In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 260:2007

ICS 59.080.30

HS 9607.00.00

EAST AFRICAN COMMUNITY

© EAC 2007

First Edition 2007

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East Africa. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Partner States in the Community through their National Bureaux of Standards, have established an East African Standards Committee.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2007 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.int

*© 2007 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iiZippers — Glossary of terms

This East African Standard covers terms or meanings used in the zipper industry.

For the purpose of this East African Standard the following definitions shall apply:

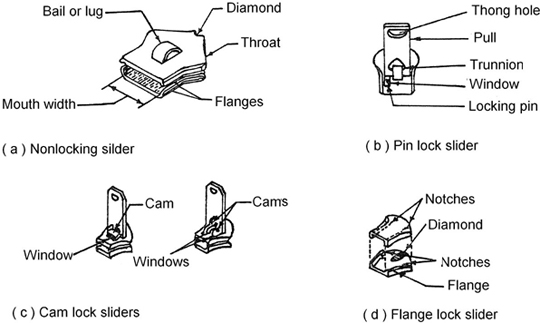

bail or lug

A portion or portions of the slider to which the pull or pulls are attached.

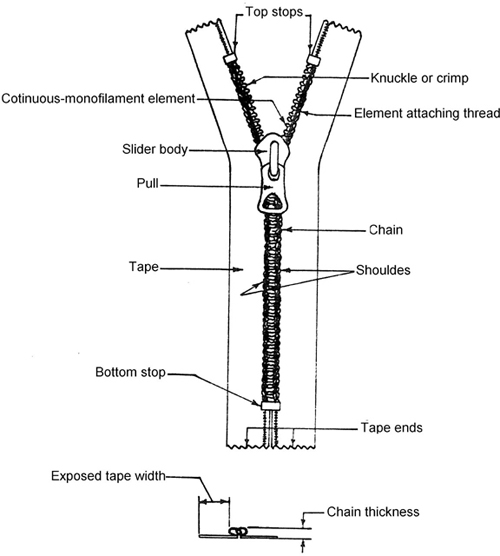

bead

The bead is optional on continuous-monofilament zippers.

cam — A portion or portions on the pull that extend through a window or windows to effect a locking action in cam-lock sliders.

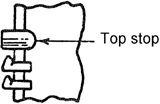

chain — The assemblages formed by interlocking several elements of two stringers.

chain thickness — The measurement from front to back of the chain.

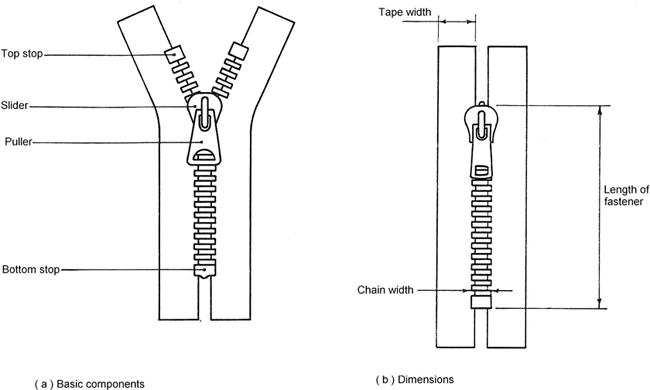

chain width — The distance between the shoulders of the interlocked elements or between the outermost edges of thee bead if the bead extends beyond the elements (see Figure 1).

connecting ring — A device used to secure special pull to bail or lug.

cord — A strand of multiple yarns for use in forming a bead.

crimp — As applied to a continuous-monofilament zipper, the predetermined formation of the monofilament cross-section at the point where the continuous-monofilament element is interlocked.

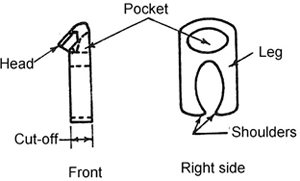

cut-off — The measurement of a scoop from the head side to the pocket side of the legs.

diamond — A wedge-shaped portion of slider between the throats.

elements interlockable

Figure 1 — Slide fasteners: Dimensions

NOTE scoops are of many designs but the nomenclature is generally the same for all types.

