In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 753:2011

EAST AFRICAN COMMUNITY

© EAS 2011

First Edition 2011

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East African Community. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to meet the above objectives, the EAC Partner States have enacted an East African Standardization, Quality Assurance, Metrology and Testing Act, 2006 (EAC SQMT Act, 2006) to make provisions for ensuring standardization, quality assurance, metrology and testing of products produced or originating in a third country and traded in the Community in order to facilitate industrial development and trade as well as helping to protect the health and safety of society and the environment in the Community.

East African Standards are formulated in accordance with the procedures established by the East African Standards Committee. The East African Standards Committee is established under the provisions of Article 4 of the EAC SQMT Act, 2006. The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

Article 15(1) of the EAC SQMT Act, 2006 provides that “Within six months of the declaration of an East African Standard, the Partner States shall adopt, without deviation from the approved text of the standard, the East African Standard as a national standard and withdraw any existing national standard with similar scope and purpose”.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2011 — All rights reserved*

East African Community

P O Box1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.org

*© 2011 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iiThis standard was developed with support from the Policy Analysis and Advocacy Programme (PAAP) of the Association for Strengthening Agricultural Research in Eastern and Central Africa (ASARECA). This was possible though a grant by the United States Agency for International Development (USAID). This support was used in the process of formulation and mobilization of stakeholders to review the standard in national and regional fora.

ASARECA is a non-political association of agricultural research institutes in: Burundi, DR Congo, Eritrea, Ethiopia, Kenya, Madagascar, Rwanda, Sudan, Tanzania and Uganda. ASARECA serves as a platform for promoting regional research and in the sharing of benefits and spillovers that derive from such research. The mission of ASARECA is to “Enhance regional collective action in agricultural research for development, extension and agricultural training and education, to promote economic growth, fight poverty, eradicate hunger and enhance sustainable use of resources in Eastern and Central Africa”.

Development of standards has been part of PAAP’s contribution to changing the way business is done in crucial agricultural sectors to increase efficiency and/or reduce waste through rationalization and harmonization of policies, laws, regulations and procedures. Rationalization focuses on how countries conduct business in a given subsector, and determines what should be done to make the procedures and processes more efficient. Harmonization brings together regionally different approaches (policies, laws, regulations and procedures) into unified approaches that are applied across the countries. This harmonization process allows commodities and factors to move freely across national boundaries, thereby improving domestic and foreign investment by expanding markets beyond national borders. Over time this will lead to gradual attainment of seamless borders for trade in potato and potato products across the region.

Removal of regulatory bottlenecks to trans-boundary movement of seed potato in the region will enhance competitiveness of trade and value addition in the sub-sector. It will improve the value chains by supporting product differentiation and hence increased trade in seed potato in the region. This will ultimately contribute to improved incomes, employment generation and welfare in the region. This fits snugly with the aspirations of ASARECA as a key player contributing to economic development of the region.

iii ivSeed potato— Specification

This draft East African Standard specifies requirements and methods of sampling and test for seed potato. It specifies requirements for varietal identity, purity; genealogy, traceability, pests and diseases, internal and external quality, physiology, sizing, packaging and labelling.

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

National seed certification legislations

EAC Plant Protection Legislation

For the purpose of this standard, the following terms and definitions shall apply.

Commonly used name of a bacterial disease of potatoes, caused by Erwinia carotovora subsp. atroseptica. Similar symptoms may, however, be caused by E. carotovora subsp. carotovora and E. chrysanthemi.

An official control procedure which aims at ensuring the production and supply of seed potato which satisfy the requirements of this standard.

a quantity of seed potato consisting of one or more lots destined to a party and covered by one set of documents.

a field whose history and regulatory action indicates presence of a designated pathogenic organism in the soil.

any disturbance of a plant caused by pathogenic organisms which interferes with its normal structure, physiological function or economic value.

