This library of books, audio, video, and other materials from and about India is curated and maintained by Public Resource. The purpose of this library is to assist the students and the lifelong learners of India in their pursuit of an education so that they may better their status and their opportunities and to secure for themselves and for others justice, social, economic and political.

This item has been posted for non-commercial purposes and facilitates fair dealing usage of academic and research materials for private use including research, for criticism and review of the work or of other works and reproduction by teachers and students in the course of instruction. Many of these materials are either unavailable or inaccessible in libraries in India, especially in some of the poorer states and this collection seeks to fill a major gap that exists in access to knowledge.

For other collections we curate and more information, please visit the Bharat Ek Khoj page. Jai Gyan!

Indian Roads Congress

Special Publication 40

Published by

The Indian Roads Congress

Copies can be had from

The Secretary General, Indian Roads Congress

Jamngar House, Shahjahan Road

New Delhi-110011

NEW DELHI 1993

Price Rs. 200/-

(Plus Packing & Postage)

MEMBERS OF THE BRIDGES SPECIFICATIONS AND STANDARDS COMMITTEE

(AS ON 31.10.92)

| 1. | Ninan Koshi (Convenor) |

... | Addl. Director General (Bridges), Ministry of Surface Transport (Roads Wing), New Delhi |

| 2. | M.K. Mukherjee (Member-Secretary) |

... | Chief Engineer (B), Ministry of Surface Transport (Roads Wing), New Delhi |

| 3. | C.R. Alimchandani | ... | Chairman & Manaing Director, STUP (India) Ltd., Bombay |

| 4. | A. Banerjea | ... | A-5/4, Golf Green Urban Complex, Phase-1, 10th Street, Calcutta |

| 5. | L.S. Bassi | ... | Addl. Director General (Bridges) (Retd.), Hat No.42, NGH Society, New Delhi |

| 6. | P.C. Bhasin | ... | 324, Mandakini Enclave, Greater Kailash-II, New Delhi-110019 |

| 7. | M.K. Bhagwagar | ... | Consultng Engineer, Engg. Consultants Pvt.Ltd., New Delhi |

| 8. | P.L. Bongirwar | ... | Chief Engineer, B-9, Camp Amravati (Maharashtra) |

| 9. | A.G. Borkar | ... | Secretary to the Govt. of Maharashtra, P.W.D., Bombay |

| 10. | S.P. Chakrabarti | ... | Chief Engineer (B), Ministry of Surface Transport (Roads Wing), New Delhi |

| 11. | S.S. Chakraborty | ... | Managing Director, Consulting Engg. Services (India) Ltd., Nehru Place, New Delhi |

| 12. | Dr. P. Ray Chaudhuri | ... | 148, Sidhartha Enclave, New Delhi |

| 13. | B.J. Dave | ... | Chief Engineer (Retd.), 702, Sampatti, Maharashtra Society, Mithakal, Ahmedabad |

| 14. | Achyut Ghosh | ... | Director, METCO, Calcutta |

| 15. | M.B. Gharpuray | ... | 838, Shivaji Nagar, Poona |

| 16. | D.T. Grover | ... | Chief Engineer (Retd.), D-1037, New Friends Colony, New Delhi |

| 17. | H.P. Jamdar | ... | Secretary to the Govt. of Gujarat, R&B Department, Gandhinagar |

| 18. | C.V. Kand | ... | Consultant, E-2/136, Mahavir Nagar, Bhopal |

| 19. | A.K. Lal | ... | Engineer-in-Chief-cum-Spl. Secretary, PWD, Road Constn. Deptt., Patna |

| 20. | P.K. Lauria | ... | Secretary to the Govt. of Rajasthan, P.W.D., Jaipur |

| 21. | N.V. Merani | ... | Principal Secretary, Govt. of Maharashtra (Retd.), A-47/1344, Adarsh Nagar, Bombay-400025 |

| 22. | Dr. A.K. Mullick | ... | Director General, National Council for Cement & Building Materials, New Delhi |

| 23. | A.D. Narain | ... | Chief Engineer (Bridges), Ministry of Surface Transport (Roads Wing), New Delhi |

| 24. | James Paul | ... | Bhagiratha Engg. Ltd., Hemkunt House, 6, Rajindra Place, New Delhi |

| 25. | Papa Reddy | ... | Managing Director, Mysore Structurals Ltd., 12, Palace Road, Bangalore |

| 26. | S.A. Reddi | ... | 72, Zenia Abad, Little Gibbs Road, Bombay |

| 27. | Dr. T.N. Subba Rao | ... | 18E, Dhanraj Mahal, C.S.M. Marg, Bombay |

| 28. | G. Raman | ... | Deputy Director (General), Bureau of Indian Standards, New Delhi |

| 29. | T.K. Sen | ... | Chief Technical Consultant, M/s. Gilcon Project Services Ltd., Calcutta |

| 30. | K.B. Sarkar | ... | Chief Engineer (Bridges), Ministry of Surface Transport (Roads Wing) New Delhi |

| 31. | N.C. Saxena | ... | 1/36, Vishwas Khand-I, Gomti Nagar, Lucknow |

| 32. | M. Shivananda | ... | Engineer-in Chief-cum-Project Co-ordinator, Mysore (Karnataka) |

| 33. | P.N. Shivaprasad | ... | Chief Engineer (B). Ministry of Surface Transport (Roads Wing), New Delhi |

| 34. | R.P. Sikka | ... | Addl. Director General (Roads), Ministry of Surface Transport (Roads Wing), New Delhi |

| 35. | Mahesh Tandon | ... | Managing Director, Tandon Consultant Pvt.Ltd., New Delhi |

| 36. | Dr. M.G. Tamhankar | ... | Deputy Director, Structural Engg. Research Centre, Ghaziabad |

| 37. | P.B. Vijay | ... | Chief Engineer, Vigyan Bhavan Project, CPWD, New Delhi |

| 38. | The Director | ... | Highways Research Station, Guindy, Madras |

| 39. | The Director Std/B&S (Arvind Kumar) |

... | RDSO, Lucknow |

| 40. | The President, IRC (L.B. Chhetri) |

... |

Secretary to the Govt. of Sikkim, Rural Dev. Deptt., Gangtok - Ex-Offico |

| 41. | The Director General | ... | (Road Development) & Addl. Secretary to the Govt. of India - Ex-Offico |

| 42. | The Secretary (Ninan Koshi) |

... | Indian Roads Congress - Ex-Offico |

| Corresponding Members | |||

| 43. | Dr. N. Rajagopalan | ... | Indian Institute of Technology, P.O. IIT, Madras |

| 44. | Dr. V.K. Raina | ... | United Nations Expert in Civil Engg. (Bridge & Structural), RIYADH (Saudi Arabia) |

| 45. | Shitla Sharan | ... | Adviser Consultant, Consulting Engg. Services (I) Pvt.Ltd., New Delhi |

| 46. | Dr. D.N. Trikha | ... | Director, Structural Engg. Research Centre, Ghaziabad |

Many of the old bridges constructed in the past are showing signs of weakness and require rehabilitation. The performance of some of the reinforced and prestressed concrete bridges built in the last few decades has also not been entirely satisfactory. One of the major thrust areas in bridge development in future will be the strengthening of weak bridges and rehabilitation of distressed bridges. The Indian Roads Congress constituted a Committee on Bridge Maintenance and Rehabilitation with a view to bringing out guidelines on various aspects of bridge management. Guidelines on ‘Inspection and Maintenance of Bridges’ (IRC:SP:35) and ‘Evaluation of Load Carrying Capacity of Bridges’ (IRC:SP:37) finalised by the Committee have already been published. The Committee has now finalised ‘Guidelines on the Techniques for Strengthening and Rehabilitation of Bridges’ which has received the approval of the IRC Council for publication.

Strengthening and rehabilitation need expert knowledge and specialisation. These guidelines cover common procedures for assessment of distresses in bridges, selection of techniques and materials as also approach to remedial measures and formulation of suitable repair plans.

They also include mention of some of the State-of-the-Art techniques for testing and repair which are yet to be adopted in India. The bibliography at the end is also a departure from the format of normal guidelines and indicate to the user the scope for further enquiry in the concerned areas.

Rehabilitation of bridges is an emerging area of activity which is bound to gain in importance in the coming years. This publication is the first document of its kind giving all the required information at one place. However, it is to be looked upon as a living document of suggested good practice which will need periodic review. Any comments or suggestions for future revision would be appreciated.

These guidelines fulfil a genuine need of the bridge engineering profession in this country and I am confident that their application will help practising engineers both in the design office and in the field in carrying out bridge rehabilitation works effectively and efficiently.

Director General (Road Development)

Government of India

Ministry of Surface Transport

(Roads Wing)

NEW DELHI, May, 1993

GUIDELINES ON TECHNIQUES FOR STRENGTHENING AND REHABILITATION OF BRIDGES

The Indian Roads Congress constituted a Committee on Bridge Maintenance and Rehabilitation (B-10) in January, 1988 in order to look into the various aspects, policies and guidelines for the general subject of bridge maintenance and rehabilitation. The Committee has already finalised “Guidelines for Inspection and Maintenance of Bridges” and “Guidelines for Evaluation of Load Carrying Capacity of Bridges” and these have already been published as IRC:SP-35 and IRC:SP-37 respectively. The present guidelines on ’Techniques for Strengthening and Rehabilitation of Bridges’ is the third in the line. The Bridge Maintenance and Rehabilitation Committee was reconstituted in January, 1991 and the Personnel of the reconstituted Committee are given below: (as on 31.10.92)

| N.V. Merani | ....Convenor |

| A.G. Borkar | ....Member-Secretary |

| Members | |

| P.C. Bhasin | S.A. Reddy |

| S.S. Chakraborty | Dr. N.S. Rangaswamy |

| S.P. Gantayet | N.C. Saxena |

| C.V. Kand | S.R. Tambe |

| P.Y. Manjure | M.K. Saxena |

| A.D. Narain | Surjit Singh |

| M.G. Prabhu | N.G. Thatte |

| Dr. T.N. Subba Rao | Maj. V.K. Verma |

| M.V.B. Rao | Director, H.R.S. |

| Ex-Officio | |

| President, IRC (L.B. Chhetri) D.G. (R.D.) | |

| Secretary, IRC (Ninan Koshi) | |

| Corresponding Members | |

| S. Sengupta | Dr. M.G. Tamhankar |

| Dr. Anil Kumar | M.R. Vinayak |

| Mahesh Tandon | |

The Committee had appointed a Sub-committee for preparing the draft of the document for the present guidelines. The Sub-committee comprised Shri A.G. Borkar (Convenor), S/Shri P.S. Gokhale, P.Y. Manjure and D.K. Kanhere. At the stage of finalisation Shri N.G. Thatte was also associated. The Committee held two meetings and finalised the guidelines in the meeting held on 7th September, 1991. The guidelines are to be looked upon as document on suggested "good practices" and not as "mandatory specifications". The Guidelines are meant to be a living document needing on-going review periodically. The guidelines approved by Committee were considered and approved by the Bridges Specifications and Standards Committee in their meetings held at Jaipur on 29-11-91 and at New Delhi on 21/22-10-92 subject to certain modifications. Later on the modified guidelines were approved by the Executive Committee and the Council in their meetings held at New Delhi and Patna on 11th November, 1992 and 28th November, 1992 respectively.

The deterioration of bridges is a world-wide phenomenon and the causes for this are also well known, such as inadequate design and construction, overloading,lack of adequate maintenance, atmospheric effects, unforeseen events like abnormal floods, earthquakes etc., and lack of knowledge of the durability and long term behaviour of structural concrete. Increasing number of bridges in the country would require major repairs for rehabilitation/strengthening. The problems faced are loss of traffic safety or reduction of structural strength with the resultant necessity for load limitations and in some cases premature bridge deterioration needing replacement. These could be avoided if adequate funds are devoted for timely repairs. Attention in the next few decades, therefore, is likely to be focussed on the preservation of integrity of large number of bridges built over the previous decades, through systematic maintenance and timely repairs.

The scope of these guidelines is as under :

A list of areas requiring further research and development has also been added in the end for information.

Though in the separate guidelines for inspection and maintenance of bridges the definitions of various operations have been given, for the convenience of the users the same are reproduced below :

This is defined as the work needed to preserve the intended load carrying capacity of the bridge and ensure the continued safety of road users. It excludes any work leading to improvement of the structure, whether by strengthening to carry heavier loads, by widening or by vertical realignment of the road surface. The maintenance operations begin with the opening of the bridge to traffic. (In fact a bridge member starts ageing the day its concrete is poured). It excludes repairs of any damage caused by exceptional causes like landslides, earthquakes, cyclones, fire etc., but it includes preventive maintenance.

These activities also meet the above definition of maintenance, but are larger in scope and cost, than maintenance. Rehabilitation operations aim at restoring the bridge to the service level it once had and has now lost. In some cases this consists of giving the bridge the service level which was intended, but which has never been attained, because of the deficiencies in the original design or construction.3

These aim at upgrading the level of service of a structure. The basic parameters to be taken into account in such improvements are :

Load carrying capacity and

Geometric parameters (width of carriageway, footpaths, vertical clearance etc.)

These works are required to be carried out when the whole structure or atleast its major components are required to be replaced, being beyond the economic level of repairs/ rehabilitation.

Rehabilitation or Strengthening of bridges may become necessary under various conditions, such as :

The bridge structures must, during their service life, have a specified level of safety and serviceability under the design working loads and the anticipated conditions of use. To achieve this purpose, a good bridge management system is essential. Management system as well as the maintenance policy have been dealt with in the "Guidelines on Inspection and Maintenance of Bridges" IRC:SP-35. In this Chapter, it is proposed to elaborate the same specifically for rehabilitation/strengthening of bridges.4

Road networks and bridges thereon are regarded as permanent installations. The bridges, however, generally deteriorate with passage of time and the society’s needs and requirements in regard to established road networks also change continuously. The former leads to need for rehabilitation and the latter to strengthening, widening of existing bridges. Regardless of whether it is a question of construction of a new bridge (s) or the rehabilitation / strengthening of an existing bridge, the work cannot be accomplished satisfactorily unless there is a reasonable understanding of society’s needs with respect to bridges as well as the requirements, needs and changes the present and future bridge stock may impose on the Bridge Authority. The following factors, therefore, need to be considered :

Both in developing countries and highly developed countries, the traffic volumes and axle weights have been observed to grow continuously, more so in developing countries. The gross weight of vehicles and the axle loads have also had a strong upward trend during the recent decades. As the cost of pay-load-ton transportation falls with gross vehicle load, the tendency is to carry as much load as possible on a single vehicle. The reason for increasing axle loads is thus an economic reason. Another important factor to be considered in traffic loads is the size of exceptionally heavy vehicles. The growth in traffic volumes and axle weights have thus to be considered for determining the strengthening measures.

