In order to promote public education and public safety, equal justice for all, a better informed citizenry, the rule of law, world trade and world peace, this legal document is hereby made available on a noncommercial basis, as it is the right of all humans to know and speak the laws that govern them.

EAS 322:2002

ICS 79.040

EAST AFRICAN COMMUNITY

© EAC 2002

First Edition 2002

aDevelopment of the East African Standards has been necessitated by the need for harmonising requirements governing quality of products and services in East Africa. It is envisaged that through harmonised standardisation, trade barriers which are encountered when goods and services are exchanged within the Community will be removed.

In order to achieve this objective, the Partner States in the Community through their National Bureaux of Standards, have established an East African Standards Committee.

The Committee is composed of representatives of the National Standards Bodies in Partner States, together with the representatives from the private sectors and consumer organisations. Draft East African Standards are circulated to stakeholders through the National Standards Bodies in the Partner States. The comments received are discussed and incorporated before finalisation of standards, in accordance with the procedures of the Community.

East African Standards are subject to review, to keep pace with technological advances. Users of the East African Standards are therefore expected to ensure that they always have the latest versions of the standards they are implementing.

© East African Community 2002 — All rights reserved*

East African Community

P O Box 1096

Arusha

Tanzania

Tel: 255 27 2504253/8

Fax: 255-27-2504481/2504255

E-Mail: eac@eachq.org

Web: www.each.org

* © 2002 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

b| 1 | Scope | 1 |

| 2 | Normative references | 1 |

| 3 | Definitions | 1 |

| 4 | Felling | 1 |

| 5 | Materials requirements | 1 |

| 6 | Dimensions and permitted tolerances | 3 |

| 7 | Manufacturing requirements | 4 |

| 8 | Stacking and preparation of poles at depots | 5 |

| 9 | Moisture content | 5 |

| 10 | Poles preservation | 5 |

| 11 | Marking and labelling | 6 |

| Annex A Stayblocks and brace blocks | 8 | |

One of the important factors involved in the design and economical use of wood poles for the support of aerial communication and power lines is the value of the maximum fibre strength for the different species of timber used for wood poles. The fibre strength is affected by the amount of seasoning the wood poles have received. The growth characteristics of timber and their freedom from decay and other defects are of importance in the determination of the mechanical strength of the poles for assessing the safe loads in service.

In this respect, the attention of pole users is drawn to the difficulty of defining and working to precise requirements on all aspects of a natural product such as timber. Some properties have of necessity been specified in general terms only. It is therefore recommended that the supervision of seasoning tests and of preservation processes and the acceptance of poles should be assigned only to qualified and experienced inspectors.

In the preparation of this East African Standard, assistance was drawn from the following:

BS 1990-1:1984, Wood poles for overhead power and telecommunication lines published by British Standards Institution.

ANSI 05.1:979, Specifications and dimensions for wood poles published by American National Standards Institute.

In reporting the results of a test made in accordance with this East African Standard, if the final value observed or calculated is to be rounded off, it shall be done in accordance with EAS 124:1999

dWood poles and blocks for power and telecommunication lines — Specification

This East African Standard specifies materials and performance requirements for solid wood poles. The poles described herein are considered as simple cantilever members subject to transverse loads only.

For the purposes of this East African Standard, the following references shall apply:

EAS 24:2001, Glossary of terms used in timber industry

EAS 324:2002, Copper/chromium/arsenic compositions for timber preservations — Methods of timber treatment

EAS 323:2002, Specification for wood preservation by means of pressure creosoting

EAS 124:1999, Rounding off numerical values

For the purpose of this East African Standard, the definitions given in EAS 24 shall apply.

Trees shall be sawn off as close to the ground as possible and no timber shall be removed, trimmed or cut from the butt end so as to reduce its natural size. The ends shall be sawn to give a flat section and branches shall be dressed down flush with the trunk. Bark shall be removed as soon as practicable after felling except for eucalyptus, which requires a longer seasoning time.

Poles shall be made from the following species and will have a minimum fibre strengths of 39 Mpa:

| Trade name | Botanical name | |

| a) | Redwood or scots pine | (Pinus sylvestris) |

| b) | Corsican pine | (Pinus nigra) |

| Douglas fir | (Pseudotsuga menziesii) | |

| Dunkeld (hybrid)larch | (Larix eurolepis) | |

| European larch | (Larix decidua) | |

| European spruce | (Picea abies) | |

| Lodgepole pine | (Pinus contorta) | |

| Sitka spruce | (Picea sitchensi) | |

| East African pencil cedar | (Juniperus procera) | |

| Eucalyptus | (Eucalyptus saligna or Eucalyptus grandis) |

NOTE The preferred dressed sizes of poles should be as given in Table 1 and Table 2.

