This library of books, audio, video, and other materials from and about India is curated and maintained by Public Resource. The purpose of this library is to assist the students and the lifelong learners of India in their pursuit of an education so that they may better their status and their opportunities and to secure for themselves and for others justice, social, economic and political.

This item has been posted for non-commercial purposes and facilitates fair dealing usage of academic and research materials for private use including research, for criticism and review of the work or of other works and reproduction by teachers and students in the course of instruction. Many of these materials are either unavailable or inaccessible in libraries in India, especially in some of the poorer states and this collection seeks to fill a major gap that exists in access to knowledge.

For other collections we curate and more information, please visit the Bharat Ek Khoj page. Jai Gyan!

IRC:SP:101-2014

Published by:

INDIAN ROADS CONGRESS

Kama Koti Marg,

Sector-6, R.K. Puram,

New Delhi-110 022

August, 2014

Price : R. 600/-

(Plus Packing & Postage)

PERSONNEL OF THE HIGHWAYS SPECIFICATIONS AND STANDARD'S COMMITTEE

(As on 7th January, 2014)

| 1. | Kandasamy, C. (Convenor) |

Director General (RD) & Spl. Secy. to Govt. of India, Ministry of Road Transport & Highways, New Delhi |

| 2. | Patankar, V.L. (Co-Convenor) |

Addl. Director General, Ministry of Road Transport & Highways, New Delhi |

| 3. | Kumar, Manoj (Member-Secretary) |

The Chief Engineer (R) S,R&T, Ministry of Road Transport & Highways, New Delhi |

| Members | ||

| 4. | Basu, S.B. | Chief Engineer (Retd.) MORTH, New Delhi |

| 5. | Bongirwar, P.L. | Advisor, L & T, Mumbai |

| 6. | Bose, Dr. Sunil | Head, FPC Divn. CRRI (Retd.), Faridabad |

| 7. | Duhsaka, Vanlal | Chief Engineer, PWD (Highways), Aizwal (Mizoram) |

| 8. | Gangopadhyay, Dr. S. | Director, Central Road Research Institute, New Delhi |

| 9. | Gupta, D.P. | DG(RD) & AS (Retd.), MORTH, New Delhi |

| 10. | Jain, R.K. | Chief Engineer (Retd.), Haryana PWD, Sonipat |

| 11. | Jain, N.S. | Chief Engineer (Retd.), MORTH, New Delhi |

| 12. | Jain, Dr. S.S. | Professor & Coordinator, Centre of Transportation Engg., Deptt. of Civil Engg., IIT Roorkee, Roorkee |

| 13. | Kadiyali, Dr. L.R. | Chief Executive, L.R. Kadiyali & Associates, New Delhi |

| 14. | Kumar, Ashok | Chief Engineer, (Retd), MORTH, New Delhi |

| 15. | Kurian, Jose | Chief Engineer, DTTDC Ltd., New Delhi |

| 16. | Kumar, Mahesh | Engineer-in-Chief, Haryana PWD, Chandigarh |

| 17. | Kumar, Satander | Ex-Scientist, CRRI, New Delhi |

| 18. | Lal, Chaman | Engineer-in-Chief, Haryana State Agricultural Marketing Board, Panchkula (Haryana) |

| 19. | Manchanda, R.K. | Consultant, Intercontinental Consultants and Technocrats Pvt. Ltd., New Delhi. |

| 20. | Marwah, S.K. | Addl. Director General, (Retd.), MORTH, New Delhi |

| 21. | Pandey, R.K. | Chief Engineer (Planning), MORTH, New Delhi |

| 22. | Pateriya, Dr. I.K. | Director (Tech.), National Rural Road Development Agency, (Min. of Rural Development), New Delhi |

