In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 325:2002

ICS 71.100.50

EAST AFRICAN COMMUNITY

© EAC 2002

First Edition 2002

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East Africa. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Partner States in the Community through their National Bureaux of Standards, have established an East African Standards Committee.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2002 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.int

* © 2002 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iiTimber has many limitations, which are dictated by its natural form. Therefore, one has understand its mature and limitation so as to apply counter measures to make it more durable hence good quality for the intended end uses as well as have long life. These limitations can be minimized or even removed by applying test standards, code of practice or design and other standards techniques for timber preservatives and treated timber analysis. This guide will assist end users, researchers and designers towards those limitations.

In the preparation of this East African Standard, assistance was derived from:

BSEN 5666-1:1987, Analysis of wood preservatives and treated timber — Guide to sampling and preparation of wood preservatives and treated timber for analysis published by the British Standards Institution.

Acknowledgement is made for assistance received from the source.

In reporting the results of a test made in accordance with this East African Standard, if the final value observed or calculated is to be rounded off, it shall be done in accordance with EAS 124, Rounding off numerical values.

The annex gives information on the relevant national Acts and Regulations relating to the reference made in this East African Standard.

iii| 1 | Scope | 1 |

| 2 | Field of application | 1 |

| 3 | Health and safety hazards | 1 |

| 4 | Guidance on sampling preservatives | 1 |

| 5 | Guidance on sampling treated timber | 4 |

| 6 | Method for the determination of the moisture content of the preservative-treated timber | 8 |

| 7 | General considerations in sampling for analysis | 9 |

Wood preservatives and treated timber — Guide to sampling and preparation of wood preservatives and treated timber for analysis

This East African Standard gives guidance on the general procedures to be followed in the sampling and preparation for analysis of preservatives and preservative-treated timber.

No attempt has been made here to define rigidly any detailed methodology to be followed in operations in these areas because this can depend upon the nature of the preservative, the method of treatment, and the particular requirements of relevant approval authorities.

This East African Standard is applicable to the provision of appropriate samples for analysis which may be used to check the content of active components in preservative formulations, and to determine the identity, location and concentration of preservatives in treated timber. The techniques described may be employed in a wide variety of applications ranging from laboratory research through to the checking of preservatives or preservative-treated timber for arbitration purposes. In most cases it is possible, by chemical analysis, to determine whether or not a sample of timber has received a preservative treatment and the results can often give an indication of the type of treatment the wood has received when due consideration is given to other relevant factors, such as timber species and heartwood/ sapwood ratio, in the samples under test.

No attempt has been made in this East African Standard, to lay down detailed procedures to be adopted for control purposes at manufacturing plants where large volumes of preservative are to be sampled.

Furthermore, the objectives of each analysis, and the demands of the individual analytical technique, may impose their own requirements with regard to sampling and subsequent handling. Therefore, it is essential that the sampling plan for each operation should be devised in the light of the particular objective, using professional judgment based on experience.

All preservatives may be considered potentially toxic both to man and to the environment and should be handled with care and in accordance with the specific recommendations for safety agreed with national and international authorities. The manufacturer’s instructions should also be observed.

In handling solid timber after treatment, protective gloves should be worn if the timber is still wet or contains solvent. Once the timber has dried, unless blooming of the preservative on the surface is noted, no special precautions are necessary in handling food or smoking.

When treated, timber is machined or mechanically sanded or sawn, an efficient dust extraction system should be used, or, failing this, the operator should be provided with, and should wear, appropriate respiratory protection.

The organic solvents commonly used for applying preservatives are flammable and it is essential that care be exercised in handling such materials.

The method of sampling chosen should ensure that the sample obtained is as representative as possible of the total consignment.

1The least number of containers, e.g. drums to be sampled from any given consignment of preservative materials irrespective of whether the materials are solid or liquid, should be the nearest whole number to the square root of half the total number of drums in the consignment (see Table 1). The drums to be sampled should be taken at random.

| Number of drums in consignment (x) | √(x/2) | Number of drums to be sampled |

|---|---|---|

| 10 20 50 100 |

2.24 3.16 5.00 7.07 |

2 3 5 7 |

It is essential in all cases that the sample container and its closure be made from material which is inert to the particular preservative under investigation. Thus, glass bottles are unsuitable for bi-fluoride solutions and polyethylene containers should not be used for petroleum solvents.

