Case No. 6,461.

HICKS v. MOLLER.

[4 Ban. & A. 434;1 16 O. G. 805.]

Circuit Court, D. Connecticut.

Aug. 13, 1879.

PATENT—INFRINGEMENT—“BOTTLE-STOPPER.”

Upon the construction given by the court to letters patent No. 48,300 granted to E. D. Mover, on June 20th, 1865, for an improved bottle-stopper, the defendants held not to have infringed.

[Bill by William H. Hicks against Constant A. Möller for infringement of a patent.]

George Gifford and E. L. Sherman, for complainant.

A. v. Briesen and Thomas H. Dodge, for defendant.

119SHIPMAN, District Judge. This is a bill in equity to restrain the alleged infringement of letters patent [No. 48,300] Which were granted to B. D. Moyer on June 20th, 1865, for an improved bottle-stopper. The plaintiff is the owner of the patent.

The object of the invention was to provide a durable and cheap substitute for the ordinary bark corks used for stopping beer and mineral-water bottles. The patentee says in his specification: “The nature of my invention consists in providing a hollow metallic cap, with an elastic water-proof filling, and attaching to its outer side a swinging frame of stiff wire so bent and fitted that when the elastic end of the cap is placed over the open mouth of the bottle and pressed firmly down thereon by hand, the lower end of the said swinging frame can be readily sprung under the lip of the bottle by one's finger, so that it will clasp it itself to the neck of the bottle, remain in that position without other fastening, and thus hold the cap firmly and tightly down on the mouth of the bottle against the pressure of the contained fermenting or expansive nature of beer, mineral water, or other similarly expansive beverage usually put up in bottles for sale, and also allow the quick removal of the said stopper when required, without breaking, deranging, or otherwise injuring any of its parts for subsequent use in like manner.”

I deem it important to describe only the construction of the swinging frame. The manner of its construction will be better understood from the following description by the plaintiff's expert than from the language of the specification: “Through the upper portion of the metallic cap-piece, and upon a line which is the diameter of the cylinder, a hole is bored from one side to the other of the cap-piece, and a wire, marked a2, is passed through the hole and made long enough to project on either side of the vertical outside walls of the cylinder, and in a horizontal direction when the cap is on the bottle, far enough to furnish bearings for a swinging frame to be pivoted to, and this wire, of course, stands vertically over the centre of the bottle mouth, and at right angles to the vertical axis of the cap-piece and rubber filling. The swinging frame, which is thus hinged to the ends of the projecting wire, a2, is furnished with loops marked b1, one on each side of the cap-piece, and the frame thus swings around the wire, a2 as a centre, and around a line which is the diameter of the cap-piece. The swinging frame is made from one piece of wire, and is called the swinging spring frame, B. It has two legs, b4, which extend from the eyes b1, nearly parallel to each other, to a circular bend marked b2 in the drawing, making also another bend or loop where the said legs join the curve, b2. The curve, b2, is made somewhat smaller in diameter than the diameter of the bottle under the projection, c1, and the curve extends more than a half-circle and less than two-thirds of a circle on the drawing when the whole apparatus is placed on a bottle. The curved portion upon both sides of the bottle just under the bends, b3, hug the bottle and clasp-it, and assist in keeping the frame in place. The operation of the apparatus is as follows: The rubber filling, a1, is introduced into the bottle mouth, pressure is applied to the top of the cap-piece, and the rubber is condensed sufficiently between the cap-piece and the rim, c1, to allow the swinging spring-frame to be thrown under the rim, c1. When this has been done the spring-frame clasps the bottle, the rim, c1; prevents the spring-frame from rising, and the cap is held down on the bottle mouth, and the bottle mouth is made tight against the escape of the contents of the bottle.”

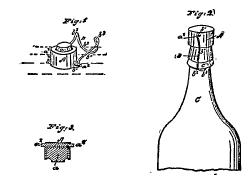

[Drawings of patent No. 48,300, published from the records of the United States patent office.]

The claim of the patent is as follows: “The bottle-stopper, described and shown, the same consisting of the cap, A, the elastic water-proof filling, a1, and the swinging spring frame, B, the whole being constructed, arranged, and combined together so as to operate, when applied to the mouth and neck of a bottle, substantially as described, for the purposes specified.” The main question in the case is that of infringement. The defendant's bottle-stoppers are made under the reissued patent of Charles De Quillfeldt, assignor to Karl Hutter, dated June 5th, 1877.

The defendant's device consists of an elastic flexible disk stopper provided with a stem which is inserted in a flanged metallic thimble. The opening and closing mechanism consists of a V-shaped yoke, made of a stiff piece of wire, the central portion of which passes loosely through the stem of the stopper. The ends of this yoke are bent inwardly, and are pivotally connected with a lever, as hereinafter described. This lever is also V-shaped, and made of stiff wire, and “has its ends pivotally connected with a wire bound around the neck of the bottle and has each of its legs coiled, with slightly less than a single turn, for the purpose of forming two eyes for the reception of inwardly bent ends” of the yoke. When the bottle is to be closed, the stopper is placed by hand upon the 120mouth of the bottle, and the lever is swung downward and inward or upon the neck of the bottle.

The marked differences between the two devices are these: In the Moyer device, the cap is slightly secured to the mouth of the bottle by the spring-clasp of the lower part of the swinging frame under the lip of the bottle. In the De Quillfeldt device the stopper is pulled into the mouth of the bottle, and is retained there by the strong, rigid, constant pulling force of the lever. The Moyer stopper is kept in place by a spring-clasp. There is no springing action or clasp in the De Quillfeldt contrivance, but there is a steady and positive pull downward upon the yoke, by the lever, as it is turned and locked. There is no permanent connection in the Moyer device between the bottle and the stopper. The stopper is held upon the bottle only when the frame is sprung under the neck. In the De Quillfeldt device, the stopper is always connected with the bottle by the linked yoke and lever by means of three pivotal connections; the stopper is pivoted to the yoke, the yoke is pivoted to the lever, and the lever is pivoted to the neck-band which encircles the neck of the bottle. I am of opinion that the two devices are substantially different in construction and mode of operation. Let the bill be dismissed.

1 [Reported by Hubert A. Banning, Esq., and Henry Arden, Esq., and here reprinted by permission.]

This volume of American Law was transcribed for use on the Internet

through a contribution from Google.