In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

CARICOM Regional Organisation for Standards and Quality (CROSQ)

2nd Floor Nicholas House

29 & 30 Broad Street

Bridgetown, St Michael

Barbados

T: 246.622.7670 | F: 246.622.7678

Website: http://www.crosq.org

© CROSQ 2010 – All rights reserved

Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without permission.

CRS 17: 2010

CARICOM Regional Organisation for Standards and Quality (CROSQ)

2nd Floor, Nicholas House

29 & 30 Broad Street

Bridgetown, St. Michael

Barbados

T: 246.622.7670 | F: 246.622.7678

Website: http://www.crosq.org

© CROSQ 2010 – All rights reserved. No part of this publication is to be reproduced without the prior written consent of CROSQ.

ISBN 978-976-8234-01-8

ICS 39.060

| AMENDMENT NO. | DATE OF ISSUE | TYPE OF AMENDMENT | NO. OF TEXT AFFECTED | TEXT OF AMENDMENT |

|---|---|---|---|---|

This CARICOM Regional Standard was prepared under the supervision of the Regional Technical Committee for General Commodities (RTC 18), (hosted by CARICOM Member State, Guyana), which at the time comprised the following members:

| Members | Representing |

|---|---|

| Mr. Andy Williams (Chairperson) | Guyana National Association of Goldsmiths and Jewellers |

| Ms Eileen | Guyana Consumer Association |

| Mr. Desmond | King’s Jewellery World |

| Mr. Stephen Narine | Steve’s Jewellery Establishment |

| Ms. Devika Prashad | Guyana Gold Board |

| Mr. Sharma Seepersaud Maraj | L. Seepersaud Maraj and sons |

| Mr. William Woolford | Guyana Geology and Mines Commission |

| Mr. Abidin Mohamed (Technical Secretary) | Guyana National Bureau of Standards |

| Foreword | 1 | ||

| 1 | Scope | 2 | |

| 2 | Terms and definitions | 2 | |

| 3 | Designation of pure gold content | 3 | |

| 4 | Requirements | 4 | |

| 4.1 | Gold | 4 | |

| 4.2 | Alloying metals | 4 | |

| 4.3 | Solder | 5 | |

| 4.4 | Settings | 5 | |

| 4.5 | Base metal parts | 5 | |

| 4.6 | Alloyed gold | 5 | |

| 4.7 | Manufacture | 6 | |

| 5 | Sampling | 6 | |

| 6 | Assaying | 6 | |

| 7 | Tolerances | 6 | |

| 8 | Marking | 6 | |

| 9 | Heat treatment | 7 | |

| Annex A (normative) Determination of gold content in articles - Cupellation method (Fire assay) | 8 | ||

| Annex B (normative) Determination of gold content in articles - Modified fire assay method | 11 | ||

| Annex C (informative) Formulae to produce alloy gold of a particular purity | 13 | ||

| Annex D (informative) Guidelines for best practice – Melting and casting | 15 | ||

| Annex E (informative) Heat Treatment or Annealing | 16 | ||

| List of tables | |||

| Table 1 — Pure gold content | 3 | ||

This CARICOM Regional Standard was developed in an effort to:

This standard was approved by the Twenty-ninth Council for Trade and Economic Development (COTED) on 8-9 February 2010.

In the development of this standard, assistance was derived from the following:

This standard specifies:

NOTE: It does not specify requirements for design of gold articles and does not apply to gold articles intended for industrial purposes such as dentistry, electronics, official coins, gold bars and other such uses.

