In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

CARICOM Regional Organisation for Standards and Quality (CROSQ)

“The Heritage”, 35 Pine Road

Belleville, St Michael

Barbados, BB11113

T: 246.437.6146 | F: 246.437.4569

Website: http://www.crosq.org

© CRS 2009 – All rights reserved

Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm, without permission.

CCS 0045: 1999 Rev 2005

CARICOM Regional Organisation for Standards and Quality (CROSQ)

“The Heritage”, 35 Pine Road

Belleville, St Michael

Barbados, BB11113

T: 246.437.6146 | F: 246.437.4569

Website: http://www.crosq.org

© CRS 2009 – All rights reserved

ISBN 978-976-95187-3-5

ICS 97.180

| AMENDMENT NO. | DATE OF ISSUE | TEXT AFFECTED |

|---|---|---|

| 1 | 2005 | Clause 3.3.4 Annex A |

ATTACHMENT PAGE FOR CRS AMENDMENT SHEETS

| Amendment no. | Date of issue | Type of amendment | No. of text affected | Text of amendment |

|---|---|---|---|---|

| 1 | 2005 | Corrigenda | Clause 3.3.4, page 5 | No more than 5 % of the splints tested for strength (see A.5) shall break when an impact of 12 mJ is applied. |

| A.5.2.1, Annex A, page 12 | Using a suitable mechanical strength tester based on the falling weight method, randomly select 100 matches from the batch and subject to an impact of 12 mJ. |

Explanatory note:

This corrigenda was made in response to a request for modification to the equipment to be used for the Splint strength test and the appropriate force to be applied when conducting this test.

The equipment for the Splint strength test was recommended to be based on the falling weight method and a reduction in the force from 28 mJ to 12 mJ was proposed, both of which were accepted by Member States.