1a defined area of land used for cultivation of seed potato.

not present in numbers or quantities that can be detected by the application of appropriate sampling, inspection and testing procedures.

the number of growing cycles since the first introduction in the field.

uniform in composition and appearance.

the initial pathogen free microplants or tubers produced and maintained under an official control programme.

examination of plants, tubers, units of presentation, equipment or facilities by National Designated Authority, to determine compliance with regulatory requirements.

a quantity of seed potato bearing the same reference number, and being of the same variety, category, class, size and origin.

organization, or agency empowered by national legislation to administer the certification of seed potato under the Standard.

officially defined area where a lot of seed potato was grown.

provisions in accordance with the National or Regional Plant Protection legislation and/or International Plant Protection Convention.

attack occurring during the current growing season and not arising from the seed tuber.

the sum of all characteristics that determine the acceptance of seed potatoes in relation to the specifications of this Standard.

2the control by the NDA of all activities encountered in the process of producing and marketing seed potato in conformance with the Standard.

Any species, strain or biotype of plant, animal or pathogenic agent injurious to plants or plant products.

A pest of potential national economic importance to the country endangered thereby and not yet present there, or present but not widely distributed and being officially controlled.

A non-quarantine pest whose presence in plants for planting affects the intended use of these plants with an economically unacceptable impact and which is therefore regulated with the territory of the importing ‘contracting’ part.

The procedure of drawing at random a number of tubers, plants or parts of plants, which may be taken as representative of the lot or the field.

tubers of Solanum tuberosum L which are certified by the NDA.

chemical substance, applied either to the plants during the growing season or to the tubers after harvest which suppresses the normal development of sprouts.

Varieties shall be accepted into the Standard only if it has been officially released by the NDA.

Seed potato shall be practically free from injurious diseases and pests and from any defects likely to impair their quality as seed.

Seed potato shall be substantially dry outside and, in general, of normal shape for the variety.

Seed potato or growing crops of potato shall not be treated with sprout inhibitors. Neither growing crops of seed potato nor seed potato shall be treated with sprout inhibitors without permission from the NDA.

3Seed potato shall be classified according to variety, standards and generations. Classification shall be subject to official control in the producing country. Seed potato shall be placed in three classes as defined in Table 1:

| Code | Classes | Seed Parents | Colour of labels |

|---|---|---|---|

| SS | Breeders Seed | Progeny of parental stock | White with a diagonal purple stripe |

| B. | Basic | Progeny of certified breeders seed or certified pre-basic seed | White |

| C.1 | Cer. 1st gen. | Progeny of certified pre-basic seed or certified basic seed | Blue |

| C.2 | Cert. 2nd Gen. | Progeny of certified basic seed or certified 1st generation | Blue |

| C.3 | Cert. 3rd gen. (Standard) | Progeny of certified 2nd generation or certified 3rd generation | Blue |

Progeny of parental stock. The breeders seed may include pre-basic seed.

Seed potato descended directly from breeders seed or produced under special provisions of a national certification scheme and are mainly intended for the production of certified seed potatoes.

Seed potato descended directly from breeder. , Basic or Certified seed and are mainly intended for the production of potato other than seed potato. Seed shall be classified as Certified I, Certified II or Certified III according to the minimum requirements given in sections 7.2, 7.3 and 7.4

The parent material shall be true to type for the variety.

Seed potato shall be produced from officially certified initial stock, which shall be practically free from the current most limiting pests and diseases including the following;

The facilities and procedures used for seed potato production shall be subject to official approval by the NDA.

Field for the production of seed potato shall meet the requirements specified under table 2.

| Seed Classes | ||||

|---|---|---|---|---|

| Basic | C1 | C2 | C3 | |

| Land requirements (seasons free of potato or related family) | 5 | 3* | 3* | 3* |

| Isolation (meters) | 10 | 5 | 5 | 5 |

| Maximum off-types % |

BR=0 PB=1 B=2 |

2/100 plants | 2/100 plants | 3/100 plants |

| Minimum number of inspections | 4 | 4 | 4 | 4 |

| *for Bacterial Wilt, 7 year rotation is required. | ||||

During storage, seed potato shall conform to the tolerance limits acceptable for pests and disease as specified under table 3;