As the awareness of environmental damages increases in the public mind, there will be more demands from them for protection against environmental damages.

The more complex the design of bridges, the more difficult it is to strengthen or rehabilitate the structure. The higher cost related to repairs and rehabilitation of such structures can sometimes make replacement more economical.5

These relate to the continuous changes in public values in regard to willingness to pay the additional cost for traffic safety and serviceability.

The increased importance of strengthening and rehabilitation of bridges can be characterised by -

The individual decision considerations will vary in accordance with the size and importance of bridge in question. For rehabilitating/strengthening major bridges,elaborate analytical techniques for evaluation of various solutions may be applied but an ordinary rehabilitation and strengthening work of minor bridges may be carried out in accordance with the general principles. In all cases, however, it should be ensured that available funds are allocated in accordance with the Authority’s overall objectives and policies. The general policy must take into account the number of parameters already described in para 2.2 above. In principle,the decision - which may vary from no action, some degree of temporary action, full rehabilitation or strengthening to, a replacement - could be reached through a cost-benefit analysis. However, such an approach may prove to be laborious in day-to-day operations and perhaps unjustified in majority of cases. A simple operational and robust framework for decision making is, therefore, advisable, as given below.

The bridges may be divided into elements, with relatively short-life-spans such as pavements, water- proofings, expansion joints, paint etc., and the bridge elements with long-life spans such as structural elements in bridge decks, columns, piers, foundations etc. Such division between6

short-life and long-life bridge elements is useful because of the stronger economic motivation to rehabilitate and strengthen long life elements than short life elements. A division between ordinary bridges and major or important bridges is also warranted while considering difference in technology and economy. On traffic considerations a division between bridges on rural roads, state highways, national highways and expressways also appears necessary. Similarly division on environmental considerations may also be necessary.The general policy for rehabilitation/strengthening of bridges must, therefore be based on the following factors :

Note. : Important bridges shall be those bridges which are on vital links or on links of strategic importance and all major bridges on national highways and major arterial State Roads. This definition is purely for the purpose of this guideline.

Apart from the factors given above, the policy decisions will have to be within certain parameters such as:

The best strategy can only be determined in the light of

The various steps involved in working out a plan for rehabilitation/ strengthening could be as below :

(a) Evaluation of the Structure from Documented Data Base and Inspections

These have been described in the Guidelines for Inspection and Maintenance of Bridges (IRC : SP-35).

(b) Locating Damages /Defects/Distresses

The deterioration of a structure can often be found visually through visible signs of damage. Therefore visual inspection by an experienced engineer is a vital step in the chain of further follow-up actions. A routine or principal inspection provides a detailed description of some of the damages where an assessment of the structure may become necessary.

The use of various testing methods may become necessary to complement the results of the visual inspection of the structure. Testing techniques and equipment should be determined relative to the extent and type of deterioration or damage and to the importance of structure (consequences of failure).To the extent possible, non-destructive test methods should be used. If necessary, the results of these tests may be8

supplemented and/or calibrated by sampling procedures in accordance with the small step principle, that is, when deficiencies are discovered from a minimum number of specimens (a small sampling) the investigation may require a more detailed analysis. These procedures are standardised.

(c) Analysis of, Causes of Damages/Defects and Distresses

The purpose of an evaluation of a distressed structure is not only to determine the effect of damage to the structure’s life expectancy/load carrying capacity, but also, and perhaps more importantly, a determination to the possible extent, of its cause so as to intelligently determine an effective retrofit. Before repair plan is implemented, the cause of the damage has to be removed or the repair measures have to be designed to accommodate the cause and protection against it in future. Otherwise the risk of repetition of damage will continue to exist.

(d) Evaluation of Results of Structural Assessment

Data resulting from the investigation of a damaged structure including monitoring of its distress, form the basis for the decision as to what corrective action must be undertaken. This depends on type and extent of the damage.

An initial concern should be as to whether or not there is a risk of failure to the damaged structure. If this risk is present,the first course of action must be to immediately provide an adequate auxiliary support mechanism and to reduce the loads to remove the risk. Where minor damage exists a determination must be made as to whether the damage is stable or will propagate with subsequent service loading. This is often a difficult and subjective assessment made on the basis of a visual examination until it can be verified with calculations. The elements of time and/or the harshness of the environment become important parameters when either the load carrying capacity is being diminished by deterioration (corrosion etc.) or when the load carrying capacity has to be increased (increased traffic load). Some evaluations will relate to whether or not an economically effective repair plan9

can limit or contain damage and thus can enhance the effective life of a structure. In some instances, an evaluation will be concerned with the degree of urgency required to implement a repair plan because of the advanced stage of damage.

The urgency of repairs, strengthening or replacement must be evaluated in a technical sense along with realistic cost estimates so that proper priorities can be established in budget planning. The question of urgency must also consider an estimation of remaining life expectancy. Although assumptions in a time dependant damage process are at best subjective, their evaluation will make an assessment of the degree of urgency less complex. Approximate estimations of life expectancy are valuable where damage is related to time dependent deterioration, e.g. corrosion of reinforcement. However, because of inherent uncertainties, the estimate will have to be presented in terms of upper and lower probability limits.

In some cases, it may be necessary to evaluate the load carrying capacity of the bridge. Guidelines for this evaluation have been issued separately (IRC : SP-37). Derating and/or regulated traffic options need also to be examined in these cases.

(e) Design of Repairs for Rehabilitation/Strengthening Works :

The most important step in the design of repairs for rehabilitation and/or strengthening work is a careful assessment of the existing structure. The purpose of this assessment is to identify all defects and damages, diagnose their causes and to evaluate the present and likely future adequacy of the structure.

Generally the structural design for repairs shall conform to the relevant IRC Codes. However, it must be recognised that the repairs for rehabilitation/ strengthening is a special type of work and many a time accurate structural analysis may not be possible both for the assessment of the existing strength as well as for the repairs for rehabilitation/strengthening. At the10

same time, the design in some cases may have to account for effects of secondary stress and composite actions. When the structural system is complex for accurate analysis, specifications more conservative than IRC specifications may have to be adopted. On the other hand, in certain special cases consciously permitting overstress may become unavoidable due to construction difficulties and thus calculated risk may have to be considered. The designer of the rehabilitation/ strengthening measures has, therefore, to be very judicious in his approach.

The technique to be chosen will depend on the needs, access, duration of lane closures for traffic, atmospheric conditions, etc..

(f) Proposals and Estimation of Costs :

The complexity and magnitude of the repair procedure will depend on whether

There are several options to be considered in evaluation of restoration of the functionality of a damaged structure such as:

The degree of restoration will depend on whether or not it is required to restore to the original or greater load carrying capacity. If for technical and/or economical reasons it is not feasible to achieve a complete restoration to original capacity and at the same time total11

replacement is not an acceptable option, a reduction of the applied

live load becomes mandatory. (Ref. IRC:SP-37).

The Bridge Authority in reaching a decision as to the course of action will have to evaluate not only the technically feasible options available,but also the costs of each option, time of execution, political considerations (economical impact on communities served by the facility), life expectancy associated with the various options available, any historical significance of the structure, any risks that may be involved with any changes in safety level or reduction in load carrying capacity etc.. The rehabilitation and/or strengthening of major bridges is a complete task requiring many a time inputs from several specialists. The bridge engineer, therefore, has to consult the experts in different fields to work out the appropriate repair plan.

Introduction

The types of road bridges built in India and usual distresses observed in each type of bridge are discussed in this Chapter. Special types of bridges like suspension bridges, cable stayed bridges, etc. have not been considered.

The following types of road bridges are known to have been built in India:

These again have the following forms

For the purpose of avoiding too many ramifications, further sub-divisions of forms and materials are not considered.

The most common defects noticed in such bridges are :

The most common distresses in R.C.C. bridges are as follows :

(a) Cracking: Cracks could be of different types. The significance of cracks depends on structure type,location of the crack, its origin and whether the width and length increase with time and load. These cracks can be due to several reasons like (1) plastic shrinkage,and plastic settlement, (2 )drying shrinkage, (3)settlement, (4) structural deficiency, (5) reactive aggregates, (6) corrosion of reinforcement, (7) Early thermal movement cracks, (8) Frost damage, (9) Sulphate attack and (10) Physical salt weathering.

Plastic shrinkage cracks occur within first few hours after initial set due to excessive bleeding and rapid early drying and result into loss of bond to bars and exposure of reinforcement. Thermal contraction cracks occur within first few weeks in thick walls and slabs due to excessive heat generation. Drying shrinkage cracks occur in walls and slabs and take a few weeks to years for development due to loss of moisture. They create path of seepage and leakage. Cracks due to corrosion in reinforcement take several months or years and lead to rapid deterioration of concrete. Alkali aggregate reaction can be a cause of cracks on account of internal bursting force caused by expansive reaction of certain aggregates in high alkali content situations while frost damage can occur at any age in porous concrete. Cracks due to sulphate attack may take several years to develop mostly near or below ground level on account of sulphate salts in damp ground reacting with the hydrated cement constituents. Physical salt weathering requires many months to many years for development of cracks in the inter tidal and splash zone or just near ground level in desert terrain, leading to deposition of salts and volume changes and final disintegration.

Plastic shrinkage and drying shrinkage cracks result into loss of bond and could be cause of path for seepage and leakages. Thermal14

contraction cracks could result into exposure of reinforcement, seepage and leaking. The settlement cracks due to movement must be recorded and the cause established. Such cracks can be critical and affect the load carrying capacity of the bridge. Structural cracks may occur due to overstressing which in turn can be due to the overloads or due to under-designed members or due to deficiency in construction. These cracks must be evaluated depending on the location, size and apparent cause. Corrosion induced cracks are located directly above or below the reinforcement. Rust stains may be visible and such cracks can indicate loss of load carrying capacity with time. Cracks caused by chemical reaction, alkali silica reaction can lead to serious damages to the concrete and loss of strength and capacity.

(b) Scaling : Scaling is the manifestation on the surface of loss of concrete in patches. If the process continues, coarse aggregates can get exposed and become loose and disintegrated and may eventually get dislodged. Kerbs and parapet walls are particularly susceptible to scaling.

(c) Delamination : Delaminations are separations along a plane parallel to the surface of the concrete. These can be caused by corrosion of reinforcement. Bridge decks and corners of concrete beams,caps and columns are particularly susceptible to delamination and delaminations ultimately can cause spalling of concrete.

(d) Spalling : Spalling of concrete is generally recognised to be a serious defect as it can cause local weakening, expose reinforcement, impair riding quality of deck and with time can cause structural failure.Spall is a depression caused by separation and removal of surface concrete. Major causes of spalling are corrosion of the reinforcement, overstresses, etc.

(e) Leaching : Leaching is the accumulation of salt lime deposits white in colour on the concrete surface. These are noticed normally on the underside of concrete decks and along cracks on vertical faces of abutment walls,wing walls etc. These indicate porous or cracked concrete. Where salts (NaCl or Sulphates) are present, the migration of moisture associated with leaching may initiate severe early deterioration.15

(f) Stains : Most significant stains is that due to rust which indicates presence of corrosion. But absence of rust is not necessarily indicative of no corrosion.

(g) Hollow or Dead Sound : If tapping with a hammer or rod produces a ’dead’ sound, this is indication of low quality concrete or delamination.

(h) Deformations : These are the effects of distress which may show in the form of deflection, spalling, delamination, scaling, cracks etc.. Swelling or expansion of concrete is usually an indication of reactive materials. However, localised swelling may be caused by compressive failure of the concrete. Twisting of substructure or superstructure units may be evidence of a settlement of foundation problem.

(i) Excessive Deflections : This could be due to deficiency in the structural capacity of the superstructure or due to passage of abnormal loads. Time dependent stresses also can cause such deflections if the estimated values of creep are different from the actual values.

(j) Holes in Deck Slab : This could be due to local weaknesses in concrete or other causes.

Most of the forms of distresses in prestressed concrete are similar to those in RCC. However, certain special features are as under :

(a) Cracking : Cracking in prestressed concrete is an indication of a potentially serious problem. Horizontal cracks near the ends of prestressed members may indicate a deficiency of reinforcing steel, to cater for bursting stresses. Vertical cracking in the lower portion of the member not near the support could be due to serious overstressing or loss of prestress. Vertical crack in the bottom of the unit and at the support may be a result of restricted movement in bearings. Vertical cracks in precast members above the neutral axis of a prestressed member can be due to mishandling during transportation or erection but these cracks close when dead load of the deck is applied.16

(b) Leaching : Leaching is also evidenced in prestressed bridges and the associated moisture movements will aggravate any corrosion risk. Particular attention needs to be paid to the concrete or mortar adjacent to joints in prestressed concrete e.g. box girders.

(c) Stains : Rust stains in prestressed concrete indicate corrosion of prestressing cables and should be considered a serious threat to structural integrity of the member. No rust stain does not necessarily mean no corrosion.

(d) Spalling : Spalling in prestressed concrete is a serious problem and can result in loss of prestress.

(e) Excessive Deformations : In prestressed members, the abnormal deflections could also occur due to loss of prestress with time.

(f) Abnormal Vibrations : These could be due to slender members or combination of various reasons.

The defects in steel bridges will be :

Deterioration of Steel

(A more detailed scale of rusting will be found in DIN 53210 and ISO 4628/1-1978.)

Abnormal Deformations or Movements :

Fracture and Cracking:

The distresses are normally the same as those for the concrete and/or steel bridges. However it is usually observed that the distresses like cracks are more common at the interface between two materials due to horizontal shear, the shear connectors being either absent or being of insufficient capacity.19

Some of the normally observed distresses are:

Distresses in bearings and expansion joints manifest themselves in various forms and have been dealt with separately.

Although the normally observed distresses have been listed above, the bridge engineer should keep an open mind to observe any new type of unusual distress/behaviour during inspection or monitoring.

