In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 385:2005

ICS 01.040.61

EAST AFRICAN COMMUNITY

© EAC 2005

First Edition 2005

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East Africa. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Partner States in the Community through their National Bureaux of Standards, have established an East African Standards Committee.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2005 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.eac.int

* © 2005 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iiGlossary of terms relating to footwear

This East African Standard gives the glossary of terms relating to footwear for use in the footwear industry.

Abrading

The roughening up of the over margin of the lasted upper.

Abrasion Resistance

The ability of a footwear material to withstand wear due to abrasion

Abrasives

Materials, such as emery paper, emery cloth, red flint and carborundum used for scouring or buffing soles, heels, etc, of footwear. Roughness of the surface of the abrasives is denoted by grits.

Accelerator

A substance added to a rubber mix to accelerate the process of vulcanisation and in other ways to improve the bottom of footwear.

Acme Backer

Plain weave cotton cloth coated on one side with thermoplastic gutta percha or with rubber and wax used for backing uppers.

Acrobatic Shoe

Shoe made with extra light uppers and soles for acrobatic works.

Adhesion

A molecular attraction exerted between the surfaces of bodies in contact.

Ammunition Boots

Ankle-high sturdy boots of Derby type with six eyelets, full tongue made by riveted, screwed and stitched method for heavy duty purposes. These are also known as Ankle Boots.

Ankle Bone

See ‘Astragalus Bone’.

Ankle Boots

See ‘Ammunition Boots’.

Ankle-Girth Measure

The girth measurement of the leg joint above the ankle.

Anatomic heel

Inner side extended forward on the shape of “S”.

Anterior Arch

The arch of the foot between the phalanges and the metatarsal bone which extends across the ball of the foot from the outside edge of the first metatarsal to the outside edge of the fifth metatarsal. This is also known as ‘Metatarsal Arch’.

Antique Finish or Dressing

A dressing applied to an upper and immediately removed except in edges and crevices so producing the appearance of old and well cared for leather.

Applique

A strip or design fixed on to a footwear for decorative purpose.

Apres Ski

A man’s or woman’s fur-lined and water proof boot.

Apron Front Shoe

A combination of the basic Derby and Moccasin designs. The difference lies in the front (that is, in the vamp), which has a separate apron laid on or underlaid and which is at Arch times one-piece with the tongue. The design is also known as the ‘Ski Design’.

Arch

The long framework of the foot extending from the heel to the toes.

Archbrace

A bandage of webbing or leather designed to support arch.

Arch of the Foot

A bridge made up by the bones of the foot, mainly to support the body weight

Arch spring

The upward curve of the arch of the last or footwear.

Arch support

Stiffening effect given on the inside of a footwear to give support to the arch of the foot. Wide steel shanks ribbed double or triple lengthwise and ribbed across as well are provided to support the arch in the high class shoes, ammunition boots and corrective footwear to give stiffening effect.

Arctic Boots

A type of Over boot originally made from buffalo hide with grain side in and with buckles to keep feet dry and comfortable in cold and wet climate. Subsequently rubber has been used for the manufacture of arctic Over boots without any change in the basic pattern.

Artificial Grain

A grain appearance given to a flesh split by pigment with or without embossing on footwear upper.

Assembling tack

A tack having a round parallel shank made from wire with a square pyramid point, used in the assembling operation. This type of tack is driven through the upper material at the top of the back seam. The head of the tack is very similar to that of the welted tack. The fine point and shank are provided to leave a mark as small as possible on, the upper.

Assembly Room

Area in which the closed uppers, the reinforcing components, the bottom components and the lasts are held and matched up into sets for the insisting room as required.

Assembling Upper

Inserting of the prepared components, such as toe-puff, stiffener and side lining, in the respective positions. The term also refers to the tacking of the upper to the last at the counter point prior to being lasted.

Astragalus Bone

A bone of the human foot located in the tarsus group of bones. Also known as ‘Ankle Bone’ or ‘Talus Bone’.

Athlete’s Foot

A kind of foot infection due to ringworm, which softens and peels the skin between the toes, and on the sole of the foot causing irritation.

Attaching

Attachment of the upper and bottom parts using one of the various methods of attachments.

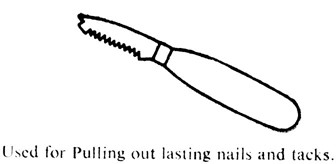

Awl

A sharp-pointed tool with a small round handle, generally known as `Pricking Awl’ which is used by the upper leather clickers to make the prick holes for the convenience of the upper closer.

or

A sharp flat pointed tool used in the outsole stitching machine, similar in shape to the outsole stitching machine needle and which has no hook for taking up the thread. The purpose of this awl is first to pierce the outsole and make it easier for the sewing needle to go through the outsole while sewing.

Backer

A fabric material used to give reinforcement and plumpness in order to reduce stretch in thin leathers like glaze kid, calf, lizard etc.

Backing

Laminating a piece of fabric to leather or other components of a footwear by adhesive.

Backing cloth

Cloth usually of thin and loose character treated with a solution of gutta percha pasted on the outside section of the upper to increase its strength and durability.

Back Splitting

Reduction of sole substance at the heel, shat and waist, mainly done for Louis Heel construction.

Back Stay

Material like taffeta used for reinforcement at the top of the back seam and down the facing. A small oblong stay piece cut out of the material is held in position while stitching the lining with the upper.

Back Strap

Strap of leather which joins the two quarters at the back of the boot or shoe to give added strength to the back seam.

Back Tacking

An operation in upper assembly for taking the lower and of the upper on the insole, before feeding it to the machine for pulling over by machine.

Bagged Edge

A method of joining a finishing of the quarter top edge all round the ankle so that the seam joining the lining with the quarters is about 5 mm below the folded edge of the quarter.

Bal

Front laced footwear in which the quarters meet at the vamp unstitched over the quarters at the front of the throat.

Ballerina

A low cut, light weight, practically flat-heeled, new-cut type shoe used by women and constructed by direct method of attachment. It has a similarity with ballet dance shoes.

Ballet shoe

A type of shoe used for dancing made of cloth (sometimes of satin) with heavily blocked toes. They are generally made by the turn shoe method and are very light and flexible.

Ball girth measurement

The circumference of the foot around the middle of the big and small toe joints.

Ball line

A line drawn across the widest portion of a foot or last.

Ball point

A point where the first metatarsal bone meets the phalanges or big toe. This joint is prominently visible on the inside of the foot just adjacent to the big toe.

Ball point of last

A point on the last where pitch line meets the baseline.

Ball position

See ‘inside foot joint position’

Balmoral

A type of gents’ boots or shoes having a closed front-laced ankle. It is characterized by the vamp wings extended to either side, to form a golosh.

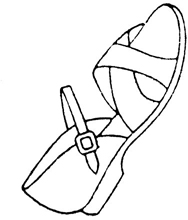

Bar shoes

A slipper type of shoes with a bar running over the instep from the inside water to outside water where it is either fastened with a button or a buckle.

Baseball shoes

Pumps shoes usually machine sewn, light and heelless with special sharp metallic reinforcement on the heel and ball of the shoes

Base of bone

The lower end of the oscalcis (or calcaneum) bone which is also known as heel bone. This is the largest and strongest bone in the tarsus group and is used mainly for transmitting the weight of the body to the ground.

Basic cutting area

The area which include pattern area and the unavoidable waste. The pattern area is the space required by the patterns individually. The area between the pattern which cannot be avoided when patterns are laid out together is termed as unavoidable waste.

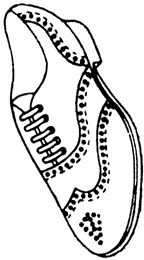

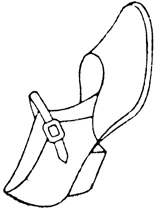

Basic Shoe Designs

There are sixteen recognized basic shoe designs, namely, (a)Balmoral, (b) Blucher/Derby, (c) Boot, (d) Brogue, (e) D’orsay, (f) Ghellic, (g) Gore, (h) Jodhpur, (j) Moccasin/Casual, (k) Monk, (m) Mule, (n) Oxford (p) Pump, (q) Sandal, (r) Fringe/Shawl, and (s) Strap (see annex A).