Figure 2 — Scoop

NOTE Scoops are of many designs but the nomenclature is generally the same for all types

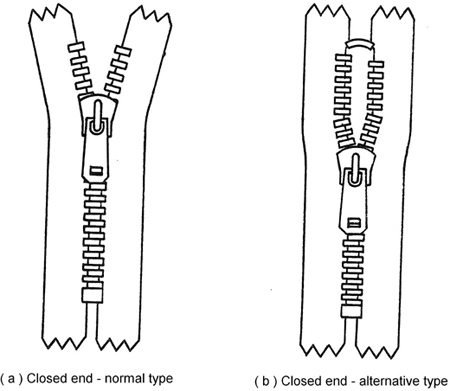

2fastener, closed-end — A slide fastener which does not permit the complete separation of the two stringers. Normally the top end of the fastener separates as the slider is lowered, although there is an additional type where the top end are permanently joined together by means of a bridge stop (see Figures 3(a) and 3(b)).

Figure 3 — Closed-end fasteners

fastener, concealed — A slide fastener with the tapes folded so that on closure neither the slider body nor the fastener are visible from the outside of the article.

fastener, length of — The distance from the top of the slider to the bottom stop, or box in the case of an open-end fastener, measured with the slider in the top position and with the puller in the downward position (see Figure 1).

fastener, open-end — A slide fastener having a special fitment at the bottom end of each stringer in place of the bottom stop, so designed as to permit the two stringers to be completely separated and re-assembled at will when the slider is in the full open position. The special fitment normally consists of a pin permanently fixed to the bottom end of one stinger which fits into a box permanently fixed to the bottom end of the other stringer.

fastener, slide — A fastening device consisting of two flexible, interlocking stringers with or without end stops and a slider so arranged that by moving the slider along the stringers in one direction an opening is formed, and by moving it in the other, the opening is closed. The end which is adjacent to the slider when the device is fully open is designated the bottom end. The other end is designated the top end.

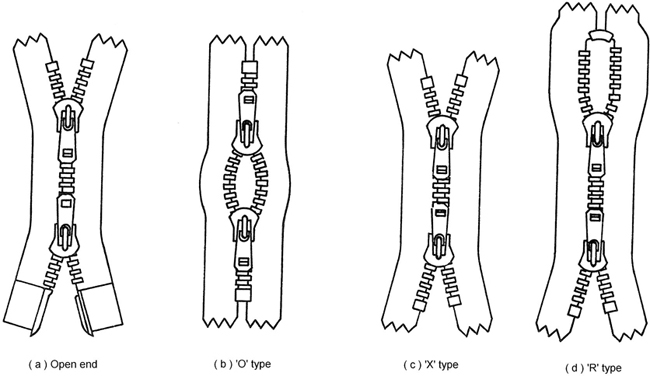

fastener, two-way — A slide fastener fitted with two sliders that operate with equal facility in either direction. This type is available in a variety of forms which are illustrated in Figure 4.

fasteners, batch of — A quantity of fasteners having one design, one performance code and one size.

flanges — The edges of the slider formed to contain the chain.

3

Figure 4 — Two-way fasteners

head or heads — The portion of a scoop that engages the pocket.

knuckle — See crimp.

legs — The two portions of a portion of a scoop that affix the scoop to the head.

locking device — A device incorporated in the slider unit restricting its free movement along the fastener length in on opening direction. The locking device may operate either automatically on release of the puller or by manual pressure on the puller.

mouth — The opening in a slider that receives the chain.

mouth width — The distance between the slider flanges at the point where they bear against the shoulders of the interlocked elements or at the outermost edges of the bead if the bead extends beyond the elements.

pin, locking — The projection on a pull that fits between adjacent scoops of a fastener when a pin-lock slider is in the locked is in the locked position.

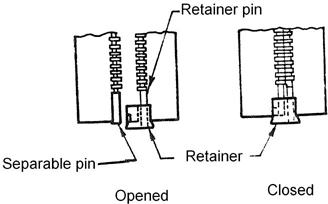

4pin, retainer — A tube-like element, similar to the separable pin, attached over the head at the bottom end of the stringer opposite to the separable pin. This element is designed to hold the fixed retainer in position.

pin-separable — A tube-like element attached over the bead at the bottom end of one stringer.