| 23. | Pradhan, B.C. | Chief Engineer, National Highways, Bhubaneshwar |

| 24. | Prasad, D.N. | Chief Engineer, (NH), RCD, Patnai |

| 25. | Rao, P.J. | Consulting Engineer, H.No. 399, Sector-19, Faridabad |

| 26. | Raju, Dr. G.V.S | Engineer-in-Chief (R&B) Rural Road, Director Research and Consultancy, Hyderabad, Andhra Pradesh |

| 27. | Representative of BRO | (Shri B.B. Lal), ADGBR, HQ DGBR, New Delhi |

| 28. | Sarkar, Dr. P.K. | Professor, Deptt. of Transport Planning, School of Planning & Architecture, New Delhi |

| 29. | Sharma, Arun Kumar | CEO (Highways), GMR Highways Limited, Bangalore |

| 30. | Sharma, M.P. | Member (Technical), National Highways Authority of India, New Delhi |

| 31. | Sharma, S.C. | DG(RD) & AS (Retd.), MORTH, New Delhi |

| 32. | Sinha, A.V. | DG(RD) & SS (Retd.), MORTH, New Delhi |

| 33. | Singh, B.N. | Member (Projects), National Highways Authority of India, New Delhi |

| 34. | Singh, Nirmal Jit | DG (RD) & SS (Retd.), MORTH, New Delhi |

| 35. | Vasava, S.B. | Chief Engineer & Addl. Secretary (Panchayat) Roads & Building Dept., Gandhinagar |

| 36. | Yadav, Dr. V.K. | Addl. Director General (Retd.), DGBR, New Delhi |

| Corresponding Members | ||

| 1. | Bhattacharya, C.C. | DG(RD) & AS (Retd.) MORTH, New Delhi |

| 2. | Das, Dr. Animesh | Associate Professor, IIT, Kanpur |

| 3. | Justo, Dr. C.E.G. | Emeritus Fellow, 334, 14th Main, 25th Cross, Banashankari 2nd Stage, Bangalore |

| 4. | Momin, S.S. | Former Secretary, PWD Maharashtra, Mumbai |

| 5. | Pandey, Prof. B.B. | Advisor, IIT Kharagpur, Kharagpur |

| Ex-Officio Members | ||

| 1. | President, IRC and Director General (Road Development) & Special Secretary | (Kandasamy, C.), Ministry of Road Transport & Highways, New Delhi |

| 2. | Secretary General | (Prasad, Vishnu Shankar), Indian Roads Congress, New Delhiii |

INTERIM GUIDELINES FOR WARM MIX ASPHALT

This document presents the guidelines for the production and construction of Warm Mix Asphalt (WMA) pavement. This technology, which is already in use in the USA and a number of European countries and on a trial basis in India as well, has a great potential of full scale use in the country because of its inherent advantages in terms of reduction of green house has emissions and economy in construction (because of less fuel consumption in construction) as well as elimination of suspected health hazards to construction workers (according to some studies the fumes from hot bituminous mixes is a health hazard). The guidelines would need to be further refined and amended in course of time with experience gained with widespread use of the technology and therefore, this document may be considered as interim guidelines.

The draft document “Interim Guidelines for Warm Mix Asphalt” was first outlined by Prof. P.S. Kandhal and thereafter brought into shape by Dr. Sunil Bose, Co-Convenor, Flexible Pavement Committee (H-2). Ms. Ambika Behl, Scientist, CRRI also assisted in the preparation of the draft document with her valuable inputs and vast field knowledge. The Committee deliberated on the draft document in a series of meetings. The H-2 Committee finally, approved the draft document in its meeting held on 21st December, 2013 and authorized the Convenor, H-2 Committee to send the final draft for placing before the HSS Committee. The Highways Specifications & Standards Committee (HSS) approved the draft document in its meeting held on 7th January, 2014. The Executive Committee in its meeting held on 9th January, 2014 approved the same document for placing it before the Council. The Council in its 201st meeting held at Guwahati, Assam on 19th January, 2014 approved the draft “Interim Guidelines for Warm Mix Asphalt” for publishing.