Most of the road bridges built in India in the past few decades, have been constructed in concrete. Similarly, in the next few decades also, concrete will continue to be the main material for bridges to be constructed. Considerable investigations and research have been done on the properties of concrete and the science of testing it and the diagnosis of distresses in it has been developed over these years although a lot still remains to be done. This chapter on testing and diagnosis is, therefore, devoted to’Concrete Bridges’.

A review of available drawings to identify vulnerable details should be done before investigation. Investigation is to be carried out at three levels, namely a visual survey to assess the overall integrity of the bridge,a general survey including a limited amount of physical testing to plan more detailed investigation and possible rehabilitation and finally a detailed survey to determine the extent and precise location of deterioration or damage for the purpose of evaluating the capacity of the structure. Careful planning is required20

to identify the required information on the human and technical resources which must be carried out under the supervision of an expert engineer, who can modify the procedures as the investigation progresses, depending upon the needs.

Broadly speaking, the visual methods are very useful to detect cracking, scaling, wear and abrasion; the electrical and the chemical methods are of some help for corrosion detection; ultrasonic methods are more suitable for crack detection, while the thermography and radar techniques are suitable for detecting delamination and scaling beneath bituminous surfacings. Radiography and air permeability techniques have only a limited applicability to detect corrosion and voids in grout.

Visual inspection by an expert who has previously handled similar situations is the essential preliminary step. The degradation processes are likely to become apparent (though not true for all prestressed concrete structures) much before the load bearing capacity gets seriously reduced as many advanced warning signs like spalling, rust stains would be available and corrosion and other types of defects like cracks, excessive deflections, excessive vibrations, loss of camber, malfunction of joints and hinges, deformation, performance of bearing, drainage system, water-proofing etc., should be observed. It is necessary to provide proper access to various components of the bridge to ensure a thorough inspection. But for sensitive details which cannot be inspected visually, drawings should be examined.

A variety of non- destructive testing methods have been developed and are under development for investigating different properties of concrete in addition to the vital visual inspection described earlier. Tests are aimed at assessment of strength and other properties and to locate and obtain comparative results indicating permeable regions, cracks or laminations and areas of lower integrity than the rest. It is essential to emphasise here, that it is not necessary to carry out all the tests in each case except the most relevant ones. Facilities for a number of tests are still not available in India, but have been mentioned as they might become available later. Also, not much may be achieved by spending time and money on carrying out other than the most essential tests in many cases. In fact, in some cases, engineering judgements could help decisions faster. The tests can be broadly21

classified under different groups as shown in the Table 4.1. Table 4.2 gives abstract of test for investigating potential corrosion of reinforcement in R.C. and prestressed concrete structures.

(i) Carbonation : The carbonation of concrete on the surface results in loss of alkaline protection of the cover over the steel against corrosion. Carbon-dioxide of atomosphere reacts with hydrated cement compounds causing reduction in alkanity of concrete and the process is referred to as Carbonation. The depth of the carbonation is measured by spraying on the freshly broken surface of concrete with 0.10 per cent solution of phenolphthalein. The concrete undergoes, a colour change (from purple red to colourless) when pH value is below 10. The colour of the concrete surface after the spraying indicates the depth of carbonation.

(ii) Sulphate attack : The concrete attacked by sulphate has a characteristic white appearance. The quantity of sulphate is estimated by the precipitation of barium sulphate and sulphate confined by identification of Calcium Sulpho Aluminate by X-ray or microscopy.

(iii) Chloride content : This test should be done under expert guidance and proper sampling procedures need to be evolved due to high variability of laboratory test results. The chloride content in concrete is measured in laboratory by Mohr’s method using potassium chromate as indicator in a neutral medium or by Volhard’s volumetric titration method in acidic medium. The presence of acid soluble chlorides in concrete beyond the permissible limit is considered as a corrosion hazard in concrete structures. Rapid tests for in-situ chloride determination are being developed.22

| Method | Principal applications | Principal Properties assessed | Surface damage | Type of Equipment | Remarks |

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 |

| Pull out test (cast-insert) |

Quality Control (in-situ-strength) |

Strength related | Moderate/ minor | Mechnical | Preplanned usage, surface zone test |

| Pull-out test (drilled hole) |

In-situ strength measurement | Strength Related | Moderate/ minor | Mechanical | Drilling difficulties on vertical surfaces of soffits. surface zone test |

| Break-off test | In situ-measurement | Flexural tensile Strength | Substantial/ moderate | Mechanical | High test variability, surface zone test, very good to check repair bond |

| Penetration resistance | In situ-measurement | Strength related | Moderate/ minor | Mechanical | Specific calibrations required, limits on minimum members size, surface zone test. |

| Surface-hardness | Comparative Surveys | Surface hardness | Very minor | Mechanical | Greatly affected by surface texture and moisture, surface test, unpresentative on concrete more than 3 months old, strength calibration affected by mix properties. |

| Initial surface absorption | Surface permeability assessment | Surface absorption | Minor | Hydraulic | Difficult to standardize in situ moisture conditions and to obtain watertight seal to surface, comparative test. |

| Surface permeability | Surface permeability assessment | Surface permeability | Minor | Hydraulic | Surface zone test, water or gas23 |

| Resistivity measurements | Durability survey | Resistivity | Minor | Electrical | Surface zone test, related to moisture content, indicates potential of reinforcement corrosion in zones of high risk |

| Half-cell potential measurements | Survey of reinforcement corrosion risk | Electrode potential of reinforcement | Very Minor | Electro-Chemical | Indicates only the probability of corrosion. Quality of results depends on moisture content. Placement of half cell has to be done carefully |

| Ultrasonic pulse velocity measurement | Comparative surveys | Elastic modulus | None | Electronic | Two opposite smooth faces preferably needed, strength calibration affected by moisture and mix properties, some surface staining possible |

| Acoustic emission | Monitoring testing | Internal crack development | None | Electronic | Increasing load required, not fully developed for site use. Not very reliable |

| Dynamic response techniques | Pile integrity | Dynamic response | None | Mechanical/ Electronic | Cannot yield bearing capacity |

| Electromagnetic measurement | Location and depth of reinforcement | Presence of embedded steel | None | Electromagnetic | Affected by magnetic- aggregates and unreliable for congested steel. |

| Radar | Location of voids or reinforcement | Relative density | None | Radioactive source or radiations generator | Some safety precautions, limit on member thickness |

| Radiography | Location of voids or reinforcement | Relative density | None | Radioactive source or generator | Extensive safety precautions, limit on member thickness. Essential for prestressed ducts24 |

| Radiometry | Quality control | Density | None | Radioactive source or generator | Safety precautions and limit on member thickness for direct method and back scatter method, surface zone test. |

| Neutron moisture measurement | Comparative moisture content | Moisture content | None | Nuclear | Surface zone test calibration difficult. Not of much use so far. |

| Depth of carbonation | Durability survey | Concrete Alkalinity | Moderate/Minor | Chemical | Good indication of extent of carbonation if area is well sampled. |

| Resonant frequency | Quality control | Dynamic elastic modulus | None | Electronic | Specially cast specimen required. Not very useful |

| Strain measurements | Monitoring movements in structure | Changes in strain | Minor | Optical, Mechanical, Electronic | Attachment & reading requires skill can only indicate changes in strain. |

| Movement measurements at joints | Monitoring movements | Changes in strain | None | Mechanical | Requires skill to read. |

| Crack movement demec gauges | Monitoring crack widths | Changes in strain | None | Mechanical | Requires skill to read. |

| Spall survey | Corrosion risk | Indicates extent of corrosion damage | None | Physical recording of all spalls, depth of rebar, thickness of corrosion and spalled concrete for chlorides and carbonation25 |

| Techniques | Direct | Indirect | Non-Destructive | Semi- Destructive | Destructive | Corrosion | Remarks | ||

|---|---|---|---|---|---|---|---|---|---|

| Rate | Defect | Cause | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Visual Inspection | X | X | X | Essential | |||||

| Weight Loss | X | X | X | Limited use | |||||

| Pit depth | X | X | X | Limited use | |||||

| Electrical Resistance Probe | X | X | X | Useful | |||||

| Linear Polarisation | X | X | X | Limited use | |||||

| Half Cell Potential | X | X | X | Useful | |||||

| Carbonation | X | X | X | Essential | |||||

| Covermeter | X | X | X | Essential | |||||

| Chloride Analysis | X | X | X | Essential | |||||

| Cement Content | X | X | X | Limited use | |||||

| Moisture Content | X | X | X | Limited use | |||||

| Resistivity | X | X | X | Useful | |||||

| Water Absorption | X | X | X | Limited usel | |||||

| Concrete Strength | X | X | X | Useful26 | |||||

| Delamination | X | X | X | Useful | |||||

| Ultrasonic Method | X | X | X | Limited use | |||||

| Hammer | X | X | X | Useful | |||||

| Gamma Radiography | X | X | X | For Prestressed Concrete only | |||||

| X-Ray Photography | X | X | X | -do- | |||||

| Winder Probe | X | X | X | Limited use | |||||

| Coring | X | X | X | limited use27 | |||||

(i) Schmidt hammer and other tests : These are used to measure hardness of concrete surface which can be related to its strength. The instrument used is very handy. The pull-out methods and penetration resistance techniques are also adopted for estimation of strength of concrete and assessment of its overall quality.