5| Seed Classes | ||||

|---|---|---|---|---|

| Basic | C1 | C2 | C3 | |

| Scab % max (No more than 50%tuber covered) per 25Kg bag | 25 | 50 | 50 | 50 |

| Rhizoctonia % | 10 | 30 | 30 | 30 |

| Pink rot (Phytophthora erythroseptica) % | 0 | 1 | 1 | 1 |

| Soft rot (Erwinia spp) % | 0 | 1 | 1 | 1 |

| Severe Tuber Moth % | 2 | 5 | 5 | 5 |

The seed potato shall be free from Globodera rostochiensis (Woll), Globodera pallida (Stone), Synchytrium endobioticum (Schilb.) Prc, Heterodera rostochiensis, Clavibacter michiganensis Spp. sepedonicus (Spieck. And Kotth.) Skapt, and Burkh., Ralstonia solanacearum (E.F. Smith) E.F. Smith, Potato spindle tuber viroid, Tomato Stolbur and Meloidogyne chitwoodi mycoplasma and fallax.

Tolerance limits for pest and disease allowed for seed potato tubers shall be as specified under table 4;

| Seed Classes | ||||

|---|---|---|---|---|

| Basic | C1 | C2 | C3 | |

| Mycoplasma | 1/1000 plants | 1/1000 plants | 1/1000 plants | 1/1000 plants |

| Potato Virus Y | 1/1000 plants | 10/1000 plants | 13/1000 plants | 13/1000 plants |

| SMV | 0 | 13/1000 plants | 15/1000 plants | 15/1000 plants |

| Fusarium wilt | 0 | 2/1000 plants | 3/1000 plants | 3/1000 plants |

| Verticilium wilt | 0 | 2/1000 plants | 3/1000 plants | 4/1000 plants |

During inspection, the allowed tolerance limits for a lot shall be as specified under table 5 below;

| S/N | Requirement | Breeders | Basic seed | Certified seed |

|---|---|---|---|---|

| 1 | Presence of earth and extraneous matter (%by weight) | 1% | 2% | 2% |

| 2 | Dry and wet rot | 0% | 1% | 1% |

| 3 | External defects (e.g. malformed or damaged tubers) | 3% | 3% | 3% |

| 4 |

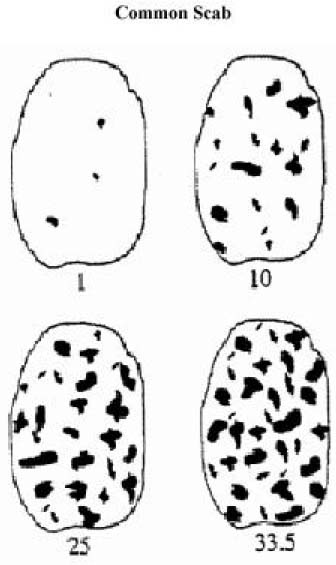

Common scab tubers affected over a specified percent of their surface Max by weight |

0%surface cover | 33.3% surface cover | 33.3% surface cover |

| 0 | 5 | 5 | ||

| 5 |

Powdery scab 5: tubers affected over a specified percent of their surface Max % by weight |

0%surface cover | 10% surface cover | 10% surface cover |

| 0 | 3 | 3 | ||

| 6 |

Rhizoctonia tubers affected over a specified per cent of their surface % by weight max |

0%surface cover | 10% surface cover | 10% surface cover |

| 0 | 5 | 5 | ||

| 7 |

Shrivelled tubers which have become excessively dehydrated and wrinkled. % by weight |

0 | 1 | 1 |

Breeder seed are exempted from the minimum sizing requirements.

Sizing shall be as specified under Table 6.

| Seed Classes | ||||

|---|---|---|---|---|

| Size | Basic | C1 | C2 | C3 |

| 28-45 mm | 5 tubers/25kg bag | 5 tubers/25kg bag | 5 tubers/25kg bag | 5 tubers/25kg bag |

| 46 – 55 mm | 5 tubers/25kg bag | 5 tubers/25kg bag | 5 tubers/25kg bag | 5 tubers/25kg bag |

The package shall not be more than 50kg, shall be clean and allow for aeration and which conforms to the regulations in the destination country. The reuse of packages shall not be allowed.

