In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

CARICOM Regional Organisation for Standards and Quality (CROSQ)

2nd Floor Nicholas House

29 & 30 Broad Street

Bridgetown, St Michael

Barbados

T: 246.622.7670 | F: 246.622.7678

Website: http://www.crosq.org

© CROSQ 2010 – All rights reserved

Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without permission.

CRS 19: 2010

CARICOM Regional Organisation for Standards and Quality (CROSQ)

2nd Floor, Nicholas House

29 & 30 Broad Street

Bridgetown, St. Michael

Barbados

T: 246.622.7670 | F: 246.622.7678

Website: http://www.crosq.org

© CROSQ 2010 - All rights reserved. No part of this publication is to be reproduced without the prior written consent of CROSQ.

ISBN 978-976-8234-02-5

ICS 67.060

| AMENDMENT NO. | DATE OF ISSUE | TYPE OF AMENDMENT | NO. OF TEXT AFFECTED | TEXT OF AMENDMENT |

|---|---|---|---|---|

This CARICOM Regional Standard was prepared under the supervision of the Regional Technical Committee for Foods (RTC 3) by Sub-Committee E – Cassava Bread (hosted by the CARICOM Member State, Guyana), which at the time comprised the following members:

| Members | Representing |

|---|---|

| Ms. Jewel Sears (Chairperson) | Food and Drug Analyst Department |

| Mr. Gary Mendonca | Department of Chemistry, University of Guyana |

| Ms. Doreen Obermuller | Carnegie School of Home Economics |

| Mr. Ovid Williams | Ministry of Amerindian Affairs |

| Ms. Andrea Thom (Technical secretary) | Guyana National Bureau of Standards (GNBS) |

Acknowledgment is made to Dr. Michael Seepersaud for his contribution to the development of this standard.

iv| Foreword | 1 | ||

| 1 | Scope | 2 | |

| 2 | Normative references | 2 | |

| 3 | Terms and definitions | 2 | |

| 4 | Requirements | 2 | |

| 4.1 | General | 2 | |

| 4.2 | Specific | 2 | |

| 5 | Packaging | 3 | |

| 6 | Labelling | 4 | |

| 6.1 | General | 4 | |

| 6.2 | Labelling of non-retail containers | 4 | |

| 7 | Hygiene | 4 | |

| 8 | Production | 4 | |

| Annex A (normative) Sampling of cassava bread | 5 | ||

| Annex B (normative) Determination of moisture content | 7 | ||

| Annex C (normative) Determination of ash yield by incineration | 9 | ||

| Annex D (normative) Detection of cyanogenic glycosides using picrate paper | 11 | ||

| List of tables | |||

| Table 1 – Methods of analysis and limits for quality factors | 3 | ||

| Table 2 — Contaminants | 3 | ||

| Table A.1 — Sampling from a lot | 5 | ||

This CARICOM Regional Standard was developed in an effort to:

This standard was approved by the Twenty-ninth Council for Trade and Economic Development (COTED) on 8-9 February 2010.

In the development of this standard, assistance was derived from the following:

NOTE At the time of development of this Standard, the CARICOM Regional Code of Practice for Food Hygiene was under development.

1This standard specifies requirements for cassava bread and related products, intended for human consumption, obtained from the processing of bitter cassava.

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

Codex Alimentarius, CODEX CAC/GL 50, General guidelines on sampling

Codex Alimentarius, CODEX STAN 1-1985 AMD 2008, General standard for labelling of prepackaged foods

Codex Alimentarius, CODEX STAN 228, General methods of analysis of contaminants

ISO 5498, Agricultural food products - Determination of crude fibre content – General method FAO/WHO 1991, Joint FAO/WHO Food Standards Programme, CODEX Alimentarius Commission, XII, Supplement 4

CARICOM Regional Code of Practice for Food Hygiene

For the purposes of this standard, the following terms and definitions shall apply.

variety of cassava that contains more than 50 mg/kg hydrogen cyanide

perennial woody shrub with an edible root

NOTE Also called yuca, yucca, manioc, and mandioca.

thin round biscuit-like bread made from cassava root

phytotoxins which occur in plant species such as cassava

Cassava bread shall be manufactured, packaged, transported, stored and sold in accordance with the latest edition of the CARICOM Regional Code of Practice for Food Hygiene or other international Codes of Practice, and other CODEX texts relevant to this product.

