In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 246:2001

ICS 67.200

EAST AFRICAN COMMUNITY

© EAC 2001

First Edition 2001

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East Africa. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Partner States in the Community through their National Bureaux of Standards, have established an East African Standards Committee.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2001 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.int

*© 2001 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iiLight mineral oil, as an oil-in-water emulsion, is added to sisal or jute fibres during spinning (conversion to yarn), and some or all of this oil is present in the sisal or jute after or at later stages of manufacture. This East African Standard describes a method for the determination of added oil in sisal or jute, based on the extraction of the oil by an organic solvent. All organic solvents, however, extract some of the natural constituents of sisal or jute and an allowance has to be made in quantitative determinations of the added oil. The recommended solvent for this method and the procedure used has been found to extract between 0.1 %and 0.2% of the natural constituents of sisal or jute.

In the development of this East African Standard, reference was made to BS 3845:1990, Method for determination of added oil content of jute yarn, rove and fabric.

Acknowledgement is hereby made for the assistance received form this source.

3Method for determination of added oil content of sisal or jute yarn or fabric

This East African Standard describes a method for determination of added oil content of sisal or jute yarn or fabric or a combination of sisal and jute fabric.

The procedure described in this East African Standard applies to all types of sisal or jute yarns and fabrics, but does not apply to products containing petroleum-soluble additives other than oil, e.g. copper naphthenate.

A known amount of a test specimen is extracted with light petroleum in a soxhlet apparatus under defined conditions. The solvent is removed by distillation and the extract is weighed.

The mass of the extract is expressed as percentage on one of the following basis:

Light petroleum, redistilled, boiling range 40 °C to 60 °C.

Soxhlet extractors, 200 ml to 300 ml capacity

Extraction flasks, flat-bottomed, 250 ml to 500 ml capacity.

Double-surface or coin type reflux condensers.

Heating unit, temperature-controlled, for use with soxhlet extractors.

Distillation unit, e.g water or steam bath.

Balance, accurate to within 0.2 mg.

Stoppered weighing bottles.

Soxhlet thimbles, previously extracted with the solvent.

Desiccator.

Ventilated oven, for drying test specimens at 105 °C ± 3 °C.

1Suction pump and adapter

If the result is to be expressed on the mass of the conditioned test specimen, conditions the test specimen in the standard atmosphere for testing of textiles as described in EAS 240, Textiles — Standard atmospheres for conditioning and testing.

If the result is to be expressed on any other basis (see 3), conduct the test in ordinary laboratory conditions.

Sample at random, a test sample, representative of the bulk and of sufficient size for at least two test specimens each weighing 5 g to 20 g. Determine the mass of the test specimen.

If the result is to be expressed on the basis of the test sample as received, divide the test sample into test specimens and place each test specimen in a separate weighing bottle (see 5.7) and stopper the bottle. Weigh the bottles with their test specimens, and calculate the mass of each test specimen.

If the result is to be expressed on the basis of the mass of the conditioned test specimen divide the test sample into test specimens and place each in a separate weighed weighing bottle (see 5.7). Condition the test specimen by placing the open bottle in an enclosure at the standard atmosphere for testing of textiles for 24 hours. Stopper the bottle. Weigh the bottle and test specimen, and calculate the mass of the conditioned test specimen.

NOTE The weighing need not be made in the standard atmosphere for testing of textiles.

If the result is to be expressed on the mass of the dry, extracted test specimen, condition the test sample, before taking the test specimens, in the ordinary laboratory atmosphere for 24h.

Place the test specimens in a thimble (5.8) in a soxhlet extractor (5.1). Add approximately 200ml of light petroleum (4.1) to a clean, dry extraction flask (5.2), previously weighed to an accuracy of 0.001 g, and carry out the extraction for a time such that the extractor siphons at least ten times. Disconnect the apparatus and remove the bulk of the solvent by distillation (5.5). Remove the remainder of the solvent by the following method. Connect the flask (5.2) by means of a suitable adapter to a suction pump (5.11). Reduce the pressure in the flask to 1.33 kPa to 4.00kPa for not less than 12 min and not more than 15 min while warming the flask at 60 °C to 65 °C. Release the vacuum through a side tube fitted with a cotton wool filter before disconnecting the adapter.

If the pressure of 1.33kPa to 4.00kPa cannot be obtained, pass a stream of air through the flask using the following method. Stopper the flask with a stopper containing an inlet and outlet tube, neither of which projects below the neck of the flask. Heat the flask on a water bath at 60 °C to 65 °C, and by means of a vacuum supply draw a stream of air (300ml/min measured at atmospheric pressure) through the flask for 15 min, with the pressure inside the flask reduced to 26.60 kPa.

If the result is required on the basis of the dry mass of the extracted test specimen or of the mass of the test sample as received, remove the thimble from the soxhlet extractor, allow the solvent to

2evaporate and transfer the extracted test specimen to a tared weighing bottle. Dry the test specimen and bottle in an oven at 105°C ± 3 °C for at least 3h, cool in a desiccator (5.9) and determine its mass.

Calculate the mass of the dry extract as a percentage of the mass of a test specimen by one of the methods detailed in 9.2 to 9.5. Express the result as the average (mean) for two or more test specimens.

Express all results to the nearest 0.1%.

NOTE In all formulae the recommended value for (a) is 17.0 and the recommended value of (b) is 0.15.

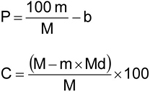

Calculate the percentage of added oil, P, and the moisture content, C (in %) of the test specimen as received using the following expressions.

where

| M | is the mass of the test specimen as received (in g). |

| b | is the percentage of naturally occurring oil and wax in the test specimen, removed during the extraction; |

| m | is the mass of the extract (in g); |

| Md | is the dry mass of the extracted test specimen (in g). |

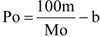

Calculate the percentage of added oil, Po, using the following expression:

where

| b | is the percentage of naturally occurring oil and wax in the test specimen, removed during extraction; |

| m | is the mass of extract (in g) |

| Mo | is the conditioned mass of the test specimen (in g). |

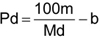

Calculate the percentage of added oil, Pd, using the following expression:

3

where

| b | is the percentage of naturally occuring oil and wax in the test specimen, removed during extraction; |

| m | is the mass of the extract (in g); |

| Md | is the dry mass of the extracted test specimen (in g). |

Calculate the percentage of added oil on the bases of dry mass plus allowance, Pr, using the following expression:

where

| a | is the recommended allowance for moisture and natural or added solvent-soluble matter |

| Pd | is the percentage of added oil based on dry mass. |

The test report shall include the following information: