In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

CARICOM Regional Organisation for Standards and Quality (CROSQ)

2nd Floor Nicholas House

29 & 30 Broad Street

Bridgetown, St Michael

Barbados

T: 246.622.7670 | F: 246.622.7678

Website: http://www.crosq.org

© CROSQ 2010 – All rights reserved

Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without permission.

CRS 33: 2010

CARICOM Regional Organisation for Standards and Quality (CROSQ)

2nd Floor, Nicholas House

29 & 30 Broad Street

Bridgetown, St. Michael

Barbados

T: 246.622.7670 | F: 246.622.7678

Website: http://www.crosq.org

© CROSQ 2010 – All rights reserved. No part of this publication is to be reproduced without the prior written consent of CROSQ.

ISBN 978-976-8234-02-5

ICS 13.030.99

| AMENDMENT NO. | DATE OF ISSUE | TYPE OF AMENDMENT | NO. OF TEXT AFFECTED | TEXT OF AMENDMENT |

|---|---|---|---|---|

The preparation of this standard was carried out under the supervision of the Regional Technical Committee (RTC # 18) for General Commodities (hosted by CARICOM Member State, Trinidad and Tobago), which at the time comprised the following members:

| Members | Representing |

|---|---|

| Dr. Angelus Pilgrim (Chairman) | Faculty of Engineering, University of the West Indies |

| Ms. Maria Doldron | Trinidad and Tobago Ministry of Legal Affairs, Consumer Affairs Division |

| Mr. Winston Fraiser | Plasti-Pak Limited |

| Mr. Wayne Herbert | Magic Mist Limited |

| Mr. Cecil Pope | Trinidad Ropeworks Limited |

| Mr. Rasheed Ramsaroop | ANSA Polymer Limited |

| Mr. Carl White | Maintenance Training Services Limited |

| Mr. Darryl Thomson (Technical Secretary) | Trinidad and Tobago Bureau of Standards |

| Foreword | 1 | ||

| 1 | Scope | 2 | |

| 2 | Normative references | 2 | |

| 3 | Terms and definitions | 2 | |

| 4 | Requirements | 3 | |

| 4.1 | General | 3 | |

| 4.2 | Labelling | 4 | |

| 5 | Compliance | 5 | |

| 5.1 | Sample selection | 5 | |

| 5.2 | Critical properties | 5 | |

| 5.3 | Non-critical properties | 6 | |

| Annex A (normative) Method for determining impact resistance | 7 | ||

| Annex B (normative) Heat seal test | 11 | ||

| Annex C (normative) Garbage bag drop test | 13 | ||

| Tables | |||

| Table 1 - Bag dimensions | 3 | ||

| Table 2 - Leakage test requirement | 4 | ||

| Table 3 - Critical properties - Sample size and compliance criteria | 5 | ||

| Table 4 - Non-critical properties - Sample size and compliance criteria | 6 | ||

| Table C.1 - Test loads for drop test | 13 | ||

| Figures | |||

| Figure A.1 - Impact resistance apparatus | 7 | ||

| Figure A.2 - Dart assembly | 9 | ||

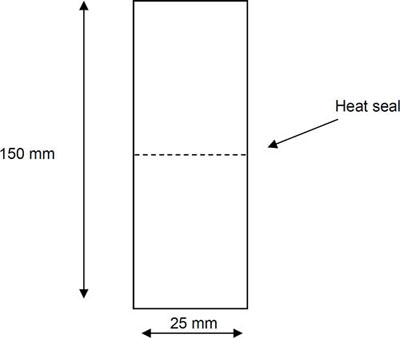

| Figure B.1 - Heat seal test specimen | 12 | ||

This regional standard was developed in response to the increasing use of high density polyethylene film in the manufacture of garbage bags and the decreasing use of low density polyethylene film in the industry.

In the development of this standard, considerable assistance was derived from:

This regional standard specifies requirements for high density polyethylene garbage bags which are normally used for the disposal of domestic and commercial waste.

It includes requirements and test methods for impact resistance, bag dimensions, burst resistance, heat seal integrity and leakage.