For the purposes of this standard, the following terms and definitions shall apply.

intimate association of gold with one or more metals

maintenance of a metal at a specified temperature for a specific length of time and then gradually cooling it at a predetermined rate

art of determining the quantity of metal contained in an ore, alloys or metallurgical products by the dry or wet method.

any non-precious alloy or metal

process of pouring molten metal in a mould

parts that jewellers use in marking jewellery

EXAMPLE clasps, hooks and settings

measure of concentration of metal or metals contained, stated in parts per thousand (0/00)

pure gold or any alloyed gold

2ornaments, jewellery and artefacts made from gold or alloyed gold

organization or individual who imports gold articles into a CARICOM Member State

measure of purity of gold; pure gold being 24 karats

organization or individual who manufactures, produces or processes any gold article for sale

soft yellow metal with a melting point of 1064.43 °C, boiling point of 2807 +2 °C and a specific gravity of 19.3 at 20 °C

quick cooling of heated metals by plunging them into liquids or subjecting them to air blast

organization or individual who offers for sale, exposes for sale and displays in such a manner so as to invite an offer for retail sale of gold articles

alloy used for setting stones in gold articles

any fusible metal or alloy used to effect the union of two metals by melting it into the joint

The pure gold content of gold articles shall be designated as outlined in Table 1 as:

| In 1000 parts by mass of alloyed gold/fineness | In 24 parts of alloyed gold/karat K or Kt |

|---|---|

| 375 | 9 |

| 416 | 10 3 |

| 500 | 12 |

| 583 | 14 |

| 625 | 15 |

| 750 | 18 |

| 833 | 20 |

| 916 | 22 |

| 958 | 23 |

Solder and findings that are made of alloyed gold shall be of the same fineness (or karat) as that of the gold article with the permissible tolerance stated in 3.3 so as not to substantially reduce the purity. However, in the case of 23 karat gold articles when it is not possible to use solder of the same karat, solder of the next immediate lower karat (22 kt) shall be used, providing the overall purity of the article is not substantially reduced.

A tolerance of not more than three (≤ 3) parts per thousand (0/00) below the stipulated fineness shall be allowed on the gold content of gold articles as sampled and tested as specified in this standard.

Importers shall ensure that all gold articles and gold findings imported into CARICOM for the purpose of sale comply with the requirements of this standard.

The seller shall ensure that all gold articles and gold findings displayed for the purpose of sale, comply with the requirements of this standard.

In the determination of the purity of gold articles as outlined in Table 1, assay methods as described in Annex A or Annex B shall be used.

Gold used in the preparation of alloys for the manufacture of gold articles, solder and findings shall be of a known purity (fineness or karat).

When necessary, the gold shall be tested to determine purity before use in the alloying process in accordance with Annex A or Annex B.

For the purpose of alloying, only the following metals or alloys shall be used:

Premixed alloy can also be used providing the metal composition is known and does not contravene the provision of 4.2.1.

The composition of the alloyed gold shall be determined by the manufacturer, and depends on the karat and or colour of alloyed gold required.

Solder used in the manufacture of gold articles shall preferably be in the form of paste. However other forms including sheet, wire and strips can be used, subject to the condition that the final purity of the jewellery is as declared.

Solder and findings used in the manufacture of gold articles shall be of the same fineness (or karat) as that of the gold article so as not to substantially reduce the purity. However, in case of 23 karat gold articles where it is not possible to use solder of the same karat, solder of next immediate lower karat may be used, provided that the overall purity of the article is not substantially reduced.

EXAMPLE 22 karat solder can be used for 23 karat articles.

Only gold, platinum or palladium alloys shall be used as settings for stones and other materials in gold articles.

The composition of settings shall be as follows:

Base metal may be used only for parts specified below and shall not be soldered or welded to gold or parts of alloyed gold:

Base metal parts shall be clearly and indelibly stamped or engraved with the word “metal” or with the name of metal or symbol of metal except where the article is too small to be labelled (see 8).

Allowance shall be made for the varying gold content in the metal used as raw material, when preparing alloys that have to conform to a fixed gold content.

5Depending on the fineness or karat of gold, the parts of gold and alloy required to produce alloyed gold of a particular purity shall be calculated from the following formulae in Annex C:

Prior to any manufacturing, alloying and testing, care shall be taken to ensure that all environmental and occupational safety and health laws are complied with.

