In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 125: 2011

ICS nn.nnn.nn

EAST AFRICAN COMMUNITY

© EAS 2011

First Edition 2011

i|

Copyright notice This EAC document is copyright-protected by EAC. While the reproduction of this document by participants in the EAC standards development process is permitted without prior permission from EAC, neither this document nor any extract from it may be reproduced, stored or transmitted in any form for any other purpose without prior written permission from EAC. Requests for permission to reproduce this document for the purpose of selling it should be addressed as shown below or to EAC’s member body in the country of the requester:

Reproduction for sales purposes may be subject to royalty payments or a licensing agreement. Violators may be persecuted |

| Page | ||||

| Foreword | v | |||

| 1 | Scope | 1 | ||

| 2 | Terms and definitions | 1 | ||

| 3 | Requirements | 2 | ||

| 3.1 | General requirements | 2 | ||

| 3.2 | Physical characteristics | 2 | ||

| 3.2.1 | Splints | 2 | ||

| 3.2.2 | Match container | 3 | ||

| 3.2.3 | Match head | 3 | ||

| 3.2.4 | Striking (friction) surface | 3 | ||

| 3.2.5 | Number of sticks | 3 | ||

| 3.3 | Defective containers | 3 | ||

| 3.3.1 | Broken and crushed | 3 | ||

| 3.3.2 | Loosely fitted | 3 | ||

| 3.4. | Unserviceable sticks | 3 | ||

| 3.4.1 | General | 3 | ||

| 3.4.2 | Badly-distorted heads | 4 | ||

| 3.4.3 | Fractured heads | 4 | ||

| 3.4.4 | Doubles | 4 | ||

| 3.4.5 | Sticks which break or bend | 4 | ||

| 3.5. | Absence of after glow | 4 | ||

| 3.6. | Additional requirements for book matches | 4 | ||

| 4 | Packing and marking | 4 | ||

| 4.1. | Packing | 4 | ||

| 4.2. | Marking | 5 | ||

| 5. | Sampling | 5 | ||

| 5.1. | Lot | 5 | ||

| 5.2. | Number of test and criteria for conformity | 6 | ||

| 5.3. | Criteria for conformity | 7 | ||

| Annex A (normative) Wearing strength of friction surface | 8 | |||

| A.1 | Principle | 8 | ||

| A.2 | Procedure | 8 | ||

| Annex B (informative) Test for functional failures of matches | 9 | |||

| Annex C (normative) Safety | 10 | |||

| C.1 | Principle | 10 | ||

| C.2 | Procedure | 10 | ||

| Annex D (normative) Ignition below 170 °C | 11 | |||

| D.1 | Principle | 11 | ||

| D.2 | Apparatus | 11 | ||

| D.3 | Procedure | 11 | ||

| Annex E (normative) Ignition under impact | 12 | |||

| E.1 | Principle | 12 | ||

| E.2 | Apparatus | 12 | ||

| E.3 | Procedure | 13 | ||

| Annex F (normative) Burning quality — Spurting | 14 | |||

| F.1 | Principle | 14 | ||

| F.2 | Procedure | 14 iii | ||

| Annex G (normative) Damp-proofness | 15 | |||

| G.1 | Principle | 15 | ||

| G.2 | Apparatus | 15 | ||

| G.3 | Procedure | 15 | ||

| G.4 | Calculation | 15 | ||

| Annex H (informative) Method of test for afterglow | 16 | |||

| Annex I (normative) Method of striking matches | 17 | |||

| Annex J (informative) Test for breaking resistant of the splint | 18 | |||

Development of the East African Standards has been necessitated by the need for harmonizing requirements governing quality of products and services in the East African Community. It is envisaged that through harmonized standardization, trade barriers that are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Community established an East African Standards Committee mandated to develop and issue East African Standards.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organizations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalization of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

This second edition cancels and replaces the first edition EAS 125:2001 of which has been technically revised.

vMatches are generally classified as strike-anywhere matches and safety matches. As the names indicate, the strike-anywhere matches can be ignited by friction on almost any surface, whereas safety matches are ignited by striking against the friction surface only on the outside of the container. At the moment strike-anywhere matches are not manufactured in this country.

