In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 57-1: 2000

ICS 67.080

EAST AFRICAN COMMUNITY

© EAC 2000

vFirst Edition 2000

Development of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in the East African Community. It is envisaged that through harmonized standardization, trade barriers that are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Community established an East African Standards Committee mandated to develop and issue East African Standards.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2000 – All rights reserved*

East African Community

P.O. Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255 27 2504255

E-mail: eac@eachq.org

Web: www.eachq.org

* © 2000 EAC — All rights of exploitation of any form and by any means reserved worldwide for EAC Partner States’ NSBs

viGroundnuts (peanuts) — Specification

Part 1:

Raw groundnuts for table use and for oil milling

This Part 1 of EAS 57 prescribes the requirements, grading and methods of test for shelled groundnut kernels.

This Part 1 of the standard shall apply to shelled groundnuts for table use, for oil milling and for making peanut butter.

For the purposes of this standard, the following definitions shall apply:

the fruit of the plant Arachis hypogea

raw groundnuts with their shells removed, and which have not been subjected to roasting and/or various forms of chemical treatment

groundnuts with part or all of the hull (shell) attached

kernels are firm and developed

the free fatty acids, in terms of oleic acid

any specific defect described in 3.6.1, which detracts from the edible quality of the groundnut

1The following specific defects shall be considered as damage:

Other defects shall mean that the groundnut kernel is not damaged as outlined in 3.6.1, but is affected by one or more of the following:

the groundnut kernel is not split or broken

the separated ‘half’ of a groundnut kernel

more than one fourth of the groundnut kernel that is broken off

pieces or loose particles of any substance other than groundnut kernels or skins

Shelled groundnut kernels shall be mature and uniform in shape, size and colour according to variety and grade.

The moisture content of shelled groundnut kernels shall be not greater than 8 % by mass of the kernels when tested in accordance to Annex A.

Aflatoxin levels shall not exceed 10 ppb when tested according to the method in EAS 74-2, Animal feedstuffs — Methods of test.

2Shelled groundnut kernels shall be classified as Grade 1, Grade 2 or Grade 3 according to either Table 1 or Table 2, as applicable.

| Factor | Requirement | Method of test | ||

|---|---|---|---|---|

| Grade 1 | Grade 2 | Grade 3 | ||

| (i) Damaged kernels, % by mass, max. | 0.5 | 1.0 | 1.0 | Annex C |

| (ii) Other defects, % by mass, max. | 0.5 | 1.0 | 1.0 | |

| (iii) Unshelled kernels, % by mass, max. | None | None | None | |

| (iv) Split/broken kernels, % by mass, max. | 1.0 | 2.0 | 3.0 | |

| (v) Foreign matter, % by mass, max. | 0.1 | 0.2 | 0.3 | |

| (vi) Total tolerance for factors 1, 2, 4, and 5, % max. | 2.0 | 3.0 | 4.0 | - |

| Factor | Requirement | Method of test | ||

|---|---|---|---|---|

| Grade 1 | Grade 2 | Grade 3 | ||

| (i) Oil content of the kernel (on moisture free basis), % by mass, min. | 48.0 | 45.0 | 42.0 | Annex B |

| (ii) FFA content, % max. | 2.0 | 4.0 | 6.0 | US ISO 729 |

| (iii) Broken, defective and damaged kernels, % by mass, max. | 3.0 | 5.0 | 7.0 | Annex C |

| (iv) Foreign matter, % by mass, max. | 0.1 | 0.2 | 0.3 | |

| (v) Total tolerance for factors 3 and 4 | 1 | 5.0 | 7.0 | - |

Shelled groundnuts shall be packed in containers such as polythene bags that are capable of protecting the produce from damage and spoilage during normal handling, transportation and storage.

In addition to the provisions in EAS 38, Labelling of pre-packaged foods, each container shall be properly labelled to conspicuously display the following information:

(normative)

The grinding mill should grind evenly and should not be operated at such a high speed that the ground material is heated.

Air currents that might cause loss of moisture shall be reduced to a minimum.

The mill-setting shall be such that at least 50 % of the ground material passes through a sieve with meshes of 3.4 mm.

Two stages of drying shall be applied when moisture content of bean grains is higher than 20 %.

The air-oven 130 °C method shall be used.

Dishes of non-corrosive metal (thickness approximately 0.5 mm) with side rounded at base and flat bottom, fitted with covers which seat so snugly that loss of moisture is reduced to a minimum.

The dimensions of the materials are applied per cm2, to ensure close fitting of the cover, the rim of the dish should be levelled by rubbing with an abrasive.