The Composition of H-2 Committee is as given below:

| Sinha, A.V. | -------- | Convenor |

| Bose, Dr. Sunil | -------- | Co-Convenor |

| Nirmal, S.K. | -------- | Member-Secretary |

| Members | ||

| Basu,Chandan | Mullick, Dr. Rajeev | |

| Basu, S.B. | Pachauri, D.K. | |

| Bhanwala, Col. R.S. | Pandey, Dr. B.B. | |

| Bongirwar, P.L. | Pandey, R.K. | |

| Das, Dr. Animesh | Reddy, Dr. K. Sudhakar | |

| Duhsaka, Vanlal | Sharma, Arun Kumar | |

| Jain, Dr. PK. | Sharma, S.C. | |

| Jain, Dr. S.S. | Singla, B.S. | |

| Jain, N.S. | Sitaramanjaneyulu, K. | |

| Jain, R.K. | Tyagi, B.R. | |

| Jain, Rajesh Kumar | Rep. of DG(BR) (I.R. Mathur) | |

| Krishna, Prabhat | Rep. of IOC Ltd (Dr. A.A. Gupta) | |

| Lal, Chaman | Rep. of NRRDA(Dr. I.K.Pateriya)1 | |

| Corresponding Members | ||

| Bhattacharya, C.C. | Kandhal, Prof. Prithvi Singh | |

| Jha, Bidur Kant | Kumar, Satander | |

| Justo, Dr. C.E.G. | Seehra, Dr. S.S. | |

| Veeraragavan, Prof. A. | ||

| Ex-Officio Members | ||

| President, IRC and Director | (Kandasamy, C.), Ministry of Road | |

| General (Road Development) & Special Secretary | Transport and Highways | |

| Secretary General | (Prasad, Vishnu Shankar), Indian Roads Congress | |

The Guidelines describe:

Since the Warm Mix Asphalt technology uses a variety of patented products as additives, which come in different forms such as solid, liquid and powder and use different processes for administering the additives and mixing, these guidelines do not prescribe any specific product or process except in a generic manner at the level of technology.

The guidelines further recommend that the contracting authorities may accept any technology that claims to meet the requirements of these guidelines provided such a claim is (a) substantiated by laboratory and field tests, and (b) backed by a collaboration between the contracting agency and the product/technology provider in a manner that ensures joint and several responsibility.

The basic principle of this technology is that by adding certain additives at the final stages of the mix production, the coating of the aggregates by the binder is greatly enhanced and can be achieved at a considerably less temperature (typically 30°C less) compared to the hot mix process wherein bitumen is heated to a sufficiently high temperature to make it fluid enough to surround the aggregates and coat their surfaces. In hot mix process, it is viscosity of bitumen alone, which is less at higher temperature, that plays the main role in coating of aggregates. In warm mix technology, this can be achieved in three different ways, viz. by increasing the volume of bitumen, by making the bitumen less viscous, by reducing the surface tension at aggregate bitumen interface etc.2

Currently there are more than 30 different WMA technologies, using patented processes and products, which have capabilities of bringing reduction in mixing, laydown and compaction temperatures of bituminous mixes in one of three different ways as described above. These guidelines covers currently adopted Warm Mix Asphalt technologies globally, classifying them into four main categories. Currently there are altogether more than 30 different WMA technologies. Although the end effect of reduction of mixing, laydown and compaction temperatures are the same, the different technologies work in different ways. The additives, which are either waxes or other hydrocarbon modifiers improve lubrication by reducing the viscosity of bitumen and allow a reduction of 28°C to 40°C in mixing and compaction temperature. Typical dosage amounts are 0.5 to 1.5 percent by weight of bitumen. Sometimes these additives are also added as modifiers for increasing the stiffness of asphalt mixes, for specialty applications, such as in racing tracks.