Basic Shoe Types

Footwear are universally classified mainly into four types, namely, (a) Sandal, (b) Moccasin, (c) Moccasin and Sandal combination, and (d) Proper shoe (a modified moccasin and sandal).

Basket Weave

A style of weave done in leather upper.

Beach sandals

Simple sandals for seaside used usually of rubber or plastic.

Beaded Edge

Forming a neat edge by turning inside the unskived edge of a section of the upper.

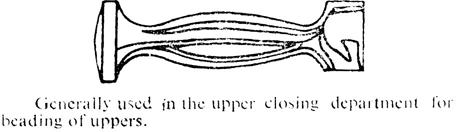

Beading

The turning in of a skived or unskived edge of an upper section. Sometimes the skived edge is turned over a cotton tape to give a pleasing appearance and more strength at the edges.

Bead on Sole Edge

The tiny ridge or bead which will be found on finished sole edge of shoe either on one or both sides. The ridges on the welt and on the sole edges are respectively know as welt bead and sole bead.

Bedding Sole

Fixing sole in its proper position so as to conform to the bottom shape of the last in mellow condition.

Bed Lasting

An operation by which upper at the toe and seat is wiped to proper position on the insole and kept in position by cement, wire or tacks.

Beech Wood

A hard slightly reddish-brown wood obtained from Fugus sylvatica L., fam. Fegacca suitable for last making. This wood does not split and is free from knots.

Beeswax

An insect wax prepared from the honey combs of either wild or domesticated bees after the removal of honey.

Bellows tongue

A broad folding tongue stitched to the quarter at each side.

Belly

The underside of a hide or skin between fore and hind legs.

Belly size

Shoe sizes that are commonly in demand.

Benching

Operation of giving final faking and fiddling to the shoes, after having passed through all the finishing operations, for any slight imperfection either in upper or bottom.

Bespoke Shoes

Shoes made to order.

Bevelling

Reducing the substance of certain components of the shoe bottom by skiving, such as sole waist bevelling, insole seat bevelling, welt bevelling, piece sole bevelling and graft sole bevelling.

Bevel Waist

The sole edge of any welted shoe is bevelled at the waist to give an appearance of a single sole or a lighter sole. The outersole channel is placed further away from the edge so that the levelling operation may not damage the stitches.

Bias Binding

Fabric binding cut diagonally as a continuous 45° spiral from a circular woven cloth. The bias or diagonal structure facilities binding on all types of curves.

Bifurcated heel pins

Round parallel shank pins used for attaching heels, made from screw wire which are without heads or points, but whose ends are bifurcated to increase their holding power.

Binding

Bit knife

A knife used to even up the inside edge of welt and middle sole in order to get the edge uniform in substance. The cutting part of this knife is a continuation of the tool itself.

Blake sewn construction

A method of construction in which there is direct attachment of upper to sole. In this method, the upper is lasted to insole with tacks, staple or thread and the sole is then attached by vertical chain or by locks stitches. In case of hand method the attachment is made by lock stitches only.

Blind eyelets

Eyelets with their surface

Blind eyeleting

A method of setting eyelets to the shoe upper and such a way that the eyelet ends show on the outside but the barrels do not penetrate the lining; the clenching being done on the reverse side of the upper material or on a reinforcing tape. The lining covers the clenched barrel and so protects the socks or stockings.

Bending sole

The portion in which soles are temporarily attached with the help of nails and are driven through the last margin of upper and insole. They do not penetrate the sole right through and thus give an appearance of blind attachment.

Blocked toe

The toe of the footwear without any opening at the toe.

Blocked fitting upper

A method of fitting the upper, in which sections of the upper are placed over a wooden block, similar in shape to the last and positioned to assume a shape relative to the final shape of the shoe.

Block forme

A method of forme cutting a hole cut paper is first folded to the last and then adhesive strips of paper are pasted all over the last in a systematic manner. The folds are removed gradually while doing so. Finally, this is cut along the feather edge all around and the blocked top position, known as blocked forma, is separated from the last.

Block insole

See ‘insole blocking’.

Blocked

Leather preshaped by the moulding operation.

Blucher Bal

A modified blucher shoe in which the vamp is stitched overlapping the quarter.

Blucher Shoe

Shoe patterned after a half boot that is an open lace shoe (derby type).

Boot

A name given to any shoe reaching above the ankle or still higher.

Bootee

A type of boot with warm lining, usually worn by women and children in cold weather. A knitted fabric foot covering for infants is also known as bootee.

Bottom

Bottom face of a footwear sole which extends from toe to heel breast.

Bootline

A short casual boot that hits the ankle and usually is worn with stretched paints.

Bottom filler

The material used to fill up the cavity formed by the lasted margin of the upper and the insole.

Bottom finishing shoe

The finishing room operations, such as trimming, scouring, inking, and polishing, in order to improve the appearance of the finished shoe.

Bottoming

The attachment of the lasted footwear to the sole by direct or indirect method of construction.

Bottom levelling

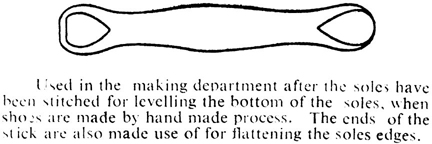

Levelling either on machine under high pressure or by hand using sleeking sticks to give the bottom a good shape and remove all bumpiness after the soles are stitched and channel-closed.

Bottom manipulation

Clicking or cutting of bottom components.

Bottom stock or rough stuff

A collective name given to various bottom components used in footwear construction, such as outer sole, insole, welt, heel lift, and heel top pieces.

Bow

A decorative accessory for women’s shoes sometimes on the vamp or sometimes at the ends of the laces.

Boxing

The final operation in which the shoes are packed in boxes in pairs, ready to go out of factory.

Box Toe

A stiffener used to maintain and reinforce the shape of the shoe to, preserve the toe-room allowed within the shoe, and to protect the wearer’s toes from blows. Rigid box toes are made of leather, thermoplastic resin-impregnated fibre, solvent softened plastic-impregnated fibre, and water softened starch-impregnated buck ram. Flexible box toes are made of thermoplastic cork combination with fabric backing, and plastic laminates placed between fabric sheets. Soft box toes are made of rubberized felt or fabric. Metal box toss are used in some safety footwears.

Boxer Top

Used to describe elastic, plain or covered with leather or synthetic when used around collar or a shoe or a boot.

Bracing

Sewing the upper temporarily to the insole shoulder, before the lasting rivets are removed to hold the upper in position firmly for welt sewing.

Braiding

The production of ribbon-like or cord-like textures by inter-lacing of threads or narrow strips of leather for decorative purposes. Each strand in braid follows a path of its own either from side to side {for flat braid) or round and round {for tabular braid).

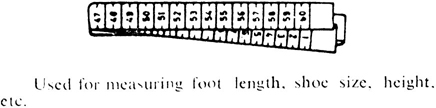

Brannock

A foot size measuring device with a sliding gauge to measure fitting.

Break

The wrinkling of leather in the fore part of the shoes caused by flexing in walking.

Breasting

Trimming or cutting down the front or the breast of the heel with either a power-driven, suitably shaped descending knife or by hand knife.

Breast scouring of heel

Smoothening the breast of the heel by scouring.

Brocades

Made of cotton, silk or rayon of metallic covering, with additional silk weft threads of gold or silver included to give a pattern usually backed with cotton cloth for fancy type of footwear.

Bregan

A heavy work shoe with pegged or nail sole construction.

Brogue

A balmoral type of low cut laced heavy soled shoe, sometimes trimmed with pinking perforations and stitching.

Brogue shoe

A balmorai type of shoe with perforations and gimpings on the upper.

Buckles

A kind of metallic fitting used in footwear for fastening straps and for decorating purposes.

Buckram

A stiff fabric laminated or otherwise used for backing light upper leathers especially at the flesh sides.

Buffing

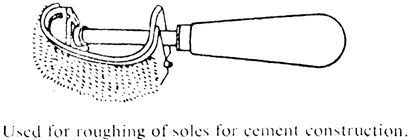

Removing a thin layer from the grain side of the sole or insole by use of abrasive to give it a final look or to allow the penetration of colour and prevent cracking.