Prior to analysis, samples should be stored in a cool dark place.

A suitable sampling device for the purpose of sampling the preservative in a drum is a sampling spear of internal diameter 32 mm and sufficiently long to reach the bottom of the drum.

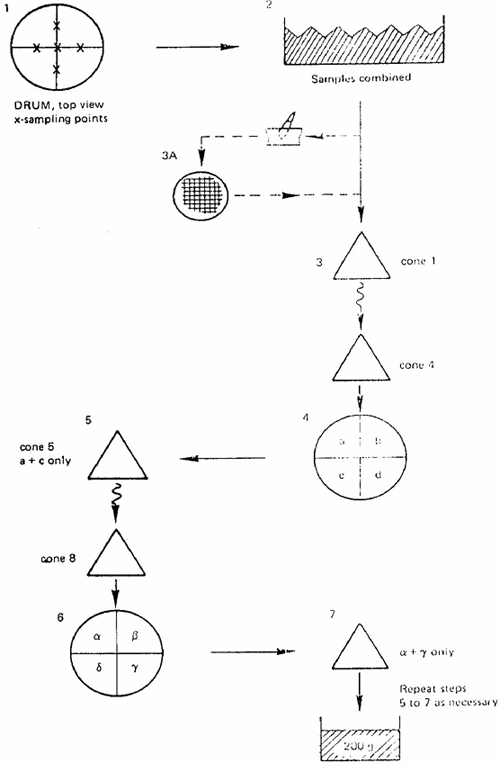

Before sampling, mix the contents of the drum as thoroughly as possible. Take great care to minimize the moisture picked up by the sample during sampling, mixing and reducing processes. Using the sampling device, take five samples (see Figure 1), one from the centre of the drum and the other, four from points on a pair of diameters at right angles to each other, which are mid-way between the central and the side of each drum selected for testing (operation). Ensure that the sampling spear reaches the bottom of the drum. Combine the five samples of approximately 400 g each in a clean, dry airtight container of about 2.5 kg capacity. (Operation 2)1. If necessary, grind the whole of the bulk sample to pass a test sieve of nominal aperture size 2.00 mm, ensuring that no residue is left on the sieve.

Mix the sample well (operation 3A). Transfer the entire sample to a clean dry surface and heap into a cone (operation 3, cone 1): Turn over to form a new cone until the operation has been carried out three times (operation 3, cone 4). Form each conical heap by depositing material on the apex of the cone so that the portions which slide down the side are distributed as evenly as possible, and that the centre of the cone is not displaced. If some of the larger aggregates of the mixture roll and scatter round the base, either push them back to the edge of the heap or break them and distribute them evenly over the heap.

Flatten the final cone from the mixed contents of the container by repeated vertical insertions of the edge of a board, commencing about the centre and working radial round the cone, lifting the board clear of the material after each insertion. Carry out this operation so that the flattened heap is of uniform thickness and diameter and the centre coincides with the centre of the original cone (operation 4).

1 To ascertain the homogeneity of the contents of a drum, individual spear samples may be analyzed.

2

Figure 1 — Sampling of a solid preservative

Quarter the heap along two diameters which interest at right angles, using a suitable divider. Shovel one pair of opposite quarters into a cone and reject the remainder (operation 5). Mix the cone three times (operation 5, cone 8) as described above, flatten the cone and quarter along two diameters (operation 6).

Repeat these operations until a reduced sample of about 200 g remains (operation 7). Immediately enclose the test sample in an airtight container until required for analysis.

A suitable device is a wide – mouthed sampling can of about 500 ml capacity fitted with a long, stiff handle so that it can be submerged in the material to be sampled. It should also carry a removable lid to which a second stiff handle is attached, so that when the can is immersed in the paste the lid can be removed, allowing the can to fill.

3A stout steel stirring rod, suitable for stirring the contents of a drum is also required.

Thoroughly mix the preservative in each drum before the samples are taken. Displace any settled material from the base of the drum using the stirring rod. Reclose the drum and homogenize the contents by rolling and shaking the drum. Mechanical agitation should be used if available. Re-open the drums and test the contents for uniformity by probing with the steel rod. Continue alternate stirring, shaking and rolling until the contents are of a homogenous consistency.