Waterbased Technologies

In essence, the “water technologies” use fine water droplets to expand the volume of binder in the mix by causing it to foam. This has the effect of increasing the volume of the bitumen, enabling it to coat aggregate at lower temperatures. The foaming technology can be further subdivided into two classes, foaming additives and water injection system. The foaming process works by creating foamed asphalt that improves coating and compaction at lower temperature. Water expands 1,600 times when converted into steam at atmospheric pressure, and the steam is encapsulated by viscous bitumen producing foam, which occupies a much greater volume compared to the original bitumen. The water for creating the foam is either added as water through a water injections stem in a specialized equipment, or from zeolites (which contain about 20 percent water). Water is added at a rate of 1.25 to 2.0 percent by weight of bitumen (about 500 ml of water per ton of mix), whereas the zeolites are added a rate of 0.1 to 0.3 percent by weight of the mix. Foaming by water allows 18°C to 30°C reduction in temperature whereas foaming by zeolites allows a reduction of 30°C to 40°C.

Natural and synthetic zeolites are mineral additives used to introduce water into the mix thereby creating “in-situ” foaming within the bitumen.

Zeolites in general are added to the mix with the filler during mixing process. As the mixing temperature increases the zeolites slowly release their absorbed water into the bitumen, which is dispersed throughout the mixture in the form of very fine foam droplets. This causes an increase in the volume of the bitumen and leading to improvement in its ability to coat the aggregate.

In this process the bituminous binder is added to the heated coarse aggregate in the mixer. Once the coarse aggregate are well coated, fine aggregate at ambient temperature with moisture content of around 3 percent is introduced. The moisture vaporizes, causing the binder coating the coarse aggregate to foam, which in turn encapsulates the fine aggregate.3

WMA technologies utilize chemical additives that have little effect on rheological properties of the binder. These products may be supplied in pellet, powder or liquid form, and then mixed into the binder or directly added to the mix. Chemical additives are Surfactants (surface active agents) that reduce surface tension between the polar aggregates and non-polar bitumen, improve wetting and reduces internal friction, and allows a reduction of 28-50°C in mixing and compaction temperatures. Typically they are added at the rate of 0.20 to 0.75 percent by weight of bitumen.

The wax based products can be described as viscosity modifying organic additives that reduce binder viscosity at high temperatures and thus allow lower mixing and paving temperatures.

Hybrid technologies utilize a combination of two or more WMA technologies to achieve the reduction in temperature. For example, Low Energy Asphalt (LEA) utilizes a chemical additive with a water injection system to improve coating at lower temperatures.

Finally, there are products that were originally developed for other uses, but do incorporate the WMA technology for reducing temperature and hence better utilization of the product. Examples are (sulfur and WMA) and TLAX (Trinidad lake asphalt and WMA technology).

The additives come in different forms, such as liquid, powder, pellet and are administered in the mix production process at different stage. Accordingly, some modification in the bituminous mixing plants is necessary to administer the controlled dosage of the additives. Some additives in liquid form can be pre-blended with bitumen and would need no modification in the conventional mixing plant provided the blended bitumen contains the right dose of additive. Other additives, which are administered in the mix at certain stage during the mix production process, would require some modification in the conventional mixing plants. These modifications would generally require a separate material (additive) feed system and a material metering system (to ensure the right dosage) which should be integrated with computerized plant control system of the mixing plant. The water-based WMA technologies would additionally need a water injection system as well.

Apart from such plant modification as required to administer the additives (described above), some modification need would arise out of the need to operate the plant at reduced temperature compared to that for the conventional hot mix production, for example recalibrating the fuel burner, aggregate drying system, bitumen heating system as also to take care of the possible consequences of lower temperature operation, such as contamination of the mix by un-burnt fuel and trapped moisture, condensation of bag house fines, etc.

around 25 to 30 percent and controls thereby global warming. This would earn tradable carbon credit. Secondly, the technology is quite compatible with Reclaimed Asphalt Pavement technology, which saves the requirement of fresh aggregates and reduces the environmental hazard associated with dumping of damaged pavement materials.