Built heel

Complete heel composed of lifts, special lifts, top piece, slugged, compressed and breasted, and made to required height.

Bunching

Term applied to action of the bottom filling shifting from its own place and bunching or depositing at different places forming humps and causing annoyance to the wearer.

Bunion

A inflammatory swelling of the borsa over the metatarso-phalangeal joint of the great toe caused by undue pressure and friction being brought upon that particular portion of the foot.

Bunking

Putting a fancy pattern on the sole edge of the shoe bottom by means of an adjustable heated tool which usually runs over the channel to hide any fault in channelling or channels laying and to improve the appearance of the footwear bottom.

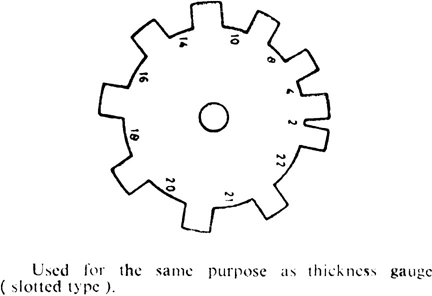

Bunking wheel

A appliance having a wheel used for giving embossed decoration on the edge of a gummed or dumped finished sole. A patterned impression is produced in a series of short straight strokes or any other design.

Burned sole

When leather is heated above 110°C, it becomes brittle and breaks off.

Burnished edge, upper

The treatment of a specially skived edge given to cheap quality footwear by a special machine in which the fibres on the edges are burnt to give a slightly curled appearance and to give a false folded edge.

Burnishing

Polishing to secure a bright glossy finish.

Burnishing heels

The application and impregnation of wax into the heel by the use of heated implements.

Butted seam

Seam produced by joining two components, edge to edge by zig-zag seam.

Butt jointed sole

A three quarter sole with tonguing at the heel end, used with fitted heels, the semi louis or Cuban type.

Buttons

Fittings used for fastening and for decorative purposes.

Cack

A small soled shoe without heel and loin soft upper. It’s of size 1-5 (KS 1632) and for infants.

Calcaneum

The largest bone in human foot and one of the bones of the tarsus group which situated at a distance of the foot length measured from the back. The body weight is transmitted to ground to a large extent through this bone.

California slip-lasted construction

In this method the upper is stitched on to the sole lining which in turn is stitched to the heel and platform cover. A last is then forced into cavity so formed. The wedge heel and platform are stuck to the soft lining into position and their edges are covered. Finally, the sole is attached by cementing.

Calf measurement

Girth measurement at the calf of the leg.

California process

See California slip-lasted construction.

Calking machine

An appliance used for to depressing to shape the inner sole to make it conform to shape.

Callous

A spot of thickened and toughened skin formed as a result of pressure and friction on the sole, heel and side of the foot, later develops into a corn.

Canvas boots

Boots of canvas upper and rubber bottom in which unvulcanized rubber sole is directly attached with the upper and then vulcanized.

Canvas lining

A plain weave heavy cotton cloth, used for lining of heavy shoes, usually combed and waterproofed.

Canvas shoes

Shoes of canvas upper and rubber bottom in which the unvulcanized rubber sole is directly attached to the upper by vulcanizing.

Cap

An attached or imitation cap with a central peak and curved on either side, sometimes perforated.

Carriage boot

A loosely made boot of leather or fabric often fur trimmed and intended to be worn in winter by women being clipped over the ordinary shoes or slippers. Commonly worn over evening slippers.

Carnauba wax

A hard, pale yellow or brown commercial wax. obtained as an exudation from leaves of the wax palm Copernicia cerifera mart, fam. Palmae,. Due to its high melting point long lasting gloss it is generally used for footwear polishes in conjunction with other waxes.

Cartons

Standard sized cardboard boxes in which the footwear are packed before being despatched from the factory.

Caster Shape

Shape of outer soles and insoles so designed as to contain within their area sufficient space to enable other shapes to be cut from them.

Casual footwear

Any footwear of light construction, suitable for informal or casual wear which is easy to slip on without any fastening device.

Cavalier boot

Men’s boot made of soft upper stock, ankle high usually with two inch folded collar, crimped or moulded front.

Celastic Toe-puff

A hard to-puff made of raised cotton cloth, either single or double, impregnated with cellulose and available either in sheet form or in pieces out to the shape of the puff. Softening of the toe-puff in solvent before insertion and quick lasting of the shoe after insertion is necessary.

Celluloid eyelets

Eyelets having brass as their base with their head covered with a heavy coating of viscous celluloid solution.

Celluloid toe-puff

Layers of fabric impregnated with cellulose solution kept in moist condition in air-tight containers. This puff requires no skiving along the cap-edge, the effect of skiving being produced by stepping the layers of fabrics when they are stuck together. Softening of the puff is not required before insertion but quick lasting is essential.

Cement

A general term applied to adhesive materials in footwear industry.

Cementing

Application of cement on roughed or scoured portion of the footwear by brush or machine.

Cemented construction

A method of footwear construction, in which the upper may be secured to the insole with threads, tacks, staples or cements (adhesive material) and then the sole is attached to upper and in sole by cement under pressure.

Cemented shoes

Shoes manufactured by cemented method.

Cement lasting

Lasting of footwear uppers using adhesives.

Chain stitch

A type of stitch, made by one thread only. The view resembles lock stitches but the under side give the appearance of a chain. It is characterized by the fact that the entire thread may be pulled when one stitch is cut or broken.

Channelling

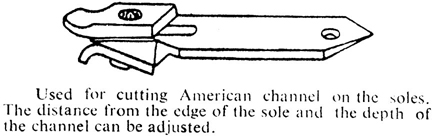

The production of a groove or channel in the leather in which the stitching is laid while attaching the soles and other parts.

Channelling insole

In the welted insoles two parallel hinged panels are cut or a single panel is cut on the flesh side between leather substance either all round or from one side of the drive of the heel to the other round the edge to enable welt sewing.

A single opening channel is also cut on the grain side or the in sole for single sole construction to enable the stitches to be embedded in the channel.

Channel laying

Closing the channel lip after sole stitching by applying cement to the channel or otherwise and rubbing the lip down.

Channelling soles

Making a slanting cut along the edge or cutting on an open groove at an angle along the edge of the sole on the grain side. The sole stitches are concealed or bedded in this channel to avoid wear with or without lip being closed.

Channel Lip

The portion of the leather, which is raised up after cutting to open the channel either insole or sole.

Channel opening

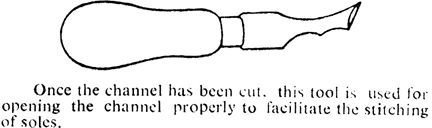

An operation to raise the lip of the channel after cutting to facilitate sewing.

Chappal

Sandals without back straps but with close-over straps on the fore part referred to as chappals (See also sandals)

Charme wood

A light coloured, close textured hard wood, free from knots, obtained from charme used in the construction of wooden lasts (also known as French wood or Hornbeam) carpinus caroliniana Walt., fam, betulaccae.

Chauffeurs foot

A vocational disorder of the fore part of the foot.

Chilblain

An inflammation of the foot following freezing or continuous exposure to extreme cold.

Chiropodist

One who is engaged in the practice of chiropody or podiatry, a service of foot care professionally administered.

Chiropody

Branch of service of science dealing with professional care and treatment of the foot.

Chrome sole

Sole made from chrome tanned leather. It’s light and strong, slippery, porous and has a rough edge.

Church

A device to measure the foot size and fitting number.

Chukka boots

See ‘Jodhpur boots’

Circles

A small horse shoe shaped oval or round tubelet of steel, drawn into the heels of shoes to prevent undue wear.

Circular vamp

A vamp so cut as to join the quarter in a seam on each side of the shoe, running down to the shank.

Clarks children foot gauge

A fitting board used for measuring children’s feet. The length is measured by one sliding block and the ball girth by a tape on the other sliding block. The board is so designed that both the feet can be measured on it without reversing the board.

Claw foot

A deformity of the foot in which the inner longitudinal arch is accentuated, and the toes are drawn up and curled.

Clearance Pulls

Careful pulls given for clearing feather edges in lining, stiffeners, toe caps, etc, prior to fastening with tacks during lasting.

Clicking

Cutting the footwear components out of upper leather or other materials with the help of templates or clicking dies.