NOTE The limitations of knots are based on past practice and satisfactory performance.

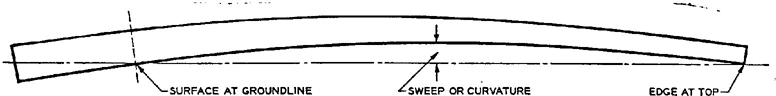

Figure 1 — Measurement of sweep in one plane and one direction

This East African Standard shall be applicable to preferred dressed sizes of poles as given in Table 1 and Table 2.

NOTE All circumferences and diameters are applicable to debarked and seasoned or dry poles.

Many nominally round poles have a natural elliptical cross section; the diameter measurements of such poles shall be of the minor axes

Length shall be measured between the extreme ends of the pole or in case of a pole with a sweep (see 5.2.3(i)); length shall be measured to the short end of the slope.

Poles shall be not more than 75 mm shorter or 150 mm longer than the nominal length (see 7.2).

The true diameter class shall be determined by measuring the diameter at 1.5 m from the butt end. This dimension will determine the true class of a pole, provided that its top diameter (measured at the minimum length point) is large enough.

3| Pole class | Pole length m |

Min. pole top diameter mm |

Max. pole top dia mm |

Min. dia 1.5 m from butt mm |

Groundline Distance from the butt m * |

|---|---|---|---|---|---|

Light |

9 10 11 12 13 |

150 150 170 180 200 |

175 180 190 200 220 |

200 210 220 240 250 |

1.5 1.8 1.8 2.0 2.2 |

Medium |

9 10 11 12 13 14 |

170 180 190 195 200 210 |

190 200 210 220 230 240 |

230 240 250 260 270 280 |

1.5 1.8 1.8 2.0 2.2 2.2 |

Stout |

9 10 11 12 13 14 |

190 190 195 200 210 220 |

240 245 250 250 255 260 |

285 295 305 320 330 340 |

1.5 1.8 1.8 2.0 2.2 2.2 |

| * The figures in this column are intended for use only when a definition of groundline is necessary in order to apply requirements relating to scars, straightness, etc. | |||||

| Pole class | Pole length m |

Pole top diameter Min. Max. mm |

Min. dia 1.5 m from butt mm |

Groundline distance from the butt * m |

|

|---|---|---|---|---|---|

| Light | 6 7 7.5 |

90 90 90 |

120 120 120 |

120 130 135 |

1.2 1.2 1.3 |

| Medium | 7 7.5 8 |

120 120 120 |

140 140 140 |

150 155 160 |

1.2 1.3 1.5 |

| Stout | 9 10 11 |

130 130 130 |

150 150 150 |

175 185 195 |

1.5 1.5 1.9 |

| * The figures in this column are intended for use only when a definition of groundline is necessary in order to apply requirements relating to scars, straightness, etc. | |||||

Outer bark shall be removed from all poles and inner bark shall not be permitted. All poles shall be round with no excessive removal of the sapwood.

The taper in a pole from top to the butt shall not exceed 10 mm per meter of the length of a pole.

The butts of the poles shall be cut perpendicular to the central axis with a tolerance of 50 mm across the sawn surface. The top of the pole shall be cut with an inverted “V” section, each side of the “V” having a 30° slope to the pole axis or flat top cut; 90° ± 5° perpendicular to the central axis and shall be bound with anti-cracking plate.

4Knots on the pole surface, whether partially or fully grown and branch stubs shall be trimmed close. Trimming may be done by shaving machine or by hand.

If shaving is used, the depth of cut shall not be more than necessary to remove inner bark and to trim all branch stubs and overgrown knots smoothly and closely. There shall be no abrupt change in the contour of the pole surface between the groundline and the above ground sections. The lower 600 mm pole section may be trimmed to remove wood fibres causing butt flare, provided sufficient sapwood remains to obtain the minimum penetration requirements.

No sapwood shall be removed from the butt of the pole to 1 m above proposed ground level, the minimum sapwood thickness being 25 mm. The remainder of the pole should be trimmed to produce a rounded pole while maintaining a minimum sapwood thickness of 20 mm.

Where practicable, poles shall be delivered predrilled to suit the different types of pole duties and configurations. Drilled holes shall be positioned at right angles to any pole top spilt. All drilling and fabrication shall be carried out before preservative treatment.

