In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 296:2011

ICS 71.100.40

EAST AFRICAN COMMUNITY

© EAC 2011

First Edition 2011

i| Page | ||

|---|---|---|

| FOREWORD | III | |

| 1 | SCOPE | 1 |

| 2 | NORMATIVE REFERENCES | 1 |

| 3 | DEFINITIONS | 1 |

| 4 | REQUIREMENTS | 1 |

| 5 | SAMPLING AND COMPLIANCE WITH THE STANDARD | 2 |

| 6 | PACKING AND MARKING | 3 |

| ANNEX A: DETERMINATION OF INSOLUBLE MATTER | 4 | |

| ANNEX B: MEASUREMENT OF PH VALUE | 5 | |

| ANNEX C: DETERMINATION OF RINSING PROPERTIES | 6 | |

| ANNEX D: DETERMINATION OF MOISTURE AND VOLATILE MATTER | 7 | |

| ANNEX E: DETERMINATION OF INORGANIC SALTS | 8 | |

| ANNEX F: BIBLIOGRAPHY | 13 | |

Development of the East African Standards has been necessitated by the need for harmonising requirements governing quality of products and services in East Africa. It is envisaged that through harmonised standardisation, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Partner States in the Community through their National Bureaux of Standards, have established an East African Standards Committee.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organisations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalisation of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2002 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.org

* © 2002 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iii ivLiquid household hand dishwashing detergent — Specification

This East African Standard specifies requirements for liquid detergent for household dishwashing. It does not cover detergent for machine dishwashing and multipurpose cleaning.

ISO 2268, Surface active agents (non-ionic) — Determination of polyethylene glycols and non-ionic active matter (adducts) — Weibull method.

ISO 2271, Surface active agents-Detergents — Determination of anionic-active matter (direct two-phase titration procedure)

For the purpose of this standard the following definitions apply.

A liquid preparation consisting of surface active agents as base and primarily used for cleaning household kitchen utensils.

A chemical compound which, when dissolved or dispersed in a liquid, is preferentially adsorbed at an interface, thereby giving rise to a number of physico-chemical properties of practical interest. The compound includes at least one group having an affinity for markedly polar surfaces, ensuring in most cases solubilisation in water, and another group which has little or no affinity for water.

A unit of the final product packed in a suitable container.

A number of containers consisting of product units of the same size type and style, which have been manufactured under essentially the same conditions.

The liquid detergent shall consist essentially of anionic, cationic, non-ionic or surface active agents or their mixture. It may contain added materials such as buffers, preservatives, emollients, opacifiers, stain removers, perfumes, viscosity controlling agents, foam control agents or approved colouring agents and these shall not have any irritant or undesirable effect on the skin and hands under normal condition of usage.

The liquid detergent shall be a uniform aqueous solution, which, if so required, may be coloured. When examined visually shall be homogenous and free from any sediment or foreign matter.

It shall be free from abrasives and organic solvents, and solids shall not precipitate from it during storage at ambient temperature.

It shall not be irritating to the skin and it shall not contain any ingredients in quantity that is toxic to human beings under normal conditions of use.

On being cooled to 4.5 °C ± 0.5 °C for 24 hours, the detergent shall show no separation and shall remain liquid.

When so required, the detergent shall be perfumed. The detergent and solution of the detergent in water at 60 °C ± 2 °C shall have an acceptable odour. During storage at ambient temperature, the odour of the detergent shall remain such as to be acceptable, and when perfumed, the fragrance shall not change.

The detergent shall not leave residual test on washed articles.

When tested according to annex c the detergent shall be free-rinsing

The detergent shall, after storage period of 12 months in the original container under normal storage conditions specified by the manufacturer, still comply with all the requirements of this standard.

When the detergent is tested in accordance with Annex G, its cleaning efficiency shall be not lower than that of the standard detergent.

The liquid detergent shall also comply with the requirements of the Table 1.

| S/N | Parameter | Requirement | Method of test |

|---|---|---|---|

| 1 | Matter insoluble in water, max, % (m/m) | 0.5 | Annex A |

| 2 | pH value range | 6.0 – 9.0 | Annex B |

| 3 | Total surface active matter content, min | 12 | ISO 2268 ISO 2271 |

| 4 | Inorganic salts content, % (m/m), max | 5 | Annex E |

| 5 | Formaldehyde | Shall be absent | Annex F |

The following sampling procedure shall be applied in determining whether a lot complies with the relevant requirements of the standard. The samples so drawn shall be deemed to represent the lot.

From the lot draw at random five containers,

Inspect the containers for compliance with the requirements of 4.1.

From each of the containers drawn take specimen of approximately equal volume so as to provide a composite sample of total volume at least one litre. Use this sample for testing.

NOTE Before drawing a specimen, thoroughly mix the contents of the relevant container.

The lot shall be deemed to comply with the requirements of this standard if, after inspection and testing, the samples taken in accordance with 5.1 are found to comply with the relevant requirements of the standard.

Liquid detergent shall be filled in suitable containers and shall be properly sealed with a tamper proof seal. The containers shall be strong enough to withstand normal handling and transportation and that will prevent leakage and contamination of the product.

The container and carton boxes where used, shall be clearly marked with the following information:

(Normative)

A known mass of sample is diluted and filtered. The residues are then dried to constant mass.

Weigh, to the nearest (to ±0.001 g) approximately 5 g of the test sample , into a 400 ml beaker and add 200 ml of distilled water. Heat on a steam bath, with frequent stirring, until the sample is completely dispersed.

Filter the solution immediately, under suction, through a previously dried and tared sintered glass crucible of porosity 2. Ensure that the insoluble matter is quantitatively transferred to the filter.

Wash the beaker and the residue in the crucible five times with 40 ml of hot distilled water.