Clicking Board

Board of suitable timber blocks, plastics, rubber, zinc sheet, glass or any other suitable material, used for clicking of uppers.

Clicking dies

See ‘Clicking knife, press’

Clicking knife, hand

A knife having a wooden or plastic handle with a metallic sleeve which is tighten by screwing the handle holding the blade, known as extension blade.

Clicking knife, press

A knife made out of high-speed steel to the exact shape of the component to be cut, used for clicking by machine.

Climbing boot

A strong, warm and waterproof boot with nails fitted at the bottom and round the edge of the sole with a special type of staples. The fitting of the boot should not be loose but should be roomy enough to allow free functioning of the circulation of blood to prevent frostbite.

Clip

Describes a shoe or a boot which fits tightly on last round the, top line.

Clipper

Same as Boxer Top.

Consumables

Same as Findings.

Closed seam

Joining two components of upper by a seam along the edge, then opening out and flattening. A fabric or leather strip is attached on the top of the seam on which two rows of stitches are made on either side of the seam.

Clog

A heavy soled very low cut boot or shoe with wooden or cork soles and used for wet ground.

Closing

Assembling the components of the upper by stitching of other fastening method.

Closing hammer

A metal tool like a hammerhead without a handle used for folding of parts of footwear by hand.

Closed Stick Assembly

An assembly made by the application of adhesive to a single workpiece or both workpieces to result forthwith in a joint, suitable for the porous material which is capable of evaporating off the solvent.

Clubfoot

Also called talipes, is a deformity of the foot. The word talipes is derived from two Latin words talus meaning ‘ankle’ and pes meaning ‘foot’. There are four types of clubfoot depending on the position in which the foot is held, that is, talipes equinus — the persons walks on the toe, talipes calcaneous — the persons walks on the heel, talipes varus — the persons walks on the outside of the foot, and talipes valgus — the persons walk on the inner side of the foot.

Cobler

A mender or maker of footwear.

Coblers Seam

A seam made by stitching through and through the pieces being laid so that the edges are even.

Code marking

Blind sizes are used in footwear.

Cold setting filler

Cold process bottom filler consisting of granulated cork, asbestos, leather or wood fibres or combination of these, bonded together with rubber or cellulose solution. The filler gets hardened on evaporation of the solvent with application of external heat or pressure.

Collor

A narrow stitched-on strip of leather around the outside of the top of the boot or shoe for ornamental effect.

Colonial

A low heeled shoe worn by women, has a tongue inside with an ornamental buckle across over the waist.

Colour marking

In this method, the lasting edges of the sectional parts are painted with definite colour to indicate the sizes. This method is also used in the identification of lasts by colouring the top projected portion of the last with definite colour to indicate the size.

Comb

The section of the last corresponding to the forepart of the foot immediately beneath the ankle. Shoe lasts are much thinner at this part than that of the foot and the hollowness in the comb assists in enabling the shoe quarters to grip the foot properly.

Combat Boot

A special type of boot with high heel and eyelets up to the highest point worn nowadays by wrestlers and originally by Roman warriors.

Combination Last

A last some part of which varies from the usual standard measurement.

Combination method of cutting leather

Method of cutting leather where components of more than one size or design and shape are cut at a time from a side of skin, with a view to utilizing leather to the maximum without affecting the quality.

Combination fabric, lining

A fabric lining for vamp attached to swansdown or flannelette with latex or paste.’

Combination shanks

Shanks prepared by combination of steel and fibre board or wood and fibreboard. The steel or wood provide rigidity and the board acts as a filler.

Common sense heel

Low flat heel.

Comfort shoe

Soft, flexible, low heeled easy shoes for women.

Compo

A proprietory name for the original modern process of cementing sole and upper together with pyroxylin cement.

Component splitting

Operation of reducing the thickness of the footwear components by passing the individual components through a splitting machine having a flat or band type knife.

Composite last

Same as combination last.

Composite method

Riveted, stitched and screwed method of construction used for heavy boots.

Composite sole

Rubber based with ingredients mixed to lighten or fortify mass of sport footwear.

Concealed wedge

The wedge heel covered in the normal way and stack to the previously covered through platform.

Conditioning of the upper

Softening the upper with heat and moisture to facilitate lasting operation.

Conforming of soles

The operation of shaping the sole before applying it to the footwear, so that it can conform to the last but carry a high heel or rounded waist.

Congress gaiter

An ankle high shoe with leather or cloth top adjusted to the ankle by a gusset or rubber.

Continental heel

A slender type of heel generally with a curved breast line but usually with less curve in the back line than the Louis heel. It has a lip which extends partly under the shank of the shoe and usually ranges in height from 50-70 mm. The breast of the heel is vertically straight. Straight front high heel with slightly shaped back to give small and modern-look.

Convalescent boot

A counterless boot used to permit early ambulation following injury or surgery.

Copper toe

A copper boxing or lip used to protect the toe in the children shoes.

Cordwainer

The very first trade guild started in the year 1087.

Cordurcy

A complex weave weft pile fabric made of cotton with ribs running the length of the material, used for uppers of sandals and casual shoes.

Cork, processed

Waste cork granulated and bonded together with suitable adhesive under heat and pressure to produce required block or sheet used for a bottom components in footwear.

Corns, Hard

A small deep-rooted horny formation usually formed on the toes due to constant friction or pressure at a particular point by using tight or ill fitting boots or shoes.

Corrective Footwear

Specially made footwear for defective foot to overcome abnormalities in the foot.

Corrugating Waist

Adorning the waist of certain classes of footwear by a heated dual knife from waist to heel-breast at an angle of approximately 30° producing a series of parallel lines.

Counter

A piece of stiffening material which passes around the heel of the boot/shoe to support the outer leather. In orthopaedic shoes the counter is extended forward in the innerside. In heavy and industrial bootslshoes for miners, furnacemen and steel workers metal counters are used on the outside of the boot and shoe. It may also mean a small piece of lining material stitched inside the boot and shoe at the back to rain the small stiffener specially in the unlined boot and shoe. One upper portion of the boot and shoe back is also known as counter.

Counter pocket

In unlined shoes a leather piece is stitched at the back to conceal the stiffener or count which forms a pocket.

Counter point

A point on the back line of the last at a distance of one-fifth of the standard last length from the bottom edge of the last. It may be lowered according to the changes in fashion.

Counpting Heel

Fitting snugly the heel to the convex seat of the sole of the shoe by making the cup of the heel concave in many ways.

Court shoes

Low cut vamp lightweight pump type shoes either with low or high heels. Originally the upper was in one piece.

Covered Wedge

The wedge heel stuck to the sock lining and covered with a wrapper which has been previously stitched with sock lining.

Cow Boy boots

Long boots with high tops and high heels worn by western cow boy’s, now known as Dude Ranch Novelty shoe.

Crease on setting iron

Either one or two creases on either side of the bed of edge setting iron which help in producing the bead in the finished sole edge. These creases produce tiny ridges on either edge of the sole or on one edge producing a bead on the trimmed sole edge.

Crepe Fabric

A plain weave silk or rayon fabric used for sandal and ladies shoe upper. Hard twisted yarns are used in the weft which by shrinking give pebble appearance to the cloth. Creedmore – A cheap, heavy boot or shoe for men, blucher cut with bellows tongue.

Crepe Rubber Sole

A rubber sheet of varying thickness used as outer sole. The sheet is produced by coagulation of latex and passed between a series of steel rollers, roughly scored on the face which imparts a pattern to the rubber which is called crepe.

Cresol

A heavy work boot or shoe of the congress type having rubber goring in the boots/shoes.

Cricket foots

Strong ankle boots having a low heel made out of either white leather or canvas, either by machine sewn or welted method.

Crimping

To make folds or pleats in the whole-cut upper to facilitate lasting in Moccasin type of slippers.

Crowning

A name given to a type of decorative emboss mark similar to bunking across the middle of the sole joining the two joints. Sometimes it is put just below the breast of the heel.

Crow heel

An indented metal wheel used for crowing.

Cuban heel

A straight fronted medium or high heel used mainly on women’s shoes and cowboy boots and some men’s fashion shoes. The height varies normally from 35 to 54 mm.

