In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 229:2001

ICS 59.080.30

HS 0804.60.00

EAST AFRICAN COMMUNITY

© EAC 2001

First Edition 2001

iDevelopment of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in East Africa. It is envisaged that through harmonized standardization, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Partner States in the Community through their National Bureaux of Standards, have established an East African Standards Committee.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2001 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.int

* © 2001 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

iiCrepe bandage is a plain weave fabric having a high stretch in the warp direction sue to the amount of twist in the warp yarns. It is used in the treatment of sprains and strains and in other surgical conditions where light support is required.

This East African Standard specifies performance requirements and includes six preferred sizes in terms of width of bandage.

In the preparation of this standard, reference made to:

| MS 2.36:1976 | Specification for crepe bandages |

| SABS 945-1969 | Standard specification for crepe bandages |

Acknowledge is made for the assistance received from the these source

iii ivCrepe bandages — Specification

This East African Standard specifies requirements for crepe bandages used for surgical dressings.

A plain weave fabric having high elasticity in the warp direction, resulting from the amount of twist in the warp and the method of weaving.

An edge defined by the outer warp thread.

the recovered extension expressed as a percentage of the imposed extension

The crepe bandage shall be a plain weave fabric in one continuous length containing no joints, having a high elasticity in the warp direction, resulting from the amount of twist in the warp yarn and the method of weaving, and with fast edges.

The bandage may be either dyed or undyed, and may have a coloured thread woven along the length.

The cotton yarns used for the manufacture of crepe bandages shall be even and of at least appearance grade C as specified in EAS 155-1*

The mass per square metre of bandage shall be not less than 90 g when tested in accordance with ISO 3801.

The width of the bandage (measured between the fast edges) shall be 50, 65, 75, 100, 150 or 200 mm as specified on the label, subject to a tolerance of minus 2 mm.

The width shall be tested in accordance with Annex A.

The unstretched length of the crepe bandage shall be as declared on the label, subject to a tolerance of minus 2 per cent. The length shall be determined in accordance with Annex B.

* Standards referred to in this East African Standard are listed at the back of this standard.

1The fully-stretched length of the bandage shall be not less than 1.5 times unstretched length, and the recovery shall be not less than 40 per cent.

The stretch shall be determined in accordance with Annex C.

The extractable foreign matter in the bandage shall not exceed one per cent of the dry mass.

This shall be tested in accordance with Annex D.

Coloured bandages shall comply with the colour fastness ratings given in Table 1.

| Agency | Rating, minimum | Method of test | |

| Washing | Colour change | 4 | EAS 237 |

| Staining | 3 | ||

| Rubbing | Wet | 3 | EAS 239-1 |

| Dry | 4 | ||

| Perspiration | Colour change | 4 | EAS 238 |

| Staining | 3 |

Each bandage shall be rolled and individually wrapped with paper or polythene.

Bandages of the same width and colour shall be packed in the same bulk container and wrapped suitably so as to be adequately protected against soiling and other contamination.

Packages shall be legibly marked on the outside with the following information:

The following information shall appear in legible marking on the outside of each bulk container:

Condition the samples in accordance with EAS 240.

Lay one bandage, without tension, on a flat table.

take width measurements (between the fast edges) perpendicular to the edges of the sample at five different positions equally distributed along the length of the sample.

Repeat the procedure on each of the five bandage samples.

Calculate the average width of each sample from the average of the five measurements.

Calculate the bandage width as the average of the widths of the five samples measured. Report this value as the bandage width.

3Condition the samples in accordance with EAS 240.

Take one bandage sample and lay it, without tension, on a flat table.

Take the length measurement parallel to the edges of the bandage.

Repeat the test on all the five bandages.

Calculate the average length from the five measurements.

Report this value as the length of the bandage.

4A suitable apparatus having the grips that hold the specimen in a horizontal plane, and capable of applying within approximately 5 s a tensile load of 27 N per 25 mm of width of bandage under test.

a steel tape of length greater than the stretched length of the sample to be measured, graduated in centimetres and millimetres.

Measure the unstretched length of the bandage under tests, according to the procedure given in Annex B. Make a pair of datum marks not less than 30 mm from each end of the bandage and measure, to the nearest 2 mm, the unstretched length between the datum marks. Secure each end of the bandage in a grip of the apparatus, apply the tensile load (see C1.1), and as soon as the full load is attained, measure, to the nearest 2 mm, the stretched length between the datum marks. Maintain the load for 1 min. Release the load, remove the bandage from the grips, lay it on a horizontal flat surface and allow it to relax for 5 min, releasing any drag on the bandage caused by adhesion to the flat surface by gently running a smooth rod under the full length of the bandage. Then measure, to the nearest 2 mm, the recovered length between the datum marks.

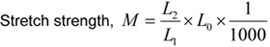

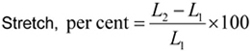

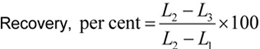

Calculate separately the stretched length, the percentage stretch and the percentage recovery as follows:

where,

L0 = mean unstretched length of bandage, in mm.

L1 = mean unstretched length between datum marks, in mm.

L2 = mean stretched length between datum marks, in mm.

L3 = recovered length between datum marks, in mm.

5a stoppered bottle

Extraction apparatus

A fine sieve No. 150 micron

Chloroform

0.5 per cent diatase solution

Dry the sample to constant weight at 105 °C. Weigh accurately 5 g of the dried sample and put it in a stoppered bottle and weigh. Repeat drying and weighing until constant weight.

Extract the dried sample with chloroform for one hour in the soxhlet apparatus. Remove the sample from the apparatus and allow the residual chloroform to evaporate.

Transfer the sample to a suitable vessel and add 400 ml of water. Heat slowly and boil for about one minute, cool by adding approximately an equal volume of water.

Decant the liquid through a fine sieve No. 150 micron, squeezing the sample by hand to remove as much of the liquid as possible.

Return the sample to the vessel and repeat the washing process for five further times with 400 ml of water each time.

Place the washed sample and any loose threads or fibres from the sieve in a beaker and immerse with a 0.5 per cent solution of diastase. Maintain the sample at 70 °C until it is free from starch.

Decant the liquid through the sieve, return any loose threads or fibres on the sieve to the sample in the beaker and repeat the washing process with boiling water.

Dry the sample at 105 °C to constant weight.

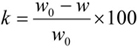

Calculate the percentage of loss in weight, which is expressed as a percentage of foreign matter, by the following formula:

where

K = percentage of foreign matter;

w = weight of residue;

w0 = weight of sample used in the test.

6EAS 240, Conditions for testing of textiles

ISO 3801, Textiles — Woven fabrics — Determination of mass per unit length and mass per unit area

EAS 237, Methods for determination of colourfastness of textile materials to washing

EAS 238, Method of determination of colourfastness of textile materials to perspiration

EAS 239-1, Method for determination of colourfastness of textile materials to rubbing — Part 1: Dry and wet rubbing

EAS 155-1, Cotton yarns — Code of practice for the grading of spun yarns — Part 1: Grading by appearance

7 8 9