The corresponding NDA shall supervise the sealing of containers. In case of need, re-sealing of the package or container shall be done under the official control by the NDA.

Units of presentation shall bear an official label in accordance with 10.2 and which has not been previously used; the label shall be white with a diagonal purple line for breeder seed white for basic seed and blue for certified seed.

Name of the product shall be “Seed potato”

The National Designated Authority (NDA) or its recognized initials

Origin of the product

Official lot number

Month and year of harvesting

Date of packaging

Variety

Class

Tuber size

Declared average net weight at packaging

Warning “Not for human consumption”

Without contracting the information on the official label, the producer may provide additional information and such information may not be misleading.

8The nature of the active substance of any chemical treatment of the seed potato shall be indicated either on the outside of the unit of presentation, on the official label or a label provided by the supplier, or printed on the unit of presentation. This information may also appear inside the unit of presentation.

If re-inspection is conducted, the authority which carried out the re-inspection shall be stated on the new label, as well as the date of the re-sealing. Re-labelling shall be done under the supervision of the NDA. The new label shall show the particulars which appeared on the old label. If a new label is necessary, this shall show the particulars, which appeared on the old label, the date of the re-closing and the authority concerned.

Sampling of seed potato for certification purposes shall be carried in accordance with Annex A.

It is recommended that trials be established by the NDA to ascertain the condition of the certified seed potato. The NDA shall provide the test guidelines to be followed. The results of such trials shall be treated in confidence but on request the results relating to individual consignments may be exchanged between the NDA of the importing and exporting countries concerned.

A seed potato lot shall be deemed to comply if upon inspection and testing, the provisions under this standard are met.

9(Normative)

The examination of seed potato in crop tests enables the quality (vigour, purity, healthiness, productivity) of home grown and imported lots put on the market to be checked at random.

Depending on the mode of transport (road, rail or waterway), the sample shall preferably be taken when the lot arrives at its destination.

The sampling shall be done by the NDA.

Samples shall be preserved in a uniform manner in favourable conditions.

A nomenclature of all the samples planted in the same field with the number of the plot concerned shall be sent to the organs responsible for evaluating them.

In order to be accurate, the evaluation shall in principle be carried out in two stages, with an interval of 10-15 days between them. Primary virus infections shall not be taken into consideration.

11(Informative)

Rhizoctonia

(Informative)

In testing seed stocks for the incidence of virus, it is seldom feasible to test the entire stock, so a test is done on a sample from the stock. Ideally, only seed stocks with infection levels below the tolerance would be accepted and those above the tolerance rejected. However, taking a sample from a stock means that only estimation of the actual incidence of virus can be made. The reliability of this estimation will vary with the size of the sample, relative to the size of the lot, and the Population standard, which is set for the test. Defining an acceptable population standard for any sample entails two types of risk.

The first is that of rejecting a stock containing less virus than the tolerance and is often described as the A grower = s at risk. The risk of accepting a stock containing more virus than the tolerance is known as the Abuyer = s at risk.