Cuboid

A bone resembling a cube and located in the tarsus group.

Cuff

A strip of feather wider than a collar sewed around the top of a shoe and boot.

Cunilforms

Three wedged shaped bones located in the tarsus group.

Cupped sole

Applied to the depressions in the sole caused by the ball of the foot in wearing.

Curtain crepe welted construction

This method is the same as ‘Goodyear welted method’ except that a strip of plain or corrugated crepe rubber of required width instead of a welt is sewn to the insole and upper. The crepe sewn is stuck and trimmed and then the crepe rubber is turned back out to the sole and stuck to its edge.

Curttie

Men’s low strip oxford shoe with silk turn. Also applied to women’s two or three eyelet ties usually on Blucher pattern.

Cushion sole

A padded inner side.

Cushion insole

A term generally used for insole covered with synthetic or natural form or sponge sheet or felt and then both the units covered with leather or other materials to give a cushioning effect to the foot during wear.

Custom made

Made by hand to the customers’ special order.

Custom toe

This designation intended to refer to a toe and last of standard type.

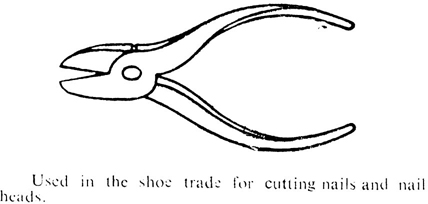

Cutlan nails

Nails in lengths from 5 to 16 mm having rectangular head and sharp column the head tapering down into the shank, used to attach as well as to reinforce top pieces and soles.

Cut off vamp

A vamp which is cut off at the tip and stitched.

Cut out

One or more pieces cut out of upper of a boot and shoe for style effects.

Cut soles

Soles cut ready for selling in different sizes and shape in different thicknesses.

Cut Stock

The ready cut components of footwears for further use in closing or making room.

Cut Tacks

Tacks used in machine construction of footwear resembling hand tacks made either with sharp or blunt points.

Cutting area

The final area obtained from the pattern area of footwear after a number of additions or coefficients have been made for to allow for the number of pieces, their shape and the interlocking properties quality of leather, size of skin and other factors.

Cutting soles, direct

A system by which entire material is brought beneath the press and cut direct into parts. This system requires duplication of knives and press with larger cutting areas.

Cutting soles from ranges

A system in which the leather is first divided into small strips or ranges before being brought to the press to be cut into soles. In this systems parts can be cut in pairs with a single knife.

Damps down bottom

A type of transparent wax finish containing some fillers and binders which is generally given to the sole good colour, used on better grades of footwear. This finish is also known as natural finish.

Dancers foot

A pain condition of the large toe joint.

Dancing shoes

Low cut, laced, light footwear with flexible soles used for dancing.

Dancing slipper

Generally applied to various types of low cuts used for dancing including low cut laced shoes used by dancers.

Dauber

A small brush used to apply polish to the shoe or boot.

Dead forme

A term used in footwear designing and pattern cutting. While cutting inside or outside forme with the help of a full piece of paper, a number of wrinkles occur particularly at the joint line. The effect of these wrinkles is to cause the toe of the forme to be twisted across the front of the last resulting in a dead forme when finally cut.

Decorating upper

Producing a fancy effect on upper by punching, stitching or gimping.

Decorative

In general, denotes a section or treatment which has no real utility value in the footwear but is only intended for decoration.

Del-Mac cemented construction

A method of construction of footwear in which no insole is used. The sole serves the purposes of sole and insole. The sole is split all round the edges to a width of about 20 mm. The upper is lasted to the flesh split and the sole grain split is attached with cement. The sole is cut to the size of the insole of the last with a little allowance for finishing.

Delwelt system

A system of construction similar to the Del-mac construction with the use of a skeleton insole. This insole is channeled on its under side and attached by horizontal chain stitched to welt. The insole has a canvas reinforcement and a full length sock is inserted.

Denailing

Removal of nails used for temporary attachment of insoles with last.

Deportment

An assembly of articles which have, from the commercial point of view certain features in common for making footwear.

Derby shoe

An open throat, laced shoe with tongue, cut in one piece with the vamp or separately. The quarter lies over the vamp.

Desmodur

An isocynate mixed in trychloroethylene solvent used with adhesives to speed up drying time and self-curing and to increase bond strength.

Dextrine Adhesive

Adhesive prepared from dextrine in water which has good tack and bond strength. It is used for toe puff and counter cementing and bottom filling. It dries brittle and therefore cannot be used for upper.

Direct attachment of sole

A method of attachment in which the upper and the insole are directly joined to the sole by stitching, riveting, pegging or screwing.

Direct cutting of the bottom

An operation of cutting the bottom stock of a particular ready shape from the bend or side which may not convenient for units producing various shapes simultaneously.

Direct moulded construction

A process involving the use of presses, where the rubber soling compound in the unvulcanized condition is pressed and cured on to the leather or canvas upper previously lasted to the insole. Moulding and vulcanization of rubber compound and adhesion to the upper are carried out simultaneously.

Direct moulded sole

The upper and sole of the footwear are formed and sole is cut to the desired shape. A mould is placed around the sole and thermostatically controlled heat softens sole and compound. Pressure applied then forces the sole into the desired shape. Chemical changes taking place in the sole result in the vulcanization of the sole with upper material for a firm bond. This method is most popular with sports shoes/boots and heavy shoeslboots.

Direct vulcanisation

The process of ‘curing’ a rubber compound (originally in soft unvulcanized condition) under high pressure to the lasted upper of the footwear. Metal moulds produce the shape required for the complete bottom.

Direct vulcanized shoe

See ‘Direct Moulded Construction’’.

Dompedro

A heavy buckle shoe.

Dorsum

The top of the foot, that is, the upper surface of the foot.

Doped finish

A finish given to the uppers having fancy colours at the stage of shoe finish. This is a coat of pigment with proper binder which is applied to the shoe upper matching with the colour of the upper.

Dorsal muscle

The muscles of the dorsal surface of the foot which helps the extensor longus, digitorum to extend the four inner toes and tends to draw them in outward direction.

D’Orsay

A pump shoe, cut low on both sides, the curves extending downwards towards the centre of the shank and meeting in a broad v-shaped.

Double Dect welt

A kind of welt prepared by splitting the edge of the welt and then doubling the grain upward to form a bead. A row of stitches is then run through the bead to give the effect of doubling welt on finished shoe.

Double eyeleting

In this method of eyeletting heavy duty footwear, two operations are performed. In the first operation, one large eyelet is inserted from inside the upper through the lining and the outside material and clenched on the surface, then in the second operation, another eyelet of smaller diameter barrel is inserted from the outside and clenched with the head of the first eyelet so that the head of the first cover completely the clench of the first eyelet.

Double guarded forepart iron

An edge iron with guard on both sides.

Dowie slipper construction

A method of footwear construction in which the upper is laid over the last before which a string is passed through the lasting edge of the upper and when drawn tightly, moulds the upper to the last. At this stage the sole is attached. This type of footwear requires very soft upper. The construction is very flexible.

Drafting

A process in which the initial stretch of the upper is taken out to give an approximate shape of the last prior to actual lasting. This consists of a series pulls taken in different directions.

Drag Knife

A cutting tool used for cutting sole edge. It has a concave blade and a projection or guard to protect the upper from being cut away.

Dressing

Cleaning and polishing footwear with liquid/paste polishes and creams.

Dressing of upper

Treatment given to footwear uppers before they are finally packed. It consist of checking evenness of the shade of footwear uppers and giving a final coat of the footwear dressing.

Dress shoe

Oxford type, black shoe without toe caps used for evening wear. It is now used for any shoe which is not casual, sport or work shoe or slipper.

Driving file

An old, cast off, flat file used for driving nails and rivets, taking out the feather edge and flattening the pleats of uppers on insole. It is better than a hammer as it has a flat surface.

Dry-stick assembly

A method by which adhesive is applied to both the surfaces of the work pieces which are then left open until the solvent is evaporated. The two adhesives coated surfaces are then brought together and pressed, when due to auto-adhesive or dry tape of the adhesive film, an adhesive strength is obtained immediately which approximates to the final strength. The state does not occur for long time in the close assembly method.