All poles other than spruce shall be stacked in open formation, before and after dressing, on suitable skids so that the lowest timber of each stack is at least 250 mm above the ground. Sufficient dunnage or cross-timbers shall be used to distribute the total mass without imposing under strain on the poles at the lower layers. The surface of the seasoning ground under and around the stacks shall be well drained and kept free from bark, shavings, grass and weeds.

Preservation of species other than spruce shall not take place until the average moisture content of each batch of the poles is reduced to not more than 28 %. No individual pole in the batch shall have a moisture content greater than 30 %.

The moisture content of the poles shall be determined prior to treatment by the oven test method or any other suitable method in accordance with the method described in annex B of EAS 323.

Poles for preservation shall be protected against heavy and continuous rain.

The following species shall be pressure impregnated with creosote in accordance with EAS 323 or with a copper/chromium/arsenic (CCA) mixture in accordance with EAS 324.

When pressure impregnating in accordance with EAS 323, the coal tar creosote used shall comply with type 2 and the average net retention of preservative in a charge shall be not less than 115 kg/m3.

5When pressure impregnating in accordance with EAS 324, the copper/chromium/arsenic mixture shall have a solution strength not less than 3 % (m/v) and the average net retention of preservatives in a charge shall be not less than 14 kg/m3

Since sitka spruce cannot be treated with preservative in the normal way by the procedures described in EAS 323 and EAS 324, it shall be treated using a suitable modification of one of the procedures described in those standards to meet the requirements for full sapwood penetration and net retention.

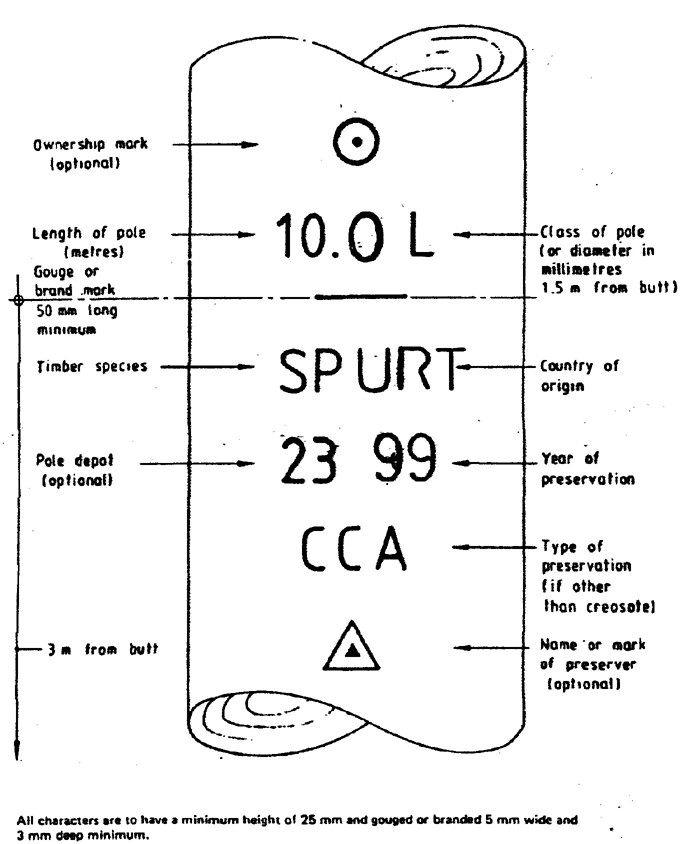

Each pole shall have a gouge or brand mark at least 50 mm long, 5 mm wide and 3 mm deep placed 3 m from the butt and shall be marked with certain information in characters not less than 25 mm high and gouged or branded 5 mm wide and 3 mm deep. Spacing between codes shall be between 20 mm and 30 mm. The coded information shall include the following:

CP Corsican pine,

SP Scots pine or Redwood,

EA East African pencil cedar,

SS Sitka spruce,

LP Lodgepole pine,

LD Larch Dunkeld,

E Eucalyptus and

The layout of these markings is shown in Figure 2.

Pole treated with creosote shall carry no other distinguishing mark. Appropriate letters shall denote other forms of preservation.

Each pole shall also have the pole length in metres and the pole class impressed on the pole butt.

6

Figure 2 — Markings layout

7Preferably stayblock and brace blocks shall be sourced from Mninga (angolensis pterocarpus angolensis) or Mtundu (croton macrostachys) but species listed in 5.1 may be used with specified preservative treatment.