Unless otherwise specified, samples shall be taken from the alloyed gold to be used in the manufacture of gold articles.

NOTE Any other sampling plan may also be followed subject to agreement between the contracting parties or as specified by the certification/inspection agency as the case may be.

Samples taken as prescribed in 4.6 shall be assayed in accordance with the test method outlined in Annex A or Annex B. The actual mass of the sample shall be as prescribed in the respective test methodology.

A tolerance of not more than 3 parts per thousand (0/00) below the stipulated fineness shall be allowed on the gold content of gold articles as sampled and tested as specified in this standard.

Gold articles shall be clearly and indelibly engraved or stamped with the following information:

EXAMPLE 500 or 12 K or 12 Kt

The mark required by this standard shall be isolated from any other symbols or code number that appears on the gold article.

Where a gold article is so configured that the marking required by this standard cannot be clearly engraved or stamped on it, the specified marking shall appear on a suitable and clearly labelled card or tag that is securely attached to the article, with the relevant information pertaining to the product.

Base metals that constitute part of gold articles because of functional reasons shall be clearly and indelibly stamped or engraved with the word “metal” or specific designation of metal, along with the mass of alloyed gold and other markings as specified in 8.1.

Any gold article which is not solid or which is made with a hollow center and then filled with base metal, cement or other substances, thereby giving the article an added mass shall indicate the mass of alloyed gold in the article, in addition to other markings as specified in 8.1.

6Where gold articles are imported and do not conform to the labeling and marking requirements of this standard, it is permissible for any designated manufacturer or goldsmith to provide the labeling and marking in conformity with this standard.

Any gold article which is plated with alloyed gold of a different purity of the gold beneath shall be stamped with the purity and thickness (in mm) of the plated layer along with other markings for the alloyed gold beneath, as specified in 8.1.

A process of heat treatment or annealing should be used to prevent a possible reduction in thickness of a cast article to one half of its original during the process of melting and casting (see Annex E).

7(normative)

This method is used as the reference method for the determination of gold content in gold articles and applies specifically to alloyed gold incorporating silver, copper and zinc.

The sample of gold article is mixed with the required quantity of silver, put on lead foil, and properly wrapped. The wrapped lead foil capsule is then placed in a cupel which is put in a cupellation furnace until a precious metal button is obtained. After flattening and rolling the metal button, the silver is extracted (parted) in nitric acid and the gold is weighed.

Possible systematic errors in the procedure can be eliminated by assaying standard proof samples simultaneously.

Only reagents/materials of recognized analytical grade and distilled water or water of equivalent purity shall be used for the analysis. The following shall be used:

General laboratory apparatus shall be used, in addition to the following:

NOTE A muffle furnace is not satisfactory for this purpose.

Take two samples of the alloy in the range of between 125 mg and 250 mg each (m1). Weigh the samples accurately to the nearest 0.01 mg and put each separately into assay grade lead foil (see A.3). The mass of foil should be at least 15 g for each sample.

Add pure silver (see A.3), equivalent to 2.5 to 3.0 times the mass of fine gold present in the sample.

Roll and compress the lead foils into tight balls.

Place each separately in magnesium oxide cupels which have been pre-heated to at least 1000 °C in the cupellation furnace.

Place the cupels in the cupellation furnace at 1050 °C to 1150 °C. Continue heating for about 30 min under oxidizing conditions.

Remove the cupels from the furnace and allow the precious metal buttons to cool down before lifting them from the cupels with the assay pliers. Squeeze the buttons and brush the undersides carefully with the assay cleaning brush (see A.4) to remove any adhering cupel material.

Flatten the buttons on a polished anvil (see A.4) with a polished hammer (see A.4) as thin as possible without contamination or loss of gold.

Place the flattened buttons separately into parting cups (see A.4).

