In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 324:2002

ICS 71.100.50

EAST AFRICAN COMMUNITY

© EAC 2002

First Edition 2002

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East Africa. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Partner States in the Community through their National Bureaux of Standards, have established an East African Standards Committee.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2002 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.int

*©2002 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

ii| 1 | Scope | 1 |

| 2 | References | 1 |

| 3 | Definitions | 1 |

| 4 | Exchange of information | 1 |

| 5 | Preservative solution | 3 |

| 6 | Condition and preparation of timber for treatment | 3 |

| 7 | Loading in treatment cylinder | 4 |

| 8 | Treatment schedules | 4 |

| 9 | Handling and drying of treated timber | 5 |

| Annex A (normative) Post-treatment operations on treated timber | 6 | |

| Annex B (normative) Method for determination of concentration of working solution | 7 | |

| Annex C (normative) Penetration | 9 | |

| Annex D (normative) Methods for determination of moisture content of timber before treatment | 10 | |

This East African Standard calls for the use of procedures and substances that may be injurious to health if adequate precautions are not taken. It refers only to technical suitability relating to the method of timber treatment against insect attack, termites and fungal decay.

This East African Standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate health and safety practices as well as determine the applicability regulatory limitations prior to use, which govern the use of wood preservatives in East Africa.

Requirements to be observed in post-treatment operations are given in Annex A and do not necessarily relate directly to treatment using CCA preservative.

NOTE Users of treated timber may also use this annex as guidance.

In addition to the definitive procedures, this East African Standard also includes details that need to be specified and/or which require prior agreement between the operator of the treatment process (the treater) and the customer.

In the preparation of this East African Standard, assistance was the derived from

ASTM D 1760:1986a, Standard specification for the pressure treatment of timber products, published by American Society for Testing and Materials, Vol. 04.09.

BS 4072:1999, Copper/Chromium/Arsenic preparations for wood preservation, published by the British Standards Institution.

Acknowledgement is hereby made for the assistance received from these sources.

In reporting the results of a test made in accordance with this East African Standard, if the final value observed or calculated is to be rounded off, it shall be done in accordance with EAS 124:1999.

ivCopper/chromium/arsenic compositions for the preservation of timber — Method for timber treatment

This East African Standard prescribes procedures for treatment of timber using water borne copper/chromium/arsenic (CCA) preservative formulations complying with EAS 326.

It does not specify details of treatment relating to specific end uses for which reference to the relevant commodity specification should be made.

For the purpose of this East African Standard, the following references shall apply:

EAS 24, Glossary of terms used in timber industry

EAS 325, Wood preservatives and treated timber — Guide to sampling and preparation of wood preservative and treated timber for analysis

EAS 326, Wood preservation by means of copper/chromium/arsenic compositions — Specification

EAS 124, Rounding off numerical values

For the purposes of this East African Standard, the definitions given in EAS 24 shall apply, together with the following;

any document providing details of preservative treatments required for a specific end use.

NOTE Examples of such documents are East African Standard specification, a published specification or recommendation of a relevant trade association of public authority.

In order to carry out a treatment according to this East African Standard, it is necessary for the operator of the treatment process to be provided with the following supplementary information, which shall be fully documented. The information required consists of

Any commodity specification to which reference is required for information or operating detail shall be clearly identified.

1The following information shall be stated where relevant:

if not specified in the relevant commodity specification.

The treatments parameters shall be identified and precise schedule, shall be specified. Including pressures and periods for each treatment stage (see Clause 8) unless these details are given in the relevant commodity specification.

If required by agreement between the treater and the customer, the items in 4.3.2 to 4.3.8 shall be stated.

It shall be stated whether timber showing signs of attack by sapstain fungi pinhole borers is an acceptable constituent of the charge (see 6.1.2)

It shall be stated whether a minimum hydraulic pressure of 10 bar may be used with a consequent lengthening of the standard pressure period (see 8.2.3)

It shall be stated whether analysis of the working solution is required.

It shall be stated whether analysis of the treated timber in accordance with TZS 660 is required and if so, the sampling procedure required.

It shall be stated whether the customer is to observe the treatment operation on site (see 8.4).

It shall be stated whether the treated timber is to be dried to specified moisture content and, if so, the moisture content required (see 9.2).