Take three sample from each drum with the sampling can, one from just below the surface of the preservative, the second at a position about halfway between the surface and the base of the drum and the third from near the base. Pour the tree samples from each drum into a clean glass or plastic container and mix together.

NOTE Should homogenization prove to be impossible, it will be necessary to dissolve or disperse the whole contents of the drum and take aliquot portions for analysis.

A suitable sampling device consists of a thick- walled glass tube of about 13 mm internal diameter, cut to a length suitable for extracting the treatment solution to a depth about 600 mm. The actual length of the tube will depend on the container to be sampled

To ensure retention of the liquid column when the tube is withdrawn from the solution, the bottom end of the tube should be softened in a flame and the glass allowed to collapse until the opening is reduced to about 6 mm diameter.

Insert the glass tube vertically into the well-mixed liquid in the can to be sampled, and allow the liquid to reach its natural height in the glass tube. Place the thumb on the upper end of the tube to prevent escape of the liquid from the tube while it is being lifted. Lift the tube from the can and insert the end into the sample bottle. Allow the liquid to drain into the sample bottle by removing the thumb. If required, bulk the sample from the various cans. Mix and remove a suitable volume for analytical purposes. Seal the sample can.

The effectiveness of any treatment depends on the introduction of suitable quantities of preservative to a sufficient depth below the surface of the wood to protect from biological attack, and to combat existing infection. The degree of protection required varies with the severity of the environment to which the treated timber is exposed.

The penetration of preservatives into the timber is governed by three main factors:

In practice, therefore, a wide range of preservative distribution ‘profiles’ is encountered within treated timber and any methods designed for the detailed examination of such materials should make provision not only for the detection and/or measurement of active components but also for the determination of their location within the timber samples or wooden members. The exact sampling technique to be employed in any particular case will depend on the factors enumerated above and should also take account of, where required, the product’s end use and location.

The primary requirement of any sampling system is that the samples taken should be as representative as possible of the main stock of treated wood. These should be selected so as to avoid knots, splits and other growth irregularities.

Samples consisting entirely of heartwood should be avoided unless the timber under test is all heartwood, otherwise the analytical results will indicate a value which is too low.

Similarly, samples consisting entirely of the more permeable sapwood should be avoided unless the timber under test is all sapwood or loading of the sapwood only has to be determined, otherwise the results will indicate a value which is too high. It should be borne in mind also that preservative enters timber most rapidly through the end grain, and relatively high loadings are obtained in these areas.

The effect of end penetration on the overall loading of a stick will thus depend on the length of the stick while the contribution of lateral penetration to this total will vary with the cross-sectional area of the timber. It is therefore import that the dimensions of the wood components to be sampled are taken into account when deciding the sampling procedure to be adopted.

The numbers and distribution of samples to be taken should be decided for each analysis (see Clause 1). Clearly, pressure-impregnation of a permeable timber will result in a relatively even distribution of preservative within the wood while, at the other extreme, dipping or brushing an impermeable species will provide only a thin, less uniform, ‘envelope’ of preservative which is confined to the outermost layers of the wood. It is evident, in this latter case, that more extensive sampling may be required to give meaningful results. When sampling of constructional timber has to be undertaken, it is important to ensure that no structural weakening arises as a result of this process, and sampling may have to be limited on this account. The advice of an experienced specialist in the building field should be sought before commencing operations.

In many situations, samples have to be taken from preservative-treated timber which has been subjected to further processing such as painting or gluing, or which has been otherwise contaminated on the surface. In such cases, care has to be taken to avoid interference in the subsequent analysis by excluding such extraneous material form the sample.

Cut a complete cross-section, 6 mm thick, from the timber. The sample should be taken, if possible; at least 300 mm from the end. In all cases, and especially in shooter billets, it is essential to take into account the effects of any penetration through the end grain.

