In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

CARICOM Regional Organisation for Standards and Quality (CROSQ)

2nd Floor Nicholas House

29 & 30 Broad Street

Bridgetown, St Michael

Barbados

T: 246.622.7670 | F: 246.622.7678

Website: http://www.crosq.org

© CROSQ 2010 – All rights reserved

Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without permission.

CRCP 4: 2010

CARICOM Regional Organisation for Standards and Quality (CROSQ)

2nd Floor, Nicholas House

29 & 30 Broad Street

Bridgetown, St. Michael

Barbados

T: 246.622.7670 | F: 246.622.7678

Website: http://www.crosq.org

© CROSQ 2010 – All rights reserved. No part of this publication is to be reproduced without the prior written consent of CROSQ.

ISBN 978-976-8234-20-9

ICS 67.120.30

| AMENDMENT NO. | DATE OF ISSUE | TYPE OF AMENDMENT | NO. OF TEXT AFFECTED | TEXT OF AMENDMENT |

|---|---|---|---|---|

This CARICOM Regional Code of Practice was developed under the supervision of the Regional Technical Committee for Foods, Subcommittee for Fish and Fishery Products (hosted by the CARICOM Member State, Jamaica), which at the time comprised the following members:

| Members | Representing |

|---|---|

| Dr. Lloyd Webb (Chairperson) | Caribbean Food and Nutrition Institute |

| Ms. Peta-Ann Hutchinson | Newport Fish and Meats |

| Mr. Garth Wright | Rainforest Seafoods |

| Mrs. Christine Fray-Aiken | University of Technology |

| Ms. Angella Smith | Consumer Affairs Commission |

| Ms. Tanille Latty (Technical Secretary) | Bureau of Standards Jamaica (BSJ) |

| Foreword | 1 | |||

| 1 | Scope | 2 | ||

| 2 | Normative references | 2 | ||

| 3 | Terms and definitions | 3 | ||

| 3.1 | General definitions | 3 | ||

| 3.2 | Aquaculture | 6 | ||

| 3.3 | Live and raw bivalve molluscs | 8 | ||

| 3.4 | Fresh, frozen and minced fish | 9 | ||

| 3.5 | Frozen surimi | 10 | ||

| 3.6 | Quick-frozen coated fish products | 11 | ||

| 3.7 | Salted and dried salted fish | 11 | ||

| 3.8 | Shrimps and prawns | 13 | ||

| 3.9 | Cephalopods | 14 | ||

| 3.10 | Canned fish and shellfish | 14 | ||

| 3.11 | Retail | 15 | ||

| 4 | Pre-requisite programme | 15 | ||

| 4.1 | General | 15 | ||

| 4.2 | Fishing and harvesting vessel design and construction | 15 | ||

| 4.3 | Facility design and construction | 17 | ||

| 4.4 | Design and construction of equipment and utensils | 18 | ||

| 4.5 | Hygiene control programme | 19 | ||

| 4.5.1 | Schedules | 19 | ||

| 4.5.2 | Requirements | 19 | ||

| 4.6 | Personal hygiene and health | 20 | ||

| 4.6.1 | General | 20 | ||

| 4.6.2 | Facilities and equipment | 20 | ||

| 4.6.3 | Personnel hygiene | 21 | ||

| 4.7 | Transportation | 21 | ||

| 4.8 | Product traceability and recall procedures | 21 | ||

| 4.9 | Training | 22 | ||

| 5 | General considerations for the handling of fresh fish, shellfish and other aquatic invertebrates | 22 | ||

| 5.1 | General | 22 | ||

| 5.2 | Time and temperature control | 22 | ||

| 5.2.1 | Minimise deterioration – time control | 23 | ||

| 5.2.2 | Minimise deterioration - temperature control | 23 | ||

| 5.2.3 | Minimise deterioration – handling | 23 | ||

| 6 | Hazard analysis critical control point (HACCP) and defect action point (DAP) analysis | 24 | ||

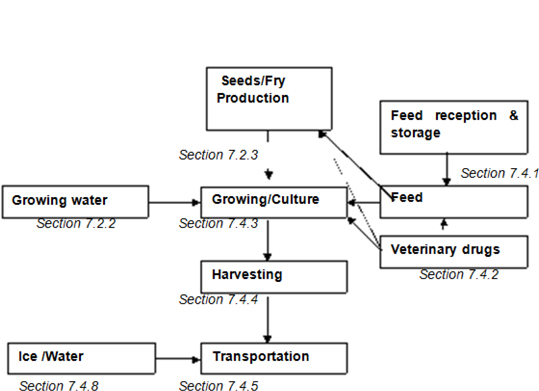

| 7 | Aquaculture production | 24 | ||

| 7.1 | General | 24 | ||

| 7.2 | General considerations of aquaculture production | 24 | ||

| 7.2.1 | Site selection | 24 | ||

| 7.2.2 | Fish growing water quality | 25 | ||

| 7.2.3 | Source of fry and fingerlings | 25 | ||

| 7.3 | Hazards and defects | 25 | ||

| 7.3.1 | Hazards | 25 | ||

| 7.3.2 | Defects | 25 | ||

| 7.4 | Production operations | 26 v | ||

| 7.4.1 | Feed Supply | 26 | ||

| 7.4.2 | Veterinary drugs | 27 | ||

| 7.4.3 | Growing | 28 | ||

| 7.4.4 | Harvesting | 28 | ||

| 7.4.5 | Holding and transportation | 29 | ||

| 7.4.6 | Storage and transport of live fish | 30 | ||

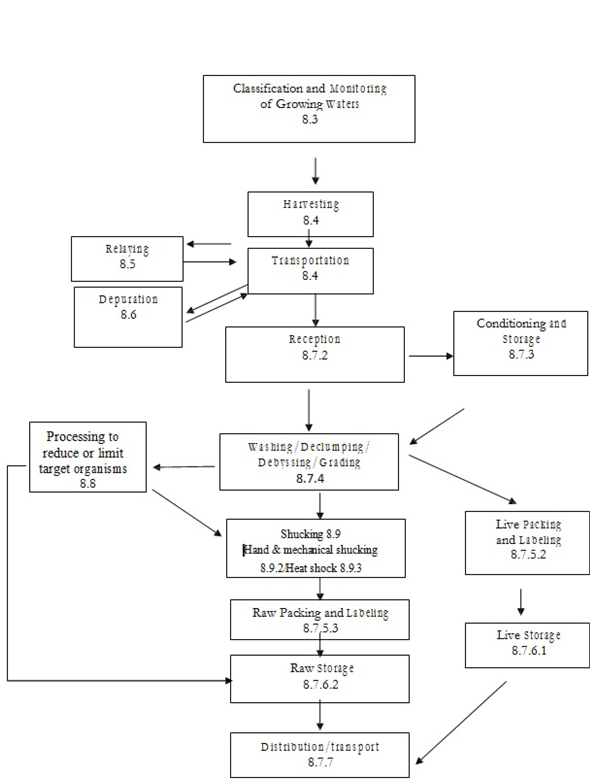

| 8 | Live and raw bivalve molluscs | 33 | ||

| 8.1 | General | 33 | ||

| 8.2 | Classification and monitoring of growing areas | 33 | ||

| 8.2.1 | Potential hazards and defects | 33 | ||

| 8.2.2 | Classification of growing areas | 34 | ||

| 8.2.3 | Monitoring of growing areas | 34 | ||

| 8.3 | Harvesting and transportation of live bivalve molluscs | 37 | ||

| 8.3.1 | Potential hazards | 37 | ||

| 8.3.2 | Potential defects | 38 | ||

| 8.3.3 | Technical guidance | 38 | ||

| 8.4 | Relaying | 38 | ||

| 8.4.1 | General | 38 | ||

| 8.4.2 | Potential hazards | 39 | ||

| 8.4.3 | Potential defects | 39 | ||

| 8.4.4 | Technical guidance | 39 | ||

| 8.5 | Depuration | 39 | ||

| 8.5.1 | General | 39 | ||

| 8.5.2 | Potential hazards | 40 | ||

| 8.5.3 | Potential defects | 40 | ||

| 8.5.4 | Technical guidance | 40 | ||

| 8.6 | Processing of bivalve molluscs in a distribution centre or an establishment | 41 | ||

| 8.6.1 | General | 41 | ||

| 8.6.2 | Reception | 41 | ||

| 8.6.3 | Conditioning and storage of bivalve molluscs | 42 | ||

| 8.6.4 | Washing, declumping, debyssing and grading | 43 | ||

| 8.6.5 | Packing and labelling | 43 | ||

| 8.6.6 | Storage | 45 | ||

| 8.6.7 | Distribution and transport | 46 | ||

| 8.7 | Processing to reduce or limit target organisms | 47 | ||

| 8.7.1 | General | 47 | ||

| 8.7.2 | Potential hazards | 47 | ||

| 8.7.3 | Potential defects | 47 | ||

| 8.7.4 | Technical guidance | 47 | ||

| 8.8 | Shucking | 48 | ||

| 8.8.1 | Hand and mechanical shucking and washing | 48 | ||

| 8.8.2 | Heat shocking of bivalve molluscs followed by packing | 48 | ||

| 8.9 | Documentation | 49 | ||

| 8.10 | Lot identification and recall procedures | 50 | ||

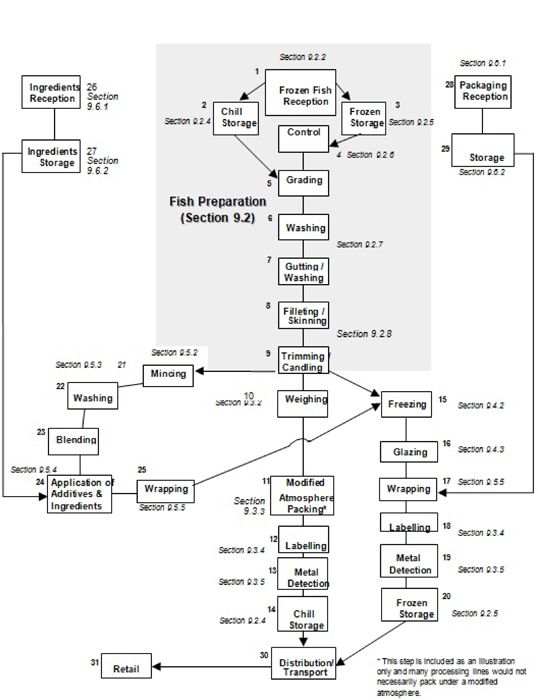

| 9 | Processing of fresh, frozen and minced fish | 50 | ||

| 9.1 | General | 50 | ||

| 9.2 | Finfish preparation | 50 | ||

| 9.2.1 | General | 50 | ||

| 9.2.2 | Raw, fresh or frozen fish reception (processing step 1) | 50 | ||

| 9.2.3 | Sensory evaluation of fish | 52 | ||

| 9.2.4 | Chilled storage (processing steps 2 and 14) | 52 | ||

| 9.2.5 | Frozen storage (processing steps 3 and 20) | 53 | ||

| 9.2.6 | Control thawing (processing step 4) | 53 | ||

| 9.2.7 | Washing and gutting (processing steps 6 and 7) | 54 | ||

| 9.2.8 | Filleting, skinning, trimming and candling (processing steps 8 and 9) | 55 | ||

