In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 745:2010

ICS 67.080.20

EAST AFRICAN COMMUNITY

© EAC 2010

First Edition 2010

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East Africa. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to meet the above objectives, the EAC Partner States have enacted an East African Standardization, Quality Assurance, Metrology and Test Act, 2006 (EAC SQMT Act, 2006) to make provisions for ensuring standardization, quality assurance, metrology and testing of products produced or originating in a third country and traded in the Community in order to facilitate industrial development and trade as well as helping to protect the health and safety of society and the environment in the Community.

East African Standards are formulated in accordance with the procedures established by the East African Standards Committee. The East African Standards Committee is established under the provisions of Article 4 of the EAC SQMT Act, 2006. The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

Article 15(1) of the EAC SQMT Act, 2006 provides that “Within six months of the declaration of an East African Standard, the Partner States shall adopt, without deviation from the approved text of the standard, the East African Standard as a national standard and withdraw any existing national standard with similar scope and purpose”.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2010 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.int

*© 2010 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iiThis standard was developed with support from the Policy Analysis and Advocacy Programme (PAAP) of the Association for Strengthening Agricultural Research in Eastern and Central Africa (ASARECA). This was possible though a grant by the United States Agency for International Development (USAID). This support was used in the process of formulation and mobilization of stakeholders to review the standard in national and regional fora.

ASARECA is a non-political association of agricultural research institutes in: Burundi, DR Congo, Eritrea, Ethiopia, Kenya, Madagascar, Rwanda, Sudan, Tanzania and Uganda. ASARECA serves as a platform for promoting regional research and in the sharing of benefits and spillovers that derive from such research. The mission of ASARECA is to “Enhance regional collective action in agricultural research for development, extension and agricultural training and education, to promote economic growth, fight poverty, eradicate hunger and enhance sustainable use of resources in Eastern and Central Africa”.

Development of standards has been part of PAAP’s contribution to changing the way business is done in crucial agricultural sectors to increase efficiency and/or reduce waste through rationalization and harmonization of policies, laws, regulations and procedures. Rationalization focuses on how countries conduct business in a given subsector, and determines what should be done to make the procedures and processes more efficient. Harmonization brings together regionally different approaches (policies, laws, regulations and procedures) into unified approaches that are applied across the countries. This harmonization process allows commodities and factors to move freely across national boundaries, thereby improving domestic and foreign investment by expanding markets beyond national borders. Over time this will lead to gradual attainment of seamless borders for trade in potatoes and potato products across the region.

Removal of regulatory bottlenecks to transboundary movement of potato products in the region will enhance competitiveness of trade and value addition in the sub-sector. It will improve the value chains by supporting product differentiation and hence increased trade in potato products in the region. This will ultimately contribute to incomes, employment generation and improved welfare in the region. This fits snugly with the aspirations of ASARECA as a key player contributing to economic development of the region.

iiiPotato crisps — Specification

This East African Standard specifies requirements and methods of sampling and test for crisps made from potato tubers (Solanum tuberosum L.)

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EAS 35, Specification for edible (fortified) salt

EAS 38, General standard for labeling of prepackaged foods

EAS 39, Code of practice for hygiene in the food and drink manufacturing industry

EAS 103, Schedule of permitted food additives

ISO 3960, Animal and vegetable fats and oils — Determination of peroxide value

EAS 321, Edible oils and fats — Specification

EAS 748, Fresh potatoes - Specification

EAS 98, Spices and condiments — Specification

potato crisps

thin slices of peeled and washed potato tubers, deep-fried until crunchy

The following materials shall be used in the manufacture of potato crisps:

NOTE Using the oil several times may lead to poor quality and affect the safety of the crisps.

In addition to the essential ingredients specified in 4.1, the following optional ingredients may be added:

Potato crisps shall;

Potato crisps, when packed, shall not contain more than 10 % by mass of small pieces, slivers and irregular pieces.