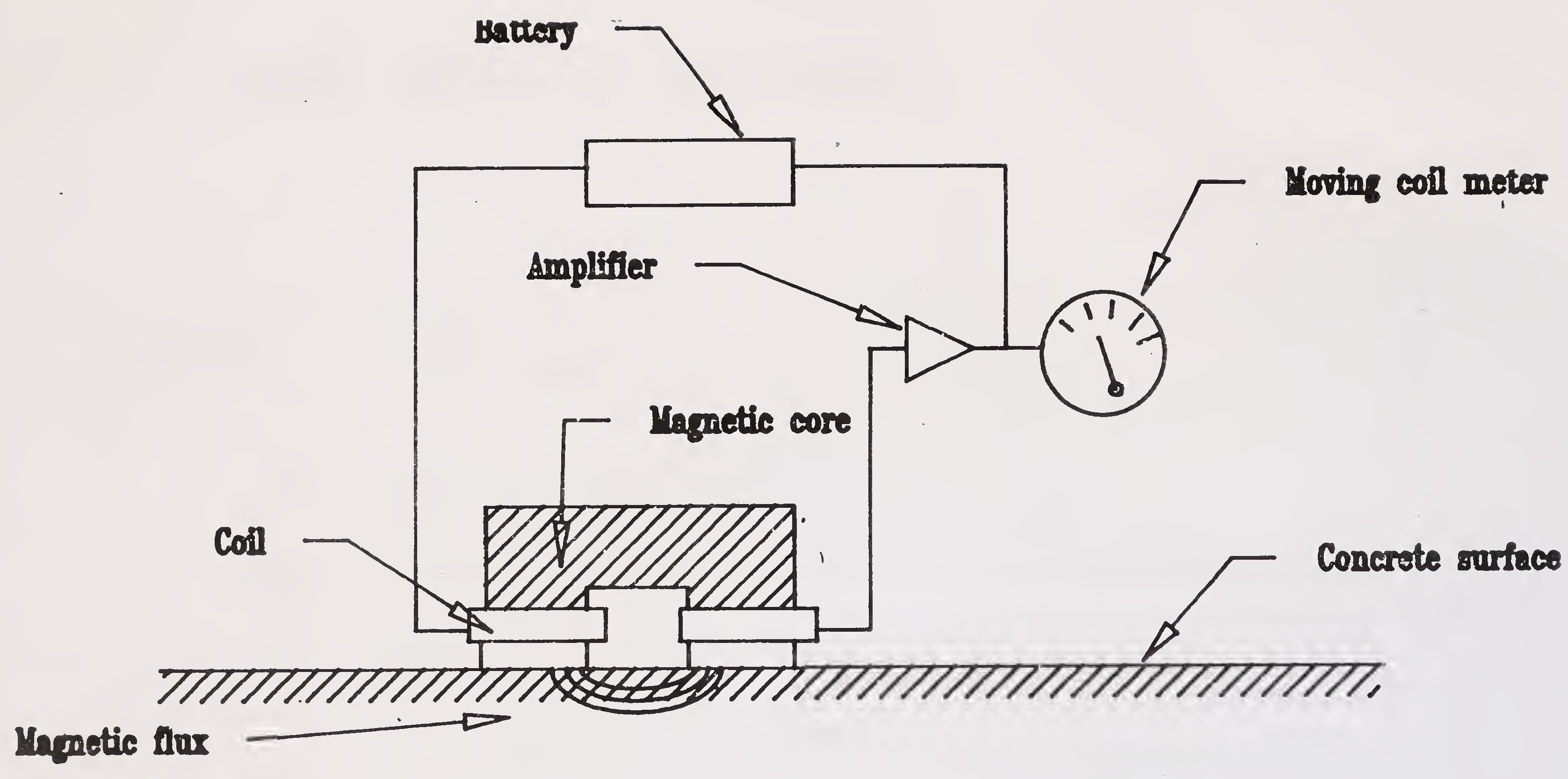

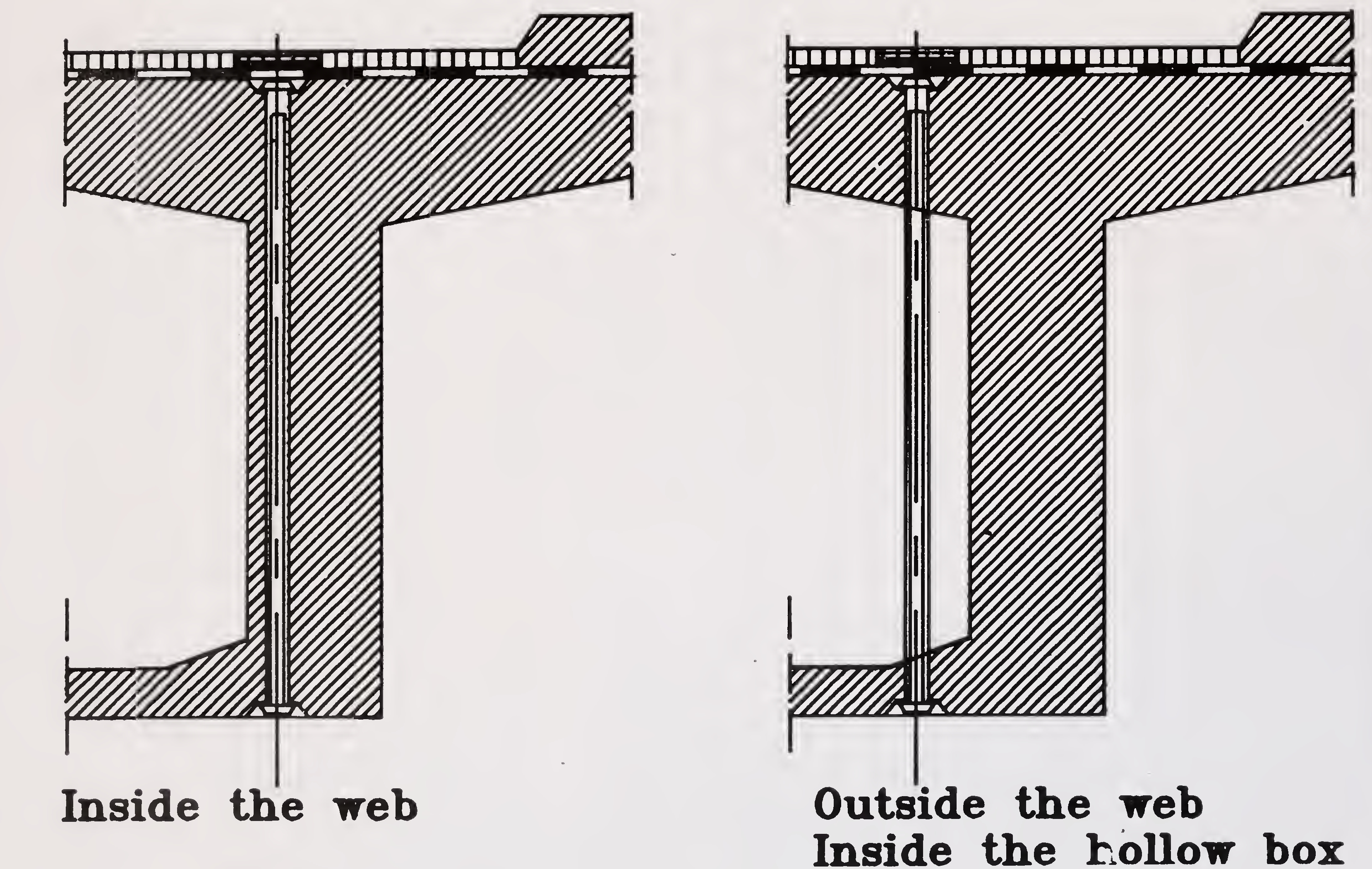

(ii) Magnetic methods : These are methods used to determine the position of reinforcement with reference to the surface of concrete and thus adequacy or otherwise of the cover over the reinforcement can be assessed. Pachometers detect position of reinforcement and measure the depth of cover. A battery is used to generate magnetic field which gets distorted where there is steel in the vicinity of the probe. Portable battery operated cover-meters (Fig.4.1) can measure the cover with an accuracy of 5 mm upto a depth of about 75 mm.

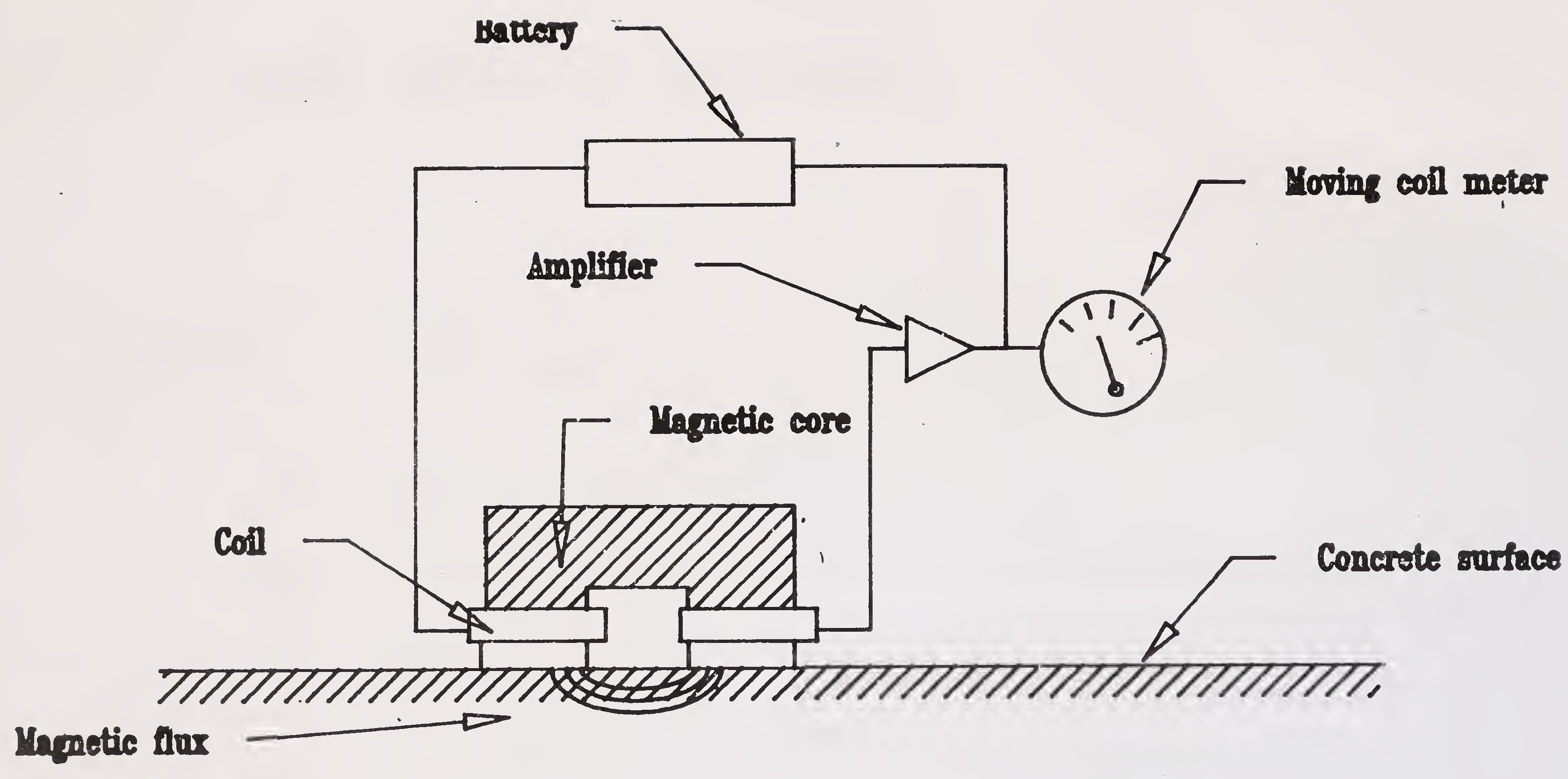

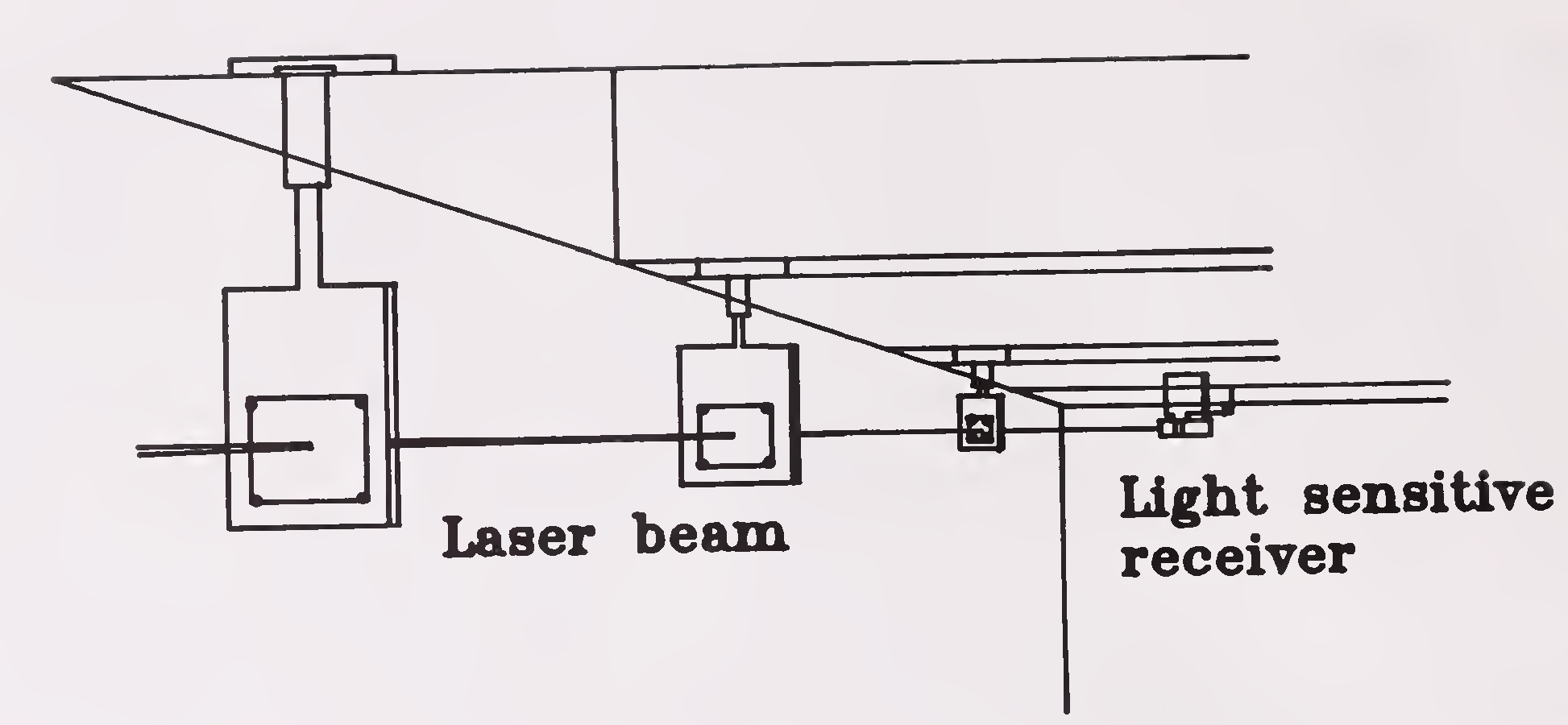

(iii) Radar technique : A high frequency pulsed radar can be used to detect deterioration in concrete decks. The echos produced from the pavement surface and the interface of the bridge deck concrete, in case of bituminous surfaced bridge decks, are very distinct so that thickness can be measured accurately, (Fig. 4.2). Short duration pulses of radio-frequency energy are directed into the deck portion and are reflected from any interface and the output is displayed on an oscilloscope. The interface can be any discontinuity or differing dielectric, such as, air to surfacing to concrete or cracks in concrete. A permanent record can be stored on magnetic tape and the unit is normally mounted on a vehicle and data are collected as the vehicle moves slowly across the deck.

(iv) Radiography : Radiographic techniques are applied on the prestressing cables to detect defects in the cable and to examine the quality of grouts within the ducts. Most applications involve transmission of wave energy rather than the reflection or refraction methods. The emerging radiation is detected by photographic emulsion or by a radiation detector. The former is called radiography and the latter radiometry. The back-scatter techniques based on reflected28

Fig.4.1 Simple covermeter29

Fig.4.2 Elements of a radar system30

intensity of X-rays can be used to detect the voids in grout and testing strands or wires which are broken or are out of position. However, small amounts of corrosion will not be detected and the technique is suitable only for isolated cables without any other obstruction in the path of the wave.

(v) Thermography : Infra-red thermography is a method of detecting delamination in bridge decks and columns exposed directly to sun. The method works on the principle that discontinuity within the concrete, such as delamination, interrupts the heat transfer through concrete. The differences in surface temperature are measured by sensitive infra-red detection systems which consist of infra- red signal, control unit and a display screen. The images get recorded on photographic plates or video tapes. The equipment can be truck-mounted permitting a lane width to be scanned by a single pass. The main disadvantage of thermography is that while a positive result is valid, a negative result may not be always reliable because it relates to results under conditions prevailing at the time of tests. Nevertheless, the method itself has a considerable promise as a rapid screening tool for determining whether a more detailed investigation is required.

(vi) Nuclear and radioactive method : The density of concrete upto 100mm depth can be assessed by using the gamma-ray back scatter device. The concrete is irradiated from a portable neutron source and absorption of neutrons by chloride ions simulates emission of gamma radiation of a particular energy. The presence of moisture can be similarly detected by measuring the simulated emission of gamma radiation by hydrogen atoms. However, the readings would not give depth of penetration of chloride ions. The test is a highly specialised one.