| 9.3 | Processing of vacuum or modified atmosphere packed fish | 56 | ||

| 9.3.1 | Weighing (processing step 10) | 56 | ||

| 9.3.2 | Vacuum or modified atmosphere packaging (processing step 11) | 56 vi | ||

| 9.3.3 | Labelling (processing steps 12 and 18) | 57 | ||

| 9.3.4 | Metal detection (processing steps 13 and 19) | 58 | ||

| 9.4 | Processing of frozen fish | 58 | ||

| 9.4.1 | Freezing Pprocess (processing step 15) | 58 | ||

| 9.4.2 | Glazing (processing step 16) | 59 | ||

| 9.5 | Processing of minced fish | 60 | ||

| 9.5.1 | Mincing fish using mechanical separation process (processing step 21) | 60 | ||

| 9.5.2 | Washing of minced fish (processing step 22) | 61 | ||

| 9.5.3 | Blending and application of additives and ingredients to minced fish (processing steps 23 and 24) | 61 | ||

| 9.5.4 | Wrapping and packing (processing steps 17 and 25) | 62 | ||

| 9.6 | Packaging, labels and ingredients | 62 | ||

| 9.6.1 | Reception of packaging, labels and ingredients (processing steps 26 and 28) | 62 | ||

| 9.6.2 | Storage of packaging, labels and ingredients (processing steps 27 and 29) | 63 | ||

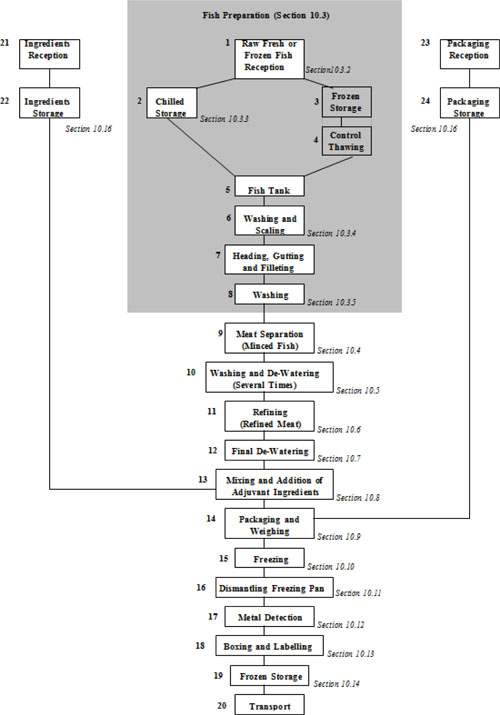

| 10 | Processing of frozen surimi | 63 | ||

| 10.1 | General | 63 | ||

| 10.2 | General considerations of hazards and defects for frozen surimi production | 64 | ||

| 10.2.1 | Hazards | 64 | ||

| 10.2.2 | Defects | 64 | ||

| 10.3 | Fish preparation (processing steps 1 to 8) | 64 | ||

| 10.3.1 | General | 64 | ||

| 10.3.2 | Raw, fresh and frozen fish reception (processing step 1) | 64 | ||

| 10.3.3 | Chilled storage (processing step 2) | 65 | ||

| 10.3.4 | Washing and scaling (processing step 6) | 66 | ||

| 10.3.5 | Washing (processing step 8) | 66 | ||

| 10.4 | Fish flesh separation process (processing step 9) | 66 | ||

| 10.4.1 | Potential hazards | 66 | ||

| 10.4.2 | Potential defects | 67 | ||

| 10.4.3 | Technical guidance | 67 | ||

| 10.5 | Washing and de-watering process (processing step 10) | 67 | ||

| 10.5.1 | Potential hazards | 67 | ||

| 10.5.2 | Potential defects | 67 | ||

| 10.5.3 | Technical guidance | 67 | ||

| 10.6 | Refining process (processing step 11) | 68 | ||

| 10.6.1 | Potential hazards | 68 | ||

| 10.6.2 | Potential defects | 68 | ||

| 10.6.3 | Technical guidance | 68 | ||

| 10.7 | Final de-watering process (processing step 12) | 68 | ||

| 10.7.1 | Potential hazards | 68 | ||

| 10.7.2 | Potential defects | 69 | ||

| 10.7.3 | Technical guidance | 69 | ||

| 10.8 | Mixing and addition of adjuvant ingredients process (processing step 13) | 69 | ||

| 10.8.1 | Potential hazards | 69 | ||

| 10.8.2 | Potential defects | 69 | ||

| 10.8.3 | Technical guidance | 69 | ||

| 10.9 | Packaging and weighing (processing step 14) | 70 | ||

| 10.9.1 | Potential hazards | 70 | ||

| 10.9.2 | Potential defects | 70 | ||

| 10.9.3 | Technical guidance | 70 | ||

| 10.10 | Freezing operation (processing step 15) | 71 | ||

| 10.10.1 | Potential hazards | 71 | ||

| 10.10.2 | Potential defects | 71 | ||

| 10.10.3 | Technical guidance | 71 | ||

| 10.11 | Dismantling freezing pan (processing step 16) | 71 | ||

| 10.11.1 | Potential hazards | 71 | ||

| 10.11.2 | Potential defects | 71 | ||

| 10.11.3 | Technical guidance | 71 | ||

| 10.12 | Metal detection (processing step 17) | 71 | ||

| 10.12.1 | Potential hazards | 71 vii | ||

| 10.12.2 | Potential defects | 71 | ||

| 10.12.3 | Technical guidance | 72 | ||

| 10.13 | Boxing and labelling (processing step 18) | 72 | ||

| 10.13.1 | Potential hazards | 72 | ||

| 10.13.2 | Potential defects | 72 | ||

| 10.13.3 | Technical guidance | 72 | ||

| 10.14 | Frozen storage (processing step 19) | 72 | ||

| 10.14.1 | Potential hazards | 72 | ||

| 10.14.2 | Potential defects | 72 | ||

| 10.14.3 | Technical guidance | 72 | ||

| 10.15 | Raw material reception - packaging and ingredients (processing steps 21 and 22) | 73 | ||

| 10.16 | Raw material storage - packaging and ingredients (processing steps 23 and 24) | 73 | ||

| 11 | Processing of quick-frozen coated fish and shellfish products | 73 | ||

| 11.1 | General | 73 | ||

| 11.2 | Identification of hazards and defects | 73 | ||

| 11.2.1 | Potential hazards | 73 | ||

| 11.2.2 | Potential defects | 73 | ||

| 11.3 | Technical guidance | 73 | ||

| 11.4 | Processing operations - fish | 74 | ||

| 11.4.1 | Reception | 74 | ||

| 11.4.2 | Storage of raw material, other ingredients and packaging material | 76 | ||

| 11.4.3 | Frozen fish block or fillet tempering | 77 | ||

| 11.4.4 | Unwrapping, unpacking | 77 | ||

| 11.4.5 | Production of fish core | 78 | ||

| 11.4.6 | Separation of pieces | 79 | ||

| 11.4.7 | Coating | 79 | ||

| 11.4.8 | Pre-frying | 80 | ||

| 11.4.9 | Re-freezing | 81 | ||

| 11.4.10 | Packaging and labelling | 82 | ||

| 11.4.11 | Storage of end products | 82 | ||

| 11.4.12 | Transport of end product | 83 | ||

| 11.5 | Processing operations of molluscan shellfish | 83 | ||

| 11.5.1 | General | 83 | ||

| 11.5.2 | Reception | 84 | ||

| 11.5.3 | Storage of raw material, other ingredients and packaging materials | 85 | ||

| 11.5.4 | Unpacking and unwrapping | 85 | ||

| 11.5.5 | Production of coated molluscan shellfish | 86 | ||

| 11.5.6 | Coating | 87 | ||

| 11.5.7 | Pre-frying | 87 | ||

| 11.5.8 | Re-Freezing – Final freezing | 87 | ||

| 11.5.9 | Packing and labelling | 87 | ||

| 11.5.10 | Storage of end product | 87 | ||

| 11.5.11 | Transport of end product | 87 | ||

| 11.6 | Processing operations of coated shrimp | 87 | ||

| 11.6.1 | General | 87 | ||

| 11.6.2 | Reception | 87 | ||

| 11.6.3 | Storage of raw material, other ingredients and packaging materials | 89 | ||

| 11.6.4 | Unpacking and unwrapping | 89 | ||

| 11.6.5 | Production of coated shrimp | 89 | ||

| 11.6.6 | Coating | 91 | ||

| 11.6.7 | Pre-frying | 92 | ||

| 11.6.8 | Packaging and labelling | 93 | ||

| 11.6.9 | Re-freezing – final freezing | 93 | ||

| 11.6.10 | Casing | 93 | ||

| 11.6.11 | Frozen storage of end product | 94 | ||

| 11.6.12 | Transport of end product | 94 | ||

| 12 | Processing of salted and dried salted fish | 94 | ||

| 12.1 | General | 94 viii | ||

| 12.2 | Preparing for salting | 94 | ||

| 12.2.1 | Splitting, washing and rinsing (processing step 7) | 94 | ||

| 12.2.2 | Filleting, skinning and trimming (processing step 8) | 95 | ||

| 12.2.3 | Round fish (processing step 9) | 95 | ||

| 12.2.4 | Nobbing (processing step 10) | 95 | ||

| 12.2.5 | Gibbing (processing step 11) | 96 | ||

| 12.3 | Salt requirements and salt handling | 96 | ||

| 12.3.1 | Salt requirements (processing step 12) | 96 | ||

| 12.3.2 | Salt handling (processing step 13) | 97 | ||

| 12.4 | Salting and maturing | 98 | ||

| 12.4.1 | General | 98 | ||

| 12.4.2 | Brining (processing step 14) | 98 | ||

| 12.4.3 | Brine injection (processing step 15) | 99 | ||

| 12.4.4 | Wet-salting (processing step 16) | 99 | ||

| 12.4.5 | Dry-salting (processing step 17) | 100 | ||

| 12.4.6 | Pickling (processing step 18) | 100 | ||

| 12.4.7 | Maturing (processing step 19) | 101 | ||

| 12.5 | Sorting, drying, weighing, packaging, wrapping and labelling | 102 | ||

| 12.5.1 | Sorting (processing step 20) | 102 | ||

| 12.5.2 | Drying (processing step 21) | 102 | ||

| 12.5.3 | Weighing, wrapping and packaging (processing step 22) | 103 | ||

| 12.6 | Chill storage (processing step 24) | 103 | ||

| 12.6.1 | Potential hazards | 103 | ||

| 12.6.2 | Potential defects | 103 | ||

| 12.6.3 | Technical guidance | 103 | ||

| 12.7 | Packaging, labels and ingredients (processing steps 25, 26, 27 and 28) | 104 | ||