iii| Foreword | v | ||

| 1 | Scope | 2 | |

| 2 | Term and Definitions | 2 | |

| 3 | Visual inspection | 3 | |

| 3.1 | General | 3 | |

| 3.2 | Book matches | 3 | |

| 3.3 | Containers | 3 | |

| 3.4 | Matches | 4 | |

| 3.5 | Dimensions | 4 | |

| 4 | Performance requirements | 4 | |

| 4.1 | Match burning properties | 4 | |

| 4.2 | Match splint | 4 | |

| 4.3 | Heat induced ignition | 5 | |

| 4.4 | Friction Surface | 5 | |

| 5 | Ordering information for splints | 5 | |

| 5.1 | General | 5 | |

| 5.2 | Dimensions | 5 | |

| 5.3 | Surface | 5 | |

| 5.4 | Strength | 5 | |

| 5.5 | Afterglow | 5 | |

| 6 | Labelling | 5 | |

| 7 | Testing | 6 | |

| 7.1 | Sampling | 6 | |

| 7.2 | Conditioning | 6 | |

| 7.3 | Testing | 7 | |

| 7.4 | Test Conditions | 7 | |

| 7.4 | Criteria for conformity | 8 | |

| Annex A (normative) Methods for testing matches and match splints | 10 | ||

| Figures | |||

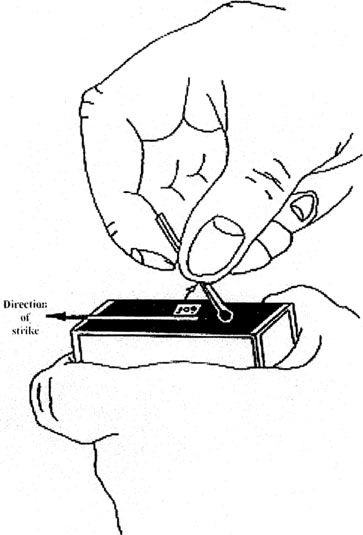

| Figure 1 — Method of striking matches | 8 | ||

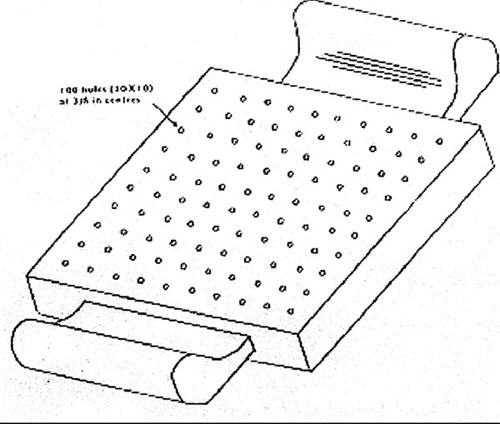

| Figure 2 — Perforated metal plate | 11 | ||

This standard was originally prepared through the Caribbean Community Secretariat under the Caribbean Common Market Standards Council (CCMSC) and approved as a mandatory standard by the Sixth Meeting of the Council for Trade and Economic Development (COTED) in 1999. A review of the standard commenced in 2002 through the CARICOM Regional Organisation for Standards and Quality (CROSQ) and was approved by the CROSQ Council in 2004 and the Eighteenth Meeting of COTED in 2005.

In developing this standard, reference was made to:

This standard specifies the requirements for the performance, sampling, packaging and labelling of safety matches. It also specifies the requirements for the purchase of match splints from suppliers.

This standard applies to matches packed in boxes for domestic purposes and book matches.

The requirements do not apply to specialty matches for advertising purposes.

For the purposes of this standard, the following terms and definitions shall apply.

visible signs of combustion in the match splint after the match has been struck and the flame extinguished

one or two rows of comb-like matches with each row of splints having its base fixed within a cover

NOTE The striking surface lies on the outer surface of the cover.

match heads which show pronounced abnormalities in shape or surface

match heads linked together by fused ignitable material

an ignited fragment of a match which discharges during ignition

match heads in which the surface is broken or cracked

materials of the same brand in a single consignment produced in the same manufacturing unit

product which comprises a splint tipped at one end with a head of ignitable material which will ignite when struck against a friction surface

container for matches consisting of an outer case having a friction surface on one or both sides and within which slides an inner tray

2unit consisting of a specified number of packets

smaller unit comprised of a specified number of match boxes or book matches

match which is designed so that it will not readily ignite unless brought into contact with a friction surface specially designed to cause ignition

cardboard or wooden stick made of combustible material providing support during ignition of a match and the fuel for its continued burning

The number of matches with heads in a container shall correspond with the declared contents within a tolerance of ± 3 for individual containers or for the average of all containers examined.

All matches shall be completely within the container and no more than 5 % of the match sticks shall be arranged other than in one direction within the inner tray of the box.

The contents shall be retained when the closed container is orientated in any direction.

The splints shall be in one or two rows wrapped round by a board cover and indented near the base to be detached easily.

Match boxes shall be of good workmanship, free from defects including:

EXAMPLE Crushed, broken or torn boxes

Match boxes shall have a uniformly distributed friction surface, none of which shall be present on the inside where contact with the match heads can occur. The friction surface shall terminate at least 2 mm from each edge of the shorter side of the box.

3The cover of book matches shall be wide enough to enclose all the matches in the book with an excess of at least 1.5 mm on either side. It shall be long enough so that the cover opening edge can be inserted at least 4 mm beneath the other edge. The friction surface shall be on the back of the cover near the lower part, on the outside.

Splints used for making matches shall be uniform, smooth, well polished and free from bristles, splits, tears, cracks or fractures along the length. They shall not have fungal or bacterial growth.

All matches shall have a head of ignitable material uniformly applied to the end of the splint.

Matches shall be free from badly distorted heads, fractured heads or doubles.

Match sticks shall have minimum dimensions of:

The variation between the lengths of matches within the same box shall not exceed 2 mm.

Book matches shall have splints not less than 35 mm in length without the base and 45 mm with the base. The composite width of 10 splints shall not be less than 30 mm.

When tested in accordance with the methods outlined in Annex A and 7.3, safety matches shall comply with the following performance requirements.

Matches shall ignite without delay when struck and no more than one shall fail to ignite when struck.

No more than 1 % of the match heads shall show fragmentation or detachment of head from splint during ignition.

No more than 5 % of the match heads shall explode or drop hot ash during ignition.

Following ignition, the flame shall transfer from head to splint to at least ⅓ of its length.