Pocket — The cavity of a scoop designed to receive the head.

pull (or puller) — The fitting attached to the slider to facilitate manipulation.

retainer, fixed — An element permanently attached onto the retainer pin at the bottom of one stringer. It has an opening shaped to fit the separable pin. In order to close, the separable pin is passed through the slider body and then inserted into this opening. Thus, the fixed retainer holds or retains the two stringers in alignment for interlocking.

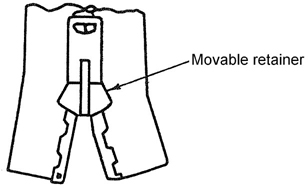

retainer, movable — A movable or sliding element performing a similar function to that of the fixed retainer, the purpose being to permit separation of the two stringers from the bottom, without the necessity of opening the zipper from the top. This element is not removable from the bottom (see Figure 5).

Figure 5 — Movable retainer

scoops — See interlocking elements.

shoulder — The bearing surface of an interlocking element by which the chain is contained inside the flanges of the slider.

slider — The part that opens the zipper when moved in one direction and closes it when moved in the opposite direction. The slider can have single or double pull (or puller) (see Figure 6).

Figure 6 — Sliders

5slider, automatic lock — A slider that provides automatic, positive locking action on the chain when the pull is released.

slider, flange lock — A slider with notches in the flanges of the slider that block the shoulders of the scoops when the stringers are pulled apart.

stops — The elements at tops and bottom of chain or stringer that prevent the slider from leaving the chain.

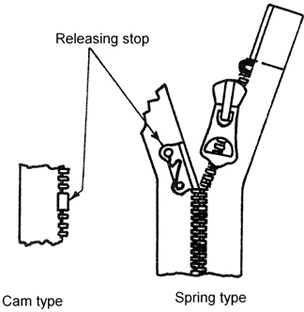

stop, releasing — An element attached at or near the top of the stringer on the separable pin side. This element limits the travel of the slider at the open end of the chain under normal closing operations. The slider may be forced beyond it when added force is exerted towards the top of the zipper. Releasing stops are used on zippers of the ‘quick release’ or ‘quick’ disassembly’ type (commonly referred to as ‘QR’ or as ‘QD’ zippers) (see figure 7).

Figure 7 — Releasing stops

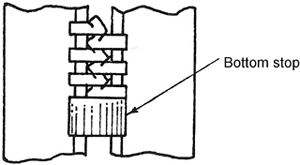

stop, bottom — A part affixed to both stringers immediately below or over, the chain, holding the two stringers together at the bottom and preventing the slider from leaving the chain (see Figure 8).

Figure 8 — Bottom stop

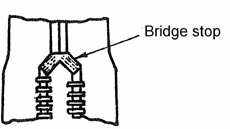

stop, bridge stop — A part affixed immediately above the chain, holding the tops of two stringers together and preventing the slider from leaving the chain (see figure 9).

6

Figure 9 — Bridge stop

stop top — A part affixed between or immediately above the scoops, on either or both stringers, to prevent the slider from leaving the chain (see figure 10).

Figure 10 — Top stop

stringer —The tape, bead and element assembly that constitutes one side of a chain.

tape — A strip of material along one edge of which the bead and scoops are attached or to which continuous-monofilament elements are attached.

tape ends — The tape extending beyond the stops at either or both ends of the stringers.

tape width, exposed — The part of the tape extending beyond the shoulders of the scoops to the outer tape edge.

thong hole —The opening at the end of the pull.

thread, element attaching — The thread that secures the continuous-monofilament to the type.

throats — The two openings in a slider that receive the stringers.

top stop — See stop, top.

trunnions — The two pivots at the end of the pull that fit into the bail or lug.

windows — The openings in pin-lock and cam-lock sliders through which the locking pin and cams, respectively may extend.

zipper — A slide fastener consisting of interlockable elements each attached to one of the opening edges of two tapes and a movable part called a ‘slider’ that spans the interlockable elements which when moved in one direction causes the elements on one tape to interlock with thee elements on the other tape, and when moved in the opposite direction causes the elements to disengage.

The various types of zippers are:

7

Figure 11 a — Principal parts of zippers — Separable element zipper

Figure 11 (b) — Principal parts of zippers — Continuous monofilament zipper

Figure 12 — Separating parts

9 10 11