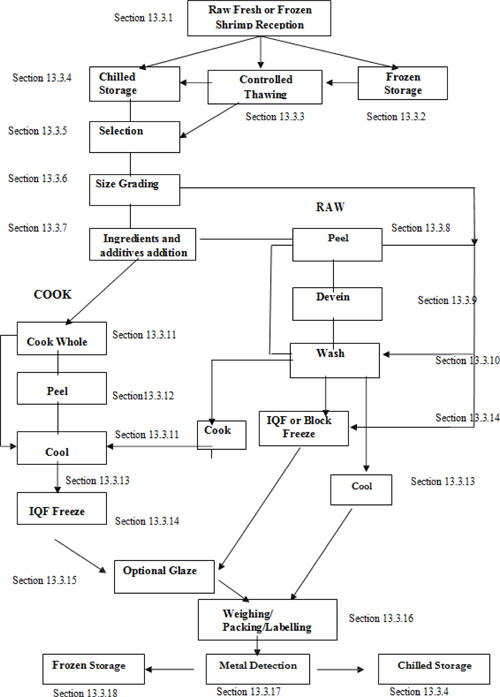

| 13 | Processing of shrimp and prawns | 104 | ||

| 13.1 | General | 104 | ||

| 13.2 | Frozen shrimp and prawns | 104 | ||

| 13.3 | Shrimp preparation (processing steps 1 to 18) | 104 | ||

| 13.3.1 | Raw fresh and frozen shrimp reception (Process steps) | 104 | ||

| 13.3.2 | Frozen storage | 105 | ||

| 13.3.3 | Controlled thawing | 106 | ||

| 13.3.4 | Chilled storage | 106 | ||

| 13.3.5 | Selection | 107 | ||

| 13.3.6 | Size grading | 107 | ||

| 13.3.7 | Addition of ingredients and use of additives | 107 | ||

| 13.3.8 | Full and partial peeling | 108 | ||

| 13.3.9 | Deveining | 109 | ||

| 13.3.10 | Washing | 109 | ||

| 13.3.11 | Cooking Process | 110 | ||

| 13.3.12 | Peeling of cooked shrimp | 110 | ||

| 13.3.13 | Cooling | 111 | ||

| 13.3.14 | Freezing process | 111 | ||

| 13.3.15 | Glazing | 112 | ||

| 13.3.16 | Weighing, packing and labelling of all products | 112 | ||

| 13.3.17 | Metal detection | 113 | ||

| 13.3.18 | Frozen storage of end product | 113 | ||

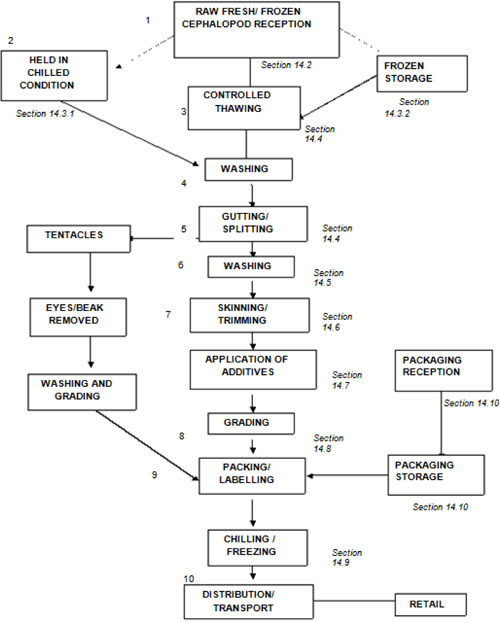

| 14 | Processing of cephalopods | 114 | ||

| 14.1 | General | 114 | ||

| 14.2 | Reception of cephalopods (processing step 1) | 114 | ||

| 14.2.1 | Potential hazards | 114 | ||

| 14.2.2 | Potential defects | 115 | ||

| 14.2.3 | Technical guidance | 115 | ||

| 14.3 | Storage of cephalopods | 115 | ||

| 14.3.1 | Chilled storage (processing steps 2 and 10) | 115 | ||

| 14.3.2 | Frozen storage (processing steps 2 and 10) | 116 | ||

| 14.4 | Controlled thawing (processing step 3) | 116 ix | ||

| 14.4.1 | Potential hazards | 116 | ||

| 14.4.2 | Potential defects | 116 | ||

| 14.4.3 | Technical guidance | 116 | ||

| 14.5 | Splitting, gutting and washing (processing steps 4, 5, 6, 11, 12 and 13) | 117 | ||

| 14.5.1 | Potential hazards | 117 | ||

| 14.5.2 | Potential defects | 117 | ||

| 14.5.3 | Technical guidance | 117 | ||

| 14.6 | Skinning and trimming (processing step 7) | 117 | ||

| 14.6.1 | Potential hazards | 117 | ||

| 14.6.2 | Potential defects | 117 | ||

| 14.6.3 | Technical guidance | 118 | ||

| 14.7 | Application of additives | 118 | ||

| 14.7.1 | Potential hazards | 118 | ||

| 14.7.2 | Potential defects | 118 | ||

| 14.7.3 | Technical guidance | 118 | ||

| 14.8 | Grading, packing and labelling (processing steps 8 and 9) | 118 | ||

| 14.8.1 | Potential hazards | 118 | ||

| 14.8.2 | Potential defects | 119 | ||

| 14.8.3 | Technical guidance | 119 | ||

| 14.9 | Freezing (processing step 10) | 119 | ||

| 14.9.1 | Potential hazards | 119 | ||

| 14.9.2 | Potential defects | 119 | ||

| 14.9.3 | Technical guidance | 119 | ||

| 14.10 | Packaging, labels and ingredients – reception and storage | 120 | ||

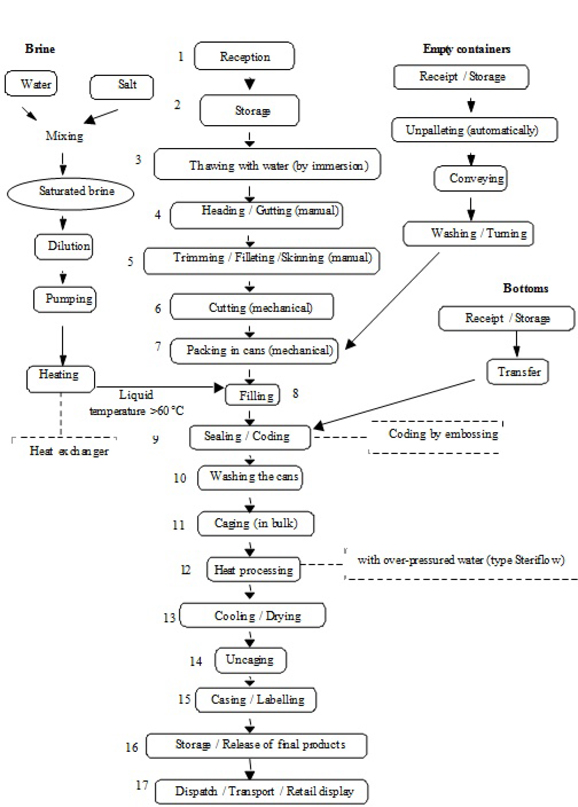

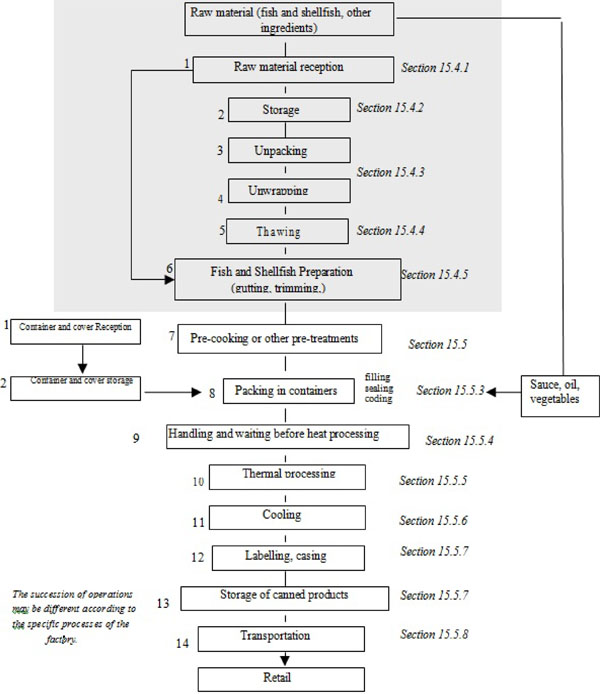

| 15 | Processing of canned fish, shellfish and other aquatic invertebrates | 120 | ||

| 15.1 | General | 120 | ||

| 15.2 | Technical guidelines | 120 | ||

| 15.3 | General hazards and defects for canned fish, shellfish and other aquatic invertebrates | 121 | ||

| 15.3.1 | Biological hazards | 121 | ||

| 15.3.2 | Chemical hazards | 122 | ||

| 15.3.3 | Physical hazards | 122 | ||

| 15.3.4 | Defects | 122 | ||

| 15.4 | Processing operations | 122 | ||

| 15.4.1 | Reception of raw material | 122 | ||

| 15.4.2 | Storage of raw material, containers, covers and packaging materials | 123 | ||