In the Section dealing with ‘overview’, the principles behind various alternative technologies and different additives have been presented. These provide the general guideline for an appropriate choice of technology. Secondly, since the plants and equipment used for producing WMA mixes would remain essentially the same (at least till such time the technology proliferates and its use becomes widespread) as that for HMA mix, it would be necessary to ascertain the nature and feasibility as well as commitment to these modifications/changes. Thirdly, the suppliers of the products to be used in works should be willing to take responsibility along with the main contractor not only for their products but for the entire technological solution.

All technologies and all commercial additives should be allowed to compete for acceptance on a work if the following conditions are satisfied:

The selection of the best WMA technology depends on many factors, and in most cases is dependent on the monetary incentives and benefits of using WMA. Important factors to consider include the reduction in temperature that is desired, the tonnage of mix that is anticipated and whether or not to invest in plant technology that are needed for certain additives. It should also be pointed out that the “green” benefits of adopting WMA technologies should not be overlooked, and that a reduction in emission through a reduction of temperature can help contractors/agencies receive significant amount of “carbon credits.”

The quality and performance of the mix shall be the same as specified for HMA in IRC: 111 except for mixing and laying temperatures, which should be at least 30°C less than those specified for HMA. The threshold of 30°C is considered technologically feasible as well as desirable from the point of view of fuel savings of some significance.

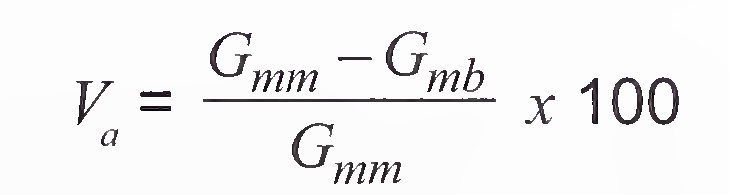

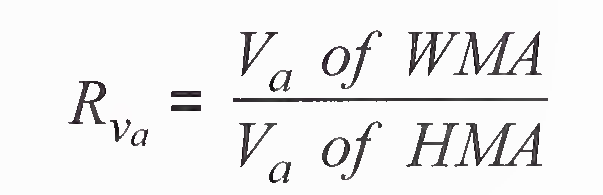

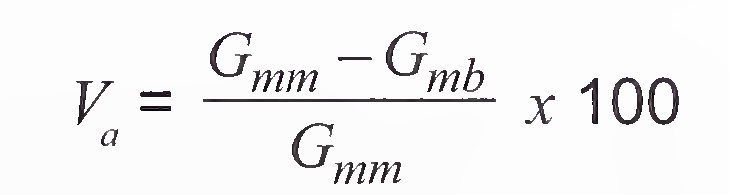

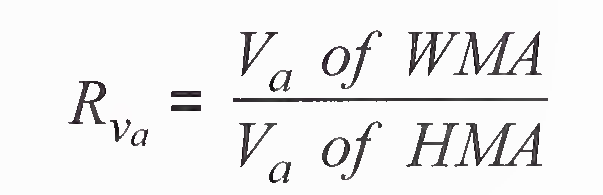

Design of mix, quality of inputs (except the additives) and tests required to be performed shall follow the same procedures as specified in IRC: 111. In addition, the following WMA specific tests shall also be performed:

The above parameters should be verified first in the laboratory, after the criteria are satisfied, a field trial of at least 500 m length shall be constructed, and the parameters obtained in the laboratory may be verified.