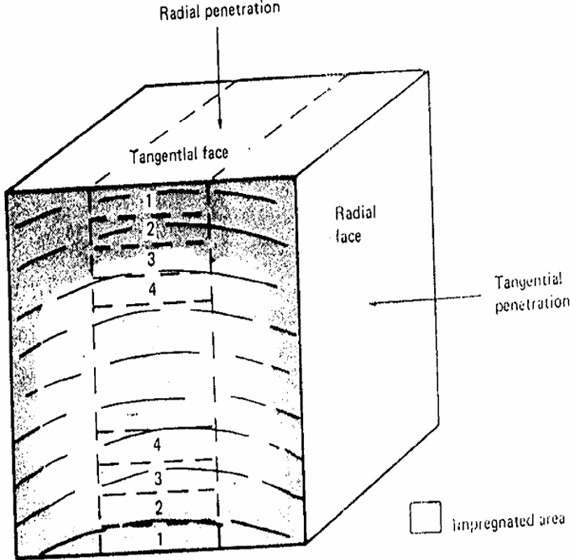

Cut a sample of the required lateral depth at least 300 mm from the end. If profiles of penetration at different depths are required, it will be necessary to eliminate edge effects. For example, if radial penetration profiles are required, zones contaminated by tangential penetration should be avoided (see Figure 2).

5

Figure 2 — Example of a sampling technique for the study of radial penetration

Depending on the purpose of the test, it may be desirable that the sample consists of sapwood only, or of heartwood only. If both are present, it may be necessary to distinguish between them before selecting analytical samples from the block, if possible.

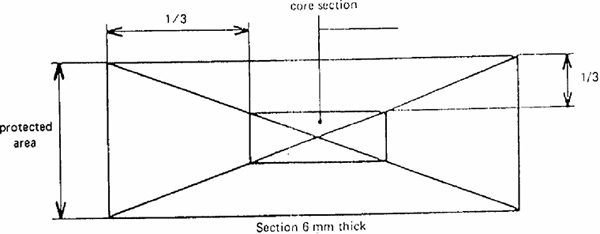

Cut a cross-section of 50 mm in the longitudinal direction form the timber at least 300 mm from the end. Dry the section to a moisture content between 8 % and 18 % by air drying or in an oven (see 6.2) at a temperature of less than 60 °C. Special precautions should be observed when dealing with volatile preservatives and oven drying may not be suitable (see Clause 7). From the centre of this 50 mm section cut a 6 mm section and cut from it the one-ninth core as illustrated in Figure 3.

6

Figure 3 — Preparation of 1/9 core section to determine core loading

If the timber to be sampled already has moisture content between 8% and 18%, the 6 mm section for core preparation can be cut directly.

Preservatives in treated wood are usually not evenly distributed, and it is often required to determine preservative loading over very small areas. To do this, cut sections up to 0.2 mm in thickness, on a microtome, from air-dry specimens sawn form the bulk of the treated wood or from borings taken with a Mattson borer. It is also possible to cut sections with a wood plane, but this method is not so accurate.

Samples may also be taken using Forstner auger bit which produces thin shavings and results in a smooth – sided, flat bottomed hole of well defined area. If incremental borings are taken it is possible to examine the distribution of preservative with respect to depth, though this method is not as accurate as that using a microtome because of the possibility of compressing the wood during sampling.

To obtain a representative sample, it is necessary to include both early and late wood in the thin sections taken for analysis. This is because concentration gradients of preservative can occur across the annual rings. Sections taken from the radial and transverse faces of the sample will contain both early and late wood but sections cut form the tangential face may contain only one or the other.

To make up a representative sample from the tangential face, thin sections should be cut over several annual rings, provided there is sufficient depth of preservative penetration to allow this.

NOTE In order to avoid loss of sample, it is necessary for the preparation of thin section samples (5.2.5) and for sawdust sampling (5.2.6) to be carried out in a draught-free environment; appropriate precautions should be taken to protect the operator (see clause 3).

Samples may be cut as solid sections (which may afterwards be converted to sawdust, for example by pulverizing the dry sample in a beater mill or hammer mill) or they may be produced as sawdust directly from the piece of timber under study (see note following 5.2.5). Since the preservative, by virtue of its original location within the timber, may well be concentrated in sawdust particles of a particular size, it is important that no fraction be rejected before analysis. The product may be homogenized, for example by continuing grinding until all the sample passes a test sieve of nominal aperture size 425 µm and mixing well before taking aliquot portions.