| 15.4.3 | Unwrapping and unpacking (processing steps 3 and 4) | 124 | ||

| 15.4.4 | Thawing (processing step 5) | 124 | ||

| 15.4.5 | Fish and shellfish preparatory processes (processing step 6) | 125 | ||

| 15.5 | Pre-cooking and other treatments | 126 | ||

| 15.5.1 | General | 126 | ||

| 15.5.2 | Use of brine and other dips | 127 | ||

| 15.5.3 | Packing in containers – filling, sealing and coding (processing step 8) | 128 | ||

| 15.5.4 | Handling of containers after closure (processing step 9) | 131 | ||

| 15.5.5 | Thermal processing (processing step 10) | 131 | ||

| 15.5.6 | Cooling (processing step 11) | 133 | ||

| 15.5.7 | Labelling, casing and storage of finished products (processing steps 12 and 13) | 134 | ||

| 15.5.8 | Transportation of finished products (processing step 14) | 135 | ||

| 16 | Transport | 136 | ||

| 16.1 | General | 136 | ||

| 16.2 | Fresh, refrigerated and frozen products | 136 | ||

| 16.2.1 | Potential hazards | 136 | ||

| 16.2.2 | Potential defects | 136 | ||

| 15.4.1 | Technical guidance | 136 | ||

| 16.3 | Live fish and shellfish | 137 | ||

| 16.4 | Canned fish and shellfish | 137 | ||

| 16.5 | All products | 137 | ||

| 16.5.1 | Technical guidance | 137 | ||

| 17 | Retail | 138 x | ||

| 17.1 | General | 138 | ||

| 17.2 | Reception of fish, shellfish and their products at retail | 138 | ||

| 17.2.1 | Potential hazards | 138 | ||

| 17.2.2 | Potential defects | 138 | ||

| 17.2.3 | Technical guidance | 138 | ||

| 17.3 | Reception of chilled products at retail | 139 | ||

| 17.3.1 | Potential hazards | 139 | ||

| 17.3.2 | Potential defects | 139 | ||

| 17.3.3 | Technical guidance | 139 | ||

| 17.4 | Chilled storage of products at retail | 139 | ||

| 17.4.1 | Potential hazards | 139 | ||

| 17.4.2 | Potential defects | 140 | ||

| 17.4.3 | Technical guidance | 140 | ||

| 17.5 | Frozen storage of products at retail | 140 | ||

| 17.5.1 | Potential hazards | 140 | ||

| 17.5.2 | Potential defects | 140 | ||

| 17.5.3 | Technical guidance | 140 | ||

| 17.6 | Preparation and packaging of chilled seafood at retail | 141 | ||

| 17.6.1 | Potential hazards | 141 | ||

| 17.6.2 | Potential defects | 141 | ||

| 17.6.3 | Technical guidance | 141 | ||

| 17.7 | Preparation and packaging of frozen seafood at retail | 141 | ||

| 17.7.1 | Potential hazards | 141 | ||

| 17.7.2 | Potential defects | 142 | ||

| 17.7.3 | Technical guidance | 142 | ||

| 17.8 | Retail display of chilled seafood | 142 | ||

| 17.8.1 | Potential hazards | 142 | ||

| 17.8.2 | Potential defects | 142 | ||

| 17.8.3 | Technical guidance | 142 | ||

| 17.9 | Retail display of frozen seafood | 143 | ||

| 17.9.1 | Potential hazards | 143 | ||

| 17.9.2 | Potential defects | 143 | ||

| 17.9.3 | Technical guidance | 143 | ||

| Annex A (informative) Potential hazards associated with fresh fish, shellfish and other aquatic invertebrates | 145 | |||

| Annex B (informative) A permanent cleaning and disinfecting schedule | 149 | |||

| Annex C (normative) HACCP and DAP analysis | 150 | |||

| Annex D (informative) Flow Diagrams | 162 | |||

| Annex E (normative) General remarks, addition to the pre-requisite programme | 174 | |||

| Annex F (informative) Examples of unacceptable sensory characteristics | 175 | |||

| Annex G (informative) Optional final product requirements - Salted fish | 176 | |||

| List of tables | ||||

| Table 1 — Fresh white fish sensory evaluation criteria | 52 | |||

| Table C.1 — A product description for canned tuna in salted water | 153 | |||

| Table C.2 — Examples of pre-harvest and harvest hazards in incoming fish and shellfish | 154 | |||

| Table C.3 — Examples of hazards introduced in the post harvest and further processing of fish and shellfish | 155 | |||

| Table C.4 — An example of potential hazards for canned tuna | 155 | |||

| Table C.5 — An example of potential defects of canned tuna | 155 xi | |||

| Table C.6 — An example of the significant hazard survival of C. botulinum at the step of heat processing for canned tuna | 157 | |||

| Table C.7 — A schematic example of a hazard analysis with corresponding control measures and the application of the CODEX decision tree for the determination of a critical control point at processing step 12 of the example process as set out in Figure D.1 | 158 | |||

| Table C.8 — A schematic example of a defect analysis with corresponding control measures and the application of the CODEX decision tree for the determination of a defect action point at processing step 2 of the example process as set out in Figure D | 158 | |||

| Table C.9 — An example of the results of the application of HACCP principles to the two specific steps in the canned tuna process (tables 8 and 9), for a CCP and a DAP, respectively | 160 | |||

| Table F.1 — A product description for canned tuna in salted water | 175 | |||

| Table G.1 — Species used to produce dried salted fish | 176 | |||

| List of figures | ||||

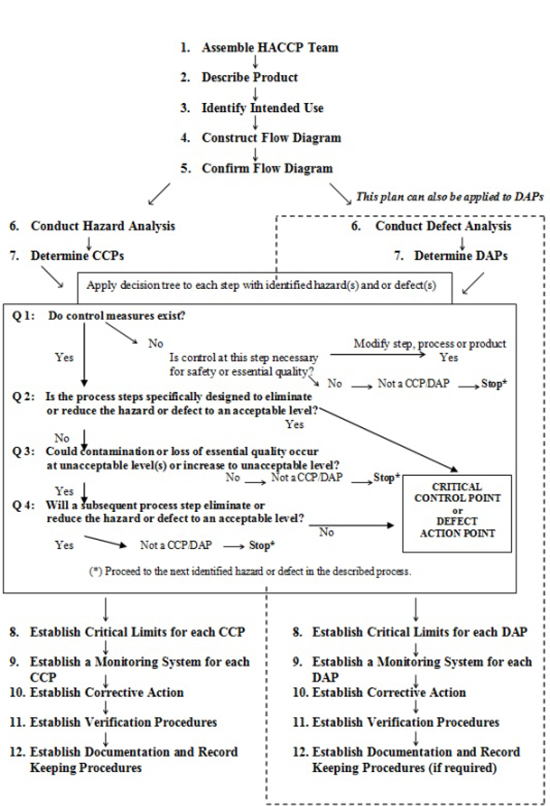

| Figure C.1 — Summary of the implementation of a HACCP and defect analysis | 151 | |||

| Figure D.1 — Example of a flow diagram for a processing line of canned tuna fish in brine | 162 | |||

| Figure D.2 — Example of a flow chart for aquaculture production | 163 | |||

| Figure D.3 — Example of a simplified flow diagram for production of live and raw bivalve molluscs | 164 | |||

| Figure D.4 — Example of a flow chart of a fish fillet preparation line, including MAP, mincing and freezing process | 165 | |||

| Figure D.5 — Example of a flow chart of a frozen surimi production process | 166 | |||

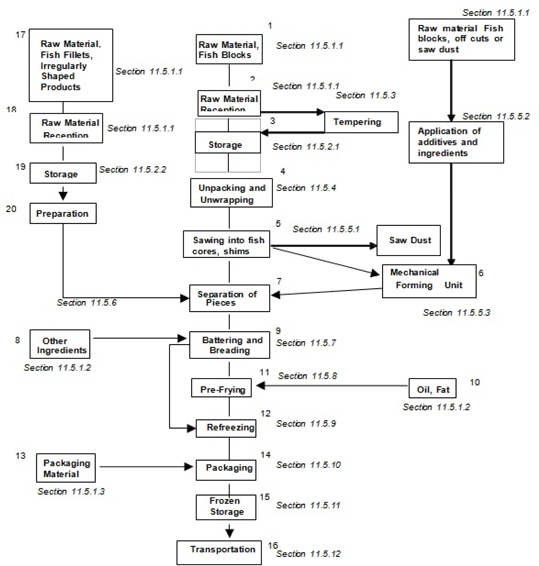

| Figure D.6 — Example of a flow chart for the processing of coated fish products | 167 | |||

| Figure D.7 — Example of a flow chart for coated molluscan shellfish processing | 168 | |||

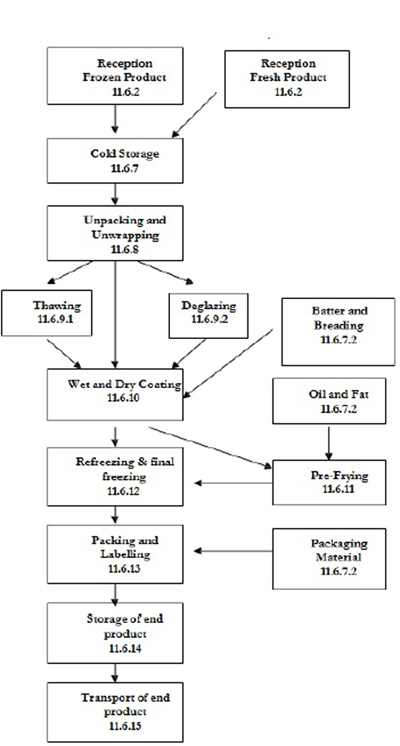

| Figure D.8 — Example of a flow chart of a coated shrimp processing line | 169 | |||

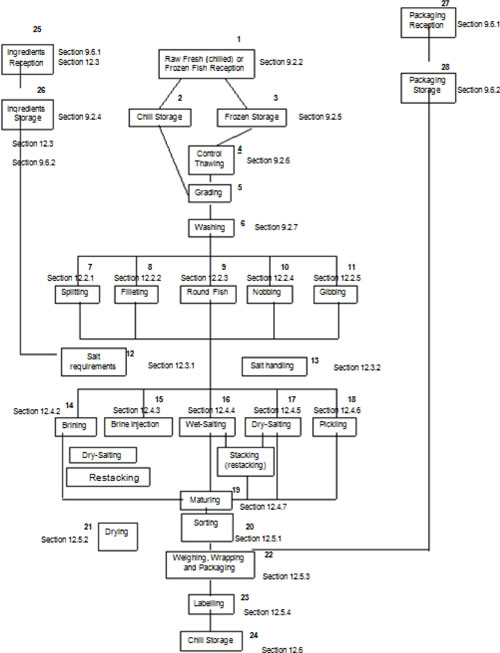

| Figure D.9 — Example of a flow chart for salted and dried salted fish processing line | 170 | |||