Since the mixing and compaction temperature of the warm-mix samples are lowered by at least 30°C compared to the conventional hot-mix, it is important for the warm-mix samples to attain specified mix densities at adopted lower temperatures. In order to verify that the warm-mix samples attain sufficient density at least 30°C lower temperatures relative to the conventional hot-mix, the following is proposed:

Warm-mixes are typically prepared at least 30°C lower temperatures, it is likely that the aggregate can retain some residual moisture, especially when the aggregate are porous and when the moisture content in the aggregate is high due to recent rains. It is recommended that the warm-mix additives or processes should also behave as anti-stripping agents, and should be able to improve the resistance of the mix to moisture susceptibility even when produced at temperatures at least 30°C lower than conventional mixes. If the warm-mix additives cannot perform as an anti-stripping agent, it must be mandated to add either hydrated lime or a liquid anti-stripping agent to the mix to improve resistance to moisture damage. However in case of WMA using foaming technology use of anti-stripping agent or lime may be detrimental.

WMA requires mix temperatures to be significantly reduced. The two basic types of bituminous mixing plant most commonly used are the batch type mixing plant and the continuous drum type plant, both of which types can be adapted to manufacture WMA.

For production of warm mixes that also contain reclaimed bituminous mixes, mixing plant design should include adequate features. When any of the various types of mixing plants are used, it should be ensured that the Recycled Asphalt (RA) and the virgin aggregates are properly blended together; the blending process shall facilitate proper heat transfer and shall prevent both physical and thermal segregation.

As with any new technology, there are a few concerns about the production of WMA, specifically because of the lower temperatures that are utilized during production. Fortunately, all of these problems are expected and solvable, in many cases through the adoption of techniques that could also be utilized for improving conventional HMA production.

The first concern is about incomplete drying of aggregates (specifically the internal moisture) at the reduced temperatures. It has been seen that for aggregates with an absorption value of less than 1 percent, drying of aggregate has not been reported to be a problem at WMA temperatures. To prevent the incomplete drying of aggregates, it is suggested that stockpiles be kept as dry as possible by sloping sides, paving surrounding areas, and keeping them under cover. To dry aggregates with high moisture content the retention time in the dryer drum could be increased and the dryer shell should be insulated properly. Ways to detect incomplete drying include a greater than 20°C fall in temperature in mix between discharge and loading, dripping water from silos and excessive steam from slat conveyors and a loss of more than 0.5 percent of the weight of mix during moisture content test.

The second concern is regarding incomplete combustion of fuel at the reduced temperature and the resulting risk of getting unburnt fuel in the mix.

Evidence of such a problem include brownish color of mix and higher than normal emissions. Proper maintenance and tuning of burner, and preheating of burner fuel are recommended8

solutions to this problem. The last but not least problem is the potential of condensation of baghouse fines, leading to the clogging and decreased efficiency of the emission control system.

Recommended solutions include proper preheating of baghouse, sealing of leaks, adjusting flights and slopes of the dryer to increase baghouse exhaust temperature, insulation of baghouse and ductwork and addition of duct heaters to increase baghouse temperatures, if needed. A high i.e. within the range of 0.28 to 0.35 kg/cm2. A high-pressure drop within a range greater than 0.28 to 0.35 kg/cm2 across the bags is an indicator of caking due to condensation.

For WMA Technologies, both rheological modifier and chemical additive types that are blended into the binder shall be added through the mixing plant’s normal binder addition system. These may also be blended at terminals and supplied to project sites through conventional transportation system.

Water carrying chemical additives, which are in powdered form, can be added manually into the pugmill of batch type mixers either through the filler system, or by intruding it through the RA collar.

Equipment to produce foamed bitumen may be installed on both batch and continuous drum mixing plant types. The systems obviously operate differently, with separate generations of foamed bitumen for each batch in the former type of plant and a continuous production of foam in the latter plant type’s case.

Conventional types of bituminous mix plants shall have the following monitoring and control systems:

Foaming systems should include integrated flow metering and pressure sensing systems for both the binder and the water used to produce the foam.