When tested as described in A.6, the flame observed between 3 s and 10 s after striking shall reach a height of at least 10 mm. The flame shall burn for at least 10 s, or if the match is less than 40 mm long, for at least 6 s.

No more than 5 % of the matches tested shall show breakage or fracture of the splints.

No more than 2 % of the matches shall exhibit afterglow other than a pin point glow beneath the head after the flame has been extinguished and a period of 3 s has elapsed (see A.2).

4Matches shall not ignite spontaneously when exposed to heated atmosphere.

After a drop of water is applied to the friction paint for 20 s, then wrapped with a dry tissue, there shall be no removal of the friction surface sufficient to expose the underlying surface of the box.

The friction surface of a match box shall be capable of igniting all of its contents on one side of the box or on the available surface for book matches.

Splints for the manufacture of box matches shall be of wood impregnated with chemicals to prevent afterglow when flame is extinguished.

Splints for the manufacture of book matches shall be of wood or any suitable material impregnated with chemicals to prevent afterglow when a flame is extinguished.

Splints shall have the following minimum dimensions:

The surface of the splints shall be smooth, well polished and free from fungal or bacterial growth.

No more than 2 % of splints examined shall show any splits or cracks along its length.

No more than 5 % of the splints tested for strength (see A.5) shall break when an impact of 12 mJ is applied.

Splints shall not glow for more than 3 s after the flame is extinguished.

The match box shall be labelled with:

EXAMPLE Safety matches

EXAMPLE ‘Close box before striking’ and ‘keep out of reach of children’

The number of packages to be selected from a lot shall depend on the size of the lot and shall be in accordance with Table 1.

| Lot size packages | Number of packages selected |

|---|---|

| 3 to 25 | 3 |

| 26 to 50 | 4 |

| 51 to 100 | 5 |

| 101 to 150 | 6 |

| 151 and above | 7 |

The number of packets selected from a package shall depend on the size of the package and shall be in accordance with Table 2.

| Number of packets in package | Number of packets selected |

|---|---|

| 10 | 3 |

| 50 | 4 |

| 100 | 5 |

From each packet, select at random two match boxes or book matches. The total number of boxes or books constitutes a sample.

Samples shall be maintained at a temperature of 27 °C ± 2 °C and a relative humidity of 65 % ± 2 % for not less than 24 h prior to testing.

6Tests shall be conducted as outlined in Annex A.

The recommended number of specimens required for each test is given in Table 3.

| Test method | Minimum number of specimen |

|---|---|

| Match burning properties | 200 matches |

| Afterglow | 100 matches |

| Heat induced ignition | 20 matches |

| Friction paint surface | 4 match boxes |

| Average count | 12 match boxes |

| Visual examination | 200 matches |

| Splint strength | 250 matches |

| Flame height | 10 matches |

Testing shall be conducted in a draught free atmosphere. Protective clothing should be worn by the operator during all tests that require the striking of matches.

The box shall be held so that the friction surface is at right angles to the body (see Figure 1).

The match shall be positioned at a connecting angle of approximately 30° to the horizontal surface of the friction paint.

The match shall be struck along the friction surface in a direction away from the body and with an upward sweep, using the minimum pressure necessary to secure ignition.

For observation of match burning performance, splints shall be held in a horizontal position after striking and allowed to burn at least ⅔ its length.

7

Figure 1 — Method of striking matches

The batch shall be considered satisfactory if the sample satisfies the requirements as stated in Table 4.

| Test | Maximum acceptable defectives % |

|---|---|

| Non-ignition/delayed ignition | 2 |

| Fragmented/detached heads | 1 |

| Exploding heads/hot ash | 5 |

| Transfer of flame | 5 8 |

| Flame height | 5 |

| Splints which break when struck | 5 |

| Afterglow | 2 |

| Heat induced ignition | 0 |

| Friction paint wearing | 0 |

| Friction paint ignition | 0 |

| Splint - splits/cracks | 2 |

(normative)

To determine any dangerous burning properties and splint breakage during striking.

Clean sheet of white paper and stopwatch which is accurate to 1 s.

Select sufficient match boxes from the conditioned sample to provide a test specimen of not less than 200 matches, taking no more than 5 matches from each box.