The basic raw materials presently used for the manufacture of safety matches includes wood, match paper, and paraffin wax for the splints, chemicals such as potassium chlorate, sulphur, metallic oxides, for example, amber black oxides of manganese and iron, zinc oxide and yellow oxide of lead for the match head and those for the friction surface include red phosphorus (amorphous phosphorus) and antimony sulphide. In addition, potassium dichromate and methanal (formaldehyde or formalin) are also used in small quantities in preparing the above two compositions. The adhesives used comprise of technical gelatine and casein, the former is used in the preparation of both the match head and friction surface compositions while the latter is mainly used for labelling purposes. Other ancilliary materials consumed by the industry are carbon black, glass powder, soda ash or borax, linseed oil, resin, rhodamine dye and tapioca flour.

However the use of other materials not included in the above list are allowed as long as they impose no safety risks and are suitable for the manufacture of safety matches.

viSafety matches — Specification

This Final Draft East African Standard specifies the requirements, sampling and methods of testing for safety matches that has been packed in any suitable material.

splint tipped with a head of composition which will ignite when struck against an appropriate surface

rigid stick of combustible material providing support during ignition of a match and the fuel for its continued burning

match designed so that it will not readily ignite unless brought into contact with a friction surface specifically designed to cause ignition

burning of the match stick (splint) without a flame, after the flame has been extinguished

NOTE Safety matches can occasionally and with difficulty be ignited upon other surfaces.

individual package for retaining matches in the form of a container, book or other shapes, incorporating a friction surface on its outer part

chemical compound used to make the striking tip of a match

that part of the container that is designed for igniting matches

matches that have splints of wood but does not include such matches if they are attached to a common base

one or two rows of comb-like matches, each row of splints having its base fixed within a cover. The striking surface lies within the outer surface of the cover.

1matches that have paper splints fully waxed with paraffin wax

The chemicals used in the manufacture of the match head shall be safe with no such risks as explosion and the splints shall comply with the safety requirements of this standard, such as the requirements of after glow.

The safety matches shall also comply with the performance requirements given in Table 1, when tested according to prescribed methods in the annexes

| No | Characteristics | Requirements | Method of test |

|---|---|---|---|

| i | Wearing strength of friction surface | To pass test | Annex A |

| ii | Safety | To pass test | Annex C |

| iii | Ignition below 170 °C | Nil | Annex D |

| iv | Ignition under impact | Nil | Annex E |

| v | Burning quality spurting, percentage, max | 5 | Annex F |

| vi | Damp proofness, percentage, min | 60 | Annex G |

The splint used for making sticks shall be uniform, smooth, well polished, and free from bristles, splits tears, cracks or decays and holes a long the length. They shall not have fungus or bacterial growth.

Compliance shall be checked by visual inspection and counting and the number failing shall not exceed ten percent of the respective package size.

The splints shall be made such that about two-thirds of its length shall burn smoothly, when held horizontally in a draft free atmosphere. The number of splints failing this test shall not exceed 6 % of the test sample.

In determining the strength of the splints, not more than 5 % of the matches tested when struck against the friction surface shall show bending, breaking or fracture of the splints

Splints shall have the following minimum dimensions:

There should be no variation exceeding 2 mm between the length of the splints within the same container.

2Book matches shall have splints not less than 35 mm length without the base and 45 mm with the base. The composite width of 10 splints shall not be less than 30 mm.

The match container shall be of good workmanship free from the following defects:

No match head shall protrude out of the container. The number of containers, if any, failing this requirement shall not exceed 4 % of the test sample.