Dutchman

A wedge inserted between the lifts of the heels or between insole and outsole to throw the foot inward or outward, used to correct posture.

Dutch heel

Wide base, slanting straight to narrower top lift.

Edge Burnishing

See ‘Burnished Edge’

Edge searing

See ‘Burnished edge’

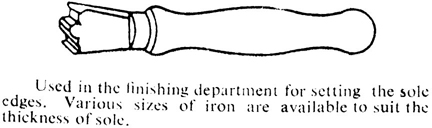

Edge setting

Finishing the edges of the soles with polish applied under heavy pressure by rubbing or ironing the edges with or without wax to give a fine uniform finish and gloss and impart waterproofness.

Edge Tie

A one eyelet tie for women, stitched close at the throat and having a small pointed tongue.

Edge Treatment

Giving different treatments to the edge of the upper components, and to the edge of the soles and heels during the manufacturing processes, such as skiving, gimping, binding and edge trimming.

Edge Trimming

Shaping the edges of the soles by trimmers to obtain required shape of edges (fudge edge, bevelled edge, round edge, square edge, extension edge etc.)

Edging

Removing the sharp edges of the leather in a variety of ways such as brushing ironing.

Elasticized

Shoes with upper surface of stretchable leather or fabric backed with flexible yarn woven fabric.

English channel

A channel which is generally cut on the soles a few millimetres away from the edge approximately at an angle of 45° to facilitate the stitching.

Elastic stocking

A surgical appliance made of rubber fabric.

Elastomee

Various macromolecular materials which materials which have rubber like properties and are used for footwear bottoms.

Embossing

A method of printing or raising up ornamentation on a surface by heat and pressure.

English Foot

Mode with a side seam in the foot.

English Last

Last with long recede toe and low heel.

English Welt

A mock welt.

Everett

A type of men’s slipper low in the back but coming up over the waist in front to the instep.

Escape Boot

Flying boot, fleece lined for warmth which in addition have a sharpnel-proof leg lining consisting of loose layers of silk. The leg part of the boot can be cut off leaving a normal Oxford shoe enabling the baled-out airmen to escape more easily from enemy territory without recognition.

Evening Shoes

Shoes usually made of patent leather by the turn shoe method of construction. For gents, evening shoes are Oxford type with laces of light construction. For ladies, these are light shoes made of fabric, gold or silver kid upper or sandals made by cemented method.

Evening soles and insoles

Levelling of the bottom components to uniform thickness by splitting a layer from the flesh side.

Everest Boot

Boots of light weight, high thermal insulation and strength; with correct fittings for climbing high altitudes. These have a provision to take easily detachable crampons for use on ice to put on and take off. These boots are modified form of boots used for Everest expedition in 1953.

Exhaustive cutting leathers

A method by which the leather unit is cut for full utilization of area.

Extensors

The muscles of the top of the foot, the contraction of which raises the toe upwards the knee.

Extension Edge

An extra wide edge.

Extosis

A bony cut growth from the surface of a bone.

Eyelets

An annular ring of metal or other material with a barrel for inserting in footwear upper to provide a durable ring for lacing. Regular eyelets are driven in from the outside of the upper. Blind eyelets are concealed on the inner side of the upper, leaving the lace hole with a raw edge on the outside. The head may be of different shapes; that is hexagonal, triangular or square.

Eyeletting

Fastening eyelets to the footwear upper.

Eyelet Tab

A reinforcement placed at the front or the quarters of boot/shoes to give added strength to eyelets or lace hoes.

Fabric Blade

A bevelled point blade used in the adjustable clicking knife for cutting of fabric lining. This blade is normally about 115 mm long. One end of this blade is sharpened to give a straight but sloping cutting edge of about 32 mm.

Facing

The portion of the quarter which carries the eyelets, for lacing which can be either whole cut with the quarter or joined.

Facing materials

The pieces of material used between the upper and the lining at the face of the quarters (where eyelets are fitted) to strengthened and to increase the holding power of eyelets on the upper.

Facing rows

Decorative stitching which is put parallel to the row of eyelets or sometimes in other decorative manner.

Faille lining

An attractive plain weave fabric with a close rayon warp and thick cotton weft. The back of this is covered with elastic material. This is generally used as reinforcement for very soft leather like suede.

Fair Stitching

Stitching applied around the sole showing on the upperside to imitate welt.

Fair stitched construction

In this method, first insole, upper and the middle sole are sewn together and then the sole is stitched to the projected edge of the middle sole.

Fake bottom

A kind of black waxy finish generally applied by hand to the bottom of footwear at the stage of bottom finishing over the buffed surface of the sole to give a shine on polishing.

Fakes

Water emulsified waxes to produce oil-in-water dispersions which may be of a thin creamy nature or in the form of thick paste.

False Welt

A strip of leather or any other suitable material stitched or stuck along with extended edge of the sole resembling a welt.

Faust slipper

A light weight shoe with V-shaped cuts at sides instead of U-shape and no goring.

Feather

Edge of the bottom of last all around.

Featherod

An edge thinned down to create minimum resistance or obstruction.

Feather Edge

Thin edge in turned or cemented footwear.

Feathering insole

Beveling of the flesh side edge of the insole either all around or only at the seat to facilitate moulding of the upper over the insole.

Felt

A sheet made of fibres of wool hair, fur, etc, matted together and rolled flat.

Felt sole

Soles compounded from felt and rubber latex to be use as outer soles for light indoor footwear.

Fibre Board

Board made out of materials based on leather fibres or alphacellulose fibres or a combination of leather and alphacellulose fibres that are generally used for insoles and counters.

Fibula

One of the two calf bones on the outer side of the leg. The lower end of this bone makes up the outer ankle bone.

Fiddle Shanks

High arched steel shanks suitable for high heeled ladies’ footwear. These are made from about 12.5 mm wide steel and are full width for about half the distance from the heel-end; then narrowing it to about 8 mm at the waist and forepart. The shank has a V-shaped cut at the seat end having a tack hold at each end.

Fiddle Waist

A method of finishing the waist of the shoe bottom in two colours. Fiddle waists are made with wax, hand finish stains and the forepart is finished in a lighter shade of the same preparation, usually of cream colour. The line separating the forepart from the waist may be straight, concave, convex or at times resembling a fish tail. Apart of the waist is sometimes coloured like upper to give a light appearance to the shoe.

Fille

A finely ribbed fabric used in women’s shoe uppers.

Filler

A composition of cork, felt, rubber, spur glass or substance made of sawdust or felt gunny to fill the gap space between sole and insole caused due to lasting operation.

Findings

A general term applied to articles which incidental or accessory to the manufacturer such as laces, trim, polishes, dressing, creams, waxes, cements rubber heel, buckles, shanks, heel plaktes, shoe horn, shoe brushes insoles etc.

Finders sole leather

Sole leather generally used by the repairers. It is usually hard and firm in nature and less wear resistance.

Finger foxed

Having a pieced quarter so cut that the heel foxing extends forward to the throat in a narrow strip below the quarter.

Finger Stitching

Stitching which reinforces the lapped quarter of a shoe or boot.

Finishing Footwear

The fined operation performed on footwear after constructional work has been completed to improve quality of the footwear by making the edge resistant to water and by improving its appearance.

Finishing Last

Specially made last on which footwear are generally finished. This last is made in two parts hinged together with half size shorter and half fitting, less than the lasting last. The last is rounded more in the heel seat portion.

Fitted heels

Wooden heels used in the ladies’ footwear. They are not placed on the top of the sole seat as is usually done but the sole is cut away to make room for the heel to be footed so that the breast of the wooden heel fits the edge and the outer edge of the heel rests directly upon the leather edge of the heel.

Fitting of foot

The ball measurement of the foot in relation to the size of the foot is denoted by the term fitting. These can be split up into any number, but tee have been considered sufficient which may be denoted by letters or by numbers. The difference between the fitting is 6.4 mm.

Fittings

Measurement of girths of the last in relation to the lengths which may be split into any number but ten have been considered sufficient. These fittings but ten have been considered sufficient. These fittings can either denoted by A, B, C, D, E, F, G, H, XH and ½ or by numbers 0, 1, 2, 3, etc. The difference between the fittings is 6.4 mm.

Fitting up

A term applied to the gathering together of the bottoming components according to the instruction.

