In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 765:2011

ICS 67.060.10

EAST AFRICAN COMMUNITY

HS 1006.20.00

© EAC 2011

First Edition 2011

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East Africa. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to meet the above objectives, the EAC Partner States have enacted an East African Standardization, Quality Assurance, Metrology and Test Act, 2006 (EAC SQMT Act, 2006) to make provisions for ensuring standardization, quality assurance, metrology and testing of products produced or originating in a third country and traded in the Community in order to facilitate industrial development and trade as well as helping to protect the health and safety of society and the environment in the Community.

East African Standards are formulated in accordance with the procedures established by the East African Standards Committee. The East African Standards Committee is established under the provisions of Article 4 of the EAC SQMT Act, 2006. The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

Article 15(1) of the EAC SQMT Act, 2006 provides that “Within six months of the declaration of an East African Standard, the Partner States shall adopt, without deviation from the approved text of the standard, the East African Standard as a national standard and withdraw any existing national standard with similar scope and purpose”.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2011 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.int

*© 2011 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iiThis standard has been developed to take into account:

| 1 | Scope | 1 | ||

| 2 | Normative references | 1 | ||

| 3 | Terms and Definitions | 1 | ||

| 4 | Quality requirements | 4 | ||

| 4.1 | Raw material | 4 | ||

| 4.2 | General requirements | 4 | ||

| 4.2 | Specific requirements | 4 | ||

| 4.2.1 | Grading | 4 | ||

| 4.2.2 | Ungraded brown rice | 4 | ||

| 4.2.3 | Reject grade brown rice | 4 | ||

| 5 | Contaminants | 5 | ||

| 5.1 | Heavy metals | 5 | ||

| 5.2 | Pesticide residues | 5 | ||

| 5.3 | Mycotoxin limits | 5 | ||

| 6 | Hygiene | 6 | ||

| 7 | Packaging | 6 | ||

| 8 | Labelling | 6 | ||

| 9 | Sampling methods | 7 | ||

Brown rice — Specification

This East African Standard specifies the requirements and methods of sampling and test for brown rice of the varieties grown from Oryza spp., intended for human consumption or for processing to milled rice.

The following normative documents contain provisions which, through reference in this text constitute provisions of this East African Standards

ISO 605, Pulses — Determination of impurities, size, foreign odours, insects, and species and variety — Test methods

ISO 711, Cereals and cereal products — Determination of moisture content (Basic reference method)

ISO 712, Cereals and cereal products — Determination of moisture content — Routine reference method

ISO 5223, Test sieves for cereals

ISO 6639-1, Cereals and pulses — Determination of hidden insect infestation — Part 1: General principles

ISO 6639-2, Cereals and pulses — Determination of hidden insect infestation — Part 2: Sampling

ISO 6639-3, Cereals and pulses — Determination of hidden insect infestation — Part 3: Reference method

ISO 6639-4, Cereals and pulses — Determination of hidden insect infestation — Part 4: Rapid methods

ISO 13690, Cereals, pulses and milled products — Sampling of static batches

ISO 16050, Foodstuffs — Determination of aflatoxin B1, and the total content of aflatoxin B1, B2, G1 and G2 in cereals, nuts and derived products — High performance liquid chromatographic method

EAS 39, Hygiene in the food and drink manufacturing industry — Code of practice

CODEX Stan 193, Codex general Standards for contaminants and toxins in Food and Feed

EAS 38, Labelling of pre-packaged foods — Specification

EAS 79, Cereals and pulses as grain — Methods of sampling

EAS 217, Methods for the microbiological examination of foods

For the purpose of this East African Standard, the following definitions shall apply.

rice (Oryza spp) from which only the outermost layer (the husk) of a grain of rice has been removed

1pieces of rice that are less than three-quarters of a whole kernel and includes grains of rice in which part of the endosperm is exposed or rice without a germ. If the piece is more than three-quarters of a kernel, it is considered whole.