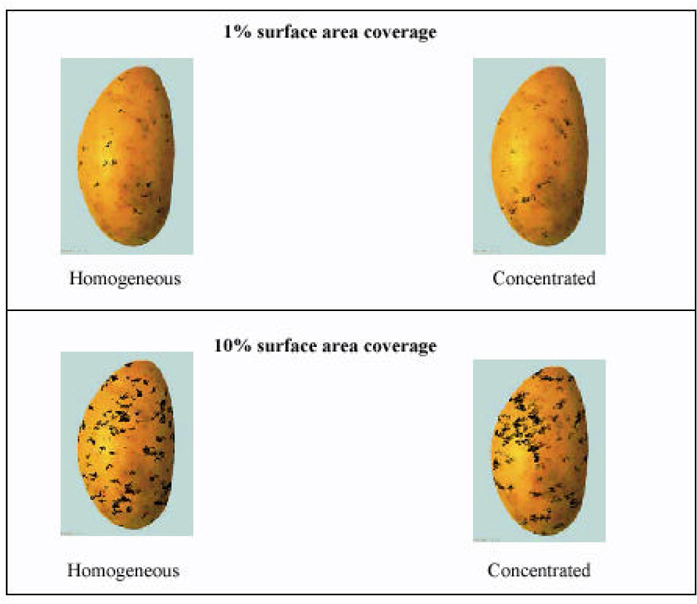

From the point of view of classification authorities, this could also be described as the risk of passing a stock which fails to meet the official tolerances. Such testing makes a number of important assumptions, which are, primarily, that the infected tubers are distributed homogeneously in the stock and that tubers are sampled randomly. In addition, the choice of the size of sample to be tested will need to be balanced by other practical factors such as cost, available facilities, labour, logistics of handling samples, seed stock size, etc. The following tables and graphs illustrate some of the principles involved in sampling tubers for testing for virus.

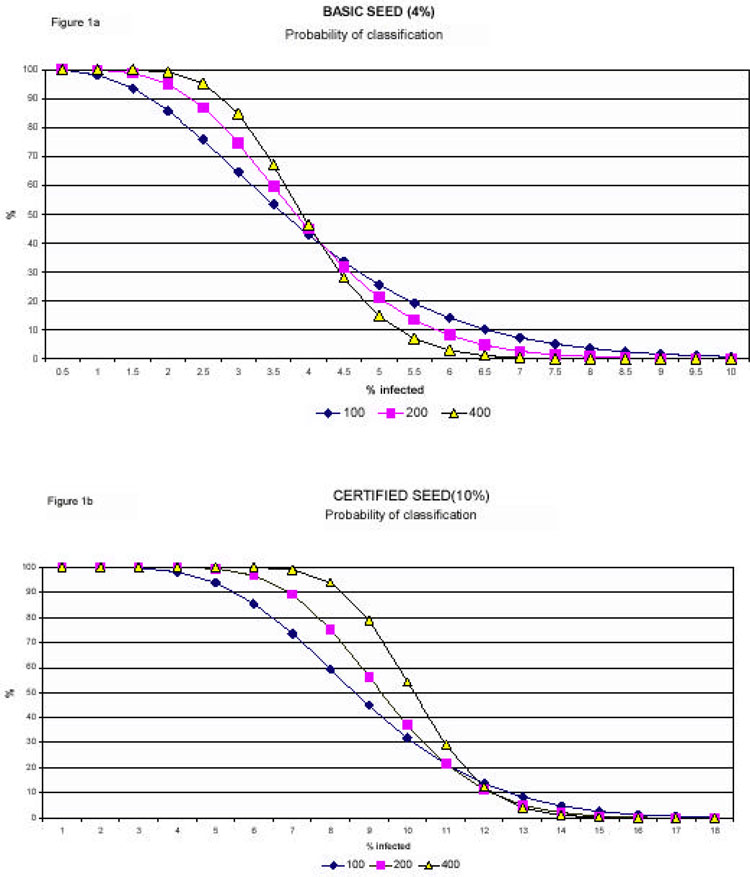

Testing different samples from the same seed stock will give a range of results, which, statistically, will lie within a specific interval with a certain percentage confidence. This interval is known as the confidence interval. The acceptable level of confidence or probability should be decided before the testing is conducted but 95% confidence/probability is normally used. The accuracy of the estimation can be improved by increasing the sample size and by adjusting the allowable number of infected tubers in the sample, i.e. the sample tolerance. (Table C.1).