This standard does not apply to bags intended for the disposal of industrial, biological or medical waste.

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

ASTM D 1709: 2003, Standard test methods for impact resistance of plastic film by the free falling dart method.

ISO 2859-1: 1999, Sampling plans indexed by acceptable quantity level (AQL) for lot-by-lot inspection.

ISO 7965-2: 1993, Sacks – Drop test – Sacks made from thermoplastic flexible film.

ASTM F 88: 2007, Standard test method for seal strength of flexible barrier materials

For the purposes of this standard, the following terms and definitions shall apply:

any solid waste retained by householders, pending its disposal

any solid waste retained by commercial enterprises such as restaurants, cafes, hotels, offices and retail shops, pending its disposal

polyethylene with a density of 950 kg/m3±10 kg/m3

thin sheet of polyethylene or polyethylene blend from which the garbage bag is made

NOTE The blend refers to additives that are commonly added to the polyethylene resin, such as colouring agents and plasticizers.

2degree of tearing that the bag can withstand, when subjected to a specified impact load

seal formed by bonding of the film by a heating process

manufacturing batch, shipment quantity or quantity available for sale at a retail outlet

quality level that is the worst tolerable process average when a continuous series of lots is submitted for acceptable sampling

NOTE This refers to the maximum percent defective that is allowed. For the purposes of this standard, an AQL of 2.5 % has been chosen for critical garbage bag properties and an AQL of 4.0 % has been chosen for non-critical properties.

Garbage bags shall be free from pinholes, cuts and tears when held up against a light source and visually examined.

Garbage bags shall be readily opened by hand.

Garbage bags shall be classified according to the sizes specified in Table 1.

| Size | Width cm | Length cm |

|---|---|---|

| Small | 51 ± 1 |  |

| Medium | 61 ± 1 |  |

| Large | 76 ± 1 |  |

| Jumbo | 96 ± 1 |  |

All heat seals on the garbage bag shall be continuous.

NOTE Bags can be either side sealed or bottom sealed. Side sealed bags have a continuous heat seal along the entire length of the two ends of the bag. Bottom sealed bags have a continuous heat seal along the entire length of the bottom of the bag.

Heat seals shall withstand the application of a 9.8 N force for a period of 10 min when tested in accordance with Annex B.

Garbage bags shall not exhibit any visible sign of leakage when filled with the volumes of water at 27 °C ± 5 °C as specified in Table 2. For this test, bags shall be held steadily and suspended in the air by grasping together the open end of the bag with a suitable holding device.

| Type | Test water volume I | Length of test min |

|---|---|---|

| Small | 1.0 | 10 |

| Medium | 1.0 | 10 |

| Large | 1.2 | 10 |

| Jumbo | 1.5 | 10 |

Garbage bags shall not show any tear in the film when tested in accordance with Annex A.

Garbage bags shall not burst open when tested in accordance with Annex C.

Packaging containing garbage bags shall be legibly labelled with lettering of minimum height 5 mm stating the following information:

EXAMPLE Small, medium, large or jumbo

Samples shall be selected at random in accordance with ISO 2859-1: 1999.

The following properties shall be regarded as critical:

The sample size and the compliance criteria for each critical property shall be as shown in Table 3.

| Lot size (up to) | Sample | X - Number of bags that fail test at 2.5 % AQL | |

|---|---|---|---|

| A – Accepta | R – Rejectb | ||

| 150 | 5 | 0 | 1 |

| 500 | 20 | 1 | 2 |

| 1 200 | 32 | 2 | 3 |

| 3 200 | 50 | 3 | 4 |

| 10 000 | 80 | 5 | 6 |

| 25 000 | 125 | 7 | 8 |

| 50 000 | 200 | 10 | 11 |

| > 50 000 | 315 | 14 | 15 |

|

|||

The following properties shall be regarded as non-critical:

The sample size and the compliance criteria for each non-critical property shall be as shown in Table 4.

| Lot size (up to) | Sample | Y - Number of bags that fail test at 4.0 % AQL | |

|---|---|---|---|

| A - Accepta | R – Rejectb | ||

| 7150 | 13 | 1 | 2 |

| 500 | 20 | 2 | 3 |

| 1 200 | 32 | 3 | 4 |

| 3 200 | 50 | 5 | 6 |

| 10 000 | 80 | 7 | 8 |

| 25 000 | 125 | 10 | 11 |

| 50 000 | 200 | 14 | 15 |

| > 50 000 | 315 | 21 | 22 |

|

|||

(normative)

This annex sets out a method for determining the impact resistance of polyethylene film by means of a falling dart.