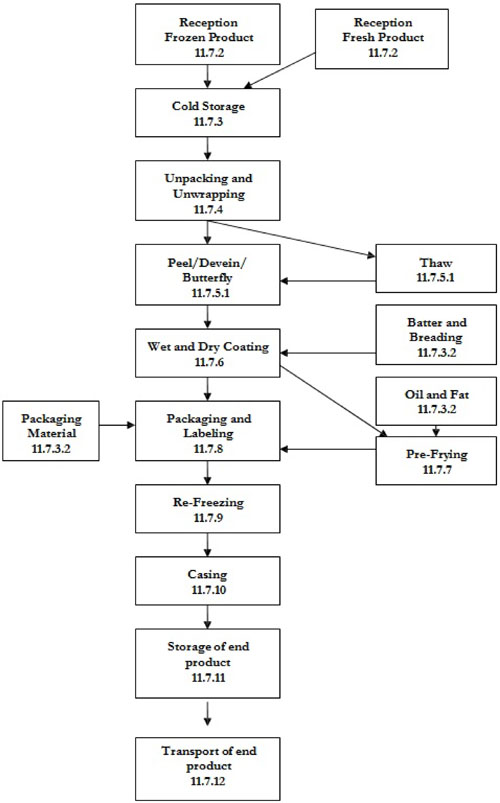

| Figure D.10 — Example of a flow chart of a shrimp and prawn processing line | 171 | |||

| Figure D.11 — Example of a possible squid processing line | 172 | |||

| Figure D.12 — Example of a flow chart for the processing of canned fish and shellfish | 173 | |||

This CARICOM Regional Code of Practice has been prepared through the CARICOM Regional Organisation for Standards and Quality (CROSQ). It is an adaptation of the CODEX Alimentarius Commission Code of Practice for Fish and Fishery Products. This Code of Practice recommends general guidelines on the production, storage and handling of fish and fishery products on board fishing vessels and on shore. It incorporates the Hazard Analysis Critical Control Point (HACCP) approach, which is recommended to ensure the hygienic production of fish and fishery products to meet health and safety requirements.

A pre-requisite programme is described in the Code of Practice covering technological guidelines and the essential requirements of hygiene in the production of fish, shellfish and their products, which are safe for human consumption, and otherwise meets the requirements of the appropriate CODEX Alimentarius Commission product standards.

This Code of Practice will assist all those who are engaged in the handling and production of fish and fishery products, or are concerned with their storage, distribution, export, import and sale in attaining safe and wholesome products which can be sold on national or international markets and meet the requirements of the CODEX Alimentarius Commission Standards.

This Code of Practice was approved by the Thirtieth Meeting of the Council for Trade and Economic Development (COTED) on 3-4 May 2010.

1This Code of Practice applies to the growing, harvesting, handling, production, processing, storage transportation and retail sale of fish, shellfish and aquatic invertebrates and products from marine and freshwater sources, which are intended for human consumption.

The following reference documents are indispensible for the application of this document. The latest edition of the referenced documents (including any amendments) applies.

CARICOM Regional Code of Practice, CRCP 5, General principles for food hygiene

CARICOM Regional Standard, CRS 5, Labelling standard for pre-packaged foods

CODEX Alimentarius Commission, Code of Practice for Fish and Fishery Products

CODEX Alimentarius Commission, General Standard for Food Additives (CODEX STAN 192-1995)

CODEX Alimentarius Commission, Guidelines for Sensory Evaluation of Fish and Shellfish in Laboratories (CAC/GL 31-1999)

CODEX Alimentarius Commission, Guidelines for the Establishment of a regulatory programme for control of veterinary drugs residues in foods (CAC/GL 16-1993)

CODEX Alimentarius Commission, Methods of Sampling and Analysis (CODEX STAN 234-1999)

CODEX Alimentarius Commission, Methods for Determination of Glaze

CODEX Alimentarius Commission, Recommended Code of Practice on Good Animal Feeding (CAC/RCP 54 – 2004)

CODEX Alimentarius Commission, Standard for Fats and Oils not covered by Individual Standards (CODEX STAN 19-1981)

CODEX Alimentarius Commission, Standard for Frozen Fish Fingers, Fish Portions and Fish Fillets – Breaded or in Batter (CODEX STAN 166-1989)

CODEX Alimentarius Commission, Standard for Named Vegetable Oils (CODEX STAN 210-1999)

CODEX Alimentarius Commission, Standard for Olive Oils and Olive Pomace Oils (CODEX STAN 33-1981)

CODEX Alimentarius Commission, Standard for Quick Frozen Blocks of Fish Fillet, Minced Fish Flesh and Mixtures of Fillets (CODEX STAN 165-1989)

CODEX Alimentarius Commission, Standard for Quick Frozen Fish Fillets (CODEX STAN 190-1995)

FAO listing of shrimps, FAO Fisheries Synopsis No. 125, Volume 1, Shrimps and Prawns of the World

Food and Agriculture Organization, 1995, Code of Conduct for Responsible Fisheries

OIE Codes of Practice, 2003, 6th Edition, International Aquatic Animal Health Code

Recommended International Code of Hygienic Practice for Low-Acid and Acidified Low- Acid Canned Food (CAC/RCP 23-1979)

2Recommended International Code of Hygienic Practice for the Transport of Food in Bulk and Semi-Packaged Food (CAC/RCP 47-2001)

Recommended International Code of Practice-General Principles of Food Hygiene, Section VIII-Transportation, CAC/RCP 1-1969

Recommended International Code of Practice for Control of the Use of Veterinary Drugs (CAC/RCP 38-1993)

For the purposes of this Code of Practice, the following terms and definitions shall apply.

poisonous substances naturally present in fish and fishery products or accumulated by the animals feeding on toxin producing algae, or in water containing toxins produced by such organisms

process of cooling fish and shellfish to a temperature between 0°C and 4 °C

water from any source where harmful microbiological contamination, substances and or toxic plankton are not present in such quantities as may affect the quality of fish, shellfish and their products

removal of soil, food residues, dirt, grease or other objectionable matter

biological or chemical agent, foreign matter, or other substance not intentionally added to food which may compromise food safety or suitability

introduction or occurrence of a contaminant in fish, shellfish and their products

action and activity that can be used to prevent or eliminate a food safety hazard or reduce it to an acceptable level

NOTE For the purposes of this Code of Practice, a control measure is also applied to a defect.

action to be taken when the results of monitoring at the CCP indicate a loss of control

NOTE For the purposes of this Code of Practice, this also applies to a Defect Action Point (DAP).

3step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level

criterion, which separates acceptability from unacceptability

NOTE For the purposes of this Code of Practice, this also applies to a DAP.

sequence of questions applied to each process step, with an identified hazard to determine which process steps are CCPs

NOTE For the purposes of this Code of Practice this also applies to a DAP.

deterioration of fish, shellfish and their products including texture breakdown and causing a persistent and distinct objectionable odour or flavour

condition found in a product which fails to meet essential quality, composition and or labelling provisions of the appropriate national, regional or international product standards

step at which control can be applied and a quality (non-safety) defect can be prevented, eliminated or reduced to acceptable level, or a fraud risk eliminated

reduction, by means of chemical agents and or physical methods, of the number of micro-organisms in the environment, to a level that does not compromise food safety or suitability

portion of fish remaining after heading and gutting

premises where fish and fishery products are prepared, processed, chilled, frozen, packaged or stored.

NOTE For the purposes of this Code of Practice, premises also include vessels.

cold-blooded (ectothermic) aquatic vertebrate excluding amphibians and aquatic reptiles

biological, chemical or physical agent in, or condition of, food with the potential to cause an adverse health effect

4process of collecting and evaluating information on hazards and conditions leading to their presence to decide which are significant for food safety

system which identifies, evaluates, and controls hazards which are significant for food safety

act of conducting a planned sequence of observations or measurements of control parameters to assess whether a CCP is under control

water, fit for human consumption and free from micro-organisms of public health significance and harmful toxic substances

programme that is required prior to the application of the HACCP system to ensure that a fish and shellfish processing facility is operating according to the CARICOM Regional Code of Practice, CRCP 4, General principles for food hygiene and appropriate national food safety legislation

fresh and frozen fish, shellfish and or their parts which may be utilised to produce fish and shellfish products intended for human consumption

clean water cooled by a suitable refrigeration system

period during which the product maintains its microbiological and chemical safety and sensory qualities at a specific storage temperature

NOTE It is based on identified hazards for the product, heat or other preservation treatments, packaging method and other hurdles or inhibiting factors.

species of aquatic molluscs and crustaceans that are commonly used for food

point, procedure, operation or stage in the food chain including raw materials, from primary production to final consumption

obtaining evidence that the elements of the HACCP plan are effective

5application of methods, procedures, tests and other evaluations, in addition to monitoring, to determine compliance with the HACCP plan

NOTE For the purposes of this Code of Practice, this also applies to a DAP.

fish as captured, un-gutted

NOTE Also known as round fish.

farming during part of or the whole life cycle of all aquatic animals, except mammalian species, aquatic reptiles and amphibians, intended for human consumption, but excluding bivalve molluscs

NOTE These aquatic animals are hereafter referred to as “fish”.

premises for the production of fish intended for human consumption, including the supporting inner infrastructure and surroundings under the control of the same management

substance either natural or synthetic which can affect the live fish, its pathogens, the water, equipment used for production or the land within the aquaculture establishment

obtaining specifically coloured feature of a targeted organism by incorporating into the fish food a natural or artificial substance or additive approved for this purpose by the national competent authority

EXAMPLE Coloured feature include flesh, shell and gonad

fish on or in which pathological changes or other abnormalities that affect safety and quality are apparent

raising fish under conditions of little or incomplete control over the growing process and production conditions

chemicals other than nutrients which are approved for fish

aquaculture production unit usually consisting of holding facilities, plant, service equipment and stock

| EXAMPLE 1 | Production units may be either land or water based 6 |

| EXAMPLE 2 | Holding facilities include tanks, ponds, raceways and cages |

| EXAMPLE 3 | Plant includes buildings, storage and processing areas |

fodder intended for fish in aquaculture establishments, in any form and of any composition

practices of the aquaculture sector that are necessary to produce quality and safe food products conforming to food laws and regulations