For example, the size of the confidence interval for a sample tolerance of 4% (4 allowable tubers) is 8.8% based on a sample of 100 tubers but, on a sample of 200 tubers, the interval decreases to 6% i.e. 7.7-1.7. The effect on the confidence interval of increasing the sample size does, however, become smaller at the larger sample sizes. Increasing the sample size from 100 to 200 tubers improves the accuracy of the estimation by 32 %, i.e. confidence interval reduced from 8.8 to 6.0%, whereas increasing the sample size from 300 to 400 tubers only gives an improvement of 15%.

14In practice, therefore, the benefits of increasing the sample size have to be weighed up against the additional cost of the testing. The accuracy of the estimation can also be affected by changing the allowable number of infected tubers in the sample (table 4). For example, by decreasing the number of allowable tubers from 4 to 3, i.e. changing sample tolerance from 4 to 3 %, the confidence interval is decreased from 8.8 to 7.9 % and the confidence limits themselves become lower. Decreasing the allowable number of infected tubers in the sample also has a significant effect on the probability of classifying at higher tolerances than those allowed in the sample as illustrated in the next paragraph.

| Tolerance (%) for virus in a seed stock | Size of sample | Allowable No of infected tubers | Confidence limits | |

|---|---|---|---|---|

| Lower | Upper | |||

| 4 | 100 | 4 (3) | 1.1(0.6) | 9.9(8.5) |

| 200 | 8(7) | 1.7(1.4) | 7.7(7.1) | |

| 300 | 12(11) | 2.1(1.8) | 6.9(6.5) | |

| 400 | 16(15) | 2.3(2.1) | 6.4(6.1) | |

| 10 | 100 | 10(8) | 4.9(3.5) | 17.6(15.2) |

| 200 | 20(18) | 6.2(5.4) | 15.0(14.0) | |

| 300 | 30 | 6.9 | 13.8 | |

| 400 | 40 | 7.2 | 13.8 | |

Probability of classifying stocks to meet specified tolerances

From the confidence intervals, it can be seen that classifying stocks based on a sample will contain a risk that some stocks, which fail a test, do, in fact, meet the tolerance and others, which pass, should fail.

Table C.2 and Figure 1 show the effect of varying sample size and the number of virus infected tubers allowed in the sample onthe probability of lassifying seed stocks with different incidences of virus infection. For example, in a test on a sample of 100 tubers where 3 virus infected tubers were allowed, there would be a 14% chance of classifying a stock containing 6% virus as meeting a tolerance of 4%. Probability of classifying seed stocks at two tolerances for virus based on a laboratory test in relation to the size of sample and the allowable number of virus-infected tubers in the sample:

15| Tolerance (%) for virus in a seed stock | Size of sample | Allowable No of infected tubers | Probability of acceptance or classification | ||||||

|---|---|---|---|---|---|---|---|---|---|

| % infected tubers in stock | |||||||||

| 0.5 | 1 | 2 | 4 | 6 | 8 | 10 | |||

| 4 | 100 | 3 | 100 | 98 | 86 | 43 | 14 | 4 | 1 |

| 200 | 7 | 100 | 100 | 95 | 45 | 8 | 1 | 0 | |

| 300 | 11 | 100 | 100 | 98 | 46 | 5 | 0 | 0 | |

| 400 | 15 | 100 | 100 | 99 | 46 | 3 | 0 | 0 | |

| 10 | 100 | 8 | 100 | 100 | 100 | 98 | 85 | 59 | 32 |

| 200 | 18 | 100 | 100 | 100 | 100 | 97 | 75 | 37 | |

| 300 | 30 | 100 | 100 | 100 | 100 | 100 | 91 | 55 | |

| 400 | 40 | 100 | 100 | 100 | 100 | 100 | 94 | 54 | |

Note: The allowable number of tubers is, often, set at a lower level than the overall seed stock tolerance of 4 and 10% respectively, particularly in the case of a relatively small sample size. By lowering the tolerance in a Sample the > buyers risk = is reduced.

Figure 1: Probability of classifying seed stocks with different incidences of virus as meeting a tolerance of 4% or 10% for virus in a laboratory test in relation to the size of sample and the allowable number of virus infected tubers in the sample;

tolerance up to 4%

tolerance up to 10%

16