Cassava bread shall:

Table 1 identifies the methods of analysis and corresponding limits for the various quality factors for cassava bread.

| Quality factor | Limit | Method of analysis (latest edition) |

|---|---|---|

| Moisture (%) | 12 - 14 | See Annex B |

| Crude fiber (%) | 3.5 – 4.0 | ISO 5498 |

| Ash (%) | 1.2-2 | See Annex C |

| Hydrogen cyanide (mg/kg) | 10 | Supplement 4, FAO/WHO 1991 |

| Food additives | Conform to legislation of the importing country. | None defined |

| Optional ingredients

Edible fats or oils Salt |

Conform to legislation of the importing country. | None defined |

When analyzed in accordance with the latest edition of the General Methods of analysis of contaminants (CODEX STAN 228), cassava bread shall be free from lead, cadmium, copper, iron and zinc in amounts which may present a hazard to human health (see Table 2).

| Contaminant | Max limit mg/kg |

|---|---|

| Copper | 20.0 |

| Lead | 1.0 |

| Zinc | 50.0 |

| Iron | 22.0 |

| Cadmium | 0.2 |

Sampling shall be done in accordance with the procedure as described in Annex A.

Cassava bread shall be packaged in such a way as to protect the product from breakage.

3The materials used inside the package shall be new, clean and of such quality so as to avoid causing any external or internal damage to the product.

The containers, including packaging material, shall be made of substances which are safe, made of food grade material and suitable for the intended use.

Containers shall not impart any toxic substance, undesirable odour or flavour to the product.

All containers shall be labelled in accordance with the latest edition of the CARICOM Regional Standard for Labelling of Pre-packaged Foods and or the Codex General standard for Labelling of Pre-packaged Foods.

A batch or lot number in clear or in code shall be included on the label, together with an expiry date in the form “Best before” or “Use by” indicating the last date on which the manufacturer can be sure that the product will be acceptable.

Where any nutritional claim is made referring to the cassava bread, full nutritional information shall be given.

NOTE Storage instructions may also be included on the label.

Information for non-retail containers shall either be given on the container or in accompanying documents, except that the name of the product, lot identification and the name and address of the manufacturer or packer shall appear on the container.

NOTE Lot identification and the name and address of the manufacturer or packer may be replaced by an identification mark, provided that such a mark is clearly identifiable with accompanying documents.

The premises, equipment and facilities shall be located, designed and constructed to ensure:

Cassava bread shall be handled by persons who meet all national health requirements pertaining to the handling and preparation of food products.

It is recommended that production of cassava bread made from bitter cassava conforms to traditional and or scientific procedures that effectively eliminate the cyanogenic glycosides naturally present in the cassava in varying concentrations.

4(normative)

The following precautions are observed in drawing, preparing, storing and handling cassava bread intended for testing:

The number of containers in the lot to be sampled depends on the size of the lot and is chosen in accordance with Table A.1.

| No. of Containers in Lot (N) | No. of containers to be sampled |

|---|---|

| Up to 50 | 1 |

| 51 - 150 | 2 |

| 151 - 300 | 3 |

| 301 - 500 | 4 |

| 501 and over | 5 |

The containers to be sampled are selected at random, using random number tables. If such tables are not available, every rth container is chosen, by starting to count at any one, and counting 1, 2, 3 …r, where r is the whole number of the fraction N/n, until n of the containers have been selected.

Either two cassava bread pieces, or the equivalent of 200 g if packed in small slices, are taken from each container selected for sampling.

One cassava bread piece or 100 g of the loose cassava bread is set aside in a sealed, labelled sample container for examination and inspection for conformity with 5.1.1 and 5.2.