7Care should be taken to minimize the risk or evaporative losses or degradation of organic preservatives due to excessive generation of heat in the conversion process.

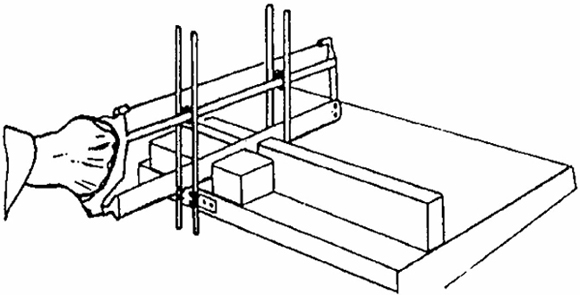

The fastest method of sampling it to make a clean uniform sawcut through the cross-section of a specimen and collect the sawdust produced for analysis. During sawing, it is important that the saw-blade is held rigidly so that sideways motion of the blade is virtually eliminated. An unrepresentative sample will be obtained if there is any variation in the width of the sawcut through the specimen.

To ensure a uniform cut, modify a mitre machine to allow easy sawdust collection by fitting it with a shallow V-shaped bed containing a simple gripping device over which the saw is supported on four rods (see Figure 4). Fit the machine with a medium cut blade with four to five points per centimetre.

Saw the specimen through, whilst it is held firmly mounted on the saw bench, and collect the sample by brushing the sawdust into a tared beaker for weighing.

Figure 4 — Modified mitre machine for the preparation of the sawdust sample

If the average moisture content of a piece of treated timber is required, cut a sample consisting of a full cross-section 13 mm to 19 mm thick, not less than 300 mm from one end. Using a test borer consisting of a hollow auger and extractor, bore from the sapwood face to the centre of the section or to the specified depth (see note) if the cross-section exceeds 6,000 mm2.

NOTE The depth to be utilized for large cross-section members should be specified in the commodity specification.

If the information is required on the moisture content of the analytical samples, matched material or sample aliquots may be employed, but not the samples to be used for chemical analysis.

If the sample cannot be weighed at once, put it into a stoppered weighing bottle or other airtight container immediately after it has been prepared (see 4.1).

Weigh the sample as soon as possible after preparation (m1) and place it in an oven which has already been adjusted to a temperature of between 100 °C and 105 °C. Remove the sample periodically, cool it in a desiccator and reweigh (m2). Repeat the drying, cooling and weighing at

8suitable intervals until any further loss in mass is at a rate not exceeding 0.1g/24 h, or for samples in excess of 20 g dry mass until the loss between two successive weighings is not greater than 0.5 % 24h.

NOTE Some loss of preservatives by volatilization or degradation may be incurred during this process and this may lead to somewhat higher values for moisture content. In calculating the results, therefore, allowances should be made for such evaporative losses as well and for any degradation of the preservatives.

If the timbers have a high content of volatile substances that are non-miscible with water, such as may arise with creosote treatment, is may be preferable to use a Dean and Stark distillation method for the determination of moisture content.

NOTE 2 It is advisable for the drying oven to be in a fume cupboard to avoid exposure of personnel to any fumes.

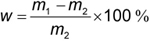

Calculate the moisture content, w, as a percentage of the dry mass, from the following formula:

where

| m1 | is the mass of sample when wet in grams |

| m2 | is the mass of sample after drying in grams |

Analytical samples isolated by the methods outlined in clauses 4 and 5 may be converted, by a variety of techniques, into a form suitable for further processing.

Subsequent operations may include preparation of the wood surface, conversion to sawdust, chemical digestion, extraction, etc.

The precise procedures to be followed depend on the requirements of the analytical methods.

However, reference has already been made (5.2.6 and 6.2) to important consideration, i.e. the need to ensure homogeneity of the sample and to avoid, as far as possible, losses of preservative by evaporation.

Drying under ambient conditions is therefore recommended and moisture content determinations should not normally be carried out on the samples selected for further analysis. In addition, migration of aqueous or organic solvents during the drying process may well cause redistribution of the active components within sold wood samples and it may be necessary to use a freeze- drying technique in distribution studies.

9