The construction operation for WMA shall same as that prescribed for HMA and shall be in accordance with the IRC:111 except that the mixing, laying and rolling temperature for WMA shall be as indicated in Table 1.9

| Bitumen Grade |

Mix Temperature (°C) | Laying Temperature (°C) | Rolling Temperature (°C) |

|---|---|---|---|

| VG-40 | 135 max | 120 min | 100 min |

| VG-30 | 130 max | 115 min | 90 min |

| VG-20 | 125 max | 115 min | 80 min |

| VG-10 | 120 max | 110 min | 80 min |

| Modified Bitumen** | 135 M max | 120 min | 100 min |

|

* In case of special conditions including but not limited to long hauls, cold paving conditions, etc. the recommendations of the WMA technology supplier shall be followed. ** The properties of modified binder shall conform to IRC:SP:53. |

|||

The extent and level of quality control of Warm Mix Asphalt shall be same as that of HMA and specified in IRC: 111. In addition, one test each for coating, compactibility, moisture susceptibility shall be carried out for each mix design. Further, when the WMA mixes include reclaimed bituminous mixes, additional testing shall be required.

The properties of the binder contained in the RA have to be taken into account at mix design stage and the consistency of the recovered binder properties shall be checked regularly.

Typically the moisture content, grading and binder content of each RA fraction shall be checked prior to the start of the day’s mix production.

WMA technology will actually be applied in works by the Contracting agency. While the quality and performance of the work is the responsibility of the Contracting agency, the product technology provider has to take responsibility for the efficacy of the product and the technology. It is essential, therefore, that both contractor and the product/technology provider come to an understanding or agreement with regard to their respective roles and formalize them in the form of Joint Venture or Contractor-Subcontractor or Contractor-Supplier arrangements, delineating therein their respective roles, committing themselves to joint and several responsibilities, and accepting these arrangements to be made a part of the contract for work to the extent it involves WMA work.

The product/technology provider should give reasonably detailed information in narrative form supported by sketches, diagrams, process flow charts, laboratory and field test evidences, etc., with regard to but not limited to the following:

The contracting agency should undertake to procure the materials, bring out modifications required in the plant and equipment as required specifically for administering the additives in a controlled and safe manner and also for the general requirement of operating the mixing plant at reduced temperature. The general requirements would be but not limited to

It is necessary that every user of the technology monitors and evaluates the performance of the WMA technology, creates a database in a standard format and uploads it on its website to make it accessible to any interested party. Over time the success stories will lead to the wide spread use of the technology, lessons can be learnt from not so successful ones and the unsuitable ones would fall by the way side.11

Annexure 1

(Refer Clause 6)

Properties of WMA to be Verified Based in Accordance with Testing Procedure as per AASHTO/ASTM Standards

AASHTO T195/ASTM D2489

The standard method of test for “Determining degree of particle coating of Asphalt Mixture”, helps in determining the particle coating in asphalt mix based on the percentage of fully coated aggregate present in a mix. The specification also helps in determining the mixing time required for satisfactory coating of aggregate in the asphalt mixture.

After producing WMA mix by lowering the temperature by at least 30°C lower than conventional hot-mix, samples of the mix are taken immediately after discharge from the pug mill. Coating is only measured on aggregate retained on 9.5 mm sieve. So the material is sieved on a 9.5 mm sieve while still hot and roughly 200-500 gram of sieved sample is collected.