5The remainder of the sample drawn from the container is weighed and the weight recorded. These are then stored in sealed containers, labelled with the number of the container in the lot they were taken, until needed for sample preparation.

The cassava bread from each sampled container is ground separately, as soon as possible. Grinding is done in a dry atmosphere.

About 15 g of ground cassava bread from each sampled container is placed immediately in a sealed container, labelled appropriately (including the number of the sampled container), for use in the test for moisture content.

The rest of the ground cassava bread from each sampled container is placed in one container, representing the whole lot, and thoroughly mixed by shaking to produce a composite sample for use in the tests for ash and cyanogenic glycosides.

In the event of a dispute between the purchaser and the vendor as to the acceptability of a lot of cassava bread, the procedure described in A.1 to A.4 may be followed, using three times the amounts mentioned, to produce separate samples for the vendor, the purchaser, and for the reference.

6(normative)

It is required to carry out two single determinations in accordance with B.2 to B.3. If the absolute difference between the two results is more than the repeatability limit r (B 5.2), repeat the determination until the results meet this requirement.

For products not requiring grinding, rapidly weigh, to the nearest 0.001 g, 5 g ± 1 g of the laboratory sample in the dish previously dried and tared, together with its lid, to the nearest 0.001 g. In the case of products which have had to be ground, rapidly weigh all the grinding obtained to the nearest 0.001 g.

In the dish previously dried and tared, together with its lid, record the mass to the nearest 0.001 g.

Do not open the oven door during drying. At the end of the drying period, remove the dried test portions before placing moist products in the oven. Otherwise partial rehydration of the dried test portions may result.

Place the open dish containing the test portions (B.2) together with the lid, in the oven and leave for 120 min ± 5 min (90 min for flours) from the moment when the oven temperature is again 130 °C ± 3 °C.

NOTE In certain cases, mainly in hot and dry climatic countries, the drying time could be reduced to 60 min ± 5 min, as samples could reach the constant weigh within this period. However this should be checked periodically.

Rapidly take the dish out of the oven, cover it and place it in the desiccator. When several tests are carried out simultaneously, never stack dishes directly one on top the other in the desiccator – always place them sideways.

When the dish has cooled to laboratory temperature (generally between 30 min and 45 min after it has been placed in the desiccator), weigh it to the nearest 0.001 g.

7The moisture content, w, expressed as a percentage by mass of the product as received, is given by the following equations:

where

m0 is the mass in g, of the test portion (B.2.1 or B.2.2)

m1 is the mass, in g, of the test portion after drying (B.4)

where

m2 is the mass, in g, of sample taken before pre-conditioning.

m3 is the mass, in g, of the pre-conditioned sample.

The result is the arithmetic mean of two single determinations which meet acceptable repeatability limits (r). The result is expressed to two decimal places.

8(normative)

For ashing dishes suitable for use at 900 °C, bring previously cleaned dishes up to the incineration temperature being employed by putting them in a muffle furnace for 5 min, leave them to cool in the desiccator, then weigh them to within 0.1 mg.

For ashing, dishes suitable for use at 550 °C, place the cleaned dishes in an oven for the time required for drying (for example, 90 min at 130 °C). Immediately before use, remove the dishes from the oven and leave them to cool in a desiccator, then weigh them to within 0.1 mg.

From the prepared sample rapidly weigh to within 0.1 mg a test portion between 3.9 g and 4.1 g in the case of incineration at 900 °C and between 4.9 g and 5.1 g in the case of incineration at 550 °C.

In the case of low density products, the test portion can be between 2 g ± 0.1 g and 3 g ± 0.1 g.

In the prepared and weighed ashing dish, spread out the product, without packing it, to form a uniform layer.

Place the ashing dish and its contents at the entrance of the furnace brought up to the ashing temperature.

At 900 °C, the products burst into flame spontaneously. At 550 °C, it is necessary to ignite them with ethanol.

For pre-ashing at 550 °C, it is permissible to put the dishes in the cool furnace and to let the temperature of the furnace rise to the target temperature.

Wait until the product has finished burning, and then place the dish inside the furnace.