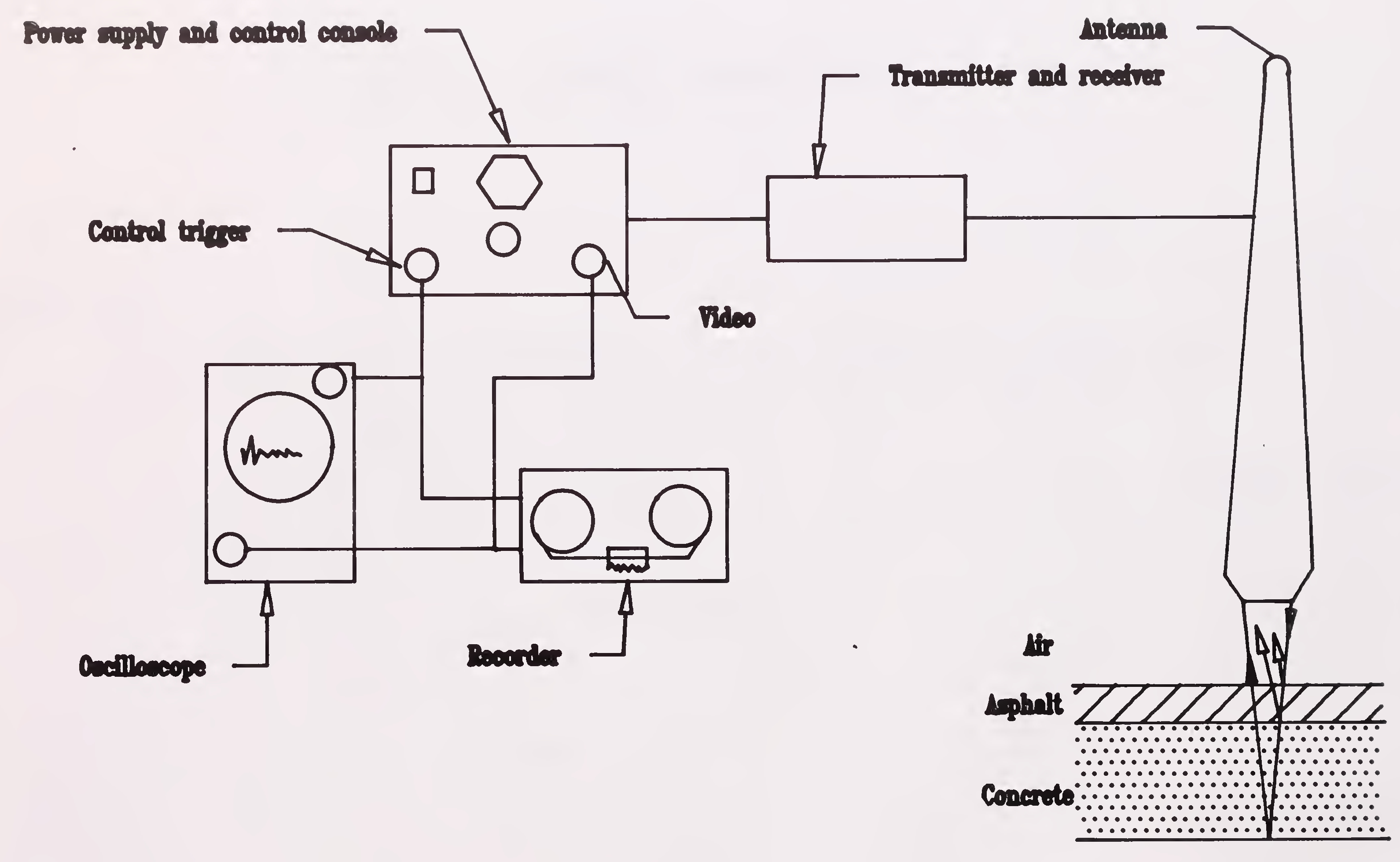

(vii) Ultrasonic pulse velocity measurement : The quality of concrete can be assessed by passing through concrete the ultrasonic pulse and measuring the velocity, (Fig.4.3). Measured values may be affected by surface texture, moisture content, temperature, specimen size, reinforcement and stress. Co-relations with strength are difficult to make and will be31

influenced by types and proportions of mix constituents and maturity. Calibration on tested cores is essential.

Fig.4.3 Methods of measuring pulse velocity through concrete

(i) Pull-out strength of hardened concrete : It is possible to assess the comparative strength of hardened concrete by co-relating it to the pulling force (required to pull the metal devices inserted in concrete). A large number of such tests need to be carried out.

(ii) Coring : This is a somewhat destructive method of assessment under which core of concrete from the structure is drilled with the help of a coring machine. The core is then analysed in a laboratory for various properties including its strength. Core drilling machines of the size of brief-case are available commercially.

(iii) Endoscopy consists of usually flexible viewing tubes which can be inserted into holes drilled in the bridge components or32

into a cable duct of the prestressed concrete. A light is provided by optical fibres from external source. The endoscopes are available with attachments for a camera or a TV Monitor and are used for detailed examination of parts of the bridge structure which cannot otherwise be assessed. They are useful in detecting voids in the grout, concrete, corrosion in steel etc. This test if required, should preferably be done in association with radiographics and should be done under expert guidance.

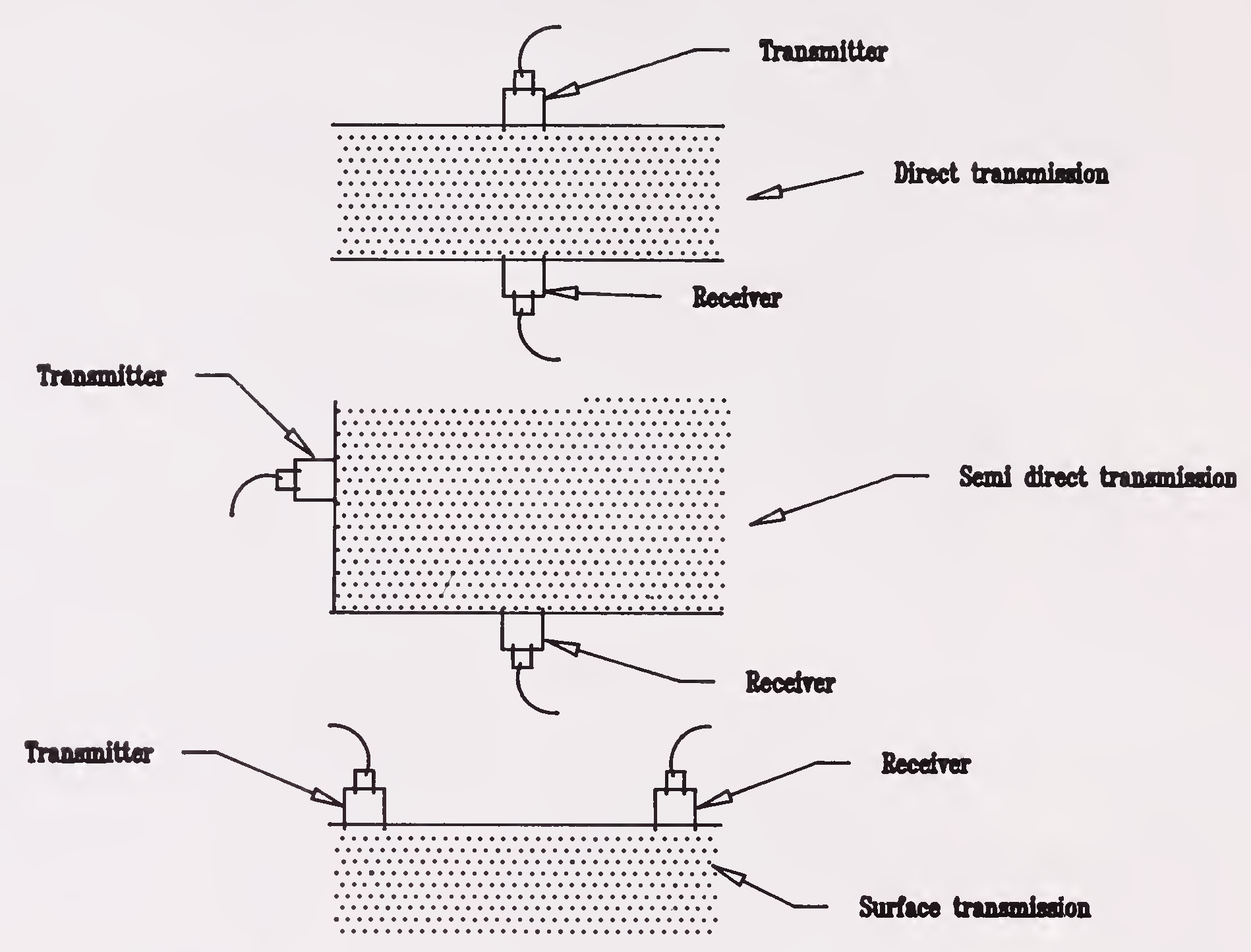

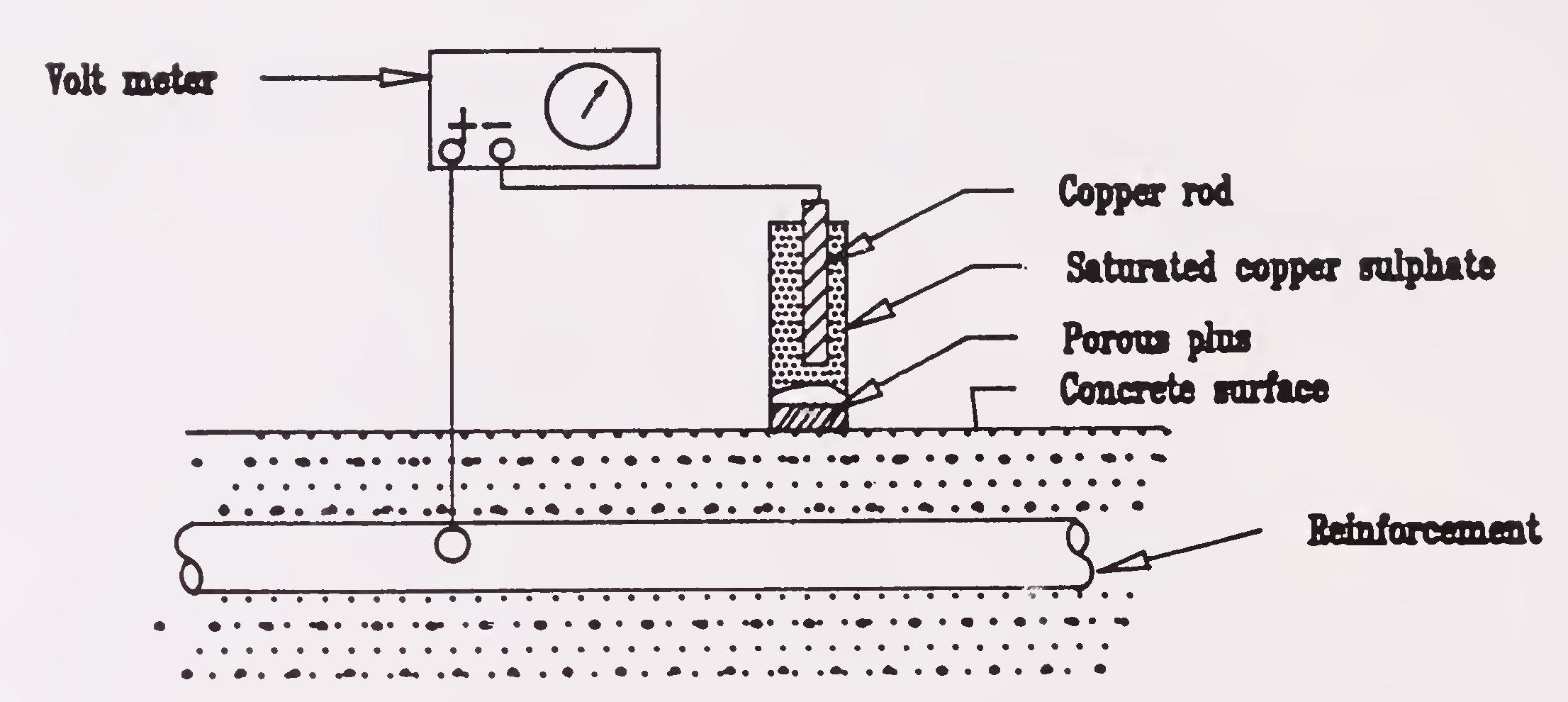

(iv) Other methods : Electrical corrosion detection device : The electrode (half-cell) potential of reinforcement embedded in concrete provides a measure of the corrosion risk and indicates whether electro- chemical reaction has taken place on the electrode surface. The electrical potential difference between the steel and electrode (concrete) is measured with copper/copper sulphate half-cell or copper calomel electrode or silver chloride electrode, (Fig.4.4). The pathfinder and potential wheel, marketed recently, are refined versions of copper/copper sulphate electrode for better scanning. However, this method does not give information on the rate of corrosion, and also it gives only the probability of activity of corrosion. However, it has been recently reported that C.E.C.R.I. Karaikudi has succeeded in giving quantitative indications of corrosion in steel by electrical devices (vide Appendix 1).

(v) Response to vibration : The objective of vibration testing is to relate the defects in the bridges to the changes in its dynamic characteristics. The vibration analysis of a structure carried out over a period of time measures loss of stiffness and not the loss of strength, although the former seldom implies loss of strength. However, a serious loss of strength in an individual member may occur before there is a measurable loss of stiffness in the overall structure. Sometimes, accelerometers are temporarily attached to the bridge and the traffic/wind induced vibrations are recorded. The modes of vibration and damping can then be determined by computerised analysis. Sometimes, a variable frequency sinusoidal force is applied at a point in the bridge the response at other points is measured which depends mainly on the fixity and stiffness of33

connections. With proper application, the cracks can also be detected by this method. The vibration methods show considerable promise although the methods of interpretation of results in terms of the type of defects and its cause are yet to be developed.

Fig.4.4 Electrical potential measurement of reinforcement

The various non-destructive and other evaluation methods have several limitations as there are various parameters influencing each test and many a time combination of different methods have to be used during investigations.

Recently, in-situ permeability testing equipment has also become available for assessing die quality of concrete although doubts are being expressed about the reliability of results.

A general summary of the capabilities of the various test methods to detect different forms of defects or deterioration is given in the Table 4.3. This Table provides comparison amongst the methods and can be used in planning an investigation.34

| Technique | Capability of Defect Detection | ||||

|---|---|---|---|---|---|

| Cracking | Scaling | Corrosion | Wear and Abrasion | Voids in | |

| Visual | G | G | P/G | G | N |

| Sonic | F | N | G | N | N |

| Ultrasonic | F | N | N | N | N |

| Magnetic | N | N | F | N | N |

| Electrical | N | N | G | N | N |

| Chemical | N | N | G | N | N |

| Thermography | N | Gb | N | N | N |

| Radar | N | Gb | N/P | N | N |

| Radiography | P | N | P | N | G/F |

| Air permeability | N | N | F | N | F |

| Water permeability. | N | F | F | P | F |

| G = good; F = fair; P = poor; N = not suitable; b = beneath bituminous surfacings. | |||||

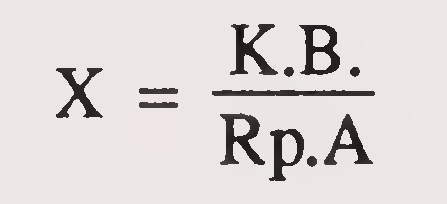

The above techniques present possibilities of making an assessment of the overall condition of the bridge or changes in the condition and of detecting faults. But, it is often difficult to analyse the effects or defects or deterioration on the overall performance of the bridge or on the stresses in individual components. A full scale load test can, therefore, be useful. Load tests can be expensive and on larger bridges they require considerable planning, involve many people and demand the use of sophisticated equipment. Testing in remote locations can present additional difficulties. Particular care is needed for bridges with brittle failure modes. However, load testing can often be justified where the effect of defects and/or deterioration on load capacity cannot be determined by analysis alone. However, a decision to carry out full scale load testing should not be undertaken without a serious thought.The actual procedure for load testing for rating of bridges and interpretation of tests have already been described in IRC:SP:37. So the procedure for load testing is not described here; but principles and instrumentation and equipment used in load testing are given below :

(a) Bridge testing is both an art and a science. In its simplest form, load testing involves measuring the response of the bridge to a known applied load. Considerable experience is required to know where to locate gauges and to determine load increments and the maximum load to be applied to prevent damage to the35

bridge. The load is applied, usually by vehicles although occasionally by dead load or through cables, to induce maximum effects. Where measurement of stress at a given location under known load is all that is required, data processing may not be a major consideration. In other cases, the amount of data recorded is often extensive such that automatic data recording and analysis is highly desirable. It is also preferable that this be done on site as the test progresses so that deviations from anticipated behaviour are known and the necessary changes in procedure or equipment can be made. Because concrete properties are required to define stress values (from strain measurements), samples must be taken from the structure.