It shall be stated whether any post treatment operations are to be undertaken prior to delivery of the timber. If so the operations shall be in accordance with Annex A.

2The working solution shall be prepared from one of the mixtures specified in EAS 326 : 2002 (see clause 2) and shall be mixed thoroughly. The concentration of this working solution before use, when determined in accordance with Annex B, shall be not less than that specified in the relevant commodity specification.

The solution shall be stored at normal ambient temperature except that it shall not at any time be allowed to exceed 40 °C.

The pH value of the working solution shall comply with Clause 5 of EAS 326.

If specified (see 4.3.4) the proportions of the active ingredients shall be determined in accordance with EAS 324 on sample prepared in accordance with EAS 325.

On visual inspection, the surface of the timber shall be free from mud, dirt, inner and outer bark, sawdust and shavings, It shall also be free from paint, polish or other surface finish.

On visual inspection, the timber shall be free from all signs of attack by wood-destroying fungi or insects unless it has been agreed (see 4.3.2) that timber showing signs of attack by sapstain fungi and pinhole borers is acceptable.

For all timber, unless otherwise specified in a relevant commodity specification, the average moisture content shall not exceed 28 % (m/m) on an oven dry basis. The moisture content shall be determined in accordance with one of the methods given in Annex D.

For overhead line poles, the maximum average moisture content in the charge shall be not more than 28 % (m/m) on an oven dry basis for the outer 50 mm and not more than 32 % (m/m) for the inner 50 mm and not more than 32 % (m/m) for the inner 50 mm to 75 mm. The moisture content of any individual pole shall not exceed 30 % (m/m).

NOTE If timber is frozen the penetration of preservative is limited. Care should be taken not to treat timber in this condition.

All timber shall be sawn or planed before treatment to achieve the finished cross-section at the moisture content at which the timber is to be used.

NOTE As far as possible, all crosscutting, boring, drilling or other fabrication should be carried out before treatment (but see A.1).

3If incising is specified, the incisions shall be made parallel to the general direction of the grain. They shall penetrate to a depth of approximately 20 mm and be spaced 25 mm apart in rows extending across all four faces of the timber. The distance between the rows shall be 60 mm and incisions in adjacent rows shall not be in direct line but staggered at intervals of approximately 6 mm, i.e. incisions in every fourth row are in direct line.

NOTE Sawn timbers rated as resistant to preservative (e.g. East African pencil cedar), 75 mm or thicker, and intended for exterior use, may benefit from incising before treatment.

If incising is specified in the relevant commodity specification for other sawn timber, it shall be carried out as described above.

If it is not possible to segregate timber for treatment so that a charge consists of timbers of the same species and/or resistance to penetration, the most resistant species in the charge shall be identified (see 8.1).

NOTE It is preferable to segregate the timber.

The pieces of timber shall be stacked so that the solution will have access to all faces of the timber.

NOTE A method of achieving this if planed timber is to be treated is to separate the pieces of timber by sticks or laths at appropriate intervals.

The timber shall be treated with an aqueous solution of the preservative in accordance with either:

The treatment schedules shall be as specified in 8.2 or 8.3 as appropriate.

The treatment schedule for charges of mixed species or of timber of different resistance to penetration shall be that appropriate to the most resistant of the timber species present (see also Annex C and Note under 6.2).

Subject the timber to an initial vacuum of at least – 0.8 bar and maintain at this pressure for the period of time specified in the relevant commodity specification.

On completion of the initial vacuum stage flood the cylinder with preservative solution before releasing the vacuum.

4Subject the timber and preservative in the cylinder to a minimum hydraulic pressure of 12.4 bar for the period of time specified in the relevant commodity specification. The pressure period begins when the pressure first reaches 12.4 bar.

At the end of the pressure stage. Empty the cylinder of preservative solution and apply a final vacuum. Release the vacuum as soon as the gauge reading reaches a vacuum of -0.8 bar or after 15 min, whichever is sooner.

After loading, flood the cylinder with preservative solution at atmospheric pressure.

Subject the timber and preservative in the cylinder to the pressure and period described in 8.2.3.

If a final vacuum stage is specified by the relevant commodity specification, carry out the procedure described in 8.2.4.