The match head shall ignite without spurting and the match head particles shall not fly when the head is struck against the friction surface of the container.

The container shall have a uniformly distributed friction surface, none of which shall be present on the inside where contacts with the match heads can occur. The friction surface shall terminate at least 2 mm from each edge of the shorter side of the container.

When tested in accordance with Annex A, the friction surface shall not peel to expose the underlying surface of the container.

When tested in accordance with Annex A, not less than 95 % of the matches in each container shall ignite.

The average number of sticks per container shall not be < 4 % of the nominal specified number when determined on the examination of any six containers from the sample and no container out of the six examined shall contain < 90 % of the nominal specified number.

The broken and crushed containers in the test sample shall not exceed 5 %.

When tested in accordance with Annex B the loosely fitted containers in the test sample shall not exceed 4 %.

The total unserviceable sticks shall not exceed 10 % of the test sample. Sticks which are considered unserviceable are classified below.

3Heads shall be considered distorted when they show pronounced abnormalities in shape or surface, especially heads which carry sharply defined peaks.

Heads shall be considered to be fractured when their surface has been broken or cracked.

Heads linked together by a bridge of composition shall be termed as doubles.

The splints which break or bend when struck against the friction surface shall be termed as splints which break/bend.

When tested in accordance with Annex H; splints shall not glow for more than three seconds. The number of matches of which the after glow persists before turning into ashed remains shall not exceed 40 % of the tested samples.

Every book of matches shall meet the following requirements:

Packing shall be in the form of containers, packets and cartons A suitable number of match containers shall be wrapped in a suitable wrapping material capable of withstanding normal handling. The material shall be securely pasted or glued to make a tight packet. Each packet shall consist of a suitable number of containers. Such packets shall be packed in a suitable wrapping paper or any other suitable material which shall be securely glued to make a tight carton.

4The match container, packet and the carton shall have a label affixed to each one of them, where applicable, indicating the following:

All materials of the same brand in a single consignment produced in the same manufacturing unit shall constitute a lot.

Samples shall be tested from each lot for ascertaining the conformity of the lot for the requirements of this specification. The number of cartons to be selected from a lot shall depend upon the size of the lot and shall be in accordance with Table 2.

| Lot size (N) | Number of cartons to be selected (n) | |

|---|---|---|

| 3 to 25 | 3 | |

| 26 to 50 | 4 | |

| 51 to 100 | 5 | |

| 101 to 150 | 6 | |

| 151 and above | 7 |

These cartons shall be selected at random from the lot and for this purpose; random number tables shall be used. In case such tables are not available, the procedure given below shall be adopted:

5| Number of packets in the carton | Number of packets to be selected |

|---|---|

| 10 | 3 |

| 50 | 4 |

| 100 | 5 |

All the match containers in a sample set shall be examined for the requirements given in 3.2, 3.2.2, 3.2.4, and 3.3.

The lot shall be considered as satisfactory in respect of these requirements, if the sample set of match containers satisfies each one of these requirements.

From the match containers in the sample set, select at random any six containers and examine them for the number of sticks. After counting the sticks, containers shall be refilled with the same sticks and replaced back into the sample.

The lot shall be considered as satisfactory, if the six selected containers satisfy the requirements given in 3.2.5.1 or 3.2.5.2 as the case may be.

From the match containers in the sample set, select four containers at random. Pool the sticks from all the four containers together and taking the requisite number of sticks at random from this pool of stick, carry out the tests as prescribed in Annexes A, C, D, and E. [See also Table, items (i) to (iv)]. The lot shall be considered as satisfactory in regard to these requirements, if none of the test fails.

From the remaining containers of the sample set, select at random five containers. Test each of the five containers for wearing strength of the friction surfaces according to Annex A [see also Table 1 item (i)].

The lot shall be considered satisfactory, if each of five containers passes the test.

From the remaining containers of the sample set, select at random five containers and carry out the test for damp-proofness as given in Annex G. [see also Table 1, item (vi)].