Fitting stool

A low slanting topped stool upon which the footwear salesman sits when trying with footwear; it has a ledge to rest the foot of the customer while adjusting the footwear.

Flange heel

A heel made with a flare towards the “top lift” or bottom of the heel as the footwear stands when worn.

Flange joint of the sole and piece sole

A method of joining piece sole with graft sole. For this purpose the ends of the components to be joined are bevelled at the same angle so that a perfect joint is possible.

Flanging upper

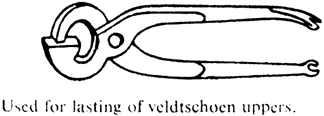

Turning out the edge of the upper as lasting allowance, instead of turning it in, in lasting operation for Veldtschoen method.

Flannel

A raised cotton cloth used for inner fining of shoes.

Flap setting

An operation by which the leathers sole edge covering the heel seat and breast area (Louis heel) is set.

Flap splitting

Dividing the sole for Louis heel at the seat to allow a part to go up the heel and the rest under the heel.

Flap sticking

Sticking up or attaching the flap to the breast and top of the heel (Louis heel construction) with the help of glue or any other suitable adhesive.

Flap trimming

An operation by which the split sole edge of heel breast area and seat area (Louis heel) is trimmed.

Flat binding

A kind of edge binding done in one operation. Special stitching machine turns the binding in U shape and then stitches through. The upper may be lined or unlined.

Flat fitting

Positioning of section of the upper on a flat base prior to stitching.

Flat foot

Human foot in which the arch or the arches specially the internal metatarsal arch have either been broken due to some reason or have not been developed as in normal foot.

Flats or Flatties

A general term for shoe styles with low wedge heels.

Flattened foot

A term for foot once normal but the arches fell down due to changes in their position.

Flat last

A last with little arch or toes spring.

Flexibility

The case with which the bottom or upper components of a footwear can be bent. This is one of the requisite properties of a footwear component which facilitates to the easy bending of footwear components along with foot movement during walking.

Flexors

The muscles of the sole of the foot, the contraction of which brings the foot in a line with the leg.

Flight boots

Fleece linked boots usually with a zipper closure worn by pilots and flight crews.

Floating Edge Finish of Sole

Boots used by airmen. These boots are light, flexible, waterproof and capable of withstanding rough service. These are made with woolled sheep skin upper with a belt fitted at the top of the foot. These boots are fitted with zip fastener and may be opened to the full length of the legs enabling easy putting on and off of the boots in a minimum time.

Folded edge

The edge of a skived upper which has been turned over to give a neat finish.

Folding skive

The skive done to facilitate folding or turning in of an edge of upper leather. This is made usually on twice the width to be folded, plus about one millimetre to cover the thickness of the material.

Football boots

Boots made of thick leather, unlined and are either machine sewn or riveted. They have no heels and the soles are covered with leather studs arranged in various patterns on the soles and heels to give the wearer a firm grip on the ground.

Foot form

A name for last or footwear made in close conformity to the natural outline of the foot.

Foot hold

A low rubber over shoe having no heel but adjusted by a light heel strap.

Footwear

Any form or footwear made of various kinds of materials or combination of materials like leather, canvas, rubber, textiles, wood synthetics to protect the foot from cold, heat, thorns, hazards, etc., and to serve as a costume in the form of sandal, shoe or boot. These shall include walking shoes, dress shoes, occasional footwear, sports footwear, occupational footwear, orthopaedic and surgical footwear meant for the use of babies, children, ladies or gents.

Footwear components

Any fabric or semi-fabricated component made of various kinds of materials or combination of materials such as leather, canvas, textiles, wood and synthetics for use in the manufacture of the footwear.

Force Lasted construction

See ‘California step-lasted’.

Force Lasting

Operation of forcing the last in the upper is called force lasting. Thus in certain construction where the insoles are stitched together with the upper, the last is to be forced in for the subsequent operations in the making department.

Forepart

The front portion of the footwear which may either refer to upper or the sole or shoe-last.

Forepart Cutter

Type of disk shaped knives with cutting blades around the circumference mounted at the end of a spindle revolving at a high speed, employed to trim the forepart of the footwear. There are various types of these cutters to give different types of edges.

Forme

The word ‘forme’ is derived from the French word for last but the term in footwear trade is used in pattern cutting to signify the shape that is produced to represent the area of one side of a last. There are, therefore, two formes, one for the inside and one for the outside. From these formes the standard can be prepared.

Forme cutting

The cutting of the forme on a flat surface.

Foundry Boots

These are protective boots modified to serve the particular purpose. The principal variation in this boot is the fitting of toe easy exit fasteners instead of eyelets, thus enabling the boot to be taken off quickly in the event of accident while handling molten metals. This footwear has also clog type wooden soles.

Foxing

A piece of leather forming the lower part of the quarter of a boot and shoe. A rubber ship of 10 to 20 mm width placed around the bottom, over sole and upper of a rubber boot/shoe or canvas boot/shoe for waterproofness and then vulcanized. It is a sort of reinforcement concealing the joint of the upper and sole.

Foxing strip

An external cover strip used to protect the sole and sole edge of the upper.

Freak last

A last, wide, almost straight across toe, having the same width as at ball of tool.

French binding

Treatment given to the edge of the uppers in certain cases, where a strip of binding material is stitched to the upper grain, very close to the edge and then pulled up over the top of the upper and down again on the other side of the upper, where it is sandwiched between the upper and lining, showing a pipe of the binding.

French Curves

Various model curves moulded in sets in celluloid used to obtain satisfactory curves in drawing and designing of pattern.

French Foot

Made with a single seam in the centre of the sole.

French Heel

A heel which is similar to Louis heel made by wood covered with leather.

Frontier Pattern of chapattis

This pattern of footwear was originally evolved by the North West Frontier Province (Pakistan) tribes as a sound, strong, cheap and hard-wearing footwear particularly suited to the rigorous, task involved in climbing rocks and hills.

Fudge Edge

An edge stitched very close to the upper and trimmed closed.

Fudge Edge Work

A variation of Mc-Kay work. All details as to the manufacture of this shoe are similar to Mc-Kay shoe, the only difference is that in fudge edge work, a ‘middle’ has to be inserted between the lasted upper and outer sole. The shoe made by this method is often called a double-sole shoe.

Fudge wheel

A rolling wheel is fixed in between two clamps which will mark the impression on the edge of the soles as a decoration.

Full Sock

A piece of leather or fabric pasted or kept on the insole of the shoe to cover any grindery and stitching inside the shoe. Sometimes full sock is also provided for better appearance.

Full sole

The whole cut sole used for costly footwear.

Full vamp

A vamp that extends forward full size and is lasted under instead of being cut off and sewed to the tip on the under side.

Full welt

Welt of full length, that is of such a length to run all round the sole-edge

Gabardine

A closely woven fabric of particular boot or shoe surface value in wear and appearance.

Gaiter

A separate ankle covering an over covering for the foot adjuster with buttons and attached with a buckle and strap.

Gallon binding

See ‘French Binding’.

Gaping Quarters

The quarter tops at the sides, at times due to various reasons do not fit snugly to the last after lasting and eventually do not fit the foot causing inconvenience to the wearer. The reasons for this are many but are mostly due to improper lasting.

Gap spring lasts

Wooden lasts are generally made in two separate blocks, namely the forepart and the back. These two sections are fixed in variety of methods, one of them being to fix a spring within the gap portion of the two parts which would break at the point where they are hinged to facilitate last slipping or forced lasting.

Gauged edge

A type of gimp having a series of round wedge shaped pieces on the edge of the upper components.

Gauged lift

A kind of seat lift, prepared by gauging out an area in the centre of the breast of the lift.

Lemming insoles

Reinforcing the insole of light substance, unsuitable for welted work in a variety of ways with a special canvas either all over or over the channel lips of the insole.

Geometric forme

Forme produced by applying geometrical method.

Geometric grading

This is a method of grading of pattern in which geometrical principles are involved.

Getting off

See ‘Benching’.

Ghillie

Ball type shoe with slotted front lace. Shoes having a slashed over tongue covering the lace stay.

Gibson

A name given to Derby shoes fior ladies with three four or five big eyelets.