During the treatment schedule records shall be kept of the actual treatment schedule.

Detailed records of the treatment schedule shall be available to the customer on request, in addition to a certificate stating that the specification has been met and including any relevant item listed in Clause 4.

Treated wood shall be held for 48 h or until drip-dry, whichever is the longer, before dispatch or erection.

NOTE Fixation of the preservative may take up to 14 days and this should be taken into account before use with metal fittings (see A.4).

CAUTION ! Skin contact with timber still wet after treatment should be avoided. If it is necessary to handle treated timber while wet, it is essential that protective gloves be worn.

If it is specified that the treated timber shall be dried to a specific moisture content (see 4.3.7) the moisture content shall be determined by the method described in EAS 325.

5(normative)

Liberally treat the exposed surfaces or bolt holes of timbers that are cross-cut, notched or drilled for bolts after any pressure impregnation treatment, by brushing, spraying or dipping with a preservation formulation recommended by the preservative manufacturer, unless otherwise specified in the relevant commodity specification.

NOTE 1 The treater may undertake post-treatment operations by agreement (see 4.3.8), or by the user of the treated timber.

NOTE 2 It should be born in mind that this remedial treatment would not replace the full preservative protection of the impregnation process.

Allow to dry to a suitable moisture content as specified for any treated timber that is to be stained, painted or varnished. Brush the surface of the dried timber to remove any dirt or excess preservative salts.

NOTE 1 Provided that the timber has been dried to a moisture content less than 25 % (m/m) any normal painting system may be used.

NOTE 2 Paint does not key satisfactorily into wet timber whether treated or untreated.

Before application of the adhesive lightly sand the treated timber or brush it with a wire brush to remove excess preservative salts. Follow the adhesive manufacturer instructions concerning the moisture content.

NOTE For internal dry conditions phenol-formaldehyde, casein or urea-formaldehyde resin adhesives are recommended. For external and damp conditions, resorcinol or pheno-formaldehyde types are recommended.

Certain types of metal fixing will be liable to corrode if the wood in which they are embedded becomes wet. The presence of CCA preservatives in these conditions will increase the risk of corrosion. Where there is a risk that the moisture content of the timber will exceed 20% (m/m), choose the metal fixings so that the effects of corrosion are minimized taking the following into account:

NOTE If only occasional dampness is expected, coated low carbon steel (e.g. sherardized, galvanized or cadmium plated) fittings may be used. Better performance will be obtained from fittings with thicker coatings.

NOTE These materials may be used if a bitumen emulsion, bitumen barrier paper or felt of other suitable water repellent barrier is placed between the timber and the aluminium sheeting.

6(normative)

Hydrometer, suitable for the uses and graduated for medium surface tension calibrated relative to water at a temperature of 15.5 °C.

Glass cylinder, of nominal capacity 500 mL preferably ungraduated.

Thermometer, total immersion type and suitable for measuring up to 40 °C.

Obtain a representative 500 mL sample of the working solution.

Transfer the solution to the glass cylinder (B.1.2) and place it on a level surface.

Insert the thermometer (B.1.3) into the solution, wait until the temperature has reached equilibrium with its surroundings and remains constant for 1 min and record the temperature before removing the thermometer.

Place the clean, dry hydrometer (B.1.1) in the solution and when the hydrometer has settled to a constant level, record the height of the solution level against the graduated scale on the stem of the hydrometer, with the eye directly in line with the surface of the solution to the nearest 0.005.