Packed potato crisps shall have not more than 1 % of the crisps with the following defects:

Potato crisps shall conform to the requirements specified in Table 1.

| Characteristic | Limit | Method of test |

|---|---|---|

| Moisture content, %, by mass, max. | 5 | Annex A |

| Free fatty acids, %, by mass on dry weight basis, max. | 0.5 | Annex B |

| Acid insoluble ash, % by mass on dry weight basis, max. | 0.05 | Annex C |

| Peroxide value, meq/oxygen per gram | 0. 5 mg/kg | EAS ISO 3960 |

| Fat content on dry weight basis | 35 | |

| Sodium chloride (NaCl) on dry weight basis, %, max | 2 |

Food additives may be used in the preparation of potato crisps in accordance with EAS 103.

2Potato crisps shall conform to those maximum residue limits established by the Codex Alimentarius Commission for this commodity.

Potato crisps shall comply with the maximum levels of the Codex General Standard for Contaminants and Toxins in Food and Feed (CODEX STAN 193).

Potato crisps shall be prepared and handled in hygienic manner in accordance with EAS 39 shall conform to microbiological limits in Table 3.

| Micro-organism(s) | Maximum limit | Method of test |

|---|---|---|

| Total viable count, CFU per gram, max | 103 | EAS ISO |

| Escherichia coli, CFU per gram | Shall be absent | ISO 7251 ISO 4833; |

| Salmonella | Shall be absent | ISO 6579 |

| Yeasts and moulds, CFU per gram | 103 | EAS ISO ISO 21527-2 |

Before packaging, the crisps excess oil shall be removed. The crisps shall be packaged within a short time after frying so as to keep the crispy taste and texture of the crisps.

The product shall be packed in food grade materials that ensure the quality, safety and integrity throughout the shelf life.

Fresh sweet cassava shall be packaged in accordance with the Weights and Measures requirements of the destination country.

In addition to the requirements of EAS 38, the following specific labelling requirements shall apply and shall be legibly and indelibly marked;

The product covered by this standard shall be tested according to the methods of test indicated in this standard.

A lot shall be declared as conforming to this standard if each sample inspected or analysed for quality requirement conforms to the provision of this standard.

4(normative)

Weigh accurately 10 g of the material in a suitable moisture dish previously dried in an electric oven and weighed. Place the dish in an electric oven maintained at 105 °C ± 1 °C for 5 h. Cool the dish in a desiccator and weigh with the lid on. Repeat the process of heating, cooling and weighing at half-hour intervals until the loss in weight between two successive weighings is less than 1 mg.

Record the lowest weight obtained.

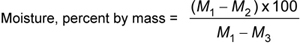

where,

5

M1 is the mass, in grams, of the dish and sample before drying; M2 is the mass, in grams, of the dish and sample after drying; M3 is the mass, in grams, of the dish only.

(normative)

Soxhlet fat extraction apparatus

Petroleum ether, distilling below 65 °C, or ethyl ether

Alcohol potassium hydroxide, 0.1 N (use absolute or alcohol denatured with methanol, [MeOH])

Alcohol-ether mixture, equal volumes of 96 % alcohol and ethyl ether

Phenolphthalein solution, 1 % in alcohol or alcohol denatured with methanol (MeOH) Add 0.3 ml per 100 ml mixture of alcohol-ether and add alcoholic KOH solution to a faint pink.

Extract 10.00 g ± 0.01 g of the sample taken in a thimble with petroleum ether for about 4 h in a Soxhlet extraction apparatus. Completely evaporate the solvent from the extraction flask (weighed previously) on a steam bath, cool and weigh the extraction flask with the residue. Dissolve the residue in the extraction flask with the 50 ml of the alcohol-ether phenolphthalein solution. Titrate the dissolved extract, with standard potassium hydroxide solution, to a faint pink colour, which persists for 10 s. If emulsion is formed during titration, dispel by adding a second 50 ml portion of the alcohol-ether phenolphthalein solution.

Make a blank titration on 50 ml of the alcohol-ether phenolphthalein solution and substract this value from the titration value of the sample. If the additional 50 ml portion of the alcohol-ether phenolphthalein solution is added, double the blank titration.

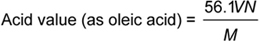

Calculate the acid value from the following formula:

where

6

V is the volume, in millilitres, of standard potassium hydroxide solution used; N is the normality of standard potassium hydroxide solution; and M is the mass, in grams, of the material taken for the test.