NOTE Also known as good fish farming practices.

operations involving removing the fish from the water

raising fish under controlled growing process and production conditions where their growth is completely dependent on externally supplied fish feed

official authority or authorities charged by the government with the control of food hygiene and sanitation in aquaculture

substance intended for preventing, destroying, attracting, repelling or controlling any pests during the production, storage, transport, distribution and processing of food, agricultural commodities, or animal feeds or which may be administered to animals for the control of ectoparasites

NOTE The term normally excludes fertilisers, plant and animal nutrients, food additives, and veterinary drugs.

specified substance in food, agricultural commodities, or animal feed resulting from the use of a pesticide

NOTE The term includes any derivatives of a pesticide, such as conversion products, metabolites, reaction products, and impurities considered to be of toxicological significance.

foreign substance including its metabolites, which remains in fish prior to harvesting as a result of either application or accidental exposure

raising fish under conditions of partial control over the growing process and production conditions where their growth is dependent upon endogenously supplied nutrient inputs and externally supplied fish feed

7amount of fish stocked per unit of area or volume

substance applied or administered to any food-producing animal, such as meat or milk-producing animals, poultry, fish or bees, whether used for therapeutic, prophylactic or diagnostic purposes or for modification of physiological functions or behaviour

period of time necessary between the last administration of a veterinary drug to fish, or exposure of these animals to a veterinary drug, and harvesting of them to ensure that the concentration of the veterinary drug in their edible flesh intended for human consumption, complies with the maximum permitted residue limits

approved by the competent authority

placing live bivalve molluscs in tanks, floats or natural sites to remove sand, mud or slime and improve product acceptability

reduction of microorganisms to a level acceptable for direct consumption by the process of holding live bivalve molluscs for a period of time under approved, controlled conditions in natural or artificial, treated or untreated sea water suitable for the process

approved establishment for the depuration of live bivalve molluscs

approved on-shore or off-shore installation or establishment for the reception, conditioning, washing, cleaning, grading and packaging of live bivalve molluscs fit for human consumption from which the bivalve molluscs are dispatched alive

brackish and marine areas approved for the production or harvesting of bivalve molluscs either by natural growth or by aquaculture destined for human consumption.

NOTE The growing areas may be approved as production or harvesting areas for bivalve molluscs for direct consumption, or they may be approved as production or harvesting areas for bivalve molluscs for either depuration or relaying.

process of subjecting bivalve molluscs in the shell to any form of heat treatment, such as steam, hot water, or dry heat for a short period of time, to facilitate rapid removal of meat from the shell for the purpose of shucking

8removal of bivalve molluscs from microbiologically contaminated growing area to an acceptable growing or holding area under the supervision of the competent authority and holding them there for the time necessary for the reduction of contamination to an acceptable level for human consumption

process of removing the edible portion of the mollusc from the shell by hand, mechanically or through heat shock with steam or hot water

passing fillets over a translucent table illuminated from below to detect parasites and other defects

loss of moisture from frozen products through evaporation

NOTE This may occur if the products are not properly glazed, packaged or stored. Deep dehydration adversely affects the appearance and surface texture of the product and is commonly known as “freezer burn”.

slice of fish of irregular size and shape removed from the carcass by cuts made parallel to the backbone

equipment designed for freezing fish and other food products, by quickly lowering the temperature so that, after thermal stabilisation, the temperature in the thermal centre of the product is the same as the storage temperature

process which is carried out in an appropriate equipment in such a way that the range of temperature of maximum crystallisation is passed quickly

facility that is capable of maintaining the temperature of fish at −18 °C

fish or fishery products which have received no preserving treatment other than chilling

fish which have been subjected to a freezing process sufficient to reduce the temperature of the whole product to a level low enough to preserve the inherent quality of the fish and which have been maintained at this low temperature during transportation, storage and distribution up to and including the time of final sale

NOTE For the purposes of this Code of Practice, the terms “frozen”, “deep frozen”, “quick frozen”, unless otherwise stated, are synonymous.

9applications of a protective layer of ice formed at the surface of a frozen product by spraying it with, or dipping it into, clean sea water, potable water, or potable water with approved additives

comminuted flesh produced by separation from skin and bones

packaging in which the atmosphere surrounding the fish is different from the normal composition of air

mechanical process for producing minced fish whereby the skin and bone are substantially removed from the flesh

mechanical device used for separation

section of fish, removed by cutting approximately at right angle to the backbone

removal of excessive wash water from the minced fish flesh

fish protein product for further processing, which has been processed by heading, gutting, cleaning fresh fish and mechanically separating the edible muscle from the skin and bone which is then minced, washed, refined, de-watered mixed with cryoprotective food ingredients and frozen

ability of surimi to form an elastic gel when fish meat is comminuted with the addition of salt and then heated

NOTE This elasticity is a function possessed by myosin as the primary component of myofibrillar protein.

generic term of skeletal muscle proteins such as myosin and actin

process of removing from washed meat, by use of a strainer, small bones, sinews, scales and bloody flesh of such sizes as may not be mixed in a final product, thereby concentrating myofibrillar protein

10variety of products produced from surimi with addition of ingredients and flavour such as “surimi gel” and shellfish analogues

fish meat that is washed and then drained of water

process of removing blood and water soluble components from minced fish with cold water by the use of a rotary filter, thus increasing the level of myofibrillar proteins thereof

water-soluble protein, organic substance and inorganic salts contained in fish meat

liquid preparation from ground cereals, spices, salt, sugar and other ingredients and or additives for coating

NOTE Typical batter types include non-leavened batter and leavened batter.

dry breadcrumbs or other dry preparations mainly from cereals with colourants and other ingredients used for the final coating of fishery products

NOTE Typical breading types include free-flowing breading, coarse breading, flour-type breading.

covering the surface of a fishery product with batter and or breading

frying of breaded and battered fishery products in an oil bath in a way so that the core remains frozen

cutting of regular shapes of fish blocks into pieces suitable for later coating

cylindrical container made from wood, plastic or other suitable food contact material with a lid for water-tight closure

parietal peritoneum; the pigmented lining of the abdominal cavity

11solution of salt in water

process of injecting brine directly into the flesh of the fish

process of placing fish in brine for a period of time, sufficient for the fish tissue to absorb a specific quantity of salt

process of mixing fish with suitable food grade salt and stacking the fish in such a manner that the resulting brine drains away

discolouration and development of the mould Sporendonema epizoum, which affect the fish surface and gives it a peppered appearance

NOTE The fish flesh is unaffected.

fish in which the main reserves of fat are in the body tissue and the fat content is more than 2 %

process of removing the gills, long gut and stomach from fatty fish, such as herring, by inserting a knife or using hands at the gills; the milt or roe and some of the pyloric caeca are left in the fish

fish in which the main reserves of fat are in the liver and less than 2 % fat in the body tissue

NOTE Also known as white fish.

process from the initial salting until the fish is salt-matured

removing the head and gut from fatty fish, such as herring, in one operation by partially severing the head and pulling the head away together with attached gut; the roe or milt is left in

brine which may contain vinegar and spices

process whereby primary fatty fish is mixed with suitable salt which may contain vinegar and spices and stored in watertight containers under the resultant pickle which forms by solution of salt in the water extracted from the fish tissue

12NOTE Pickle may be added to the container. Pickled products will always remain in a brine solution.

discolouration caused by red halophilic bacteria which damages the flesh of the fish

crystalline product consisting predominantly of sodium chloride

NOTE It is obtained from the sea, from underground rock salt deposits or from vacuum processed and refined brine.

salted fish that has an appearance, consistency and flavour characteristic of the final product

fish or fillets which have been treated by either brining, brine injection, dry-salting, pickling or wet-salting, or a combination of these

water phase of the fish muscle which is saturated with salt (26.4 g salt/100 g water phase).

fish that have been cut open from throat or nape to the tail, with gills, guts, roe or milt removed

NOTE Head and whole or part of backbone may be left in or removed.

laying fish in piles with salt spread evenly on the surface

process whereby primary lean fish is mixed with suitable food grade salt and stored in watertight containers under the resultant brine which forms by solution of salt in the water extracted from the fish tissue

NOTE Brine may be added to the container. The fish can be removed from the container and stacked so that the brine drains away.

removing the head from the entire shrimp or prawn

shrimp which has been peeled; the back of the peeled segments of the shrimp have been opened out and the gut (vein) removed

freshly caught shrimp which has been chilled or has not been otherwise preserved

13NOTE This does not include freshly cooked shrimp.

shrimp with head and shell removed

raw shrimp with head removed and the shell left intact

species covered by the most recent edition of the FAO listing of shrimps, FAO Fisheries Synopsis No. 125, Volume 1, Shrimps and Prawns of the World.

NOTE Also called prawn.

process of cutting cephalopods along the mantle to produce a single fillet

commercially sterile food in hermetically sealed containers

condition achieved by application of heat, sufficient, alone or in combination with other appropriate treatments, to render the food free from micro-organisms capable of growing in the food at normal non-refrigerated conditions at which the food is likely to be held during distribution and storage

containers which are sealed to protect the content against the entry of microorganisms during and after heat treatment

pressure vessel designed for thermal processing of food packed in hermetically sealed containers

thermal process chosen by the processor for a given product and container size to achieve at least commercial sterility

NOTE Also known as sterilisation schedule.

temperature maintained throughout the thermal process as specified in the scheduled process

time between the moment sterilisation temperature is achieved and the moment cooling started

14heat treatment to achieve commercial sterility and is quantified in terms of time and temperature

thorough removal of the air from steam retorts by steam prior to a scheduled process

operation that stores, prepares, packages, serves, or otherwise provides fish, shellfish and their products directly to the consumer

NOTE This may be free standing seafood markets, seafood sections in grocery or department stores, packaged chilled or frozen and or full service.

placed in a container and displayed chilled or frozen for direct consumer pick-up

display of chilled fish, shellfish and their products to be weighed and wrapped by establishment personnel at the request of the consumer

Prior to the application of HACCP to any segment of the product processing chain, that segment should be supported by pre-requisite programmes based on good hygienic practices or as required by the competent authority.

NOTE 1 The establishment of pre-requisite programmes will allow the HACCP team to focus on the HACCP application to food safety hazards which are directly applicable to the product and the process selected, without undue consideration and repetition of hazards from the surrounding environment. The pre-requisite programmes would be specific within an individual establishment or for an individual vessel and will require monitoring and evaluation to ensure their continued effectiveness.