Place the sheet of white paper on the surface over which the matches are to be struck.

Using the method of striking matches in 4.3.3.2, strike all matches, observe and record any of the following defects:

NOTE Splints which break during striking should be replaced by the same number of matches to ensure a specimen of 200 matches for the test burning property.

For book matches, ensure that the match is struck in the orientation most likely to cause failure.

To determine if splints have been properly treated to prevent afterglow.

10Perforated metal plate (see Figure 2).

Figure 2 — Perforated metal plate

Insert the bases of 100 matches, randomly selected from the conditioned samples, into the holes of the metal plate.

Ignite the taper and apply the flame to the outside row of the matches.

Tilt the plate so as to ignite all the matches as quickly as possible.

Allow the splints to burn completely until the flame dies out.

Start the stopwatch simultaneously and after 3 s, record any afterglow, ignoring any pinpoint glow immediately beneath the head.

11To determine whether matches will ignite spontaneously in a heated atmosphere.

Metal plate to hold matches vertically 10 mm apart and an air circulating oven.

Insert 20 matches randomly selected in the metal plate with heads pointing upwards.

For book matches, a length of comb containing 12 matches shall be suitably supported at its base.

Place in the oven maintained at 120 °C ± 2 °C and leave for 15 min.

After the time has elapsed, remove from the oven and record the number of matches, if any, which ignited.

To determine the efficiency of the striking surface and the likelihood of ignition during striking.

Select four full match boxes from the conditioned sample.

Using the method of striking matches in 4.3.3.2, strike all the matches in each box on only one side of the box.

Observe and record whether all the matches were successfully ignited. Also report whether any of the friction surfaces ignited during striking.

To assess the strength of splints supplied for the production of matches.

Using a suitable mechanical strength tester based on the falling weight method, randomly select 100 matches from the batch and subject to an impact of 12 mJ.

Observe and record the number of splints which fracture or break during this procedure.

12To assess flame height achieved during the burning of match splints.

Hold the match in position by inserting the stem 5 mm into a metal tube clamped in the horizontal position.

Position the match 25 mm ± 3 mm away from a vertical plane mirrored plate scribed with two horizontal lines separated by 10 mm.

Adjust the height of the plate so that the upper surface of the match splint, its mirror image and the lower line are all coincident.

Ignite the match by touching the tip of the head with a heated soldering iron. At the same time start a stop watch.

Observe the flame carefully during the period between 3 s and 10 s from ignition and record whether the flame does not exceed 10 mm in height. This is indicated if the tip of the flame does not cross the upper of the two lines scribed on the mirrored plate.

At all times during the observation of the flame ensure that the stem, its mirror image and the bottom line remain coincident in order to prevent parallax errors.

Record whether the flame does not remain alight for 10 s. If the match is less than 40 mm in length, record whether the flame does not remain alight for 6 s.

NOTE Alternative arrangements for measurement of flame height are acceptable, provided adequate arrangements to prevent parallax errors are incorporated.

13

The CARICOM Regional Organisation for Standards and Quality (CROSQ) was created as an Inter-Governmental Organisation by the signing of an agreement among fourteen Member States of the Caribbean Community (CARICOM). CROSQ is the regional centre for promoting efficiency and competitive production in goods and services, through the process of standardization and the verification of quality. It is the successor to the Caribbean Common Market Standards Council (CCMSC), and supports the CARICOM mandate in the expansion of intra-regional and extra-regional trade in goods and services.

CROSQ is mandated to represent the interest of the region in international and hemispheric standards work, to promote the harmonization of metrology systems and standards, and to increase the pace of development of regional standards for the sustainable production of goods and services in the CARICOM Single Market and Economy (CSME), and the enhancement of social and economic development.

CROSQ VISION:

The premier CARICOM organisation for the development and promotion of an Internationally Recognised Regional Quality Infrastructure; and for international and regional harmonized CARICOM Metrology, Standards, Inspection, Testing and Quality Infrastructure

CROSQ MISSION:

The promotion and development of standards and standards related activities to facilitate international competitiveness and the sustainable production of goods and services within the CARICOM Single Market and Economy (CSME) for the enhancement of social and economic development

14 15