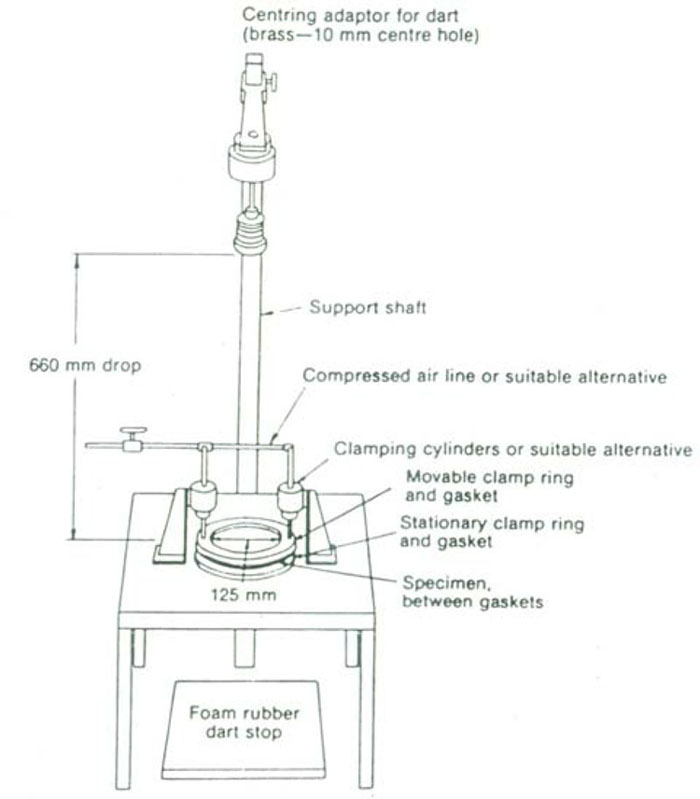

The apparatus consists of the components specified in A.2.2 to A.2.6 and is constructed essentially as shown in Figure A.1 or in conformance to ASTM D 1709: 2003.

Figure A.1 - Impact resistance apparatus

7The apparatus includes a two-piece annular specimen clamp having an inside diameter of 125 mm which complies with the following requirements:

NOTE Pneumatically-operated clamps have been successfully employed.

NOTE 1 Rubber gasketing 3 mm thick, 50 to 60 Shore A Durometer hardness, 125 mm ID, and 150 mm OD has been found satisfactory for the purpose.

NOTE 2 Slippage during the test may be determined by inserting straight pins into the clamped specimen periphery in contact with the outside wall of the clamps. Elongation of the holes after test indicates slippage. An applied pressure of 600 Pa has been found sufficient to minimize slippage.

The device should be capable of supporting a dart assembly with a mass of up to 1 kg. The device should also be equipped with a centering and release device to ensure reproducible drops.

NOTE Electromagnetic or pneumatic support and release devices are considered suitable.

