is unnecessary for me to express an opinion upon the other grounds of objection to this claim taken by the defendants, and I pass to a 827consideration of the fifth claim of the Shaw reissue, upon which, also, the plaintiff bases a right to maintain this action. The fifth claim is as follows: “The arranging of the smutter or scourer, and the suction separating fan, within or between the legs of the blast or air-trunk, in which the entire separation is made, and which passes over or around them, for the purpose of economizing space, and cheapening the construction of the machine, substantially as described.” The idea here expressed, which the patentee has embodied in his machine, and claims to secure as his own, is, that, in a machine having a scourer and fan connected by an air-trunk, as described, economy of space and cheapness of construction would be gained by placing the smutter or scourer between the legs of the air-trunk, instead of elsewhere. Certainly, no invention was required to reach such a result. It would rather require invention to find any reasonably convenient place to locate a fan and scourer so connected, other than the one chosen by the patentee. No advantage, or change in the operation of the machine, is claimed for the arrangement, but simply economy of space and cheapness in the construction. That this would be gained by such an arrangement as the patentee claims, could not fail to occur to the mind of any intelligent person seeking to combine a scourer and fan with an air-trunk, as described. A similar arrangement of materials, for the same reason, is to be seen everywhere. I am, therefore, of the opinion, that the fifth claim of the Shaw reissue is invalid, because of insufficiency of invention. The decree must accordingly be, that the bill be dismissed, with costs.

1 [Reported by Hon. Samuel Blatchford, District Judge, and by Samuel S. Fisher, Esq., and here compiled and reprinted by permission. The syllabus and opinion are from 9 Blatchf. 205 and the statement is from 5 Fish. Pat. Cas. 174.]

2 [From 5 Fish. Pat. Cas. 174.]

3 [From 5 Fish. Pat. Cas. 174.]

This volume of American Law was transcribed for use on the Internet

through a contribution from Google.