In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 326:2002

ICS 77.100.50

EAST AFRICAN COMMUNITY

© EAC 2002

First Edition 2002

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East Africa. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Partner States in the Community through their National Bureaux of Standards, have established an East African Standards Committee.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2002 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.int

* © 2002 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iiCopper, chromium and arsenic composition is a water borne salt timber preservative for application to timber by vacuum pressure impregnation.

The preservative is a finely dispersed paste of viscosity and solubility so as to facilitate easy and rapid preparation of aqueous treating solutions so as to preserve timber against insect attack, termites and fungal decay.

This East African Standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this East African Standard to establish appropriate safety and health practices and determine the applicability of suitable regulatory limitations prior to utilization. Such regulations shall govern the use of wood preservatives in East Africa.

In the preparation of this East African Standard assistance was drawn from the following standards:

BS 4072:1999, Copper/chromium/arsenic preparations for wood preservation published by the British Standards Institution.

ISO 4793:1980, Sintered filter for laboratory use — Specification published by the International Organization for Standardization.

In reporting the results of a test made in accordance with this East African Standard, if the final value observed or calculated is to be rounded off, it shall be done in accordance with EAS 124, Rounding off numerical values.

The annexes are integral parts of this East African Standard. They record the apparatus necessary for testing. However, for the purpose of this East African Standard, it is supposed that equipment at testing laboratories will meet the demands given in this East African Standard.

iiiCopper/chromium/arsenic composition for the preservation of timber — Specification

This East African Standard specifies requirements for two types of water-borne preservatives containing mixtures of compounds of copper (ii), chromium (vi) and arsenic (v).

For the purpose of this East African Standard, the following references shall apply:

EAS 123, Water — Distilled quality — Specification

EAS 325, Wood preservatives and treated timber — Guide to sampling and preparation of wood preservative and treated timber for analysis

TZS 660, Wood preservatives and treated timber — Quantitative analysis for copper/chromium/arsenic formulations

EAS 124, Rounding off numerical values

For the purpose of this East African Standard, the following definitions shall apply:

any junction between two electrolyte solutions of different composition

a filter produced from porous materials formed by the thermal bonding of particles

a characteristic of a filter related to pore diameter

a characteristic of a filter related to the rate of flow through it under specified conditions

the solution of which the pH value is required

a high impedance instrument by means of which either the pH of a solution or the potential difference between a pair of electrodes immersed in a solution is indicated

an external system that incorporates a fitting solution and a means, such as a ceramic plug or forming the liquid junction

iThe preservative shall consist essentially of a mixture of compounds of copper (ii), chromium (vi) and arsenic (v).

The mixture of compounds shall be selected to be consistent with this Clause and 7.1.

The preferred mixtures of compounds are either

NOTE Attention is specially drawn to the toxic nature of the formulations and their solutions that may be injurious to health if adequate precautions are not taken. Therefore, particular care and the use of appropriate protective clothing is necessary. Also special precautions are required for disposal of these solutions.

The nominal composition of the two types of preservatives (designated Type 1 and Type 2) together with minimum concentration of each component shall be as given in Table 1. The sum of the concentrations of the individual components shall be not less than 95 % m/m.

NOTE Variation in composition from the nominal composition may arise because of variations in the purity of the ingredients and the lack of homogeneity of the mixture.

The preservatives shall be supplied as mixtures.

NOTE The usual forms are dry ingredients, paste or concentrated solutions.

Containers shall carry information on the mass of preservatives equivalent to unit mass of nominal composition.

Preservatives as supplied may differ in composition from the nominal composition as a result of removal or addition of water. In such cases the ratio of the active ingredients shall be in the same proportions by mass as are the nominal compositions given in Table 1.

| Ingredients | Type 1 | Type 2 | ||

|---|---|---|---|---|

| Nominal | Minimum | Nominal | Minimum | |

| Copper (expressed as CuSO4.5H2O)% m/m | 32.6 | 29.5 | 35.0 | 31.5 |

| Chromium (expressed as Na2Cr2O7.2H20)% m/m | 41.0 | 37.0 | 45.0 | 40.5 |

| Arsenic (expressed as As205.2H2O)% m/m | 26.4 | 23.5 | 20.0 | 18.0 |

| Total composition | 100.0 | 90.0 | 100.0 | 90.0 |

When tested in accordance with Annex A, the pH value of a solution equivalent to 20g/L of the nominal preservative composition shall be neither lower than 1.8 nor higher than 2.8.

2When tested in accordance with Annex B the content of insoluble matter shall not be greater than 0.1 % m/m for paste or concentrated solutions, and shall not be greater than 0.25 % m/m for dry powder formulations.

The preservative shall be sampled in accordance with EAS 325.

The copper, chromium and arsenic content shall be determined in accordance with TZS 660 on a sample prepared in accordance with EAS 325.

3(normative)

Ordinary laboratory apparatus, together with the following:

sintered glass filter, suitable for laboratory uses with reasonable pore size index and permeability;

pH meter, capable of making a measurement with tolerance ± 0.2 in a limiting accuracy class and fitted with suitable electrodes; and

one-mark volumetric flask, 500 mL capacity suitable for laboratory use.

Water, complying with EAS 123.

Take a mass of the preservative sample equivalent to 10 g ± 1.1 g of the nominal composition and weigh it to the nearest 0.001g. Transfer this test portion to a beaker and dissolve it in 250 mL of hot water around 40 °C,, stirring continuously. Cool the solution to room temperature and filter it through the pre-weighed sintered glass filter into the one mark volumetric flask. Wash the beaker and the residue on the filter five times with 10 mL portions of hot water at approximately 40 °C, collecting the washings in the flask. Dilute to the mark with water. Reserve the filter and residue for the determination of insoluble matter if required (see Annex B).

Determine the pH of the test solution prepared in accordance with (A.3) at 27 °C ± 2 °C using the pH meter which is intended for determining a pH value within a broad range.

4(normative)

Sintered glass filter, suitable for laboratory uses with reasonable pore size index and permeability.

Laboratory drying oven, capable of being adjusted to 105 °C ± 5 °C.

Weigh a mass of the preservative sample equivalent to 10 g ± 0.1 g of the nominal composition to the nearest 0.001 g and dissolve it in water, filter and wash as described in (A.3) or, if the pH has already been determined, use the residue on the filter.

Transfer the sintered filter containing the residue from (B.2) to the drying oven (B.1.2) previously adjusted to 105 °C ° ± 5°C. Dry initially for a period of 1h, cool in a desiccator to room temperature and re-weigh. Repeat the drying, cooling and re-weighing operations at suitable intervals until the difference between two successive weighings is not greater than 0.5 mg.

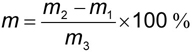

The percentage by mass of insoluble matter in the preservative m is given by the following equation:

where

| m1 | is the mass in g of the sintered glass filter; |

| m2 | is the mass in g of the sintered filter and residue after drying; |

| m3 | is the mass in g of preservative taken for the determination. |