whole or large broken kernels of rice which are one-half or more chalky

part of kernel which passes through a metal sieve with round perforations 1.4 mm in diameter

whole or broken kernels of rice which are distinctly discoloured or damaged by water, insects, heat, or any other means (including parboiled kernels in nonparboiled rice and smutty kernels).

the germ has been removed through the mechanical handling process or by insect attack

all organic and inorganic material other than pearl millet, broken kernels, other grains and filth.

glutinous brown rice for processing shall be special varieties of rice (Oryza sativa L. glutinosa) which contain more than 50 percent chalky kernels. Grade 1 shall contain not more than 1.0 percent of nonchalky kernels, Grade 2 not more than 2.0 percent of nonchalky kernels, Grade 3 not more than 4.0 percent of nonchalky kernels and Grade 4 not more than 6.0 percent of nonchalky kernels.

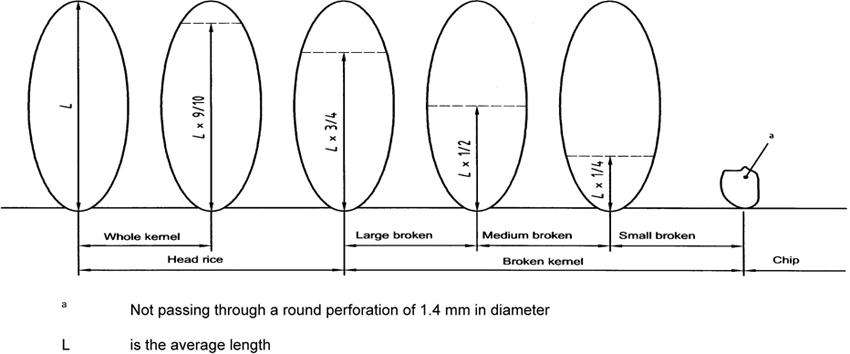

whole kernel or part of the kernel with a length greater than or equal to 75 % of the average length of the test sample kernels (see Figure 1)

Figure 1 — Size of kernels, broken kernels and chips

2head rice or broken kernel which is unripe and/or badly developed

grains eaten in part by stored grain insects and any field pests of grains including Heliothis spp. Grains may have a hole (commonly referred to as bored) or have a chewed appearance on any part of the grain.

seeds not removed by the cleaning process, usually large seeds

an estimate of the quantity of whole kernels and total milled rice (whole and broken kernels combined) that is produced in the milling of brown rice for processing to a well-milled degree

any stain on kernels caused by contact with natural substances such as bunt spores, soil or weeds

whole or broken unhulled and whole or broken hulled kernels of rice having a portion or portions of the hull remaining which cover one-half (1/2) or more of the whole or broken kernel

rice in which the starch has been gelatinized by soaking, steaming, and drying.

head rice or kernel of parboiled rice which is not fully gelatinized and shows a distinct white opaque area

any seed which if present in quantities above permissible limit may have damaging or dangerous effect on health, organoleptic properties or technological performance such as Jimson weed — dhatura (D. fastuosa Linn and D. stramonium Linn.) corn cokle (Agrostemma githago L., Machai Lallium remulenum Linn.) Akra (Vicia species), Argemone mexicana, Khesari and other seeds that are commonly recognized as harmful to health

head rice or broken kernel with red bran streaks of length greater than or equal to 50 % of that whole kernel, but where the surface covered by these red streaks is less than 25 % of the total surface

whole or broken kernels of parboiled rice with distinct white or chalky areas due to incomplete gelatinization of the starch

There are four classes of brown rice. The following four classes shall be based on the percentage of whole kernels, and types of rice:

Long Grain Brown Rice.

Medium Grain Brown Rice. 3

Short Grain Brown Rice.

Mixed Brown Rice.

The rough rice from which the brown rice is obtained shall be of sound quality, free from sand, have characteristic odour and flavour complying with the relevant East African Standards

Brown rice shall meet the following general requirements/limits as determined using the relevant standards listed in Clause 2:

Brown rice for human consumption shall be graded into three grades on the basis of the tolerable limits established in Table 1 which shall be additional to the general requirements set out in this standard.