Allow the wash solution to drain completely and dry the crucible to constant mass at 105 ± 2 °C in an air oven.

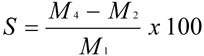

The insoluble matter content S is given, as a percentage by mass, by the formula

where,

| M1 | is the mass, in grams, of the test sample; |

| M2 | is the mass in grams of the sintered glass crucible; |

| M4 | is the mass, in grams, of the sintered glass crucible and the residue after drying. |

(Normative)

Dissolve 1.0 ml of the test sample in 100 ml of carbon-dioxide free distilled or de-ionised water and measure the pH, at room temperature, using a pH meter equipped with a glass electrode capable of measuring pH values to an accuracy of 0.1 or better.

5(Normative)

Accurately weigh (to ±0.001 g) approximately 0.4 g of the test sample into a thoroughly cleaned 500 ml conical flask and add 200 ml of the distilled water.

Stopper the flask and shake it vigorously for 1 minute

Pour out the solution and rinse the flask by adding 200 ml of the distilled water, shaking vigorously for 1 minute and pour off the water.

Invert the flask and allow to dry.

Carry out a blank repeating the above procedure but omitting the test sample.

Compare the two flasks.

6(Normative)

A known mass of sample is oven-dried to constant mass.

Weigh, to the nearest 0.001 g, 5 g of the sample in a tared evaporating dish, which has been previously dried and cooled. Heat the dish and its content on a steam bath until most of the volatile matter has escaped. Continue heating at 105 °C ± 20 °C in an oven for 2 hours. Cool in a desiccator and weigh. Repeat the operation of heating, cooling and weighing until the difference in mass between two successive weighing is less than 0.01 g. Retain the residue in the dish for subsequent test as per E.3.

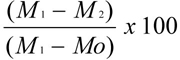

The moisture and volatile matter content is given, as a percentage by mass, by the formula

where

| M0 | is the mass, in grams, of the dish |

| M1 | is the mass, in grams, of the dish and the sample before heating |

| M2 | is the mass, in grams, of the dish and the sample after heating |

(Normative)

Take the dish containing the material after evaporation as obtained in 6.2. Heat it at 450 °C in a muffle furnace to destroy organic matter. Cool the dish and its contents, add a few drops of concentrated sulphuric acid and heat again to dryness. Cool and weigh. Repeat the process of heating, cooling and weighing until constant mass is obtained.

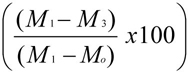

The inorganic salts content is given, as a percentage by mass, by the formula

where

| M0 | is the mass, in grams, of the dish as per D. |

| M1 | is the mass, in grams, of the dish and the sample before heating as per D. |

| M3 | is the mass, in grams, of the dish and the residue. |

(normative)

Ammonium nitrate, 15 g

Acetyl acetone, 0.2 mL

Acetic acid (glacial), 0.3 mL

Distilled water, dilute to 100 mL

Add 2.5 mL of the reagent to the sample in a clean glass container. Sample size is about 0.5 g solids and liquids. Heat the mixtuew for 10 min at 60 °C. A yellow colour develops if formaldehyde is present. This is due to the formation of 3,4-diacetyl-1,4-dihydrolutidine

Positive controls (0.025 % to 0.1 % formaldehyde) and negative control (distilled water) should be tested for comparison.

(normative)

2) Whatman GF/A glass fibre filler paper or equivalent is suitable.

smoothly and continuously at 60 rpm-62 rpm;

3The softening point is determined as follows:

Cut three softening point tubes of length 50 mm to 60 mm from capillary tubing of inside diameter 0.83 mm to 1.1 mm and wall thickness of 1 mm. Heat the soil to approximately 80°C and remove any impurities and traces of moisture by filtering it at this temperature through a bed of chemically pure anhydrous sodium sulphate on filter paper. So dip three tubes into the soil (at ± 80°C) that the soil rises to a height of approximately 10 mm in each tube, and chill immediately by holding the tubes against a piece of ice. When the soil has solidified, place the tubes in a tingly stoppered test tube and keep them for 10 min in a refrigerator or water bath at 4ºC-10°C. Transfer the stoppered test tube and contents to another water bath maintained at 10ºC -12°C and leave in this water bath for 20 min. Remove the tubes and attach them by means of a rubber band to a total immersion thermometers having a range of −2°C to + 80°C

10and conforming to the requirement for low softening point thermometers. So position them that the lower ends of the tubes are level with the bottom of the mercury bulb. Add distilled water at 10ºC – 12ºC to a 500 ml beaker to a depth of 70 mm and suspend the thermometer and tubes vertically in the water so that bottom of the thermometer is immersed to a depth of about 30 mm, agitate the water with a slow stream of air or by some other suitable means and heat in such a manner that the temperature of the water is raised uniformly at a rate of 2°C per min. Continue heating until the soil column in each tube rises and note the temperature at which each column commences to rise. Take the mean of the three results as the softening point of the soil.

Carry out simultaneously three determinations on the test sample taken in accordance with 5.1.2 and three determinations on the standard detergent as follows:

NOTE – With certain products the foam layer may still persist after 2 h Disregard such foam layer and continue with 6.6.3 below.

NOTE – The preparation of the panel and the washing and rinsing procedure shall be done in a room maintained at 25 ± 2°C, G.4 Calculation

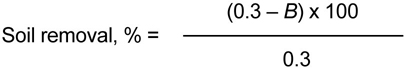

where

B = mass of soil recovered in the basin.

Report the soil removal of the test sample as the mean of the five determinations.

12SABS 825, Hand dish washing and light duty detergent (liquid)

SABS 20825, Environmentally acceptable hand dish washing and light duty detergent (liquid)

MS 80, Specification for liquid detergent for household hand dish washing

13 14 15