(b) Several types of strain gauges can be used in conjunction with load testing bridges and jacks can be used to determine reactions at the supports.

(c) Comparators are mechanical, electrical or electronic instruments used to measure the distance between studs attached to the structure. The distance between the studs is usuallty in the range of 50 to 200mm and the sensitivity of the instruments is typically 0.01 to 0.05 mm. The main application of comparators is to measure the change in width of a crack under load or over time.

(d) Resistance wire strain gauges are cemented directly to the material under investigations. Dummy gauges are incorporated in the electrical circuit to compensate for temperature effects. Strains, which are measured by the change in the electrical resistance of the gauges, can be determined very accurately, generally between 1 and 3 micro-strain. The interpretation of the result is, however, often difficult because of the small size of the gauges and the non-homogenous nature of concrete. Several gauges must therefore be attached to the structure in the area of interest in order to identify anomalous results. Resistance wire gauges are not suitable for use on cracked concrete because a change in strain may stress them beyond their linear range.36

(e) Rosette gauges, which contain three resistors set in a known angle (generally 45 degrees or 60 degrees), can be used to calculate the direction and magnitude of the principal stresses.

(f) Vibrating wire gauges consist of a metal wire stretched inside a tube which is embedded in the concrete. The wire is vibrated by an electromagnet and the frequency of vibration is measured, from which the strain in the concrete can be calculated. Since the gauge is about 150mm long, the results are not affected by localised heterogenetics in the concrete, but cracks cause the same kind of problems as with resistance strain gauges.

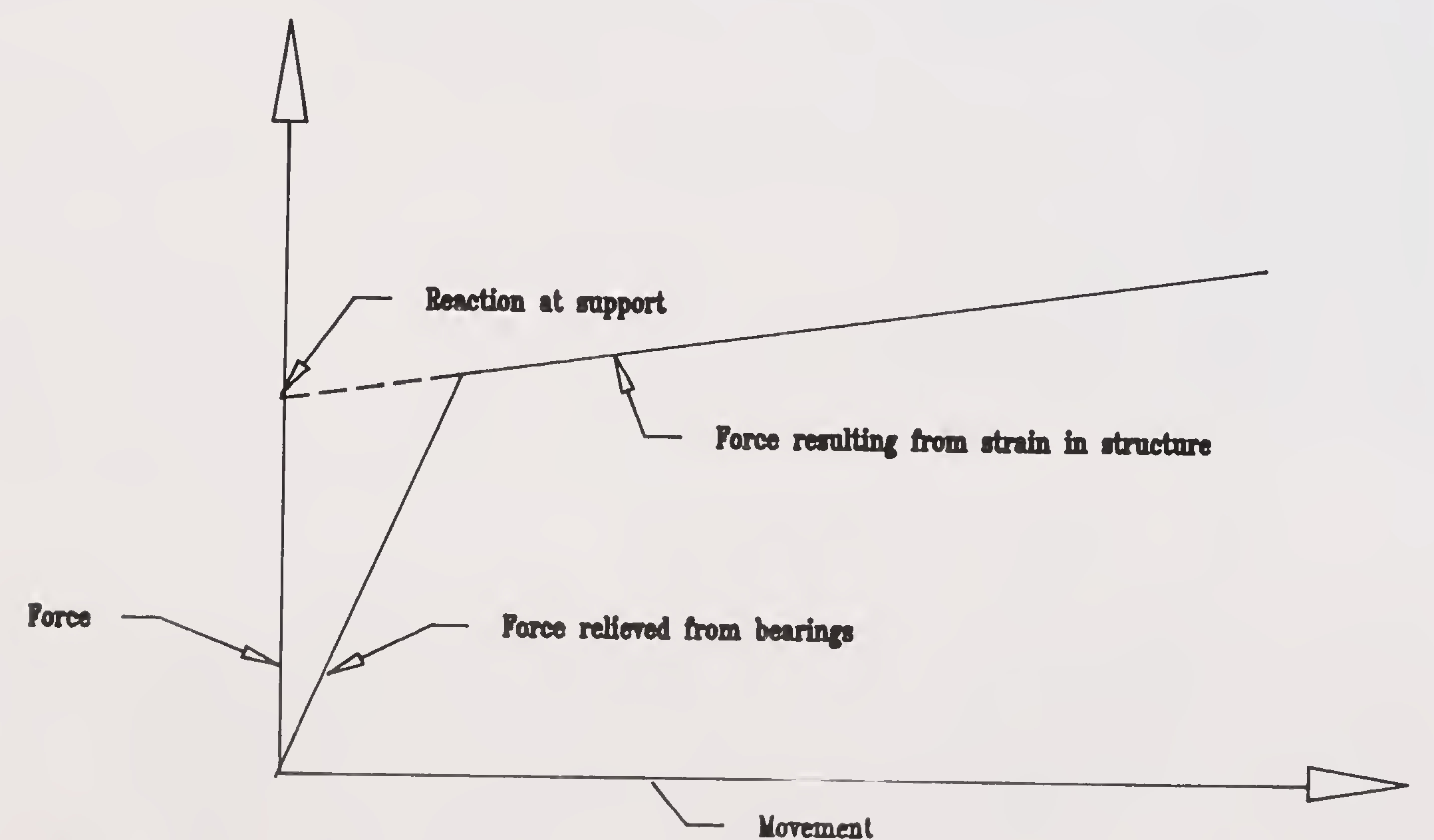

(g) Jacks can be used to measure the reactions at the supports of the structure. This may be required for such purpose as assessing the impact of thermal gradients, or the re-distribution of stresses due to creep, settlement or faulty construction. The technique consists of measuring the force and movement as the structure is raised. A relationship such as that shown in (Fig. 4.5) is obtained, from which the reaction at the support can be determined. This type of test is expensive and, in addition to the requirement for suitable jacking points,

Fig.4.5 Tipical force-movement relationship resulting from jacking a support37

the deck joints must be removed together with any other feature which might interfere with the free movement of the jack. Using good quality, properly calibrated equipment, an accuracy of 0.3 to 1.0 per cent is attainable, with load cells. It may however be noted that even calibrated jacks are about ±5% accurate if only the hydraulic pressure is monitored.

It is intended to cover in this chapter only the more important techniques and materials used for bridge repairs and strengthening. The maintenance techniques described in the separate guidelines for inspection and maintenance of bridges are not repeated. The criteria for selection of materials and techniques for repairs and strengthening could be :

It is not possible to evolve a general method for repairs and/or strengthening of foundations. Each case has to be analysed individually and may require special investigations. Most repair works for foundations are in the category of protection and strengthening. Some examples are given below:

Note : Foundation movements can substantially increase the loads and moments in some parts of the superstructure by redistribution. This must always be checked for.

It is not possible to list causes of deficiency of underwater structures as they are too numerous. The same, also, applies to the combinations of conditions requiring repairs. Given the wide range of materials and repairs techniques the choice of the most appropriate technique is difficult. Table 5.1 gives a list of possible remedial measures according to the nature of the problems. Some of the repair works carried out for foundations are described below for information and guidance though, as already mentioned, each case has to be decided on its merit. Guidance could be obtained from IRC:89-1985 "Guidelines for Design and Construction of River Training and Control Works for Road Bridges".

(1) Erosion problems : Stone rip-rap is placed on a mattress at or beneath the channel bed level. The weight of the mattress sha11 be designed keeping in view the maximum velocity of flow but preferably shall not be less than 150 kg. per sq.m. The slope of the protective rip-rap should be between 1 in 3 ana 1 in 3.5. Heavier stones should be used for rip rap in case steeper slope is necessary.39

| Type of Repairs (Underwater & in splash zone) | Scour | Deterioration | Structural Damage | Structural Failure | Foundation Distress | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete | Steel | Timber | Concrete | Steel | Timber | Concrete | Steel | Timber | Concrete | Steel | Timber | ||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| Replacement of Material | X | ||||||||||||

| Steel Piling | X | ||||||||||||

| Modification of Structure | X | ||||||||||||

| Training Works | X | ||||||||||||

| Cement/Epoxy injection | X | X | X | X | X | X | X | X | |||||

| Quick Setting Cement | X | X | |||||||||||

| Cement/Epoxy/ Polymer modified Mortar | X | X40 | |||||||||||

| Placing Concrete Underwater | |||||||||||||

| a) Underwater Bucket | X | X | |||||||||||

| b) Tremie Concrete | X | X | X | X | X | X | X | X | X | ||||

| c) Pumped Concrete | X | X | X | X | |||||||||

| d) Protective Coatings | X | X | |||||||||||

| e) Cathodic Protection (Experimental) | X | X | X | ||||||||||

| f) Splicing New Steel Section | X | X | X | ||||||||||

| g) Pile Jacket | X | X | X | X | X | X | X | X | X | ||||

| h) Wood Treatment | X41 | ||||||||||||

(2) Protection against scour : Excessive scour is one of the more frequent factors that may cause or lead to structural failure or distress of the foundation. The degree of damage depends on factors such as the stream bed material, the intensity of discharge, the silt charge, obliquity of stream flow and the shape of the structure.

For deciding the extent and type of repair arising out of excessive scour, ascertaining the causative factors, such as change in the alignment of the stream, an inadequate waterway or the presence of debris, is of great help. Determining the most effective solution to a scour problem is often difficult and may require model studies to be carried out.

Spur dykes, jetties, deflectors and other devices may be constructed to direct water away from a fill, bridge pier, or abutment. Caution is needed because only correctly designed and constructed training works are helpful in controlling scour and erosion. Repair of damages caused by channel scour may vary from simple solutions such as replacement of displaced material to complicated solutions like redesigning the footing, construction of training works or sheet piling, or other modifications of the structure or channel.

At sites, where soil erosion has occurred because of stream or tidal action, it is a common practice to place rock or rip-rap material in the void or to protect the replaced soil with rip-rap, bagged concrete rip-rap or grouted or wire enclosed boulders. Piers and abutments may be protected or repaired by placing sheet piling to keep material in place or to prevent further scour. Sheet piling should be driven to a depth where non-erodible soil conditions or rock exist. The overhead clearance required or under substructures may be a major disadvantage in using sheet piling. If supporting material has been removed from under a large area of the footing, consideration should be given to redesigning the foundation, including filling the void with concrete. In some cases, the footing may be extended by using sheet piling as forms for the extension and as stay-in-place protection against further scour. If scour has exposed supporting piles, it may be necessary,42

particularly if they are short, to drive supplemental piles that are part of the extended footing.

To restrict scour around piers it is also common to utilise what is known as ‘garlanding technique’. In this, very heavy concrete blocks or stones of designed weight are placed around the pier foundations below the bed level by excavation. The size of the garland and the weight should be properly designed.

It is advisable to consult experts before deciding/undertaking the solution of a serious repair problem.

(3) Foundations on soft rock subject to erosion can be protected by reinforced concrete curtain walls enclosing the footing or piles.

(4) Increasing the bearing capacity of the soil by injecting cement or chemical grout taking care that grout pressure does not exceed the overburden pressures.

(5) Rock or ground anchors are often used for abutments where protective slope had to be removed for say widening of navigable channel, road, etc. Normally a protective sheet pile wall is driven first in the case of ground anchors. Design and execution of rock ground anchors requires great care and should take into account all factors likely to affect the bearing capacity and durability of the anchoring system. Now a days, prestressed anchors are also used.

(6) Extension of existing foundations : This would be necessary while widening an existing bridge.

(7) Liquefaction of foundation soil : Some foundation failures during earthquakes could be the result of excessive soil movements especially due to liquefaction. There are two approaches to retrofitting that will mitigate these types of failures :

Some methods are available for stabilising the soil at the site of the structure. Each method should be individually designed making use of established principles of soil mechanics to ensure that the design is effective and that construction procedures will not damage the existing bridge. Possible methods for soil stabilisation include :

At a site subjected to excessive liquefaction,methods to improve the structure may be ineffective unless coupled with methods to stablilise the site.

(8) Underwater work : While dealing with underwater work, it will be relevant to refer to underwater inspection also. Inspection of underwater portions of the structures is very difficult because of the harsher environment, poor visibility, deposition of marine organisms etc. To do an effective underwater inspection, it is necessary to deploy properly trained and equipped supervisory personnel. The quality of inspection underwater should be equal to the quality of inspection above water. Clearing the marine growth from underwater portions of a bridge is almost always necessary. Visual inspection is a primary work of detecting underwater problems. In turbid waters, the inspector should use tactile examination to detect flaws, damage or deterioration. In some cases sophisticated techniques, ultra-sonic thickness gauges, computerised tomography or TV monitors may be required. After the initial identification of a trouble spot of the damage, for the purpose of detailed examination and carrying out repairs it may be necessary either to expose the member by means of a cofferdam and dewatering or by providing a small air-lock as described later.44

Normally, inspection of under water components of a bridge is carried out with the use of divers who are usually non-qualified as bridge inspectors. It would be useful to train some of the engineers in diving techniques so that they as qualified divers can interpret the observations in a more scientific way. Underwater photographic techniques are also available wherein damages are detected by divers who can then take photos of affected areas. Similarly, underwater cameras (mounted on diver’s head gears) can be used to scan the various components of submerged portions of the structure continuously and signals can be read on a TV monitor kept on the bridge deck.