Shall be brown rice which does not fall within the requirements of Grades 1, 2, and 3 of this standard but is not rejected rice.

Note: For Tanzania and Burundi this requirement shall not apply.

This comprises brown rice which has objectionable odour, off flavour, living insects or which do not possess the quality characteristics specified in Table 1. It cannot satisfy the conditions of ungraded brown rice and shall be graded as reject brown rice and shall be regarded as unfit for human consumption.

| Characteristics | Maximum limits | Test Method | ||

|---|---|---|---|---|

| Grade 1 | Grade 2 | Grade 3 | ||

| Broken, %, max | 2 | 5 | 7 | ISO 605 |

| Heat damaged rice, %, max | 1.5 | 1.5 | 2.0 | |

| Damaged rice, %, max | 1.0 | 2 | 4.0 | |

| Chalkya %, max. | 2 | 4 | 6 | |

| Red or red streaked, %, max. | 1,0 | 4 | 12 | |

| immature grains, %, max | 2 | 6 | 12 | |

| Other contrasting varieties, % max | 1 | 2 | 5 | |

| Organic matters, %, max | 0.1 | 0.5 | 1 | |

| Inorganic matters, %, max | 0.1 | 0.1 | 0.1 | |

| Live weevils/kg, max | Nil | Nil | Nil | |

| Filth, %, max | 0.1 | 0.1 | 0.1 | |

| Paddy grains, %, max. | 1 | 2 | 2.5 | |

| Moisture contents, %, max | 13 | 13 | 13 | EAS 82 |

| Total Aflatoxin (AFB1+AFB2+AFG1 +AFG2)), ppb | 10 | ISO 16050 | ||

| Aflatoxin B1 only, ppb | 5 | |||

| Fumonisin ppm | 2 | |||

Brown rice shall comply with those maximum limits for heavy metals established by the Codex Alimentarius Commission for this commodity.

Brown rice shall comply with those maximum pesticide residue limits established by the Codex Alimentarius Commission for this commodity

Note: where the use of certain pesticides is prohibited by some Partner States, then it shall be notified to all Partner States accordingly.

Brown rice shall comply with those maximum mycotoxin limits established by the Codex Alimentarius Commission for this commodity. In particular, total aflatoxin levels in brown rice for human

5consumption shall not exceed 10 μg/kg (ppb) with B1 not exceeding 5 μg/kg (ppb) when tested according to ISO 16050.

Brown rice shall be produced, prepared and handled in accordance with the provisions of appropriate sections of EAS 39

When tested by appropriate standards of sampling and examination listed in Clause 2, the products:

| Type of micro-organism | Limits | Test method | |

|---|---|---|---|

| i) | Yeasts and moulds, max. per g | 102 | EAS 217 |

| ii) | S. aureus per 25 g | Not detectable | |

| iii) | E. Coli, max. per g | Not detectable | |

| iv) | Salmonella, max. per 25 g | Not detectable |

Brown rice shall be packed in suitable packages which shall be clean, sound, free from insect, fungal infestation and the packing material shall be of food grade quality.

Brown rice shall be packed in containers which will safeguard the hygienic, nutritional, technological and organoleptic qualities of the products.

The containers, including packaging material, shall be made of substances which are safe and suitable for their intended use. They shall not impart any toxic substance or undesirable odour or flavour to the product.

Each package shall contain rice of the same type and of the same grade designation.

If brown rice is presented in bags, the bags shall also be free of pests and contaminants.

Each package shall be securely closed and sealed.

In addition to the requirements in EAS 38, each package shall be legibly and indelibly marked with the following:

Note: EAC partner states are signatory to the International Labour Organizations (ILO) for maximum package weight of 50kg where human loading and offloading is involved

Sampling shall be done in accordance with the EAS 79/ISO 13690.

7 8