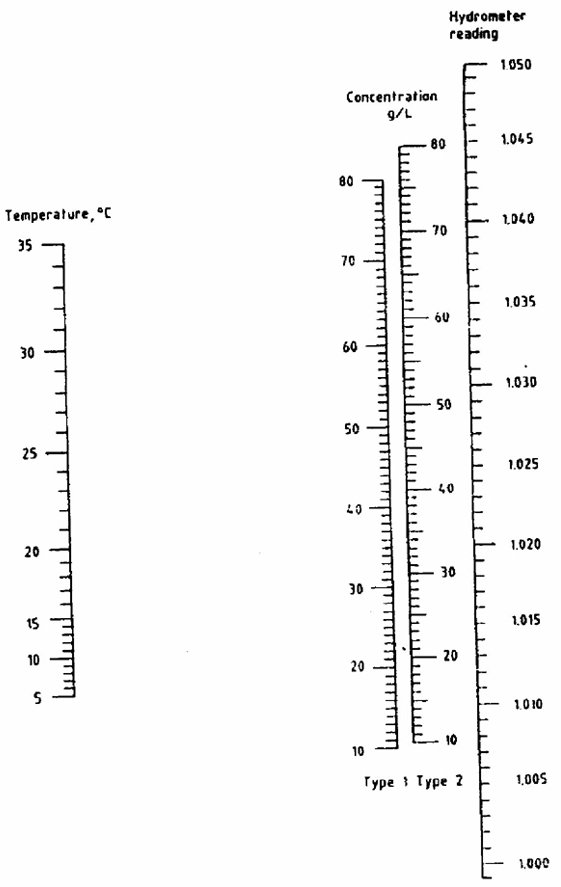

Using a hydrometer calibration, chart the accuracy which has been verified by analysis (see Figure B.1). Place a straight edged ruler across the temperature and hydrometer reading scales at the points recorded for the solution sample.

The concentration of the solution (in g/L) of the preservative type under test is read at the point of intersection on the concentration scale.

7

Figure B.1 — Hydrometer reading: Concentration calibration chart for working solutions of type 1 and type 2 CCA preservatives

8(normative)

The effectiveness of any preservative treatment depends not only on the amount of preservative taken up by the timber, but also on the depth of penetration achieved during the treatment process.

However, in all cases, sapwood defined as permeable should be completely penetrated.

If it is a requirement of the relevant commodity specification to determine the degree of penetration, this shall be carried out in accordance with the respective commodity specification.

9(normative)

Cut a sample consisting of a full cross section not less than 300 mm from one end and13 mm to 19 mm thick.

Alternatively, if it is not possible to cut the timber, take borings totaling not less than 8 g, not less than 230 mm from one end. Using a test borer consisting of a hollow auger and extractor, bore from the sapwood face to the centre of the section. For timbers having a smallest dimension of 150 mm or over, take borings to a depth of 25 mm or the full depth of the sapwood if this exceeds 25 mm.

Put the sample into a stoppered weighing bottle or other airtight container immediately after extraction if it cannot be weighed at once.

Ordinary laboratory apparatus together with the following:

Electrically heated drying oven, suitable for the uses.

Weigh the sample as soon as possible after cutting or extraction, m1 and place it in the oven (D.1.2.1) which has been already adjusted to a temperature of 103 °C ± 2 °C. Remove the sample periodically, cool it in a desiccator and reweigh it (m2).

Dry the sample to constant mass such that the loss in mass for a drying interval of 6 h does not exceed 0.1 %.

Calculate the moisture content (w) as a percentage of the dry mass according to the following equation:

where

m1 is the mass in grams of the sample when wet; m2 is the mass in grams after drying.

Take components to be measured from random positions in the charge.

NOTE The number of heartwood and sapwood faces to be sampled should reflect the relative proportions of these types of wood in the charge as a whole.

10Moisture meter, electrical resistance type, provided with insulated electrodes and calibrated for the species of wood to be measured. It shall be capable of making an individual measurement with an error of not more than 2 % (m/m) for moisture contents between 7 % and 29 % (m/m).

If the total number of components in the charge is n, take moisture readings on at least √(n/2) separate components. Measure the moisture content in the middle of each face. Drive the electrodes into the wood to a depth appropriate to the type of wood as given in Table 1, so that the line between the tips of the electrodes is in the direction of or perpendicular to the grain, in accordance with the instructions for the type of meter used.

Make at least three measurements in each measuring area 10mm to 15 mm apart to avoid any accidental error due to electrodes penetrating an inner invisible defect in the wood.

The moisture content is given by the mean of the averages of the three measurements on each face.

| Type of timber | Depth (mm) |

|---|---|

| (a) Sapwood | 25, or sapwood thickness if less than 25 |

| (b) Heartwood of wood species other than those listed in (c) | |

| Posts | 25 |

| Other components | 12 |

| (c) Heartwood of Newtonia, East African camphorwood and Mvule | 5 |