Gimped edge

A kind of edge treatment of upper done by punching the raw edge of the upper so as to form an angle or semi-circle. Gimping is sometimes done in the edge of sock lining of fancy shoes and sandals.

Girth

The distance round the foot, for example, at the joints.

Glue paste

A cheap and effective adhesive used for labelling and Louis heel attachment. Glue and gelatine are both derived from the skins and bones of animals.

Golf Disks

Small rubber or metal inserts placed in the bottom of golf boot or shoes to prevent slipping.

Golfers foot

A temporary disorder with strain at outer side of leg.

Golf shoe

A kind of sport shoe with or without hot nails used by golf players.

Golosh

An over shoe or boot usually of rubber and also with a type of vamp having its wings extended along either side.

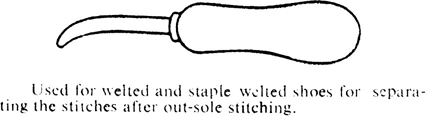

Goodyear welted construction

A very flexible method of boot or shoe construction in which the insole and the upper are sewn to the welt which in turn is stitched to the sole. No seam is visible inside the boot or shoe.

Gore shoe

A shoe with elasticized side or front.

Goring

A strong kind of rubberized fabric used in style footwears.

Grading patterns

This is to produce patterns of different sizes and fittings, proportionately from a model either by machine or by a hand tool.

Graft sole

A term referring to three quarter length sole, which may be either straight or curved graft.

Grecian slipper

A slipper with a separate counter which can either be whole cut or in two pieces with a plain vamp.

Grinderies (Metallic)

Metallic auxilliaries, such as eyelets, nails, tacks, rivets, heel tips, toe tips, screws, etc., used in footwear construction are grouped under the name grinderies.

Groove channel

A type of open channel where an open groove in the shape of ‘U’ is cut in the sole at a uniform distance along the edge to allow the stitches to bed in it. This is generally done on hard or thick leather, rubber, plastic nitric or resin soles.

Groover

A small cutting tool, used in making grooves on soles.

Gun boot

These are knee high waterproof rubber boots generally used in chemical factories to protect the feet against injurious chemicals, and also against rain water.

Gun spray

An item of kit resembling the shape of a revolver which enables the footwear upper finisher to spray the dressing uniformly all over the footwear. The gun operates under compressed air pressure, the pressure and the range of the spray can be adjusted to suit the requirement.

Gusset

A side piece or insert of rubber webbing in the side of a congress shoe.

Gypsy seam

A seam running from throat, straight down the front of a boot or shoe to the toe, making a vamp.

Half bellows

A full length tongue attached to the vamp’ and all the way up on both sides of quarters.

Half double sole

An out sole composed of one full sole to heel with a slip sole above it.

Half sock

Soles of half length, extended usually about 12 mm below the joint line, used by repairers.

Half Soles

Soles of half length, extended usually about 12 mm below the joint line, used by repairers.

Hallux Regidus

This is a condition in which the big toe joint is enlarged, and movement in it is very limited or absent. The toe itself is not deflected from its normal position, as in hallux valgus.

Hallux valgus

Hallux valgus is a displacement or buckling of the bones of the first metararsoPhalangeal joint with the great toe being displaced towards the other toes and the head of the first metatarsal bone being forced inward. This is also known as bunion.

Hammer Toe

The toe that is contracted or buckled up in the middle which resembles a hammer in form and is called a hammer toe. This is caused by wearing short or narrow shoe.

Hand Lasting

Lasting of footwear by hand method.

Hand made footwear

A name given to the process of hand made footwear of any construction, generally applicable to welted method of construction.

Hand Tacks

These are used for insole tacking, assembling, jointing, corner tacking and cobbling operation done by hand method. These are not used in machine. The tacks are produced by cut tack method with heads somewhat thicken than the machine cut tacks and with a fine sharp point which enables the user to push them far enough into the material by light finger pressure.

Hand welting

Attaching of welts with stitches by hand.

Hassock Heel

Descriptively rounded heel.

Head of the Base

The upper end of a bone of the foot.

Heel

The seat part of the footwear bottom sometimes attached separately and sometimes an integral part of the sole. It may be of leather, rubber, wood, plastics (like PVC, polyurethane, etc,) nitrite, masonite board, particle board, etc, and may be of various types given under their non names, namely, Spanish, Louis, Wedge, etc. The heel tip/top lift is an integral part of the heel.

Heel Attaching

Fixing the heel to the seat of the footwear permanently.

Heel Ball

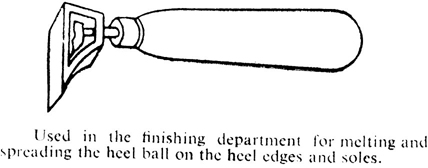

Fakes, prepared from wax with other ingredients, used for polishing sole and heel edge and bottom of footwear.

Heel Base

The part of the heel next to the sole usually made concaved, to fit the seat of the sole.

Heel Bone

See ‘Base of Bone’.

Heel Breast

The front edge of the heel facing towards the toe.

Heel Breasting

Removing the surplus material from the heel breast by cutting.

Heel Brace

A metal brace or frame to the outside of a footwear to keep the heel straight.

Heel Building

Process of attaching several lifts having a rand or skeleton lift at the base according to required thickness. Heels of inside attachment have their top pieces attached by slugging wire or nails.

Heel Girth Measurement

The girth measurement around the tip of the back of the heel and the middle of the curve of the foot (where the leg joints with the foot).

Heel Grip

A name given to a counterpiece of either suede or sheep skin with flesh side out inserted at the back of the quarter where this serves as a counter lining and does not allow the foot to slip out of the footwear while walking and due to its rough surface, holds back the sock from moving.

Heel Height

The thickness of the heel in relation to the toe spring. It is determined by the style of the last. The correct heel height is that which gives from 6 mm to 8 mm toe spring for normal walking shoes.

Heel Iron

A hand tool used for hell ironing.

Heel ironing

See ‘Burnishing Heel’.

Heel of the Footwear

Support placed under the quarter to ensure that the footwear lies correctly. The seat part of the footwear bottom, sometimes attached separately and sometimes as an integral part of the sole. It may be of leather, rubber, wood or any synthetic material. They are of various types given under their own names, like Spanish, Louis, Wedge, etc.

Heel pad

A pad of leather, felt, rag, etc. placed in the heel of the footwear inside and covering the insole at the point where the heel of the foot rests.

Heel Lifts

Layers of material used for intermediate heel building.

Heel pins

Nails, grooved or spiralled specially for attaching heels of boots and shoes.

Heel plate

Steel plate made to the size of the heel in U-shaped having four to six nail holes for attaching it to the heel.

Heel scouring

Shaping and smoothening out the edge or surface of the heel with abrasive.

Heel sent

The portion of the boot or shoe bottom where the heel is lifted.

Heel shave

A tool just like a spoke shave with holding device and a blade in the middle. The blade may be flat or convex to fit the shape of the heel.

Heel sock

See ‘Seat Soak’.

Heel Stay

A pasted lining placed in the heels of Oxford or other low cut shoes to prevent the shoe from slipping at the heel.

Heel tip

A reinforcement of metal, rubber or plastic fixed to the back outside edge of a heel top piece to give increased wear resistance at this point during walking.

Heel trimming

Removing the surplus material around the heel edge and to shape it.

Held Together Closing Upper

A system of closing of upper in which the machinist positions section to section to the mark provided and stitches along while maintaining the fit by holding the sections firmly.

Himalayan boot

See ‘Everest boots’.

Hinged lasts

Lasts made in two parts, hinged together for easy insertion and withdrawal of it from the footwear.

Hob cutter

Extra large sized cutters having sixteen cutting blades around the circumference creases and are used for trimming low heel, like those of children’s footwear. These are also used by footwear repairers for their trimming machines for cutting the forepart where no creases are required like in new footwear.

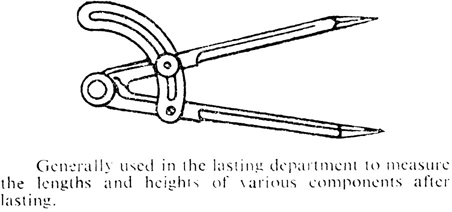

Hob nails