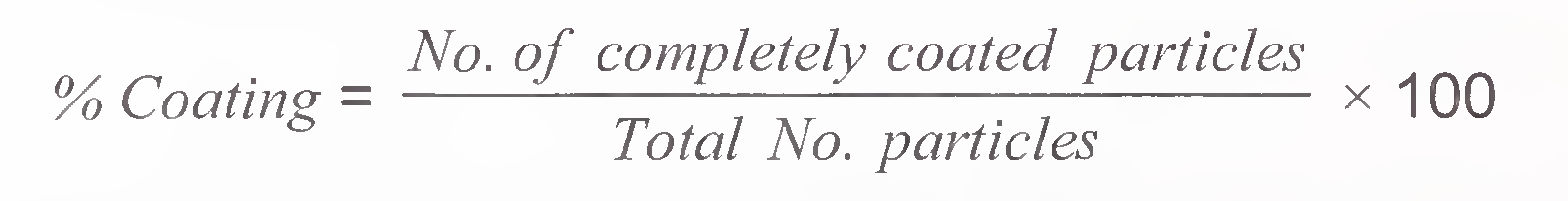

The percentage of coated particles is determined by

At least 95 percent of the coarse aggregate particles shall be fully coated at a temperature at least 30°C lower than conventional hot-mix.

AASHTO T245/ASTM D1559

The standard method of test for “Resistance to plastic flow for bituminous mixture using Marshall Apparatus” covers the measurement of resistance to plastic flow of cylindrical bituminous mixture samples by the means of a Marshall Apparatus.

This test method is specified to verify that the warm-mix samples attain equivalent resistance to plastic deformation relative to conventional mixes at temperatures at least 30°C lower than conventional hot-mix. The specification details the procedure for preparing a cylindrical bituminous mixture sample of 100 mm diameter consisting of around 1200 g of material. The sample is prepared by compacting using a standard Marshall Hammer. The samples are checked for Marshall Stability and flow under a constant displacement rate testing using a Marshall Apparatus after being immersed in water at 60 ± 1°C for 30 to 40 minutes.

WMA mixes shall have at least 9kN Marshall Stability value (12 kN if sample prepared with PMB) and flow between 3 to 6 mm.12

AASHTO T283/ASTM D1075

The standard method for “Resistance of compacted asphalt mixture samples to moisture-induced damage” covers preparation of specimens and the measurement of the change of diametrical tensile strength resulting from the effects of water saturation and accelerated water conditioning, with a freeze-thaw cycle, of compacted asphalt mixtures. The results may be used to predict long-term stripping susceptibility of the asphalt mixtures and evaluate liquid anti-stripping additives that are added to the asphalt binder.

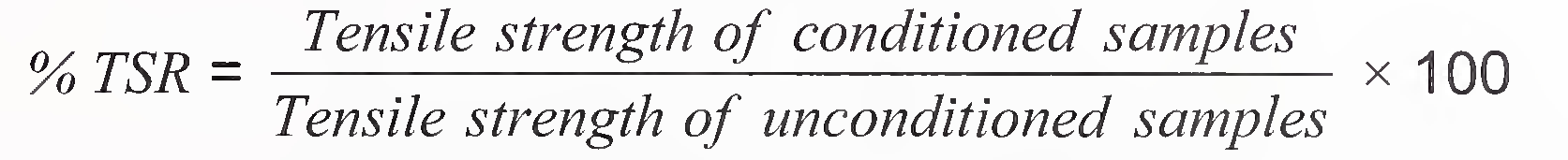

The test is performed by compacting cylindrical bituminous mixture specimens to an air void level of six to eight percentages. Three specimens are selected as a control and tested without moisture conditioning, and three specimens are selected to be conditioned by saturating with water undergoing a freeze cycle (-18°C for at least 16 hours), and subsequently having 60 ± 1°C water soaking cycle for 24 hours. The specimens are then transferred to a 25 ± 1°C water bath for two hours and then tested for indirect tensile strength by loading the specimens at a constant rate and measuring the peak force required to break the specimen. The tensile strength of the conditioned specimens is compared to the control specimens to determine the Tensile Strength Ratio (TSR).

The Tensile Strength Ratio (TSR) of the hot-mix and the warm-mix shall be determined as per the AASHTO T283. A TSR of above 80 percent for the warm-mix that is prepared at least 30°C below corresponding hot-mix will ensure sufficient resistance against moisture susceptibility.13