In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 60: 2000

ICS 67.160.200

EAST AFRICAN COMMUNITY

© EAC 2000

First Edition 2000

vDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in the East African Community. It is envisaged that through harmonized standardization, trade barriers that are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Community established an East African Standards Committee mandated to develop and issue East African Standards.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2000 – All rights reserved*

East African Community

P.O. Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255 27 2504255

E-mail: eac@eachq.org

Web: www.eachq.org

* © 2000 EAC — All rights of exploitation of any form and by any means reserved worldwide for EAC Partner States’ NSBs

viPeanut butter – Specification

This East African Standard prescribes the requirements and methods of test for peanut butter.

For the purposes of this standard, the following definition shall apply:

peanut butter

a cohesive, comminuted food product prepared from clean, sound shelled peanuts (groundnuts) by grinding roasted mature kernels from which the seed coats have been removed, and to which not more than 10 % of other optional ingredients have been added

This shall be peanut butter to which any suitable ingredient(s) has been added to reduce oil-meal separation.

This shall be peanut butter to which no ingredient(s) has been added to reduce oil-meal separation.

Peanut butter shall be prepared from the ingredients in Table 1.

1| Ingredient | Percent by mass | Method of test |

|---|---|---|

| Peanuts (groundnuts), min. Salt as NaCl, max. |

90 2 |

Annex A |

In addition to the essential ingredients specified in Table 1, the following ingredients may be added at in accordance with EAS 103, Schedule for permitted food additives:

Only slight mixing shall be required to re-disperse any separated fat in the non-stabilized type.

There shall be no noticeable oil separation in the stabilised type.

Peanut butter shall conform to the compositional requirements in Table 2.

| Characteristic | Requirement | Method of test |

|---|---|---|

| Moisture content, %, max. | 2.0 | Annex B |

| Fat (on dry weight basis) | 48 - 55 | Annex C |

| Acid value | 4.0 | Annex D |

| Total ash (on dry weight basis) | 5.0 | Annex E |

| Aflatoxin content | 10 | EAS 74 |

Peanut butter shall be manufactured and handled according to the provisions of EAS 39, Hygiene in the food and drink manufacturing industry — Code of practice.

Peanut butter shall be free of pathogenic organisms and shall conform to the microbiological requirements in Table 3.

| Characteristic | Requirement | Method of test |

|---|---|---|

| Moulds, max. E. Coli |

103/g 0/g |

EAS 217 |

Peanut butter shall be packaged in food grade containers such as glass or plastic jars, or arc-welded tins or aluminium packaging. The packages shall be properly sealed.

3The packages shall be labelled according to EAS 38 Labelling of pre-packaged foods — Specification, and in addition the following shall be indicated:

(normative)

Acetone

10 % calcium acetate solution

HNO3

0.1N AgNO3

Ferric indicator

0.1N NH4SCN3

Weigh 2 g of a thoroughly mixed sample into a platinum or silica dish.

Disperse the sample with 10 mL of acetone.

Remove acetone, at room temperature, with an air current.

Add, and thoroughly mix, 10 mL of 10 % calcium acetate solution.

Carefully dry on a steam bath.

Ash in a muffle oven at 500 °C (1 022°F). Complete ashing not necessary.

Place the ash in a beaker and dissolve the ash in 25 mL HNO3 (1+3).

Add at least 2 mL - 4 mL of 0.1N AgNO3 that is just enough to precipitate all chloride present.

Add at least 5 mL of 0.1N AgNO3 in excess, to A.2.8.

Heat to boil, cool, then add 5 mL ferric indicator.

Titrate excess Ag with 0.1N NH4SCN (which has been standardized to equalize normalities) to a permanent light brown end point.

Subtract the amount of NH4SCN used (in A.2.11) from the total AgN03 used (in A.2.8 and A.2.9). The resulting difference is the mL of 0.1N AgNO3 used in the calculation of salt (A.2.13).

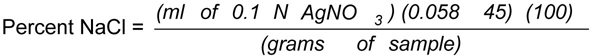

Calculate as:

5

(normative)

Oven, 95 °C — 100 °C, 100 mm Hg (13.3 kPa)

Analytical balance

Dishes with lid, aluminium, nickel or thin stainless steel of diameter 60 mm

Glass rod

Sand — Washed with 5 % hydrochloric acid solution and rinsed free from hydrochloric acid; sieved so that the grains are sizes within the range 100 mm to 400 mm and calcinated.