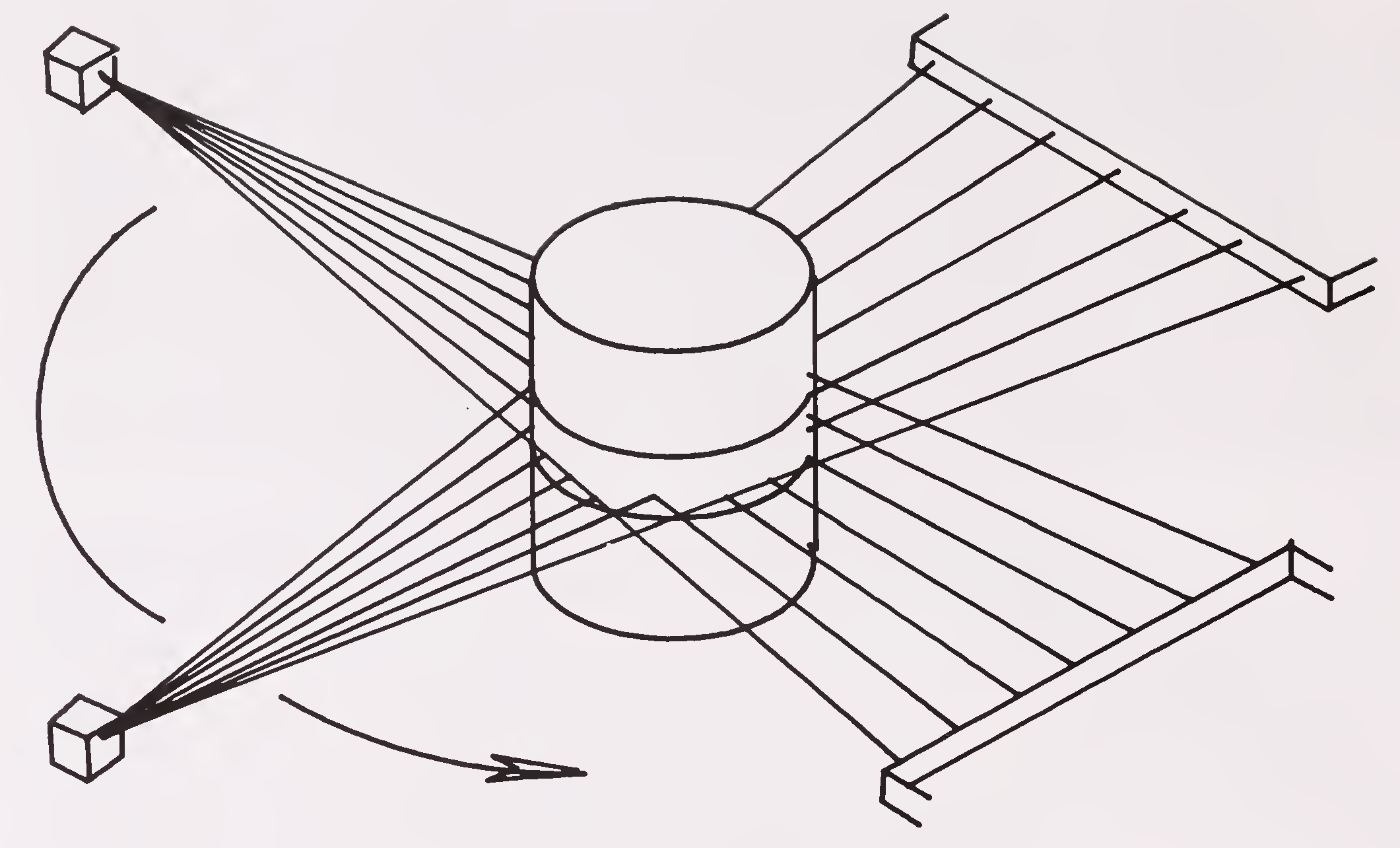

A new technique using acoustic microscopy* measurements has been developed abroad for underwater study. In this, measurement of small electrical potential differences caused by corrosion current in sea water is combined with acoustic inspection to determine the crack width and depth. Computerised tomography is yet another recent method to locate voids and steel reinforcement in underwater concrete. A gamma ray source is collimated to form a flat fan of rays which are attennuated as they pass through the approach to a set of detectors. The source detector apparatus is rotated to obtain a series of projections through the same cross sections (Fig.5.1). It is, however, reported that this technique is not yet well developed and is reliable in laboratory conditions only. But, Sonar procedures for mapping scour are useful.

Placing of concrete under water can be carried out with the help of conventional underwater bucket or tremie concrete, although under certain conditions placing of pre-packed concrete or bagged concrete or pumped concrete may be more suitable. In all such underwater repairs the surfaces of the pile or well or pier have to be cleaned of the dirt and other foreign material and after removing the cracked and unsound concrete the surface is to be prepared for receiving new concrete. Suitable priming coat by materials like moisture compatible epoxy resin is helpful to ensure proper bonding. The piles or columns are substantially deteriorated through actions of corrosion or other factors can be provided with integral jackets which may or may not be reinforced depending on the thickness of the jacket. It is often useful to provide temporary cofferdam which can be fixed to the pile at the base and the water can be pumped out. Joint of the jacket at its ends has to be properly detailed out and treated with epoxy. Grouting with quick setting cement or epoxy can also be carried out where necessary.

* Not yet introduced in India45

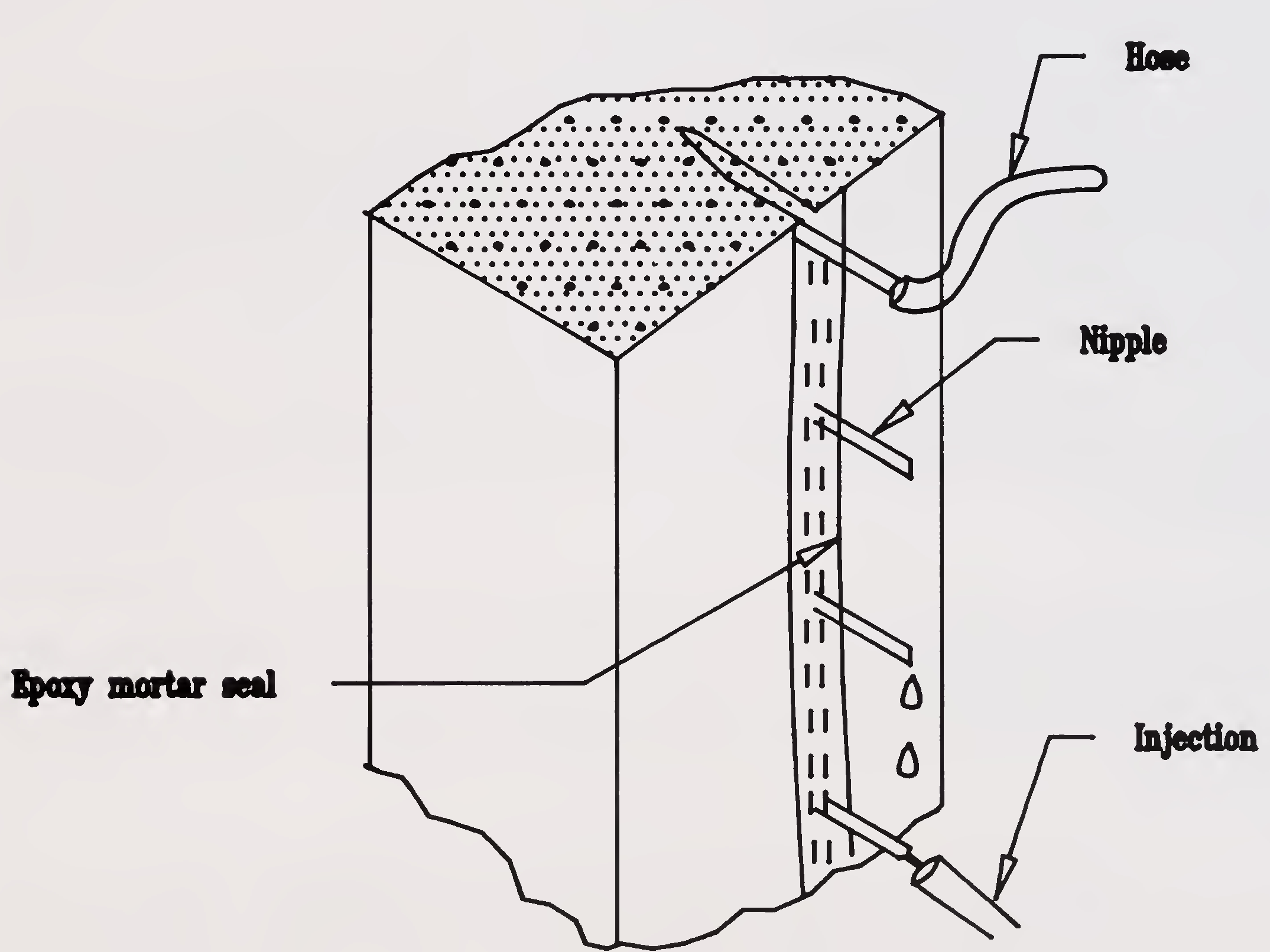

Fig.5.1 Scanning procedure for computerised tomography

Methods used by divers to perform underwater sealing and repairing of cracks by epoxy injections are similar to methods used above water, except that the epoxy surface sealer takes several days to harden sufficiently to withstand injection pressure. For underwater use, epoxies must be water insensitive. Before the application of epoxy surface sealer, cleaning is necessary. If oil or other contaminants are present in the cracks, and the epoxy is used for restoring the strength of the cracked concrete pier or pile instead of simply blocking the free entry of water in the crack, bonding will be improved by mixing detergents or special chemicals with a water jet to clean the crack interiors. After all cracks are prepared and sealed and the nipples positioned the low viscosity epoxy adhesive is injected under pressure into the crack network. A surface-mounted, positive-displacement pump is used to dispense the two components of the adhesive to the submerged injection sites where the components are mixed in the injection head as it is pressure-pumped into concrete.Water temperatures must be above 4 degrees centigrade. The adhesive cures to full strength in about 7 days. Cracks upto 2mm width may be sealed with straight epoxy resin (without filler). For wider cracks, the46

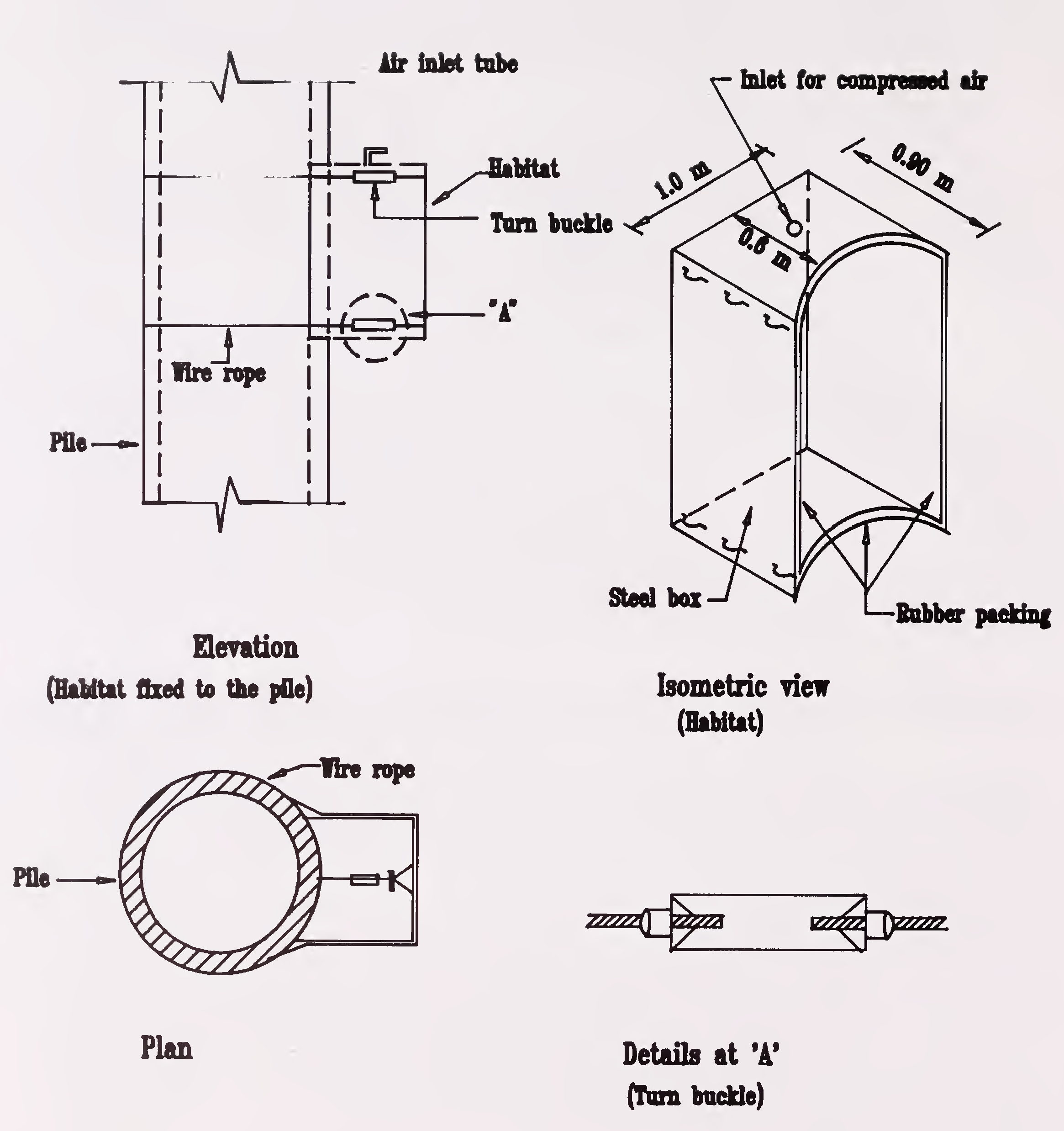

addition of a filler is generally required. Now-a-days, for underwater repair works, devices called ’Habitat’ are used. Habitat is a multi- cell metal unit open at the bottom with water- tight joints. This is installed around the member to be repaired. With compressed air, the Habitat is kept dry so that the divers can undertake repairs (Fig.5.2).