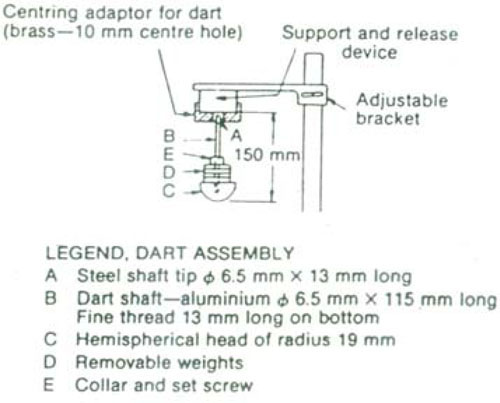

The apparatus includes a dart of known mass consisting of a hemispherical head with a radius of 19 mm fitted with a 6.5 mm diameter shaft 115 mm long to accommodate removable weights (as shown in Figure A.2). The head should be constructed of aluminium, phenolic plastics, or other low-density material of similar hardness. The shaft is attached to the centre of the flat upper surface of the head with its longitudinal axis at 90 ° to the surface. The shaft should be made of aluminium with a 13 mm long steel tip at the end which is attached to the support and release device.

8

Figure A.2 - Dart assembly

The apparatus should include sufficient weights of approximate diameter 32 mm with a 6.5 mm hole in the center to achieve a total mass of dart and weights as specified in A.4.

The apparatus should include a method for positioning the dart at a height of 660 mm from the impinging surface of the dart head to the surface of the test specimen.

Test specimens should be large enough to extend outside the specimen clamp gaskets at all points and should include samples from both the body and folds of the film. The test specimens are representative of the material under study and should be free of pinholes, wrinkles, or other obvious imperfections.

The test samples are selected according to 5.1. The following test procedure is employed:

NOTE If the dart does not drop centrally and vertically onto the test specimen, the result cannot be taken into account. Care should be taken to avoid multiple impacts in cases where the dart bounces off the test specimen. The operator should attempt to catch the dart in such cases to prevent damage to the impinging surface and to the hemispherical head of the dart. Such damage will affect the test results.

NOTE Failure is defined as any break through the film. Such a break can be observed readily by viewing the test specimen under backlighting conditions.

The report on film impact strength states the following:

(normative)

This annex sets out a method for determining the resistance of the garbage bag heat seal to a tensile force.

The following equipment is required:

Alternatively, a universal testing tensile machine with pneumatic action grips which satisfies the requirements of ASTM F 88: 2007 may also be used.

Garbage bag samples are selected from the lot in accordance with 5.1 and are prepared in the following manner:

Figure B.1 - Heat seal test specimen

The test procedure using clamps is as follows:

If a universal tensile testing machine is used, the procedure should be in accordance with ASTM F 88: 2007.

The report on the heat seal test states the following:

(normative)

The drop testing machine should be in accordance with ISO 7965-2: 1993 and should be capable of suspending and dropping a mass of 15 kg from a height of 2.4 m.

The test load consists of several weights. Each weight consists of a sealed garbage bag, filled with polyethylene resin for a total mass of 500 g each.

Ten (10) balls with a diameter D, such that 38 mm ≤ D ≤ 61 mm.

The test procedure is as follows:

| Size | Test load kg |

|---|---|

| Small | 3 |

| Medium | 6 |

| Large | 10 |

| Jumbo | 15 |

The report on the drop test states the following:

The CARICOM Regional Organisation for Standards and Quality (CROSQ) was created as an Inter-Governmental Organisation by the signing of an agreement among fourteen Member States of the Caribbean Community (CARICOM). CROSQ is the regional centre for promoting efficiency and competitive production in goods and services, through the process of standardization and the verification of quality. It is the successor to the Caribbean Common Market Standards Council (CCMSC), and supports the CARICOM mandate in the expansion of intra-regional and extra-regional trade in goods and services.

CROSQ is mandated to represent the interest of the region in international and hemispheric standards work, to promote the harmonization of metrology systems and standards, and to increase the pace of development of regional standards for the sustainable production of goods and services in the CARICOM Single Market and Economy (CSME), and the enhancement of social and economic development.

CROSQ VISION:

The premier CARICOM organisation for the development and promotion of an Internationally Recognised Regional Quality Infrastructure; and for international and regional harmonized CARICOM Metrology, Standards, Inspection, Testing and Quality Infrastructure

CROSQ MISSION:

The promotion and development of standards and standards related activities to facilitate international competitiveness and the sustainable production of goods and services within the CARICOM Single Market and Economy (CSME) for the enhancement of social and economic development

15 16