Desiccator

Dry in the oven at 95 °C — 100 °C under a pressure of 100 mm Hg (13.3 kPa) a metal dish and its lid in which has been put 10 g – 20 g of prepared sand and a glass rod. Dry for an hour, weigh the dish to the nearest 0.000 2 g after cooling in a desiccator.

Transfer to the pre-dried dish about 2 g to 5 g of the homogenized (blended) sample and weigh. Mix it intimately with the sand by means of the rod taking care to avoid any loss of product or sand to the dish. Dry the prepared sample in the oven for 5 hours at 95 °C – 100 °C.

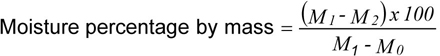

where,

| M0 | is the mass in g of the dish and accessories (sand, rod and lid), |

| M1 | is the mass in g of the dish (and its accessories) and sample before drying, and 7 |

| M2 | is the mass in g of the dish (and its accessories) and sample after drying. |

(normative)

Petroleum ether, of boiling range 40 °C to 60 °C.

Hexane, analytical grade.

Weigh accurately about 2.5 g of the sample, dried as in B.1.1, and extract with petroleum ether or hexane, analytical grade, in a Soxhlet or other suitable extractor. The extraction period may vary from 4 h at a condensation rate of 5 - 6 drops per second. Dry the extract on a steam bath for 30 min, cool in a desiccator and weigh. Continue at 30 min intervals this alternative drying and weighing until the difference between two successive weighings is less than one milligram.

Note the lowest mass.

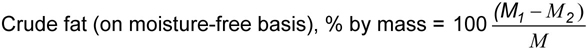

where,

| M1 | is the mass in g of the extraction flask with dried extract, |

| M2 | is the mass in g of the extraction flask, and |

| M | is the mass in g of the dried sample taken for the test. |

(normative)

Soxhlet fat extraction apparatus

Petroleum ether, distilling below 65 °C, or ethyl ether

Alcohol potassium hydroxide, 0.1N (use absolute or alcohol denatured with methanol (MeOH))

Alcohol ether solution, equal volumes of 96 % alcohol and ethyl ether

Phenolphthalein solution, 1 % in alcohol or alcohol denatured with MeOH. Add 0.3 mL per 100 mL mixture of alcohol-ether and add alcoholic KOH solution to a faint pink colour.

Extract 10.00 g ± 0.01 g of the sample taken in a thimble with petroleum ether for about 16 h in a Soxhlet extraction apparatus. Completely evaporate the solvent from the extraction flask (weighed previously) on a steam bath, for 30 min, cool in a desiccator and weigh. Continue at 30 min intervals this alternative drying and weighing until the difference between two successive weighings is less than one milligram. Dissolve the residue in the extraction flask with 50 mL of the alcohol-ether phenolphthalein solution. Titrate the dissolved extract, with standard potassium hydroxide solution, to a faint pink colour, which persists for 10 s. If emulsion is formed during titration, dispel by adding a second 50 mL portion of the alcohol-ether phenolphthalein solution.

Make a blank titration on 50 mL of the alcohol-ether phenolphthalein solution and subtract this value from the titration value of the sample. If the additional 50 mL portion of the alcohol-ether phenolphthalein solution is added, double the blank titration.

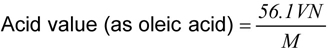

Calculate the acid value from the following formula:

where

| V | is the volume in ml of standard potassium hydroxide solution used, |

| N | is the normality of standard potassium hydroxide solution, and |

| M | is the mass in g of fat extract taken for the test. |

(normative)

Ignite the dried material in the dish (see B.2.1) with flame of a suitable burner for about one hour. Complete the ignition by keeping in a muffle furnace at 550 °C to 600 °C until grey ash results, cooling and weighing at half-hour intervals until the difference in mass between two successive weighings is less than one milligram. Note the lowest mass.

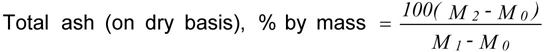

Calculate total ash as follows:

where,

| M0 | is the mass in g of the dish with its accessories, |

| M1 | is the mass in g of the dish, its accessories and the dried material after drying as in (B.2.1), and |

| M2 | s the mass in g of the dish, its accessories and ash after ignition (see B.2.2). |

- EAS 74, Animal foodstuffs – Methods of test

- EAS 217, Methods for the microbiological examination of foods

12