Close the furnace door.

Continue the ashing until combustion of the entire product, including the carbon particles contained in the residue, is complete, namely 1 h minimum at 900 °C, and 4 h minimum at 550 °C.

Once the ashing is completed, remove the dish from the furnace and place it in the desiccator to cool. In order to maintain the efficiency of the desiccator, do not stack dishes.

9Due to the hygroscopic nature of the ash, as soon as the dish has reached ambient temperature (namely 15 min to 20 min for metallic dishes and 60 min to 90 min minimum for quartz or silica dishes), weigh rapidly to within 0.1 mg.

For test portions incinerated at 550 °C, special precautions shall be taken to avoid flaky residues being swept away with the influx of air on opening the desiccator.

The validity of the results obtained on this sample shall be checked with respect to the laboratory’s self-inspection criteria or any internationally acceptable validation method.

EXAMPLE An example of a laboratory’s self-inspection criteria is a control chart

Conduct at least two determinations on the same test sample.

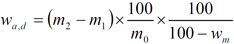

The ash yield, as mass fraction on the dry matter basis expressed as a percentage, wa,d, is given by the following equation :

where

m0 is the mass, in grams, of the test portion

m1 is the mass, in grams, of the ashing dish

m2 is the mass, in grams, of the ashing dish and the incinerated residue

wm is the moisture content, as a percentage by mass, of the sample

Take as a result to the nearest 0.01 % by mass.

Express the result to the nearest 0.01 % by mass.

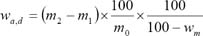

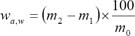

If needed, the ash yield, as mass fraction on the wet matter basis, expressed as a percentage, wa,w, is given by the following equation :

(normative)

Soak strips of filter paper (5.0 cm × 1.5 cm) in an aqueous solution of 0.05 M picric acid, previously neutralized with sodium bicarbonate and filtered. Leave the impregnated paper to dry at ambient temperature.

Cut cassava bread into small pieces and place in a test tube with 1.5 ml of distilled water, and 6 drops of chloroform, followed by briefly crushing the mixture with a glass rod. Stopper the tube with a cork containing a strip of picrate-impregnated paper hanging down from the stopper, and incubate at ambient temperature for 2 h.

A colour change of the picrate – impregnated paper, from yellow to brown-red, indicates the release of HCN by the sample. If there is no release of HCN within 2 h, indicating a negative test, leave the tube at ambient temperature for 24 h and 48 h, so that it can be re-examined.

A brown-red colouration within 2 h indicates the presence of cyanogenic glycosides and the respective hydrolytic enzyme, and the samples are considered cyanogenic in the field.

A brown-red colour appearing within 48 h indicates that the cyanogenic glycosides spontaneously released HCN without the action of enzyme.

No colour change after 48 h indicates that the test was negative for cyanogenic glycosides.

11

The CARICOM Regional Organisation for Standards and Quality (CROSQ) was created as an Inter-Governmental Organisation by the signing of an agreement among fourteen Member States of the Caribbean Community (CARICOM). CROSQ is the regional centre for promoting efficiency and competitive production in goods and services, through the process of standardization and the verification of quality. It is the successor to the Caribbean Common Market Standards Council (CCMSC), and supports the CARICOM mandate in the expansion of intra-regional and extra-regional trade in goods and services.

CROSQ is mandated to represent the interest of the region in international and hemispheric standards work, to promote the harmonization of metrology systems and standards, and to increase the pace of development of regional standards for the sustainable production of goods and services in the CARICOM Single Market and Economy (CSME), and the enhancement of social and economic development.

CROSQ VISION:

The premier CARICOM organisation for the development and promotion of an Internationally Recognised Regional Quality Infrastructure; and for international and regional harmonized CARICOM Metrology, Standards, Inspection, Testing and Quality Infrastructure

CROSQ MISSION:

The promotion and development of standards and standards related activities to facilitate international competitiveness and the sustainable production of goods and services within the CARICOM Single Market and Economy (CSME) for the enhancement of social and economic development

12 13