The lot shall be considered as satisfactory in regard to this test requirement if the test result satisfies the requirements given in Table 1.

6Take three containers out of the sample at random and examine for the defects given in 3.4. The lot shall be considered as satisfactory if the total number of unserviceable sticks in these containers does not exceed 10 %.

Take the sticks from these containers and test for the requirements as given in 3.2.1. The lot shall be considered as satisfactory, if the total number of sticks not contributing does not exceed 6 %.

The lot shall be declared as conforming to the requirements of this specification, if the different test results as obtained in 5.2.1 to 5.2.6 meet the corresponding requirements given in this standard.

7(normative)

The test is carried out by striking the match sticks against the friction surface.

Take five containers from the sample and condition them at a temperature of 27 °C ± 1 °C and 65 % ± 2 % relative humidity for one hour before carrying out the test. The cover of the container shall be removed during conditioning. Strike all the sticks in the container one by one on one friction surface side of the container. The sample shall be taken to have passed this test, if one friction surface side is sufficient to ignite all the sticks, The friction surface shall be suitably used so that the entire area of one side is utilised in the test.

8(informative)

In determining the correct fit of tray, use a test set of 50 % of containers at random selected from the gross sample, and test each container as follows:

(normative)

The test is carried out by striking the match sticks against a flint paper or equivalent.

Take three containers from the selected containers of the sample and strike over a sheet of flint paper. The average length of stroke on the flint paper shall be about 50 mm.

The sample shall be taken to have passed the test, if none of the sticks in the container catches fire.

10(normative)

The test is carried out by placing the match sticks in an oven maintained at 170 °C and examined for ignition.

Oven, the size and shape of the oven shall be such that the inner chamber shall be approximately 150 mm × 150 mm × 225 mm. It wall be fitted with a shelf of perforated sheet metal at a distance of 120 mm from the top lining of the oven. A vent shall be provided at the top of the oven to permit air circulation.

Thermometer to read up to 250 °C

Wooden block, of 30 mm thick and 50 mm square having a hole of 10 mm diameter to a depth of 25 mm in the centre to serve as a receptacle to hold the sticks

Take 10 matches from the selected containers of the samples and place them with the heads up in the receptacle of the wooden block or a metal holder. Place the block/holder in the centre of the oven maintainer at 170 °C. After 10 min remove the block/holder, note and record as defectives the number of matches that have ignited. The sample shall be taken to have passed the test, if the sticks do not catch fire.

11(normative)

The test is carried out by striking the match sticks with a hammer of 170 g and examined for ignition.

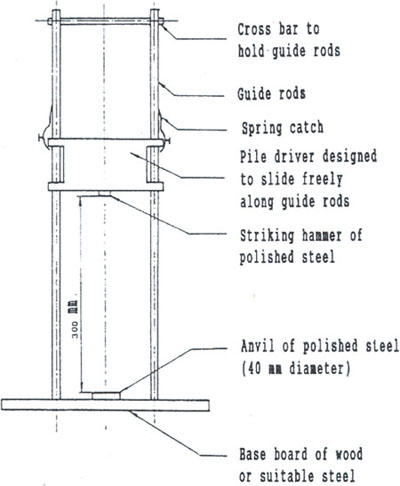

The apparatus shall be assembled as shown in Figure 1.

Figure 1 — Apparatus for ignition under impact test

12Take 10 sticks from the selected containers of the sample and test each stick separately Place the stick on the anvil of polished steel, in such a way that the stick is horizontal and the head is at its centre.

Drop the striking hammer by releasing the spring catch. Observe whether the head catches fire under this impact.

13(normative)

The test is carried out by striking the match sticks against the friction surface and examine for spurting, if any.

Take three containers from the selected containers of the sample and strike against the friction surface of these containers. Observe the number of heads which spurt out while burning

14(normative)

The test is carried out by keeping the match containers in a desiccator containing water for 24 h and examined for their burning quality.