Immerse the flattened buttons in 15 ml of 30 % nitric acid which has been reheated to at least 5 °C below boiling temperature and bring to the boil. Continue heating for 30 min or until the evolution of nitrous fumes has ceased, whichever is longer.

Decant and add 15 m of 70 % nitric acid (see A.3). Leave for 30 min.

Decant and repeat (see A.5.10) at least 3 times.

Decant and wash the gold with warm distilled water (60 °C to 70 °C) until it is free of silver nitrate.

Transfer the gold to parting cups (see A.4), dry on a hot plate and anneal at 700 °C to 750 °C for about 5 min. Cool down and weigh the gold (m2).

NOTE For coated articles, appropriate precautions that have been agreed upon shall be taken to exclude the coatings from the determination. Two samples are used in order to increase the degree of accuracy. The average gold present in both samples is taken.

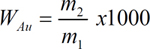

9Calculate the gold content WAu in parts by mass per thousand (0/00), of the alloy using the formula:

where

| WAu | is the gold content; |

| m1 | is the mass, in mg, of the sample; |

| m2 | is the mass, in mg, of the gold button. |

When the composition of the samples is unknown, use a preliminary assay for the estimation of the fineness of gold. If the gold button breaks up during the parting process, this is often an indication of excess silver.

The cupel should be examined carefully to ensure that the precious metal button contains all the sample gold. Small droplet residues indicate the need to repeat the determination in a smaller cupel.

10(normative)

This method is used as a reference method in the determination of gold content in gold articles and applies specifically to alloyed gold incorporating silver and copper.

The sample of gold article is mixed with the required quantity of silver and then melted on a piece of Purple Heart wood. The metal button, after flattening and rolling, is immersed in nitric acid where the silver is extracted and the remaining gold is weighed. Possible systematic errors in the procedure can be eliminated by assaying standard proof samples simultaneously.

The reagents include:

The apparatus include the following:

Weigh accurately 200 mg to 250 mg of a sample of alloy to the nearest 0.01 mg (m1).

Add pure silver 600 mg to 750 mg (equivalent to 3 times the mass of the gold present in the sample).

Using a jeweller’s torch, melt the sample (containing copper and silver) on a piece of Purple Heart wood.

NOTE 1 Purple Heart is the most suitable wood as other woods give off moisture leading to inaccurate masses.

NOTE 2 Borax is used as a flux to ensure fusion while melting (no more than a few grains).

Flatten the button on a clean anvil with a clean hammer and mill the flattened button as thin as possible without contamination or loss of gold.

Wash the strip with detergent/soda bicarbonate to remove the oil or rust gathered from the mill.

Using jewellers shears, cut the strip into small pieces. Care should be taken not to lose any piece while cutting.

Immerse the small pieces in 80 ml of 30 % nitric acid which has been preheated to just below boiling temperature. Continue heating for 30 min until the evolution of nitrous fumes has ceased.

Decant and wash the gold with water at least three or four times with preferably clean or distilled water.

Repeat step B.5.7 using 70 % nitric acid.

Repeat step B.5.8.

Anneal for about 1 min, allow to air cool for 5-10 min and weigh the gold (m2).

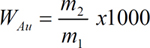

Calculate the gold content WAu in parts by mass per thousand, of the alloy using the formula:

where

| WAu | is the gold content; |

| m1 | is the mass, in mg, of the sample; |

| m2 | is the mass, in mg, of the gold. |

(informative)

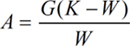

where

| A | is weight of alloying metal needed to lower the purity; |

| K | is purity of gold to be alloyed in fineness (parts per 1000) [raw material]; |

| G | is weight of gold to be alloyed (raw material); and |

| W | is purity of alloyed gold wanted in fineness (parts per 1000) [gold article]. |

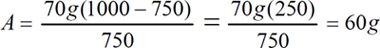

EXAMPLE 1 A jeweller has 70 grams of pure gold (fineness 1000) which he wants to alloy down to 18 karat (fineness 750). How many grams of alloy must be added?