Various methods are currently used to prevent the corrosion of steel piling in sea water, including application of protective coatings, encasement of the steel in concrete or a combination of these procedures. Cathodic protection can also work well for this.

Existing masonry bridges are sometimes considered as historical landmarks and need preservation. Strengthening and widening will, therefore, mean maintaining the same appearance. Widening is usually not possible but strengthening can often be done. Strengthening of Masonry Bridges ensuring pleasant appearance is a delicate task and needs advice from experts in these fields.The following gives an idea of the general defects and remedial measures for such arch bridges in stone or brick masonry.

(i) Loss of Bond for the Crown stone: Flat jacks have been successfully used for pushing the stone back to its original position. Generally, low pressure cement grouting is done to strengthen the old mortar. The mortar is sometimes replaced by epoxy mortar also, though epoxy is not ideal.

(ii) Longitudinal cracks along the direction of traffic : It is possible to rake mortar joints and refill with cement mortar. However it must be mentioned that the depth of penetration is important as usually it is not possible to suspend traffic. If possible, the portion of earth fill could be removed to ensure that penetration is limited to masonry only. Fine cement grouting (injection) can be adopted for remedial measures. Generally it is cheaper and better to grout the cracks with cement than with epoxy.

(iii) Transverse Cracks : Injection of cement will provide a good bond between stones and brick masonry.47

Pig. 5.2 Typical habitat for under-water repairs48

(iv) Strengthening of Arch Rings : The arch ring can be strengthened in two ways - by adding material to the intrados or to the extrados. Adding to the intrados causes the least disturbance but is more difficult to complete successfully. Also it results in a reduction in headroom or clearance which is often restricted and will, in most cases be the cause of new damage to the intrados as experienced on many bridges even where the headroom/clearance satisfies legal limits. Extra material may be placed by shuttering and pumping concrete (which is difficult to compact at the crown) or by fixing a mesh to the intrados and spraying concrete. In both cases, any shrinkage of the new concrete will tend to make the old and the new material separate radially. Also these impervious rings prevent natural drainage between the stones or brick work of the arch so that special provision must be made to deal with water or under severe climatic conditions,such as inmountainous regions, with ice. Sprayed-on concrete will in any case change the appearance of an arch constructed of stone, brick or a combination of the two.

A more effective, but at times a more expensive, treatment is to remove the fill and cast the extra required thickness on the extrados of the arch. Usually, a full ring is cast but occasionally only the end quarters are strengthened to act as cantilevers and reduce the effective span of the arch. Normal concrete placing techniques are satisfactory. Replacement backfill may be with normal or lightweight concrete. The latter will reduce dead load on the foundations but may also reduce the factor of safety for stability of the substructure.

Another expedient which is satisfactory where the increase in load carrying capacity is relatively small, especially for small span bridges, is to cast slab at road level to act as an auxiliary deck which spreads the wheel loads.

For cracks in arches, grouting with cement, at pressure 4 to 6 Kg/Sq.cm is sometimes quite effective, though care should be taken to see that pressure will not damage the surrounding masonry.49

Since the majority of bridge structures will be of concrete, RCC as well as Prestressed Concrete, the techniques are described in a separate Chapter VI.

Comparatively very few defects have been reported with well designed and fabricated shear connectors. Problems with concrete decks in composite structures are essentially of the same kind and order of magnitude as those found in concrete decks in regular structure. It is likely that some early structures are seriously inadequate with regard to shear connectors for the heavier design loads now specified. The same can be also said for the main load carrying structural steel components.

Difficulties may be encountered with deck replacement or even major deck rehabilitation and strengthening operations in those composite bridges in which residual relieving stresses have been introduced by sophisticated erection procedures combined with an elaborate casting sequence for the bridge deck. Such cases would be very few in this country.

In reconstructing deck slabs, use of very high pressure water jetting say 10,000 psi, to remove the concrete around shear connectors is considered preferable to jack hammers so as to minimise damage.

Many of the old bridges (usually truss or arch bridges)have either warped steel plates with a bituminous surfacing or a concrete deck. Due to insufficient waterproofing the steel plates are often corroded.

Bridge decks can be replaced by new concrete decks or by new orthotropic steel decks, though these have not been used in India so far. Usually,when a reduction in dead load or additional widening (adding cycle or pedestrian lanes) are necessary, replacement by an orthotropic steel deck is preferred. Bolting is the preferred method of connecting the new deck system to existing structural members.

Depending on the type of bridge and the load carrying capacity of its structural components, the new concrete deck is placed as a non-composite50

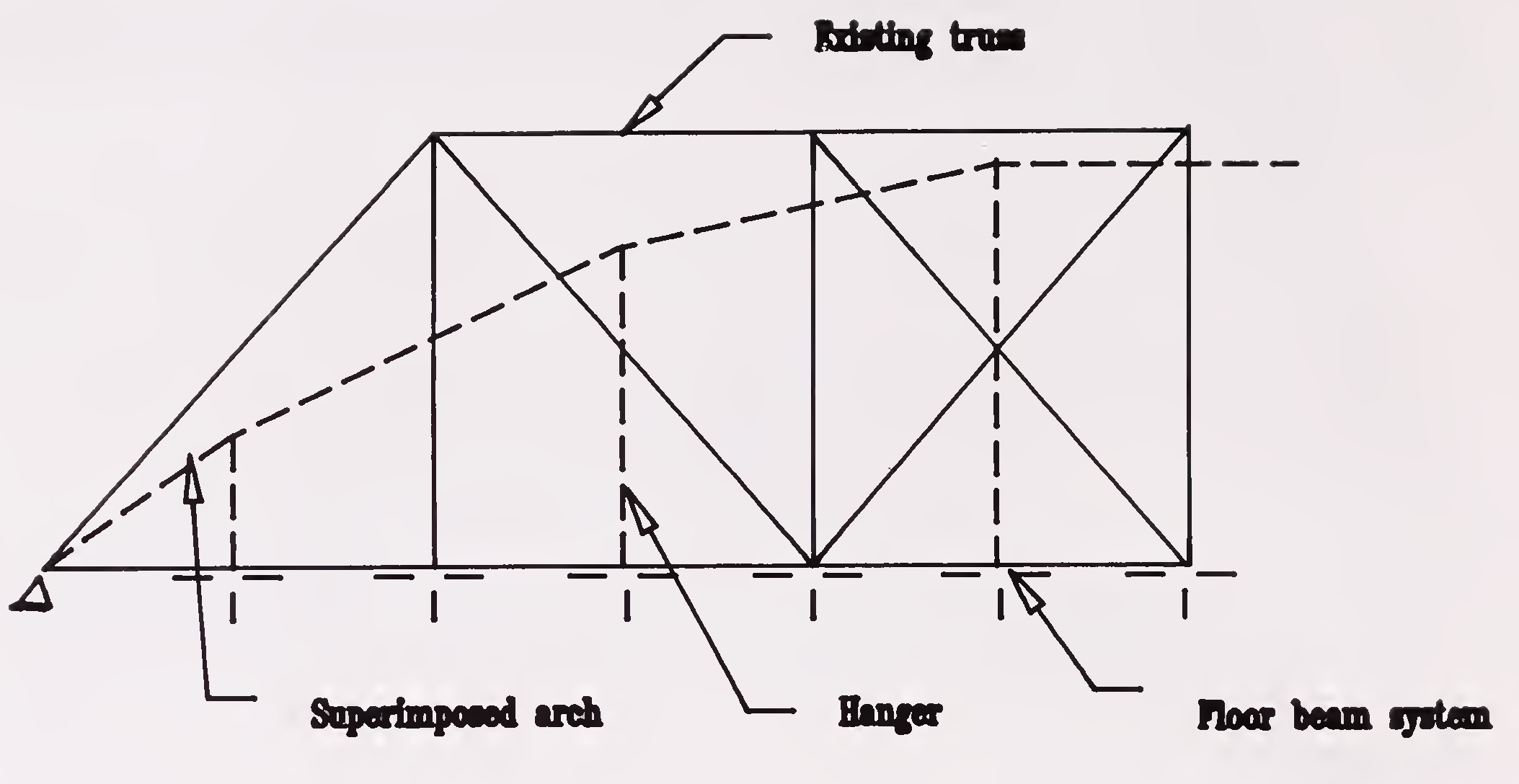

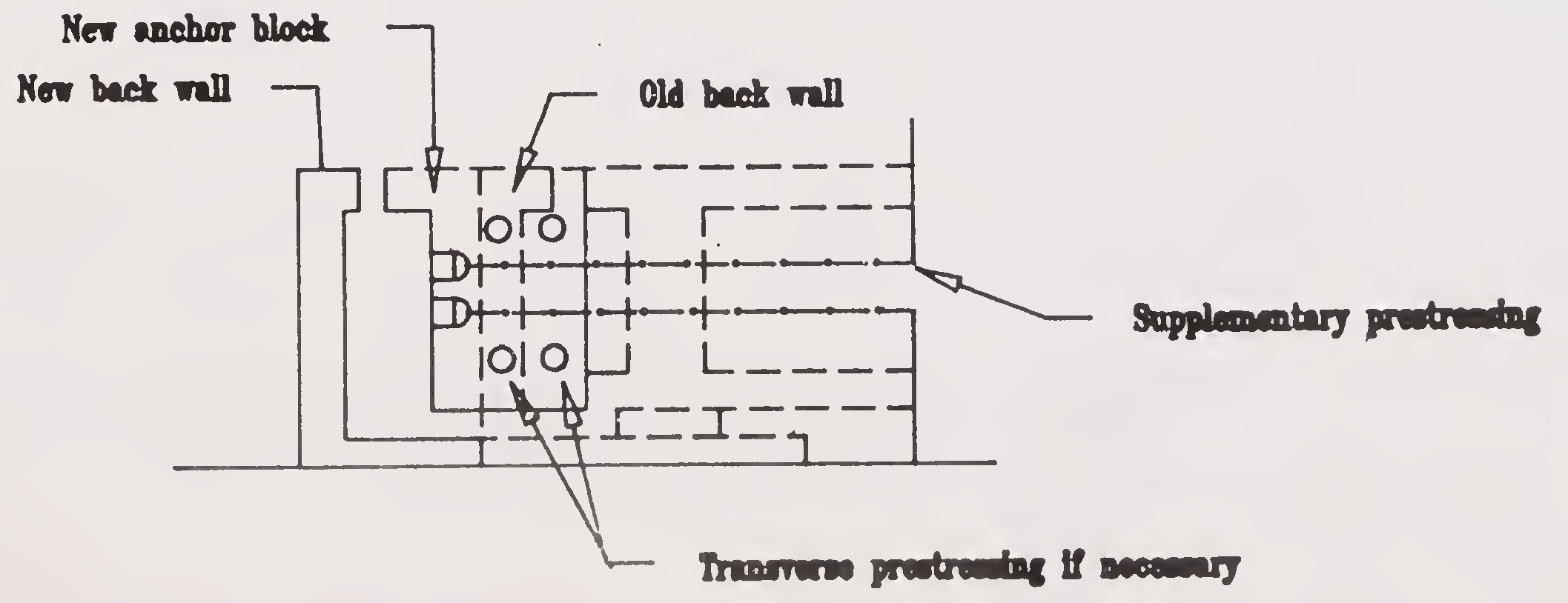

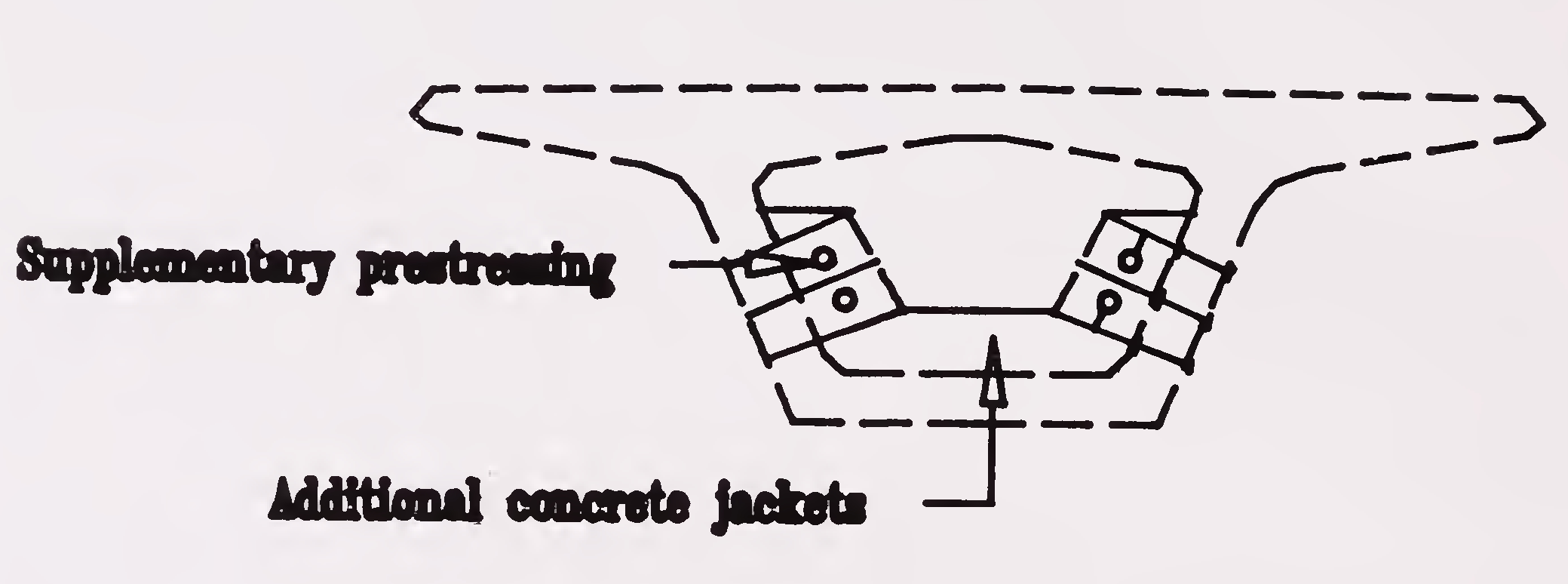

element, as a partially composite element (e.g. in composite action with the stringer and/or cross beams) or as a totally composite element (i.e. in composite action with all main load carrying elements).