Desiccator, with a plate having an inside diameter of about 250 mm

Carry out this test at a temperature of 27 °C + 1 °C. Place a sufficient amount of water in the desiccator so that the distance between the surface of the water and the nearest portion of the exposed matches kept over the plate is about 25 mm. Take five containers from the sample and place these containers on the desiccator’s plate so that the head side of each container is half open and each container resting on its edge with the friction surface vertical as well as with the heads up. The containers shall be placed at a distance of at least 20 mm away from the walls of the desiccator. Close the desiccator and leave it undisturbed for 24 h (see Note). Remove the container at a time from the desiccator, and strike each stick not more than twice over its own friction surface until all the sticks inside each container are exhausted or there is no more friction surface available for striking. Count the number of sticks which ignited during the test.

NOTE If condensation of water is likely to take place during the test, then the match head may be suitably shielded with a glass plate.

Calculate the damp-proofness as follows

where

15

n is the total number of sticks ignited in five containers; and N is the nominal stick of each container.

(informative)

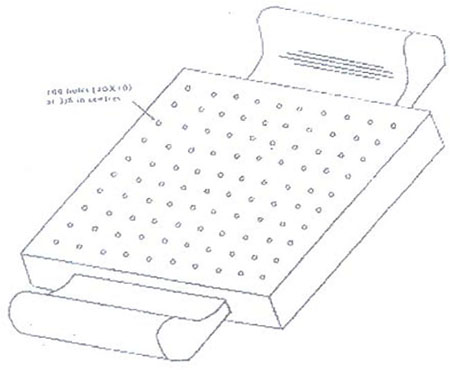

Place the bases of the splints of 25 matches into holes in a metal plate 20 mm ± 0.5 mm apart, arranged in a 5 × 5 array as shown in Figure 2.

In a darkened room, apply a flame to an outside row of the matches and tilt the metal plate so as to ignite all of the matches on the plate as quickly as possible.

Allow the splints to burn away completely and, when the flame dies out, examine the ashed remains of the splints for any afterglow, ignoring any pinpoint glow immediately beneath the head.

Where afterglow is considered to persist for longer than 3 s, repeat the test on a further 25 matches struck as directed in Annex I and examine them individually.

Repeat H.1 to H.4 on a second group of 25 matches and record a cumulative result for the 50 matches tested.

Figure 2 — Perforated metal plate

16(normative)

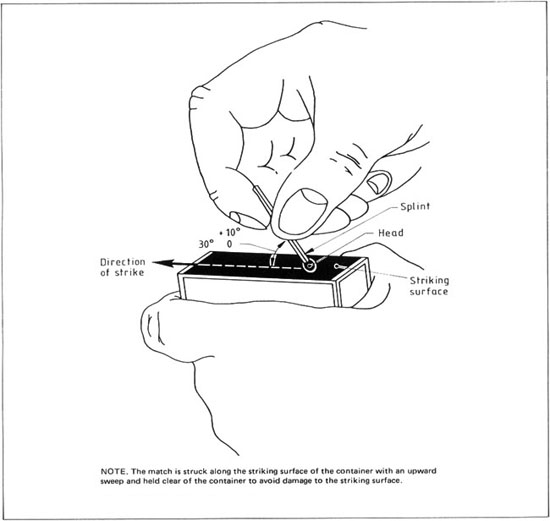

Wherever any of the tests calls for striking of matches, the match is struck along the container with an upward sweep and held clear out of the container to avoid damage to the friction paint (see Figure 3).

Figure 1. Method of striking matches

17(informative)

The apparatus illustrated in Figure 2 is used to conduct this test.

The moment arm on the apparatus is,

The match is inserted in the apparatus as illustrated in figure 2 and the clamp and match gradually lowered until the match breaks.

The maximum force registered on the scale or balance required to break the splint is recorded.

18 19