Thus, 23.33 g of alloy added to 70 g of fine gold will give (70 + 23.33), 93.33 g of 18 K mixture of alloyed gold.

EXAMPLE 2 How many grams of alloy must be added to 120 grams of 18 K gold to lower it to 12 K?

Thus, 60 g of alloy added to 120 g of 18 K gold will give (120 + 60), 180 g of 12 K mixture of alloyed gold.

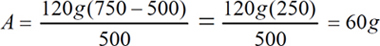

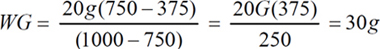

When it is necessary to raise the karat of gold (usually scrap) the following formula it used:

where:

| WG | is weight of gold to be used in raising the karat; |

| PW | is purity of alloyed gold wanted expressed as fineness (0/00) [gold article]; |

| PS | is purity of scrap expressed as fineness (0/00); 13 |

| PG | is purity of gold to be used in raising the karat expressed as fineness (0/00); and |

| S | is weight of scrap. |

EXAMPLE 1 A jeweller has 20 grams of 9 K scrap which he desires to raise to 18 K. How much fine gold (24 K) must be added?

Thus, 30 grams of 24 K gold added to 20 g of 9 K gold will give 50 g of 18 K gold.

14(informative)

Accessories including crucibles, furnace, mould and mould dressing shall be used for the preparation of alloyed gold.

The suitable torch capable of attaining a temperature of 2000 °C shall be used for melting.

The following process shall be used for melting and casting:

(informative)

Annealing shall be carried out under non-oxidising conditions to prevent oxidation of the base metals present in the alloys.

NOTE 1 Some oxidation is inevitable and particularly with large pieces, annealing may not be perfectly uniform.

NOTE 2 The duration of annealing will depend on the size of article, however, as a general rule, articles shall be removed as soon as they are uniformly heated to annealing temperature and shall not be allowed to soak for more than a minute or two.

Quenching is an essential operation after annealing and shall be performed from a temperature of 400 °C. It is advantageous to quench the alloy in dilute sulpuhric acid of about 5 % to 10 % strength.

NOTE Experience and judgment of the craftsman are important guides in this process.

A suitable temperature between 550 °C and 650 °C is required for annealing. However, the exact temperature suitable for annealing any particular alloy may only be ascertained by practice.

NOTE For ideal results, a muffle furnace equipped with pyrometer and heated by gas or electrically, and with attachment for maintaining non-oxidising atmosphere is the best equipment. Generally a torch can be used for annealing small articles. In this process, the article is thinly coated with a mixture of boric acid and methylated spirit and dried. It is next placed in a charcoal block and heated as far as possible to the time and temperature combination.

16

The CARICOM Regional Organisation for Standards and Quality (CROSQ) was created as an Inter-Governmental Organisation by the signing of an agreement among fourteen Member States of the Caribbean Community (CARICOM). CROSQ is the regional centre for promoting efficiency and competitive production in goods and services, through the process of standardization and the verification of quality. It is the successor to the Caribbean Common Market Standards Council (CCMSC), and supports the CARICOM mandate in the expansion of intra-regional and extra-regional trade in goods and services.

CROSQ is mandated to represent the interest of the region in international and hemispheric standards work, to promote the harmonization of metrology systems and standards, and to increase the pace of development of regional standards for the sustainable production of goods and services in the CARICOM Single Market and Economy (CSME), and the enhancement of social and economic development.

CROSQ VISION:

The premier CARICOM organisation for the development and promotion of an Internationally Recognised Regional Quality Infrastructure; and for international and regional harmonized CARICOM Metrology, Standards, Inspection, Testing and Quality Infrastructure

CROSQ MISSION:

The promotion and development of standards and standards related activities to facilitate international competitiveness and the sustainable production of goods and services within the CARICOM Single Market and Economy (CSME) for the enhancement of social and economic development

17 18