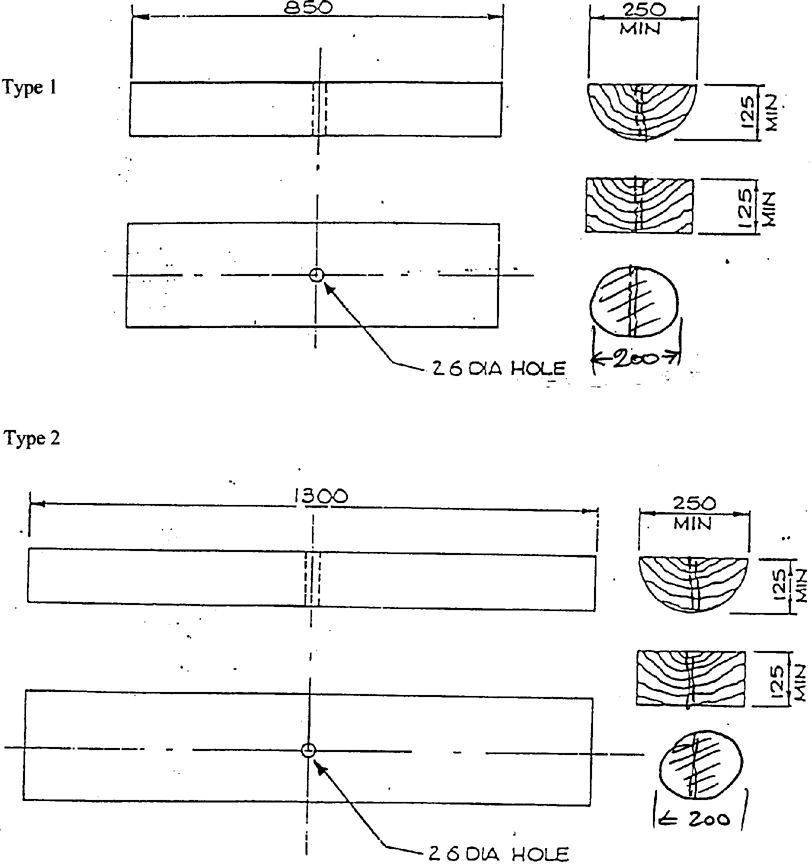

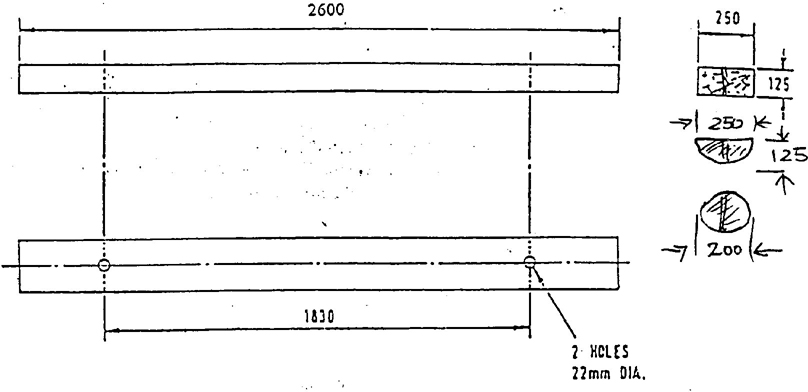

The stayblocks and brace blocks may be cut from sawn timber or from the round timber to produce rectangular, round or half round sections, whichever is economical, from the available material. Stayblocks and brace blocks shall be in accordance with Figure 3 and figure 4 respectively; and with the following requirements:

The width of stayblocks and brace blocks shall be as near as possible to the dimension stated but must be within the range of 200 mm to 300 mm. If it is convenient to cut stayblocks and brace blocks from larger size poles, then the side shall be cut as indicated in the figures to reduce the maximum width. The longitudinally cut surfaces of stayblocks and brace blocks shall be straight and clean-cut, while annual rings shall be approximately parallel to the wide face. Planing is not required. Wain is permitted on one face. The blocks shall be bored as indicated in Figures 3 and 4.

These stayblocks and brace blocks have been designed for a minimum failing load and resistance to uplift of 65 kN. Uplift calculations are based on installation of sand of density of 550 kg/m3, which is considered to be representative of average worst ground conditions, with a minimum angle between stay pole of 30°.

The blocks shall be treated by either coal tar creosote in accordance with EAS 323 or copper/chromium/arsenic mixture in accordance with EAS 324 after fabrication using Bethel/Rueping processes.

8

Figure 3 — Stayblocks dimensions

9

Figure 4 — Brace blocks dimensions

10