An electrically heated oven with adequate ventilation and thermostatic control which permits the temperature to be maintained at 130 °C.

The heating capacity of the oven must be such that after pre-heating capacity to temperature 130 °C, followed by opening and loading with dishes, the oven will again reach 130 °C within 45 min (preferably within 30 min).

4A desiccator (with a suitable desiccant), preferably fitted with a thick metal plate to promote rapid cooling of the dishes

A balance on which accurate weighings can be made in grams to three decimal places

Weigh the dish with its cover. Weigh out 4 g to 5 g of the sample previously mixed. Place the working sample in the dish, distributing it evenly over the bottom surface. Put the cover on the dish and weigh again. Place the dish on top of its cover in an oven-heated before-hand to 130 °C. In order to limit the loss of heat, the dishes must be placed in the oven rapidly. From the time that the oven again reaches 130 °C, the drying period should be 60 min at this temperature. After termination of the drying period, cover the dishes immediately and place them in a desiccator to cool for 30 min to 45 min. Weigh the dishes with their contents and covers. All weighings should be made to an accuracy of 0.001.

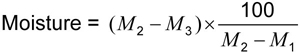

where

| M1 | is the weight in g of the dish and its cover, |

| M2 | is the weight in g of the dish, its cover and its contents; and |

| M3 | is the weight in g of the dish, covers the contents after drying, then moisture content calculated on wet basis and expressed in percentage is: |

The determination shall be made in duplicate. The results of duplicate determinations shall not differ by more than 0.2 %. Should the difference be greater than this, the determination shall be repeated in duplicate.

Weigh out approximately 50 g of the sample. Then transfer this working sample to a suitable weighed container and place in an air-oven at a temperature of 130 °C for 5 min to 10 min. The length of this preliminary drying period will depend on the amount of moisture. It may be necessary to remove the sample from the oven, the objective being to reduce the moisture content to 12 % to 15 %. Spread the partly dried seeds in an open tray and leave exposed in the laboratory for 2 h. Transfer the material to the container in which it was oven dried, and weigh. Calculate the loss of moisture as stated in A.2.3.

The determination shall be made in duplicate, with the weighings being made to an accuracy of 10 mg. Grind separately the two partly-dried working samples, and on the ground material from each, make a single moisture determination as stated above, and calculate the loss of moisture.

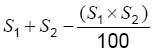

From the results obtained in the first and second stages of the procedure, calculate the moisture content of the sample if S1 is the moisture lost in stage 1 and S2 is the moisture lost in stage 2, each expressed as a percentage, then the original moisture content of the sample, calculated on the wet basis and expressed as percentage, is:

(normative)

Petroleum ether, of boiling range 40 °C to 60 °C

Hexane, food grade

Weigh accurately about 2.5 g of the dried sample and extract with petroleum ether or hexane, food grade, in a Soxhlet or other suitable extractor. The extraction period may vary from 4 h at a condensation rate of 5.6 drops per second. Dry the extract on a steam bath for 30 min, cool in a desiccator and weigh. Continue at 30 min intervals this alternative drying and weighing until the difference between two successive weighings is less than one-milligram.

Note the lowest mass.

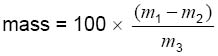

Crude fat (on moisture-free basis), % by

where;

| m1 = | is the mass in grams of the extraction flask with the dried extract; |

| m2 = | is the mass in grams of extraction flask; |

| m3 = | is the mass in grams of the dried sample taken for the test. |

(normative)

The representative sample shall be reduced by riffle type sample divider to obtain a portion weighing 1 000 g to 1 500 g. Sub-samples weighing approximately 200 g shall be drawn from the representative sample by use of a riffle divider.

Bags of groundnuts, which are not of the sample quality as the bulk of the consignment, shall be graded separately.

Foreign matter shall be separated by hand picking of such material from the sub-sample, weighing the picked material and expressing the weight as a percentage.

The percentage of damaged groundnuts shall be determined by hand picking from the sub-sample, weighing such groundnuts and expressing the weight as a percentage.

The percentage of splits shall be determined by hand separation of the splits from the sub-sample, weighing splits and expressing the weight as a percentage.

Other defective groundnuts, which are not, splits broken or damaged shall be weighed and expressed as percentage of total sample.

The percentage of total defective groundnuts is the sum of splits and broken, damaged and other defectives. The percentage of splits shall be determined by hand separation of the splits from the sub-sample, weighing these splits and expressing the weight as a percentage.

The percentage of groundnuts of other varieties shall be determined by picking such grains from the sub-sample, weighing these groundnuts and expressing the weight as a percentage.

8