NOTE 2 HACCP principles can also be applied to defect action points.

The design and construction of a fishing vessel, and vessels used to harvest farmed fish and shellfish should take into consideration the following:

EXAMPLE CO2, O2, temperature and nitrogenous wastes

The facility should be designed to facilitate rapid processing and subsequent storage taking into consideration the following:

The condition of the equipment and utensils should be such that it minimises the build-up of residues and prevents them from becoming a source of contamination. The design and construction of equipment and utensils should take into consideration the following:

Schedules should be implemented to:

The hygiene control programme should take into consideration the following:

NOTE Pest control programmes could include preventing access, eliminating harbourage and infestations, and establishing monitoring detection and eradication systems.

Personal hygiene and facilities should ensure that an appropriate degree be maintained to avoid contamination.

Facilities and equipment should include:

Personal hygiene should be as follows:

Vehicles should be designed and constructed:

Product traceability and recall procedures should take into consideration the following:

21All personnel should be aware of their role and responsibility in protecting fish or shellfish from contamination and deterioration.

Handlers should have the necessary knowledge and skill to enable them to handle fish or shellfish hygienically.

Personnel who handle strong cleaning chemicals or other potentially hazardous chemicals should be instructed in safe handling techniques.

Each fish and shellfish facility should ensure that managers arrange for adequate and periodic training of relevant employees in the principles and application of HACCP.

NOTE Training of personnel in the use of HACCP is fundamental to the successful implementation and delivery of the programme in fish or shellfish processing establishments. The practical application of such systems will be enhanced when the individual responsible for HACCP has successfully completed a course.

Fish, shellfish and other aquatic invertebrates should not be accepted if they are known to contain parasites, undesirable microorganisms, pesticides, veterinary drugs or toxic, decomposed or extraneous substances known to be harmful to human health, unless they can be reduced to an acceptable level by normal sorting and or processing.

When fish and shellfish determined as unfit for human consumption are found, they should be removed and stored separately from the catch and either reworked and or disposed of in a proper manner.

All fish and shellfish deemed fit for human consumption should be handled properly with particular attention being paid to time and temperature control.

Fresh fish, fillets, shellfish and their products which are to be chilled should be held at a temperature as close as possible to 0 °C.

22NOTE Temperature is the single most important factor affecting the rate of fish and shellfish deterioration and multiplication of micro-organisms. For species prone to scombrotoxin production, time and temperature control may be the most effective method in controlling food safety.

To minimise the deterioration, it is important that:

Where temperature control is concerned:

To minimise handling damage:

EXAMPLE CO2, O2, temperature and nitrogenous wastes

NOTE Poor handling practices can lead to damage of fresh fish, shellfish and other aquatic invertebrates which can accelerate the rate of decomposition and increase unnecessary post-harvest losses.

An effective HACCP system should reduce the reliance on traditional end-product testing. The HACCP plan, which should be incorporated into the food management plan should be well documented and be as simple as possible. This section will demonstrate one format, which may be considered in the development of the HACCP plan. The establishment should follow the guidelines outlined in Annex C on how to use the principles of HACCP in the production of various fishery products.

Aquaculture establishments should comply with the recommendations of the Food and Agriculture Organization, Code of Conduct for Responsible Fisheries, 1995 in order to minimize any adverse impacts on human health and environment.

Fish farms should operate effective fish health and welfare management. Fry and fingerlings should be disease free and should comply with the OIE Codes of Practice (International Aquatic Animal Health Code, 6th Edition, 2003).

Growing fish should be monitored for disease.

When using chemicals at fish farms, special care should be exercised so that these substances are not released into the surrounding environment.

It should be recognised that in preparing a HACCP and or DAP plan it is essential to consult Annex C which provides guidance for the application of the principles of HACCP and DAP analysis.

NOTE See Annex D for an example of a flow diagram (figure D.2) for some of the common steps in aquaculture production.

The general principles in 4 apply to aquaculture production, in addition to the following:

The water should be suitable for the rearing of fish which are safe for human consumption.

The water quality should be monitored regularly such that the health of the fish and sanitary condition of the water are continuously maintained to ensure aquaculture products are safe for human consumption.

Fish farms should be sited where there is no risk of contamination of the water in which fish are reared.

Fish farms should be appropriately designed and constructed to ensure control of hazards and prevention of water contamination.

The source of post-larvae, fries and fingerlings should be such to avoid the carryover of potential hazards into the growing stocks.

Potential hazards that are specific to aquaculture products include: residues of veterinary drugs in excess of recommended guidelines and other chemicals used in aquaculture production, contamination of faecal origin where the facilities are close to human habitation or animal husbandry (see Annex C.4.1).

During transport of live fish stress should be reduced and care should be taken to minimise physical damage to fish (see Annex C.4.1).

25Feeds used in aquaculture production should be in accordance with the relevant national requirements and or the CODEX Alimentarius Commission Recommended Code of Practice on Good Animal Feeding (CAC/RCP 54 – 2004).

Potential hazards include, but are not limited to:

Potential defects include, but are not limited to:

Feed supply should be in accordance with the following:

Potential hazards include, but are not limited to residues of veterinary drugs.

Potential defects are unlikely.

The use of veterinary drugs should be in accordance with the following:

Potential hazards include, but are not limited to, microbiological and chemical contamination.

Potential defects include, but are not limited to:

Growing of fish should be in accordance with the following:

Potential hazards are unlikely.

28Potential defects include, but are not limited to:

Harvesting of fish should be carried out in accordance with the following:

Potential hazards include, but are not limited to, microbiological and chemical contamination.

Potential defects include, but are not limited to:

Holding and transportation of fish should be carried out in accordance with the following:

Potential hazards include, but are not limited to:

EXAMPLE Oil, cleaning and disinfecting agents

Potential defects include, but are not limited to:

Storage and transport of live fish should be in accordance with the following:

Potential hazards include, but are not limited to:

EXAMPLE Oil, cleaning and disinfecting agents

Potential defects include, but are not limited to:

Storage and transportation of live fish at ambient temperature should be in accordance with the following:

NOTE It may be necessary to insulate the holding tanks and install a temperature control system.

NOTE An alternative method is reduction of temperature.

Potential hazards include, but are not limited to:

EXAMPLE Oil, cleaning and disinfecting agents

Potential defects include, but are not limited to:

Storage and transportation of live fish at low temperature should be in accordance with the following:

NOTE Conditioning is a biological operation to reduce the metabolic rate of fish thereby minimising the stress caused by storage and transportation.

NOTE There is a range of temperature in which fish do not exhibit or have reduced physical activity. The limit is attained at the temperature at which the metabolic rate of the fish is minimised without causing adverse effects to them.

Annex C outlines the application of HACCP principles and Annex E provides additional information for pre-requisite programmes for live and raw bivalve molluscs.

Potential hazards include, but are not limited to:

NOTE There are five different types of important hazards coming from the bivalve molluscs growing environment:

EXAMPLE Salmonella spp.

EXAMPLE Norovirus, viruses causing hepatitis

EXAMPLE Vibrio spp

EXAMPLE okadaic acid group (DSP), saxitoxin group (PSP), brevetoxin group (NSP), domoic acid group (ASP), azaspiracid group (AZP)

EXAMPLE heavy metals such lead, cadmium and mercury

Potential defects are unlikely.

33Surveys of the growing area, shoreline and land catchment should be conducted to determine sources of both domestic and industrial pollution which may affect the quality of the growing area water and bivalve molluscs. Resurveys should be conducted at an acceptable frequency and known pollution sources should be re-evaluated on a regular basis to determine any changes to their impact on the growing area.

NOTE 1 Sources may include municipal sewage outputs, industrial outputs, mine wastes, geophysical contaminants, domestic animal holding pens, nuclear power plants, refineries or other sources.

NOTE 2 The need to reschedule hygiene surveys will be determined by population shifts and changes in agricultural and industrial activities in the coastal area.

When pollution sources have been identified and evaluated, sampling stations for water and or bivalve molluscs and or sediments should be established and studies conducted to determine the effects of the pollutants on water and bivalve molluscs quality. The data should be evaluated by the national competent authority and growing areas should be classified according to national requirements and criteria.

When interpreting growing area data, the national competent authority should take into account variations which may affect the level of pollution during the most unfavourable hydrographical and climatic conditions as influenced by rainfall, tides, winds, methods of sewage treatment, population variations and other local factors. The authority should also consider that bivalve molluscs have the ability to accumulate toxic chemicals in their tissue in concentrations greater than the levels found in the surrounding water.

NOTE FAO, WHO, or other international or national food standards may be used as a guide to acceptable levels.

The national competent authority should immediately announce decisions concerning the classification of growing areas to the affected producers, depuration and distribution centres.

When sampling shellfish meats for classification purposes, if the limits of any biological or chemical hazard stipulated by the national competent authority are exceeded, appropriate measures should be taken under the responsibility of the national competent authority.

Classified growing areas should be clearly defined by the national competent authority as either:

Growing areas should be routinely monitored for changes in water quality and or bivalve molluscs quality, and sub-standard areas patrolled to prevent harvesting for purposes other than that established by the national competent authority.

NOTE For early warning purposes, where appropriate, it is recommended to have a programme present to monitor growing areas for the species of plankton that can produce toxins and to recognize other environmental signals that a toxic event may be developing.

Harmful chemical substances within bivalve molluscs should not be present in amounts so that the calculated dietary intake exceeds the permissible daily intake.

34When routine monitoring programmes or resurveys show that the growing area no longer meets the classification criteria, the area should be reclassified or closed for harvesting immediately by the national competent authority.

In determining the public health suitability of bivalve molluscs classified growing areas, the national competent authority should consider the following actions:

Under the responsibility of the national competent authority, the growing areas providing bivalve molluscs for direct human consumption should meet the following requirements at time of harvest:

NOTE This can be determined by examination of mollusc’s flesh or through adequate monitoring of the water, as appropriate.

All growing water and or molluscan flesh should be monitored for the presence of E. coli, faecal coliforms or total coliforms at an appropriate frequency based on the probability and degree of faecal contamination.

Tests for suitable indicator bacteria such as faecal coliforms or E. coli, total coliforms should be used to determine the degree of faecal contamination. The effectiveness of indicator bacteria used should be kept under constant review for their reliability as measures for the degree of faecal contamination. These indicators do not correlate well with the presence of viruses, other controls such as shoreline surveys should always be employed If faecal contamination exceeds a certain threshold-level relaying or depuration for a time approved by the national competent authority may be allowed.

NOTE Other methods such as bacteriophage and viral detection could also be used as indicators when validated analytical methods become available in the future.

The species, and typically the actual strain of the pathogen should be known to ensure that monitoring addresses the source of the pathogen. Predetermined acceptance or rejection levels for the pathogen should be established in order to use such monitoring results for decision making. Other conditions including the sanitary survey requirements should be satisfied for the reopening of the harvest area.

35NOTE Shellfish sanitation programs rely upon the use of indicator organisms for the presence of contamination rather than upon attempts to monitor for specific pathogens. However, where there has been a shellfish borne outbreak caused by an identified pathogen such as Salmonella and others (Vibrio and viruses), monitoring the bivalve molluscs may be appropriate as part of the process of closure or reopening the affected harvest area.

Growing areas should also be monitored for environmental signals of toxicity such as, dead or dying birds, mammals, or fish. The risk of toxic algae blooms should be recognised when drawing up monitoring schedules.

NOTE 1 Toxic algae blooms show seasonal variability. Areas may also be affected by toxic algae previously unknown in the surrounding sea or coastal waters.

NOTE 2 Phytoplankton monitoring is a valuable complementary tool that can be used, in combination with the required monitoring of marine biotoxins in shellfish tissue, to optimize program management and resources.

The implication that the absence of toxicity in indicator shellfish species signifies the absence of toxicity of other species in the growing area should be verified for each species and for each group of toxins before defining a particular species as an indicator for that growing area.

The national competent authority should immediately close and effectively patrol affected areas when acceptable levels of toxins are exceeded in edible portions of bivalve molluscs meats. These areas should not be re-opened before a toxicological investigation has revealed that the bivalve molluscs meat is free from hazardous amounts of biotoxins.

The national competent authority should immediately announce these decisions to the affected producers, depuration and distribution centres.

In establishing a sampling programme, consideration should be given to ensure an adequate location and number of sampling sites. Sampling frequency should be sufficient to address spatial-temporal changes in micro-algae, toxins in shellfish and to cover the risks of rapid rises in shellfish toxicity.

NOTE Testing for a particular biotoxin may not be appropriate when it has been demonstrated that this biotoxin has not been associated with bivalve molluscs in the growing and harvesting areas.

The selection of sampling stations for both benthic and suspended culture should be based on sites which have historically presented toxicity in the early stages of a toxic event In order to protect public health, the selection of sampling stations should give appropriate coverage of the extent of a toxic event or the likely “worst case scenario” in a growing area. This should be based on the following factors:

EXAMPLE Toxic micro-algae from cyst beds

When a toxic event is in progress or developing, targeted, depth-specific sampling should be considered.

NOTE Routine sampling for micro-algae generally means taking an integrated sample from the water column.

Sampling for shellfish grown in suspension should at least involve an integrated sample composed of shellfish taken from the top, middle and bottom of the lines.

Minimum weekly sampling frequencies should be adopted by most monitoring programmes in areas where toxicity is prevalent and where harvesting is taking place or about to take place. Decisions on the frequency of sampling should be based on risk evaluation.

NOTE Inputs into the decision may include factors such as seasonality (toxicity and or harvesting), accessibility, historical baseline information, including toxin and micro-algal data, and the effects of environmental factors such as wind, tide and currents.

Sampling frequency and the factors that may lead to changes should be described in a “Marine Biotoxin Action Plan” for the growing area.

The number of shellfish sampled should be sufficient to address the variability of toxicity among individual shellfish. The number of shellfish in the sample, rather than the mass of the shellfish flesh should be the determining factor for the sample size. Additionally, the size of the sample should be sufficient to allow the test or tests for which the sample is being taken to be carried out, and the shellfish sampled should be of the size marketed.

NOTE There is no internationally agreed sample size for different shellfish species.

Methods suitable for the determination of marine biotoxins should be approved by the national competent authority.

Growing areas should be monitored for chemical contaminants on a sufficiently frequent basis to provide confidence that any identified sources of chemical contamination are not contaminating the shellfish. Shellfish growing areas where there are no known point sources of likely chemical contamination should only require occasional checks every few years. Where there are known point sources of specific contamination, shellfish should be checked more frequently on a routine basis. There should also be the capacity to sample shellfish reactively if a defined event occurs such as spillage of anti-fouling paint.

Potential hazards include, but are not limited to:

Potential defects include, but are not limited to, physical damage.

The harvesting and transportation of live bivalve molluscs should be carried out in accordance with the following:

NOTE The water could be re-circulated if it meets the definition for clean water.

The requirements for classification and monitoring of growing areas should also apply to relaying areas.

38Bivalve molluscs harvested for relaying should only be harvested from areas that are so designated or classified by the national competent authority.

NOTE Relaying is intended to reduce the level of biological contaminants that may be present in bivalve molluscs which have been harvested from contaminated areas to such levels that the bivalve molluscs will be acceptable for human consumption without further processing.

Potential hazards include, but are not limited to:

Potential defects are unlikely.

Relaying should be carried out in accordance with the following:

Bivalve molluscs harvested for depuration should only be harvested from areas that are so designated or classified by the national competent authority.

NOTE Depuration is intended to reduce the number of pathogenic micro-organisms that may be present in bivalve molluscs which have been harvested from moderately polluted areas to such levels that the bivalve molluscs will be acceptable for human consumption without further processing. Depuration alone is not suitable for cleansing bivalve molluscs from more heavily contaminated areas or areas subject to contamination by hydro-carbons, heavy metals, pesticides, viruses, vibrios or biotoxins.

39For natural functioning and for depuration to occur, molluscs should not be over-stressed or damaged during harvesting or handling and should not be in a seasonally weak or spawning condition.

Depuration centres should maintain the same hygiene standards as outlined in 4.3, 4.4, 4.5 and 4.6.

Potential hazards include but are not limited to, microbiological contamination.

Potential defects include, but are not limited to, physical damage.

Depuration should be carried out in accordance with the following:

NOTE Viruses and Vibrio spp. are more persistent during depuration than the indicator bacteria mostly used for microbiological monitoring and that the reducing of the number of indicator bacteria does not always reflect the real situation with respect to contamination by viruses and Vibrio spp.

Distribution centres that prepare live bivalve molluscs suitable for direct consumption and establishments that prepare live and raw bivalve molluscs suitable for direct consumption should maintain the same hygiene standards as 4.3, 4.4, 4.5 and 4.6.

Potential hazards include, but are not limited to, microbiological, chemical and physical contamination.

Potential defects include, but are not limited to:

Reception of bivalve molluscs should be carried out in accordance with the following:

Potential hazards include, but are not limited to:

Potential defects include, but are not limited to:

Conditional storage of bivalve molluscs should be carried out in accordance with the following:

NOTE Optimum salinity will vary with bivalve molluscs species and with the harvesting area. Water condition has to be satisfactory adequate for the process.

Potential hazards include, but are not limited to microbiological contamination, chemical and physical contamination.

Potential defects include, but are not limited to mechanical damage.

Washing, declumping, debyssing and grading should be carried out in accordance with the following:

All steps in the process of packaging should be performed without delay and under conditions that will prevent the possibility of contamination, deterioration and the growth of pathogenic and spoilage micro-organisms.

The packaging material should be appropriate for the packaging and storage of the product and should not transmit to the product harmful or other objectionable substances or odours and tastes. The packaging material should be sound and should provide appropriate protection from damage and contamination.

Potential hazards include, but are not limited to microbiological, physical and chemical contamination.

43Potential defects include, but are not limited to:

Packing and labelling of live bivalve molluscs should be carried out in accordance with the following:

NOTE The packaging material may be used to bear an indication as to how the bivalve molluscs should be kept at the time they were bought at the retailer. It is recommended to include the date of packaging.

Potential hazards include, but are not limited to, microbiological and physical contamination.

Potential defects include, but are not limited to:

Packing and labelling of raw bivalve molluscs should be carried out in accordance with the following:

NOTE The packaging material or label may be used as a means to convey appropriate storage instructions to the consumer after retail purchase. It is recommended to include the date of packaging.

44NOTE Slow freezing will damage meat.

Potential hazards include, but are not limited to microbiological contamination, chemical and physical contamination.

Potential defects include, but are not limited to physical damage.

The storage of live bivalve molluscs should be carried out in accordance with the following:

Potential hazards include, but are not limited to, microbiological contamination, chemical and physical contamination.

Potential defects include, but are not limited to physical damage.

The storage of raw bivalve molluscs should be carried out in accordance with the following:

Potential hazards include, but are not limited to, microbiological contamination.

Potential defects include, but are not limited to, physical damage.

The distribution and transport of live bivalve molluscs should be carried out in accordance with the following:

NOTE See also 4.7 and 16.

Potential hazards include, but are not limited to, microbiological contamination.

Potential defects are unlikely.

The distribution and transportation of raw bivalve molluscs should be carried out in accordance with the following:

Live and raw bivalve molluscs should meet all microbiological criteria associated with traditional harvest water controls designed to prevent faecal contamination and resulting introduction of enteric pathogens as well as toxins and other contaminants.

NOTE Processing to reduce or limit target microorganisms is intended to retain the sensory qualities of a live bivalve mollusc. However, these growing area controls are not designed for control of pathogens that are independent from faecal contamination.

Potential hazards include, but are not limited to microbiological contamination.

Potential defects include, but are not limited to:

Processing to reduce or limit target organisms should be carried out in accordance with the following:

Dirt, mud and detritus should be removed before further processing through washing or other means.

Potential hazards include, but are not limited to, microbiological contamination and physical contamination.

Potential defects include, but are not limited to:

Shucking should be carried out in the accordance with the following:

Potential hazards include, but are not limited to physical contamination.

Potential defects are unlikely.

Heat shocking and packing of bivalve mollusc should be carried out in the accordance with the following:

The transport of live bivalve molluscs from a growing area to a distribution centre, depuration centre, relaying area or establishment should be accompanied by documentation for the identification of batches of live bivalve molluscs.

Storage and transport temperatures should be indicated.

Permanent, legible and dated records of relaying and depuration, pertaining to each lot, should be retained for a minimum period of one year.

Depuration centres or tanks and distribution centres and establishments should only accept lots of live bivalve molluscs with documentation issued by or accepted by the national competent authority. Where appropriate, this documentation should contain the following information: